battery INFINITI FX35 2008 Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 2891 of 3924

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-29

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Close the relay and probe at the solenoid. voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

Testing for “Shorts” in the Circuit

To simplify the discussion of shorts in the system, please refer to the following schematic.

RESISTANCE CHECK METHOD

Disconnect the battery negative cable and remove the blown fuse.

Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground.

Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

Close SW1 and jump the relay contacts with jumper wir e. Put probes at the load side of fuse terminal and a

known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

VOLTAGE CHECK METHOD

Remove the blown fuse and disconnect all loads (i .e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

Turn the ignition key to the ON or START position. Veri fy battery voltage at the battery + side of the fuse ter-

minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

With SW1 closed, relay and solenoid disconnected and t he DMM leads across both fuse terminals, check for

voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

With SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

Ground Inspection

Ground connections are very important to the proper oper ation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted re sistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

Remove the ground bolt or screw.

Inspect all mating surfaces for tarnish, dirt, rust, etc.

SGI847-A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2893 of 3924

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-31

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

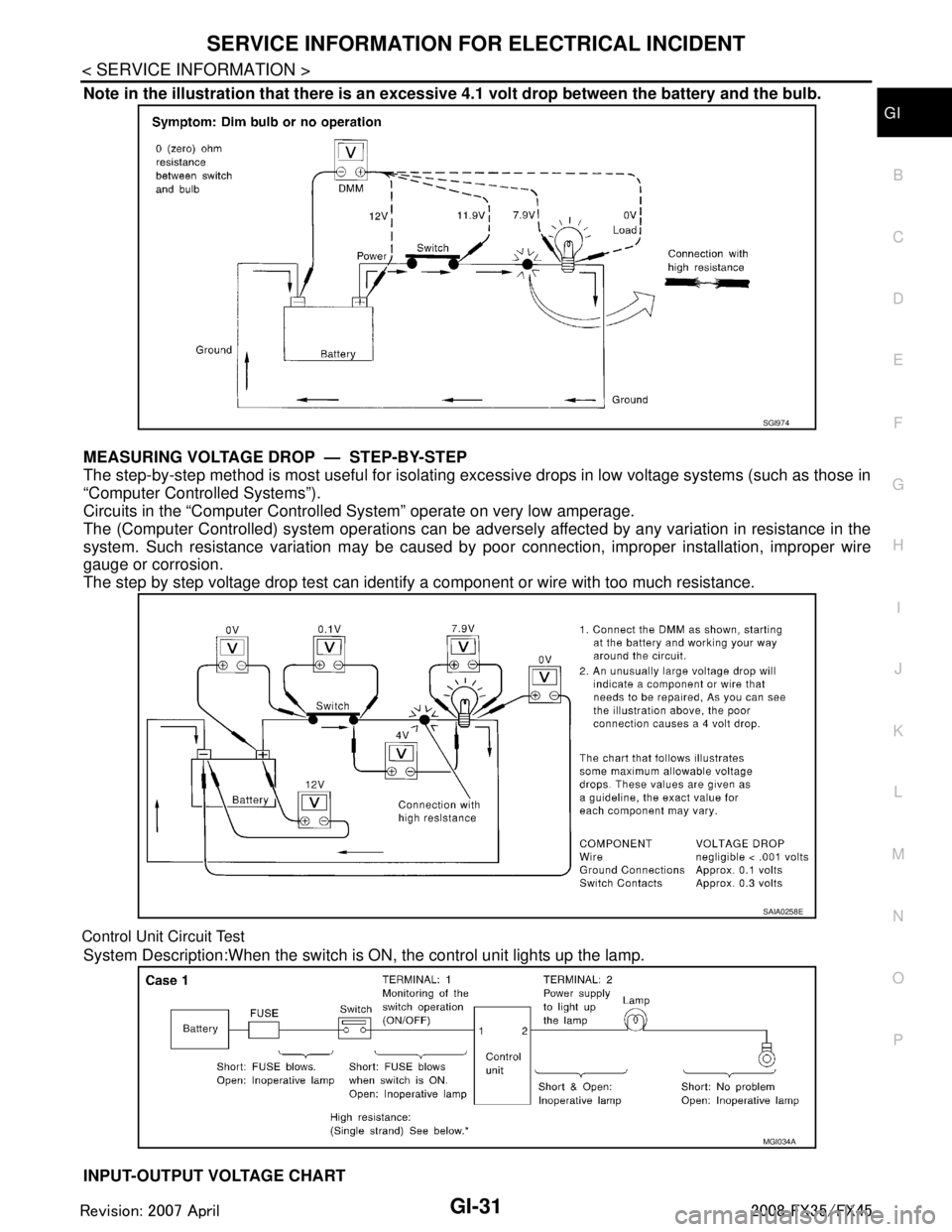

Note in the illustration that there is an excessi ve 4.1 volt drop between the battery and the bulb.

MEASURING VOLTAGE DRO P — STEP-BY-STEP

The step-by-step method is most useful for isolating ex cessive drops in low voltage systems (such as those in

“Computer Controlled Systems”).

Circuits in the “Computer Controlled System” operate on very low amperage.

The (Computer Controlled) system oper ations can be adversely affected by any variation in resistance in the

system. Such resistance variation may be caused by poor connection, improper installation, improper wire

gauge or corrosion.

The step by step voltage drop test can identify a component or wire with too much resistance.

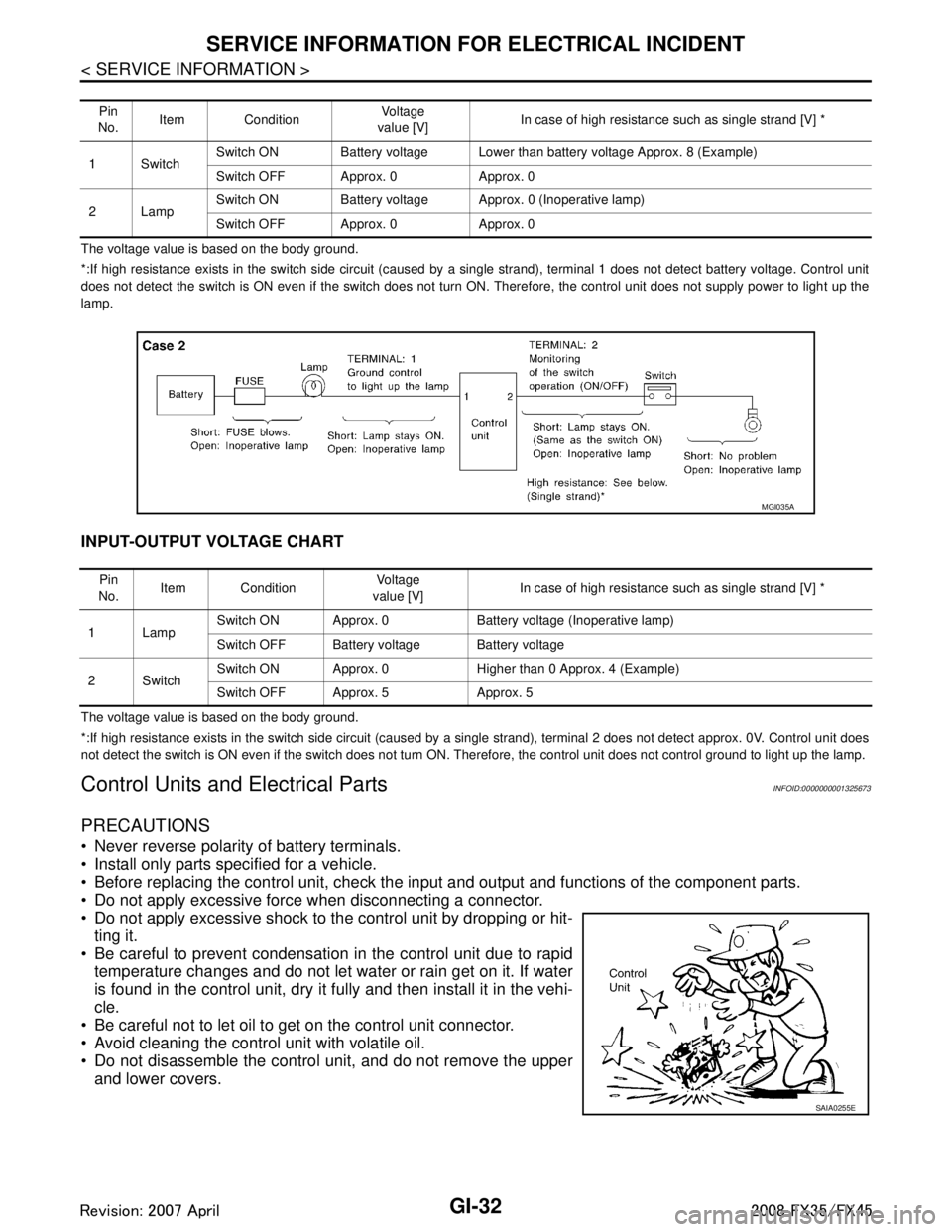

Control Unit Circuit Test

System Description:When the switch is ON, the control unit lights up the lamp.

INPUT-OUTPUT VOLTAGE CHART

SGI974

SAIA0258E

MGI034A

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2894 of 3924

GI-32

< SERVICE INFORMATION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

The voltage value is based on the body ground.

*:If high resistance exists in the switch side circuit (caused by a single strand), terminal 1 does not detect battery voltage. Control unit

does not detect the switch is ON even if the switch does not turn ON. Therefore, the control unit does not supply power to ligh t up the

lamp.

INPUT-OUTPUT VOLTAGE CHART

The voltage value is based on the body ground.

*:If high resistance exists in the switch side circuit (caused by a single strand), terminal 2 does not detect approx. 0V. Cont rol unit does

not detect the switch is ON even if the switch does not turn ON. Therefore, the control unit does not control ground to light u p the lamp.

Control Units and Electrical PartsINFOID:0000000001325673

PRECAUTIONS

Never reverse polarity of battery terminals.

Install only parts specified for a vehicle.

Before replacing the control unit, check the input and output and functions of the component parts.

Do not apply excessive force when disconnecting a connector.

Do not apply excessive shock to the control unit by dropping or hit- ting it.

Be careful to prevent condensation in the control unit due to rapid temperature changes and do not let water or rain get on it. If water

is found in the control unit, dry it fully and then install it in the vehi-

cle.

Be careful not to let oil to get on the control unit connector.

Avoid cleaning the control unit with volatile oil.

Do not disassemble the control unit, and do not remove the upper and lower covers.

Pin

No. Item Condition

Vo l ta g e

value [V] In case of high resistance such as single strand [V] *

1Switch Switch ON Battery voltage Lower than battery voltage Approx. 8 (Example)

Switch OFF Approx. 0 Approx. 0

2Lamp Switch ON Battery voltage App

rox. 0 (Inoperative lamp)

Switch OFF Approx. 0 Approx. 0

MGI035A

Pin

No. Item Condition

Vo l ta g e

value [V] In case of high resistance such as single strand [V] *

1Lamp Switch ON Approx. 0 Battery voltage (Inoperative lamp)

Switch OFF Battery voltage Battery voltage

2Switch Switch ON Approx. 0 Higher than 0 Approx. 4 (Example)

Switch OFF Approx. 5 Approx. 5

SAIA0255E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2895 of 3924

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-33

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

When using a DMM, be careful not to let test probes get close to each other to prevent the power transistor in the control unit from

damaging battery voltage because of short circuiting.

When checking input and output signals of the control unit, use the

specified check adapter.

SEF348N

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2902 of 3924

GI-40

< SERVICE INFORMATION >

TOW TRUCK TOWING

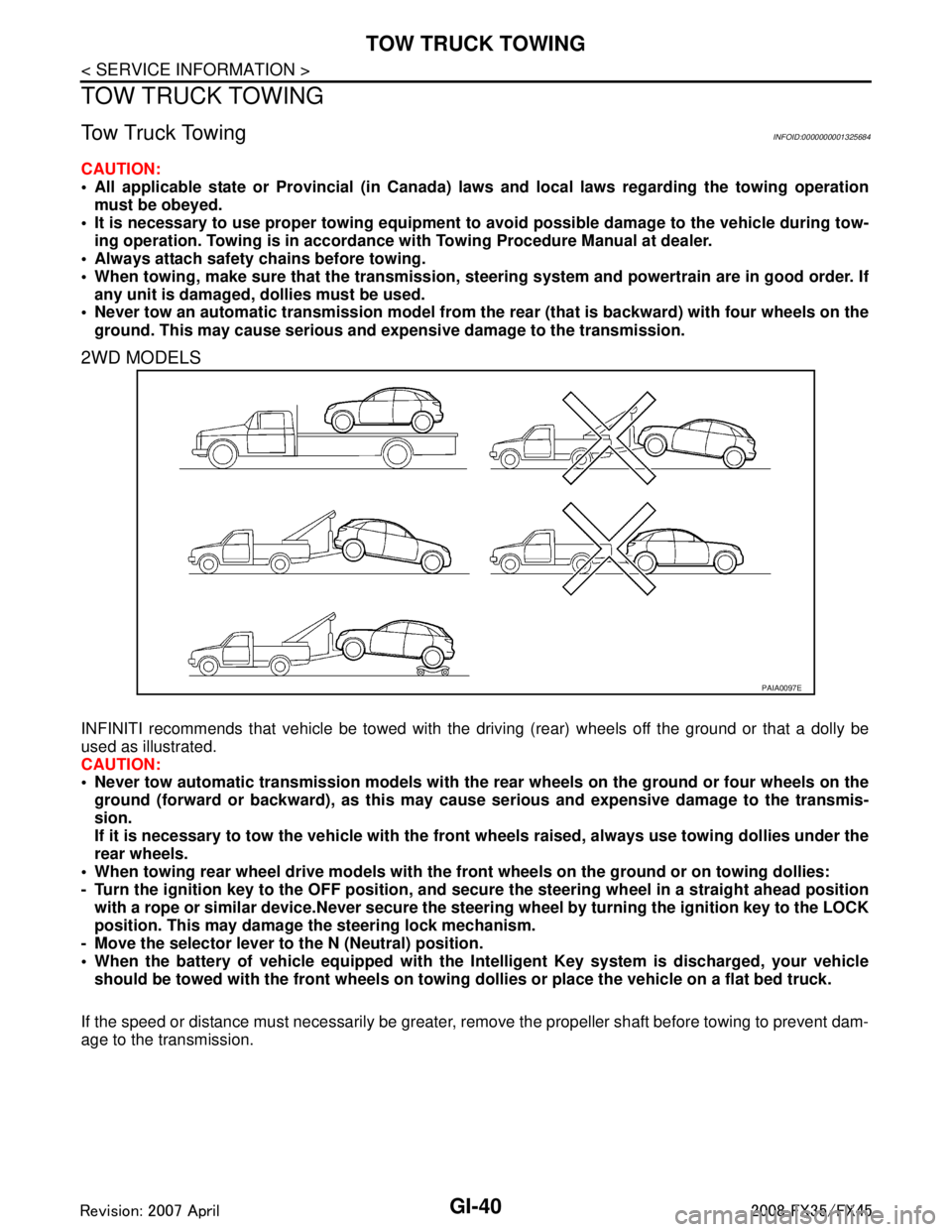

TOW TRUCK TOWING

Tow Truck TowingINFOID:0000000001325684

CAUTION:

All applicable state or Provincial (in Canada) laws and local laws regarding the towing operation

must be obeyed.

It is necessary to use proper towi ng equipment to avoid possible damage to the vehicle during tow-

ing operation. To wing is in accordance with Towing Procedure Manual at dealer.

Always attach safety chains before towing.

When towing, make sure that the transmission, steering system and powertrain are in good order. If

any unit is damaged, dollies must be used.

Never tow an automatic transmission model from the rear (that is backward) with four wheels on the

ground. This may cause serious and exp ensive damage to the transmission.

2WD MODELS

INFINITI recommends that vehicle be towed with the dr iving (rear) wheels off the ground or that a dolly be

used as illustrated.

CAUTION:

Never tow automatic transmission models with the r ear wheels on the ground or four wheels on the

ground (forward or backward), as this may cause serious and expensive damage to the transmis-

sion.

If it is necessary to tow the vehicle with the fron t wheels raised, always use towing dollies under the

rear wheels.

When towing rear wheel drive mo dels with the front wheels on the ground or on towing dollies:

- Turn the ignition key to the OFF position, and secure the steering wh eel in a straight ahead position

with a rope or similar device.Never secure the st eering wheel by turning the ignition key to the LOCK

position. This may damage the steering lock mechanism.

- Move the selector lever to the N (Neutral) position.

When the battery of vehicle equipped with the Intelligent Key system is discharged, your vehicle

should be towed with the front wh eels on towing dollies or place the vehicle on a flat bed truck.

If the speed or distance must necessarily be greater, re move the propeller shaft before towing to prevent dam-

age to the transmission.

PAIA0097E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2936 of 3924

POWER WINDOW SYSTEMGW-23

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

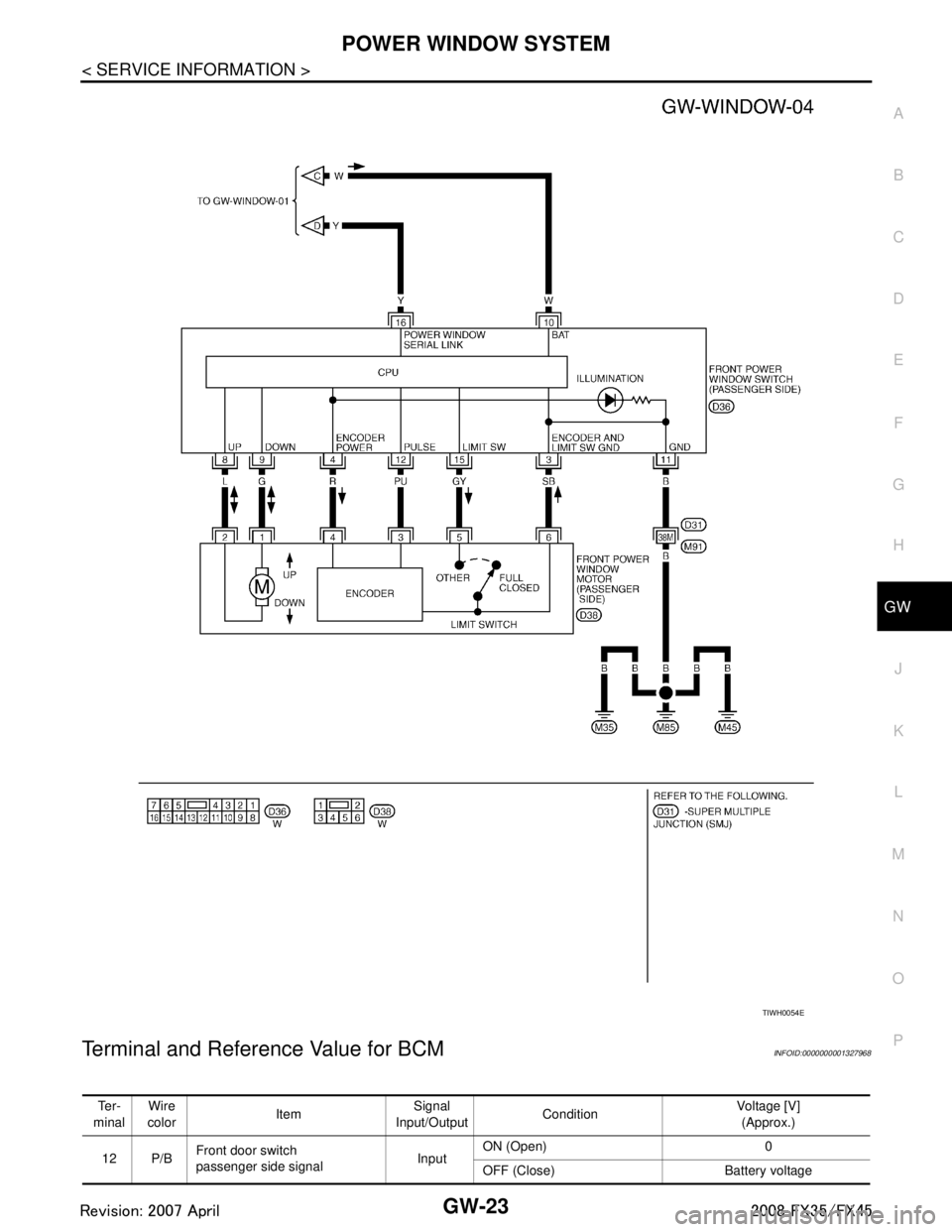

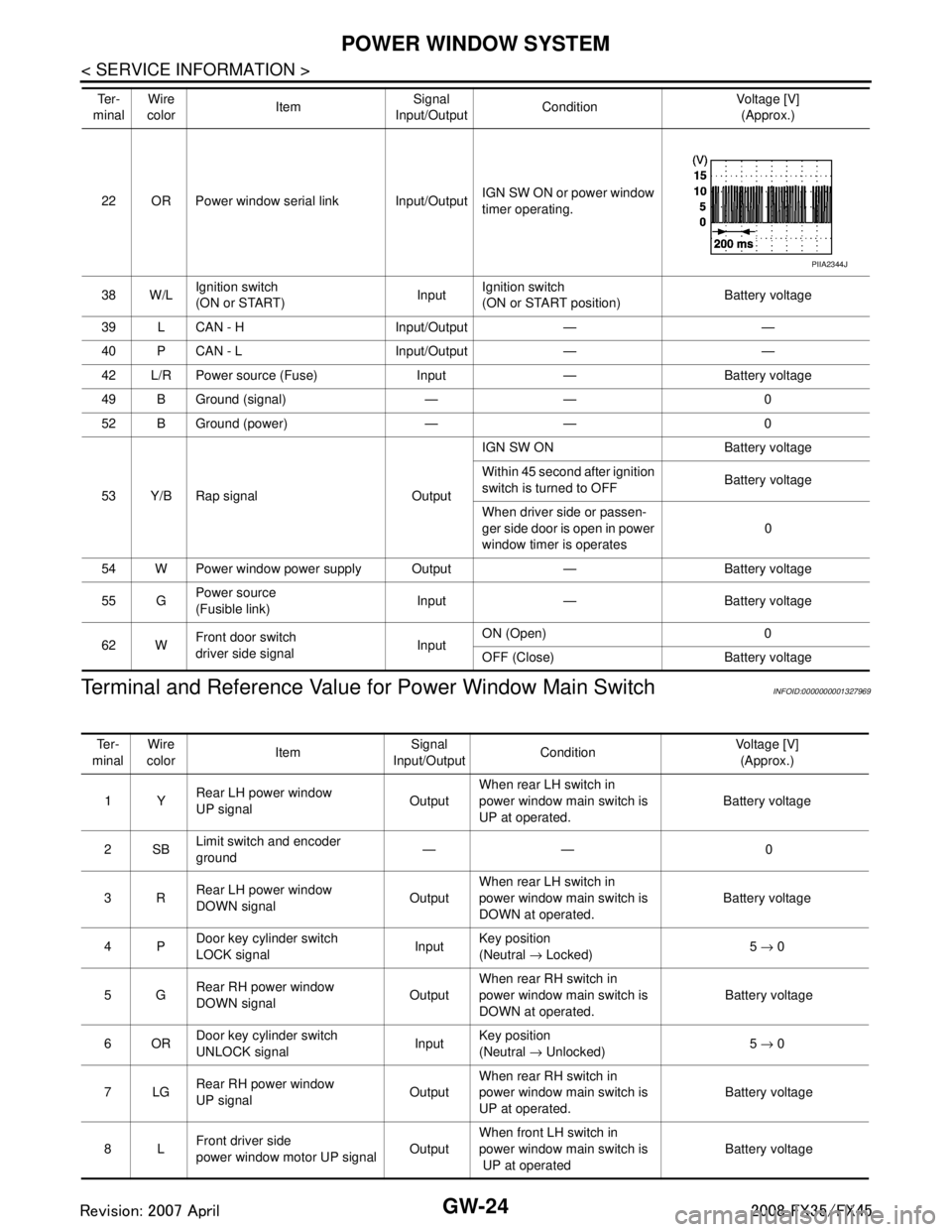

Terminal and Reference Value for BCMINFOID:0000000001327968

TIWH0054E

Te r -

minal Wire

color Item Signal

Input/Output Condition Voltage [V]

(Approx.)

12 P/B Front door switch

passenger side signal InputON (Open) 0

OFF (Close) Battery voltage

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2937 of 3924

GW-24

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

Terminal and Reference Value for Power Window Main Switch

INFOID:0000000001327969

22 OR Power window serial link Input/Output IGN SW ON or power window

timer operating.

38 W/L Ignition switch

(ON or START) InputIgnition switch

(ON or START position) Battery voltage

39 L CAN - H Input/Output — —

40 P CAN - L Input/Output — —

42 L/R Power source (Fuse) Input — Battery voltage

49 B Ground (signal) — — 0

52 B Ground (power) — — 0

53 Y/B Rap signal Output IGN SW ON Battery voltage

Within 45 second after ignition

switch is turned to OFF

Battery voltage

When driver side or passen-

ger side door is open in power

window timer is operates 0

54 W Power window power supply Output — Battery voltage

55 G Power source

(Fusible link)

Input — Battery voltage

62 W Front door switch

driver side signal InputON (Open) 0

OFF (Close) Battery voltage

Te r -

minal Wire

color Item Signal

Input/Output Condition Voltage [V]

(Approx.)

PIIA2344J

Te r -

minal Wire

color Item Signal

Input/Output Condition Voltage [V]

(Approx.)

1Y Rear LH power window

UP signal OutputWhen rear LH switch in

power window main switch is

UP at operated. Battery voltage

2SB Limit switch and encoder

ground —— 0

3R Rear LH power window

DOWN signal OutputWhen rear LH switch in

power window main switch is

DOWN at operated. Battery voltage

4P Door key cylinder switch

LOCK signal InputKey position

(Neutral

→ Locked) 5

→ 0

5G Rear RH power window

DOWN signal OutputWhen rear RH switch in

power window main switch is

DOWN at operated. Battery voltage

6OR Door key cylinder switch

UNLOCK signal Input

Key position

(Neutral

→ Unlocked) 5

→ 0

7LG Rear RH power window

UP signal OutputWhen rear RH switch in

power window main switch is

UP at operated. Battery voltage

8L Front driver side

power window motor UP signal

OutputWhen front LH switch in

power window main switch is

UP at operated

Battery voltage

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2938 of 3924

POWER WINDOW SYSTEMGW-25

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

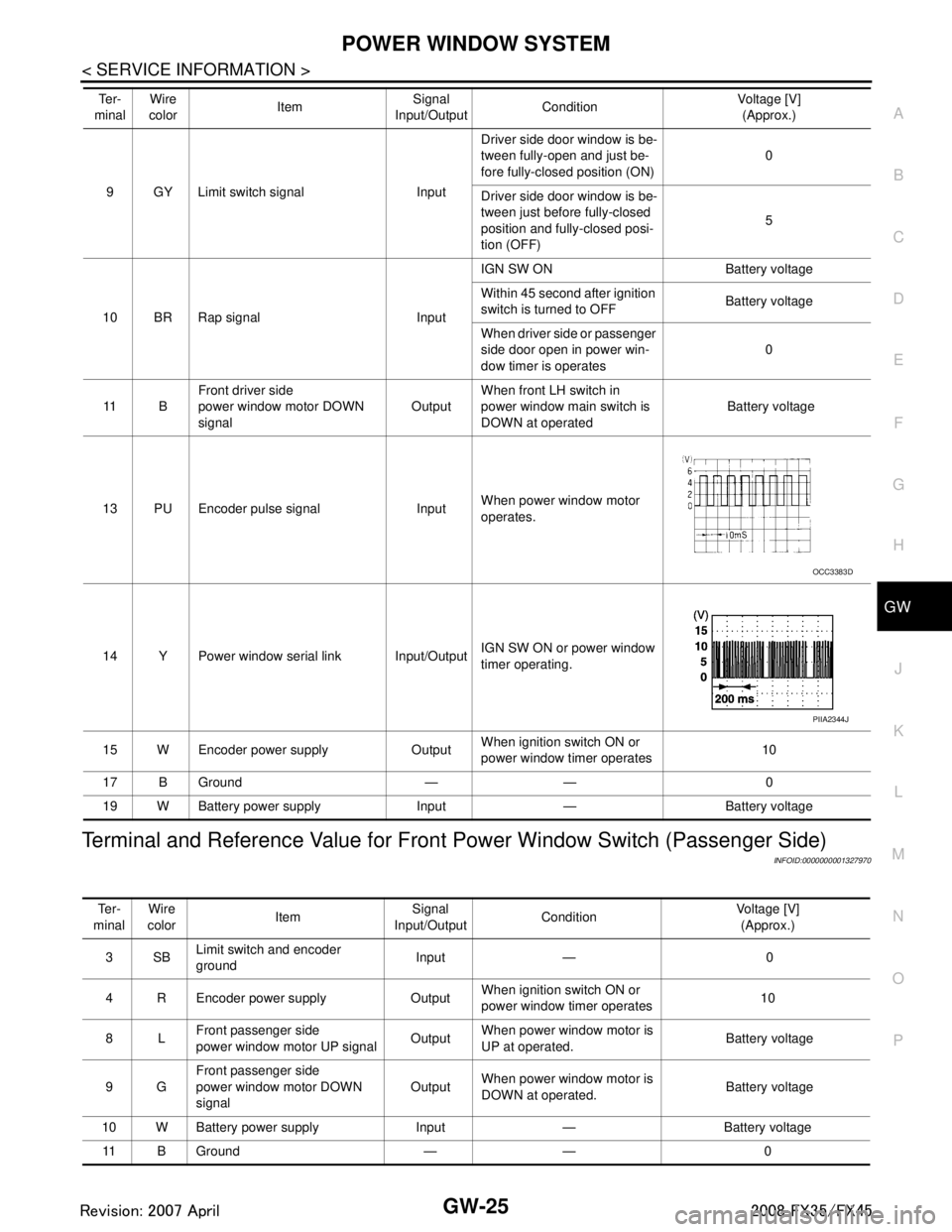

Terminal and Reference Value for Front Power Window Switch (Passenger Side)

INFOID:0000000001327970

9 GY Limit switch signal Input Driver side door window is be-

tween fully-open and just be-

fore fully-closed position (ON)

0

Driver side door window is be-

tween just before fully-closed

position and fully-closed posi-

tion (OFF) 5

10 BR Rap signal Input IGN SW ON Battery voltage

Within 45 second after ignition

switch is turned to OFF

Battery voltage

When driver side or passenger

side door open in power win-

dow timer is operates 0

11 B Front driver side

power window motor DOWN

signal Output

When front LH switch in

power window main switch is

DOWN at operated Battery voltage

13 PU Encoder pulse signal Input When power window motor

operates.

14 Y Power window serial link Input/Output IGN SW ON or power window

timer operating.

15 W Encoder power supply Output When ignition switch ON or

power window timer operates10

17 B Ground — — 0

19 W Battery power supply Input — Battery voltage

Te r -

minal Wire

color Item Signal

Input/Output Condition Voltage [V]

(Approx.)

OCC3383D

PIIA2344J

Te r -

minal Wire

color Item

Signal

Input/Output Condition

Voltage [V]

(Approx.)

3SB Limit switch and encoder

ground Input — 0

4 R Encoder power supply Output When ignition switch ON or

power window timer operates

10

8L Front passenger side

power window motor UP signal Output

When power window motor is

UP at operated. Battery voltage

9G Front passenger side

power window motor DOWN

signal Output

When power window motor is

DOWN at operated. Battery voltage

10 W Battery power supply Input — Battery voltage 11 B Ground — — 0

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2941 of 3924

![INFINITI FX35 2008 Service Manual

GW-28

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

Check BCM Power Suppl y and Ground Circuit

INFOID:0000000001327974

1.CHECK FUSE

Check 15A fuse [No. 1, located in fuse block (J/B)]

Check 15A fus INFINITI FX35 2008 Service Manual

GW-28

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

Check BCM Power Suppl y and Ground Circuit

INFOID:0000000001327974

1.CHECK FUSE

Check 15A fuse [No. 1, located in fuse block (J/B)]

Check 15A fus](/img/42/57017/w960_57017-2940.png)

GW-28

< SERVICE INFORMATION >

POWER WINDOW SYSTEM

Check BCM Power Suppl y and Ground Circuit

INFOID:0000000001327974

1.CHECK FUSE

Check 15A fuse [No. 1, located in fuse block (J/B)]

Check 15A fuse [No. 22, located in fuse block (J/B)]

Check 50A fusible link (letter M, located in the fuse and fusible link box).

NOTE:

Refer to GW-15, "

Component Parts and Harness Connector Location".

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown out, be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3

.

2.CHECK POWER SUPPLY CIRCUIT

Check voltage between BCM connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Check BCM power supply circuit for open or short.

3.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check continuity between BCM connector M4 terminal 49, 52 and ground.

OK or NG

OK >> Power supply and ground circuit are OK.

NG >> Check BCM ground circuit for open or short.

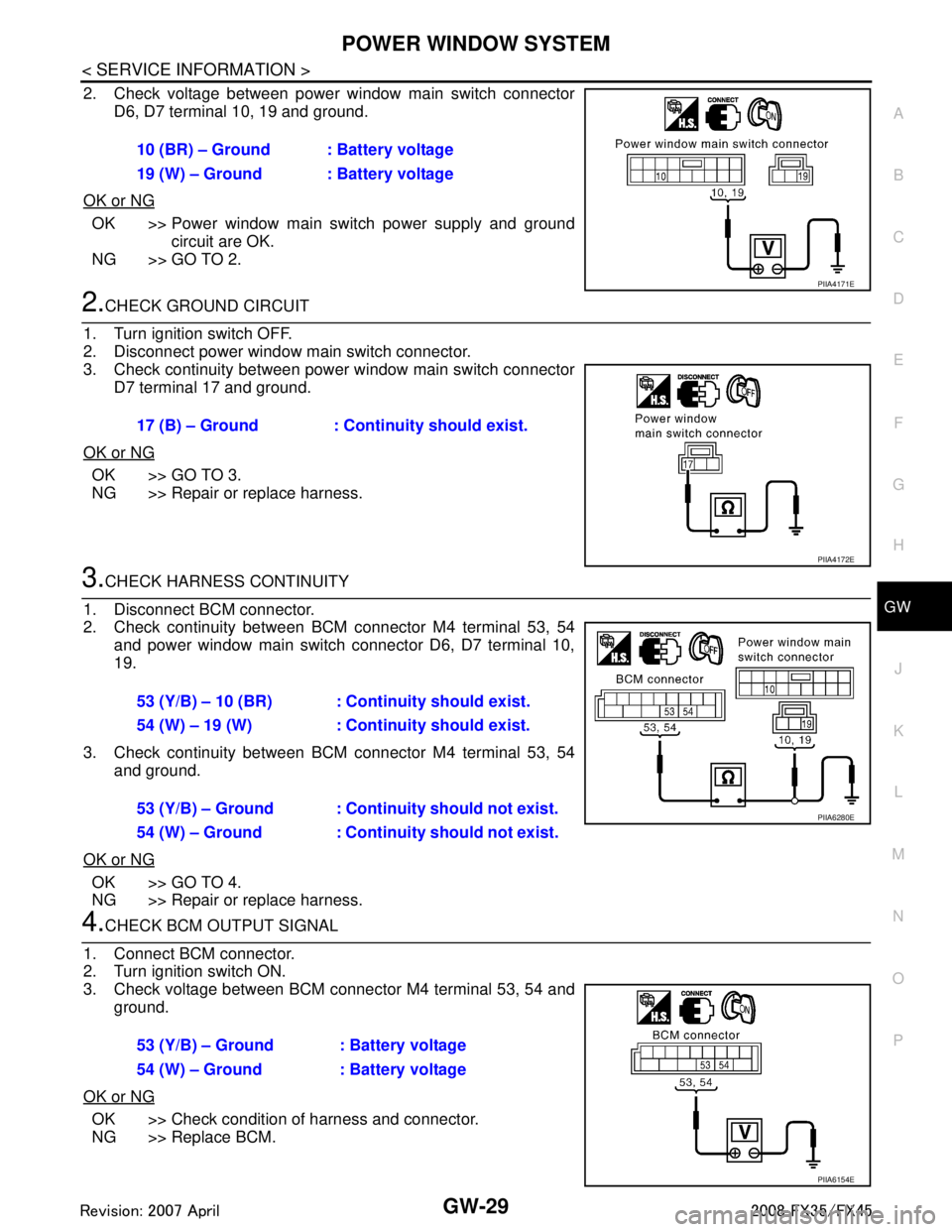

Check Power Window Main S witch Power Supply CircuitINFOID:0000000001327975

1.CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

Power window lock switch does not function Check power window lock switch GW-46

Auto operation does not operate but manual operates normally

(driver side)1. Check encoder ci

rcuit (driver side) GW-39

2. Replace power window main switch. —

Auto operation does not operate but manual operates normally

(passenger side) 1. Check encoder circuit (passenger side)

GW-40

2. Replace front power window switch (passen-

ger side) —

Symptom Repair order Refer to page

Connector

Terminal (Wire color)

Condition of

ignition switchVoltage [V]

(Approx.)

(+) (–)

M3 38 (W/L) GroundON

Battery

voltage

M4 42 (L/R)

OFF

55 (G)

PIIB1383E

49 (B) – Ground : Conti nuity should exist.

52 (B) – Ground : Conti nuity should exist.

PIIA6161E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 2942 of 3924

POWER WINDOW SYSTEMGW-29

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

2. Check voltage between power window main switch connector D6, D7 terminal 10, 19 and ground.

OK or NG

OK >> Power window main switch power supply and ground circuit are OK.

NG >> GO TO 2.

2.CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect power window main switch connector.

3. Check continuity between power window main switch connector D7 terminal 17 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK HARNESS CONTINUITY

1. Disconnect BCM connector.

2. Check continuity between BCM connector M4 terminal 53, 54 and power window main switch connector D6, D7 terminal 10,

19.

3. Check continuity between BCM connector M4 terminal 53, 54 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Turn ignition switch ON.

3. Check voltage between BCM connector M4 terminal 53, 54 and ground.

OK or NG

OK >> Check condition of harness and connector.

NG >> Replace BCM. 10 (BR) – Ground : Battery voltage

19 (W) – Ground : Battery voltage

PIIA4171E

17 (B) – Ground : Continuity should exist.

PIIA4172E

53 (Y/B) – 10 (BR) : Continuity should exist.

54 (W) – 19 (W) : Continuity should exist.

53 (Y/B) – Ground : Continuity should not exist.

54 (W) – Ground : Continui

ty should not exist.

PIIA6280E

53 (Y/B) – Ground : Battery voltage

54 (W) – Ground : Battery voltage

PIIA6154E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C