check oil INFINITI FX35 2008 Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 1006 of 3924

BR-22

< SERVICE INFORMATION >

FRONT DISC BRAKE

2. Apply rubber grease to piston boot. Cover the piston end withpiston boot, and install cylinder side lip on piston boot properly

into groove on cylinder body.

CAUTION:

Do not reuse piston boot.

3. Apply brake fluid to piston, and press piston into cylinder body by hand to assemble piston side lip on piston boot properly into

groove on piston.

CAUTION:

Press piston evenly and vary the pressing point to prevent

cylinder inner wall from being rubbed.

4. Install sliding pins and sliding pin boots to torque member.

5. Install the torque member to the knuckle spindle and tighten the mounting bolts to the specified torque. Refer to BR-18, "

Compo-

nent".

CAUTION:

Before installing torque member to vehicle, wipe oil and

grease on the washer seats on steering knuckle and the

mounting surface of the torque member.

6. Install pad retainers to torque member.

7. After assembling shims and shim covers to pad, install it to torque member.

CAUTION:

Inner pad and outer pad have pad-return mechanism on the

upper side of the pad retainer. When installing pad, be sure to install pad return lever to pad wear

sensor securely as shown in the figure.

8. Install cylinder body, and tighten sliding pin bolt to specified torque. Refer to BR-18, "

Component".

9. Install a projection of brake hose metal fitting by aligning with protrusions on cylinder body, and then tighten union bolts to specified torque. Refer to BR-10, "

Hydraulic Circuit".

CAUTION:

Assemble brake hose securely to protrusions on cylinder body.

Do not reuse copper washer for union bolts.

10. After installing caliper assembly, refill with new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake

System".

DISC ROTOR INSPECTION

Visual Inspection

Check surface of disc rotor for uneven wear, cracks, and serious damage. If any of them is detected, replace

applicable part.

Runout Inspection

1. Using wheel nuts, fix disc rotor to wheels hub. (2 or more positions)

SFIA2432E

SFIA2279E

SBR557E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1011 of 3924

REAR DISC BRAKEBR-27

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

5. Using a flat-bladed screwdriver, remove piston seals from cylin- der body.

CAUTION:

Be careful not to damage cylinder inner wall.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

CAUTION:

Use new brake fluid to clean. Do not use mine ral oils such as gasoline or kerosene.

Check inside surface of cylinder for score, rust wear , damage or foreign materials. If any of the

above conditions are obser ved, replace cylinder body.

Minor damage from rust or foreign materials m ay be eliminated by polishing surface with a fine

emery paper. Replace cylinder body if necessary.

Torque Member

Check for wear, cracks, and damage. If damage or def ormation is present, replace the torque member.

Piston

CAUTION:

Piston sliding surface is plated, do not polish with emery paper even if rust of foreign materials are

stuck to sliding surface.

Check piston for score, rust, wear , damage or presence of foreign materials. Replace if any of the

above condition are observed.

Sliding Pin Bolts and Sliding Pin Boots

Check sliding pin bolts and sliding pin boots, for wear, damage and cracks. If damage or deformation is

present, replace the applicable part.

ASSEMBLY

1. Apply polyglycol ether based lubricant to the piston seal, and install them to the cylinder body.

CAUTION:

Do not reuse piston seal.

2. Apply rubber grease to piston boots. Cover the piston end with piston boot, and install cylinder side lip on piston boots properly

into groove on cylinder body.

CAUTION:

Do not reuse piston boot.

SFIA0999E

SFIA2278E

SFIA2498E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1020 of 3924

![INFINITI FX35 2008 Repair Manual

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI INFINITI FX35 2008 Repair Manual

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOI](/img/42/57017/w960_57017-1019.png)

PRECAUTIONSBRC-5

< SERVICE INFORMATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612923

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Brake SystemINFOID:0000000001327654

Recommended fluid is brake fluid “DOT 3”. Refer to MA-9.

Do not reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas such as body. If brake fluid is splashed, wipe it off and flush area with water immediately.

Do not use mineral oils such as gasoline or kerosene to clean. They will ruin rubber parts and cause improper operation.

Using a flare nut crowfoot and torque wrench, securely tighten brake tube flare nuts.

Brake system is an important safe ty part. If a brake fluid leak is

detected, always disassemble the affected part. If a malfunction is

detected, replace part with a new one.

Before working, turn ignition switch OFF and disconnect electrical

connectors of ABS actuator and elec tric unit (control unit) or bat-

tery negative terminal.

When installing brake piping, be sure to check torque.

WARNING:

Clean brake pads and shoes with a waste cloth, then wipe with

a dust collector.

Precaution for Brake ControlINFOID:0000000001327655

During VDC/TCS/ABS operation, brake pedal lightly vi brates and a mechanical noise may be heard. This is

normal.

Just after starting vehicle after turning ignition switch ON, brake pedal may vibrate or motor operating noise

may be heard from engine room. This is a normal status of operation check.

Stopping distance may be longer than that of vehicles without ABS when vehicle drives on rough, gravel, or

snow-covered (fresh, deep snow) roads.

When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnostic

servicing. Besides electrical system inspection, c heck booster operation, brake fluid level, and fluid leaks.

If tire size and type are used in an improper combinat ion, or brake pads are not Genuine NISSAN parts,

stopping distance or steering stability may deteriorate.

If there is a radio, antenna, or antenna lead-in wire (including wiring) near control module, VDC/TCS/ABS

function may have a malfunction or error.

If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness

pinches, open circuits, and improper wiring.

SBR686C

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1085 of 3924

![INFINITI FX35 2008 Repair Manual

CO-14

< SERVICE INFORMATION >[VQ35DE]

RADIATOR

4. Remove reservoir tank and reservoir tank bracket.

5. Disconnect A/T fluid cooler hoses from radiator.

Install blind plug to avoid leakage of A/T fl INFINITI FX35 2008 Repair Manual

CO-14

< SERVICE INFORMATION >[VQ35DE]

RADIATOR

4. Remove reservoir tank and reservoir tank bracket.

5. Disconnect A/T fluid cooler hoses from radiator.

Install blind plug to avoid leakage of A/T fl](/img/42/57017/w960_57017-1084.png)

CO-14

< SERVICE INFORMATION >[VQ35DE]

RADIATOR

4. Remove reservoir tank and reservoir tank bracket.

5. Disconnect A/T fluid cooler hoses from radiator.

Install blind plug to avoid leakage of A/T fluid.

6. Removal radiator hoses (upper and lower) and reservoir tank hose. CAUTION:

Be careful not to allow engine coolant to contact drive belts.

7. Remove radiator cooling fan assembly. Refer to CO-20, "

Component".

8. Rotate two radiator upper mount brackets 90 degrees in the direction shown in the figure, and remove them.

9. Lift up and remove radiator. CAUTION:

Do not damage or scratch A/C condenser and radiator core

when removing.

INSTALLATION

Installation is the reverse order of removal.

INSPECTION AFTER INSTALLATION

Check for leaks of engine coolant using the radiator cap tester adapter (commercial service tool) and the

radiator cap tester (commercial service tool). Refer to CO-10, "

Inspection".

Start and warm up the engine. Visually make sure t hat there is no leaks of engine coolant and A/T fluid.

Checking Radiator CapINFOID:0000000001325849

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

SBIA0447E

SBIA0448E

PBIC2816E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1095 of 3924

![INFINITI FX35 2008 Repair Manual

CO-24

< SERVICE INFORMATION >[VQ35DE]

WATER PUMP

b. Screw M8 bolts [pitch: 1.25 mm (0.0492 in) length: approx. 50

mm (1.97 in)] into water pumps upper and lower mounting bolt

holes until they reach t INFINITI FX35 2008 Repair Manual

CO-24

< SERVICE INFORMATION >[VQ35DE]

WATER PUMP

b. Screw M8 bolts [pitch: 1.25 mm (0.0492 in) length: approx. 50

mm (1.97 in)] into water pumps upper and lower mounting bolt

holes until they reach t](/img/42/57017/w960_57017-1094.png)

CO-24

< SERVICE INFORMATION >[VQ35DE]

WATER PUMP

b. Screw M8 bolts [pitch: 1.25 mm (0.0492 in) length: approx. 50

mm (1.97 in)] into water pumps upper and lower mounting bolt

holes until they reach timing chain case. Then, alternately

tighten each bolt for a half turn, and pull out water pump.

CAUTION:

Pull straight out while pr eventing vane from contacting

socket in installation area.

Remove water pump without causing sprocket to contact timing chain.

c. Remove M8 bolts and O-rings from water pump. CAUTION:

Do not disassemble water pump.

INSPECTION AFTER REMOVAL

Check for badly rusted or corroded water pump body assembly.

Check for rough operation due to excessive end play.

If anything is found, replace water pump.

INSTALLATION

1. Install new O-rings to water pump. Apply engine oil and engine coolant to O-rings as shown in the

figure.

Locate O-ring with white paint mark to engine front side.

2. Install water pump. CAUTION:

Do not allow cylinder block to nip O-rings when installing

water pump.

Make sure timing chain and water pump sprocket are engaged.

Insert water pump by tightening mounting bolts alternately and evenly.

3. Install timing chain tensioner (primary) as follows:

JLC357B

SLC943A

PBIC1397E

PBIC1058E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1098 of 3924

![INFINITI FX35 2008 Repair Manual

WATER INLET AND THERMOSTAT ASSEMBLYCO-27

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

WATER INLET AND THERMOSTAT ASSEMBLY

ComponentINFOID:0000000001325858

Refer to

GI-8, "Compo INFINITI FX35 2008 Repair Manual

WATER INLET AND THERMOSTAT ASSEMBLYCO-27

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

WATER INLET AND THERMOSTAT ASSEMBLY

ComponentINFOID:0000000001325858

Refer to

GI-8, "Compo](/img/42/57017/w960_57017-1097.png)

WATER INLET AND THERMOSTAT ASSEMBLYCO-27

< SERVICE INFORMATION > [VQ35DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

WATER INLET AND THERMOSTAT ASSEMBLY

ComponentINFOID:0000000001325858

Refer to

GI-8, "Component" for symbols in the figure.

Removal and InstallationINFOID:0000000001325859

REMOVAL

1. Remove front engine undercover using power tool.

2. Drain engine coolant from radiator drain plug at the bottom of radiator, and from water drain plug at the

front of cylinder block. Refer to CO-10, "

Changing Engine Coolant" and CO-22, "Component".

CAUTION:

Perform this step when the engine is cold.

Do not spill engine coolant on drive belts.

3. Remove air duct (inlet). Refer to EM-17, "

Component".

4. Disconnect radiator hose (lower) and oil cooler wate r hose from water inlet and thermostat assembly.

5. Remove water inlet and thermostat assembly. CAUTION:

Do not disassemble water inle t and thermostat assembly.

Replace them as a unit, if necessary.

INSPECTION AFTER REMOVAL

1. Check valve seating condition at ordinary r oom temperatures. It should seat tightly.

1. Water inlet and thermostat assembly 2. Gasket

PBIC5002E

SLC962AB

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1113 of 3924

![INFINITI FX35 2008 Repair Manual

CO-42

< SERVICE INFORMATION >[VK45DE]

RADIATOR

11. Lift up and remove radiator.

CAUTION:

Do not damage or scratch A/C condenser and radiator core

when removing.

INSTALLATION

Install in the reverse or INFINITI FX35 2008 Repair Manual

CO-42

< SERVICE INFORMATION >[VK45DE]

RADIATOR

11. Lift up and remove radiator.

CAUTION:

Do not damage or scratch A/C condenser and radiator core

when removing.

INSTALLATION

Install in the reverse or](/img/42/57017/w960_57017-1112.png)

CO-42

< SERVICE INFORMATION >[VK45DE]

RADIATOR

11. Lift up and remove radiator.

CAUTION:

Do not damage or scratch A/C condenser and radiator core

when removing.

INSTALLATION

Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Check for leaks of engine coolant using radiator cap tester adapter (commercial service tool) and radiator

cap tester (commercial service tool). Refer to CO-37, "

Inspection".

Start and warm up engine. Visually Check if t here is no leaks of engine coolant and A/T fluid.

Checking Radiator CapINFOID:0000000001325873

Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

Pull negative-pressure valve to open it, and make sure that it close

completely when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that there are no unusualness in the opening and clos- ing conditions of negative-pressure valve.

Check radiator cap relief pressure.

- When connecting radiator cap to the radiator cap tester adapter (commercial service tool) (B) and t he radiator cap tester (commer-

cial service tool) (A), apply engine c oolant to the cap seal surface.

Replace radiator cap if there is an unusualness.

PBIC1536E

PBIC2816E

SMA967B

Standard : 78 - 98 kPa (0.8 - 1.0 kg/cm2, 11 - 14 psi)

Limit : 59 kPa (0.6 kg/cm

2, 9 psi)

PBIC5122J

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1134 of 3924

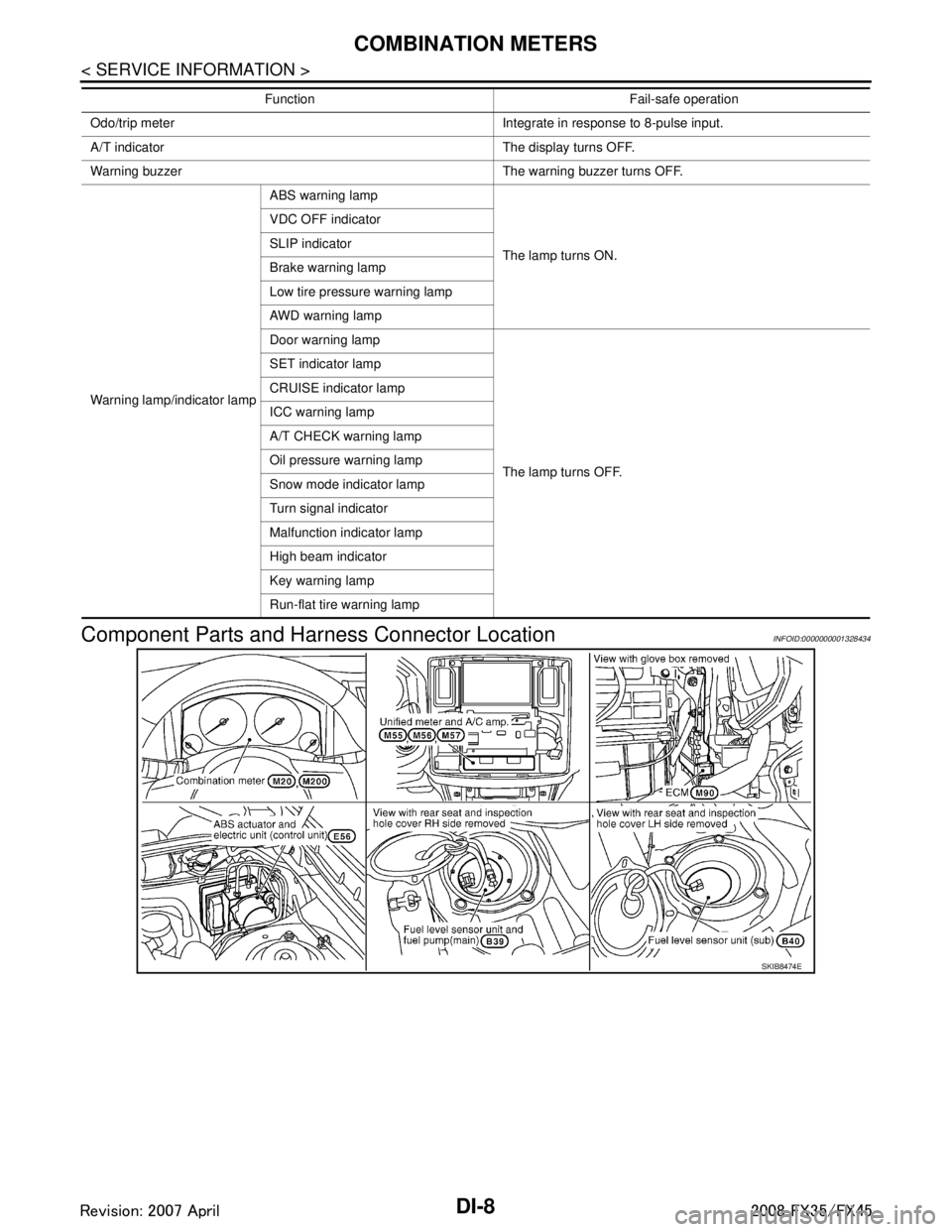

DI-8

< SERVICE INFORMATION >

COMBINATION METERS

Component Parts and Harn ess Connector Location

INFOID:0000000001328434

Odo/trip meter Integrate in response to 8-pulse input.

A/T indicator The display turns OFF.

Warning buzzer The warning buzzer turns OFF.

Warning lamp/indicator lamp ABS warning lamp

The lamp turns ON.

VDC OFF indicator

SLIP indicator

Brake warning lamp

Low tire pressure warning lamp

AWD warning lamp

Door warning lamp

The lamp turns OFF.

SET indicator lamp

CRUISE indicator lamp

ICC warning lamp

A/T CHECK warning lamp

Oil pressure warning lamp

Snow mode indicator lamp

Turn signal indicator

Malfunction indicator lamp

High beam indicator

Key warning lamp

Run-flat tire warning lamp

Function Fail-safe operation

SKIB8474E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1152 of 3924

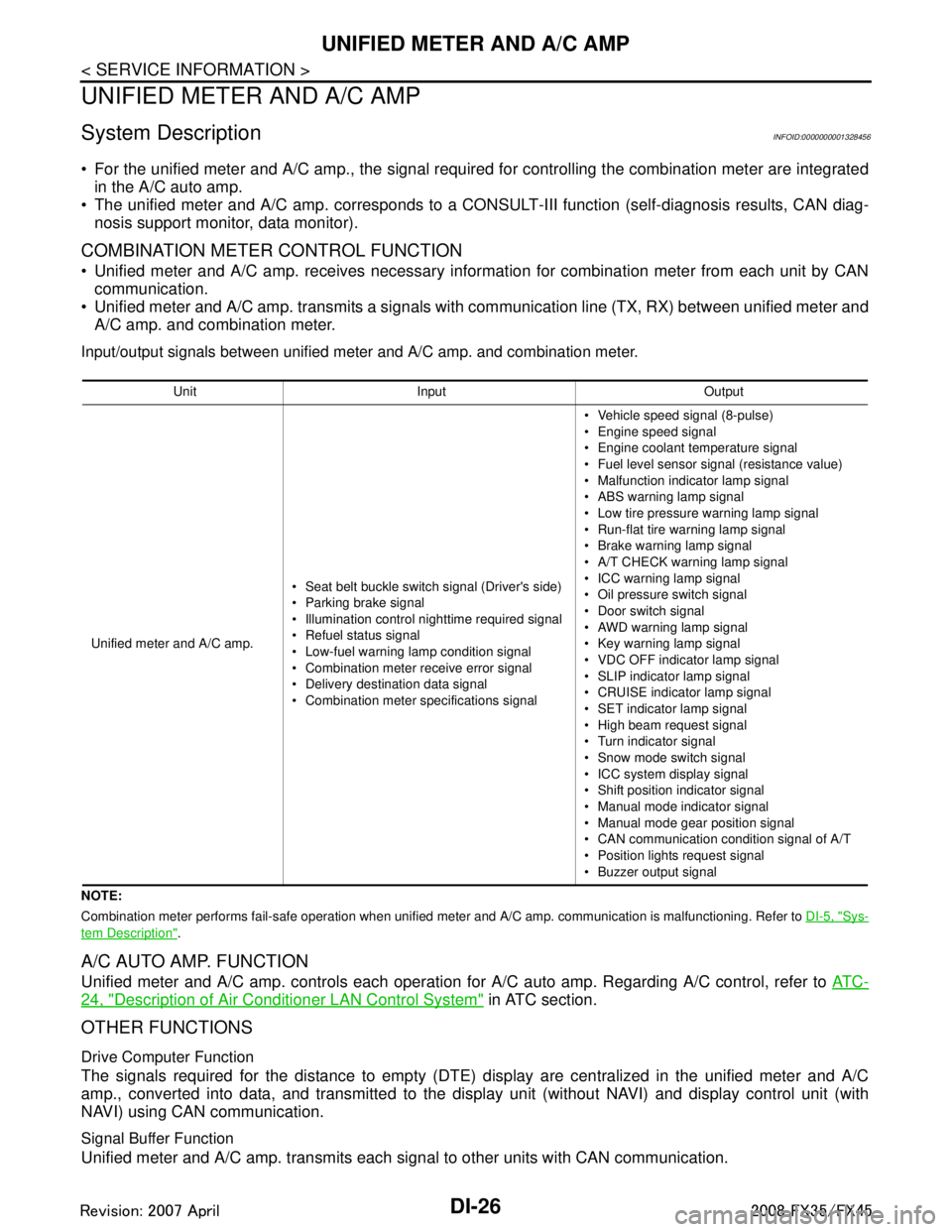

DI-26

< SERVICE INFORMATION >

UNIFIED METER AND A/C AMP

UNIFIED METER AND A/C AMP

System DescriptionINFOID:0000000001328456

For the unified meter and A/C amp., the signal required for controlling the combination meter are integrated

in the A/C auto amp.

The unified meter and A/C amp. corresponds to a CONS ULT-III function (self-diagnosis results, CAN diag-

nosis support monitor, data monitor).

COMBINATION METER CONTROL FUNCTION

Unified meter and A/C amp. receives necessary information for combination meter from each unit by CAN communication.

Unified meter and A/C amp. transmits a signals with communication line (TX, RX) between unified meter and A/C amp. and combination meter.

Input/output signals between unified meter and A/C amp. and combination meter.

NOTE:

Combination meter performs fail-safe operation when unified meter and A/C amp. communication is malfunctioning. Refer to DI-5, "

Sys-

tem Description".

A/C AUTO AMP. FUNCTION

Unified meter and A/C amp. controls each operation for A/C auto amp. Regarding A/C control, refer to AT C -

24, "Description of Air Conditioner LAN Control System" in ATC section.

OTHER FUNCTIONS

Drive Computer Function

The signals required for the distance to empty (DTE) display are centralized in the unified meter and A/C

amp., converted into data, and transmitted to the disp lay unit (without NAVI) and display control unit (with

NAVI) using CAN communication.

Signal Buffer Function

Unified meter and A/C amp. transmits each signal to other units with CAN communication.

Unit Input Output

Unified meter and A/C amp. Seat belt buckle switch signal (Driver's side)

Parking brake signal

Illumination control nighttime required signal

Refuel status signal

Low-fuel warning lamp condition signal

Combination meter receive error signal

Delivery destination data signal

Combination meter specifications signal Vehicle speed signal (8-pulse)

Engine speed signal

Engine coolant temperature signal

Fuel level sensor signal (resistance value)

Malfunction indicator lamp signal

ABS warning lamp signal

Low tire pressure warning lamp signal

Run-flat tire wa

rning lamp signal

Brake warning lamp signal

A/T CHECK warning lamp signal

ICC warning lamp signal

Oil pressure switch signal

Door switch signal

AWD warning lamp signal

Key warning lamp signal

VDC OFF indicator lamp signal

SLIP indicator lamp signal

CRUISE indicator lamp signal

SET indicator lamp signal

High beam request signal

Turn indicator signal

Snow mode switch signal

ICC system display signal

Shift position indicator signal

Manual mode indicator signal

Manual mode gear position signal

CAN communication condition signal of A/T

Position lights request signal

Buzzer output signal

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1155 of 3924

UNIFIED METER AND A/C AMPDI-29

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

DI

N

O P

NOTE:

Monitored item that does not match the vehicle is deleted from the display automatically.

*1: It dose not change when fastening or unfastening the passenger seat belt.

*2: Monitor keeps indicating “off” when brake warning lamp is on by the parking brake operation or low brake fluid level.

Power Supply and Gro und Circuit InspectionINFOID:0000000001328459

1.CHECK FUSE

Check for blown unified meter and A/C amp. fuses.

OK or NG

OK >> GO TO 2.

NG >> Be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-3, "

Schematic".

2.CHECK POWER SUPPLY CIRCUIT

OIL W/L [On/Off] X Indicates [On/Off] condition of oil pressure warning lamp.

VDC/TCS IND [On/Off] X Indicates [On/Off] condition of VDC OFF indicator lamp.

ABS W/L [On/Off] X Indicates [On/Off] condition of ABS warning lamp.

SLIP IND [On/Off] X Indicates [On/Off] condition of SLIP indicator lamp.

BRAKE W/L [On/Off]

*2X Indicates [On/Off] condition of brake warning lamp.

KEY G W/L [On/Off] X Indicates [On/Off] condition of key warning lamp (green).

KEY R W/L [On/Off] X Indicates [On/Off] condition of key warning lamp (red).

KEY KNOB W/L [On/Off] X Indicates [On/Off] condition of key knob warning lamp.

M RANGE SW [On/Off] X X Indicates [On/Off] condition of manual mode range switch.

NM RANGE SW [On/Off] X X Indicates [On/Off] condition of except for manual mode range

switch.

AT SFT UP SW [On/Off] X X Indicates [On/Off] condition of A/T shift-up switch.

AT SFT DWN SW [On/Off] X X Indicates [On/Off] condition of A/T shift-down switch.

BRAKE SW [On/Off] X Indicates [On/Off] condition of brake switch (stop lamp switch).

AT-M IND [On/Off] X X Indicates [On/Off] condition of A/T manual mode indicator.

AT-M GEAR [5-1] X X Indicates [5-1] condition of A/T manual mode gear position.

P RANGE IND [On/Off] X X Indicates [On/Off] condition of A/T shift P range indicator.

R RANGE IND [On/Off] X X Indicates [On/Off] condition of A/T shift R range indicator.

N RANGE IND [On/Off] X X Indicates [On/Off] condition of A/T shift N range indicator.

D RANGE IND [On/Off] X X Indicates [On/Off] condition of A/T shift D range indicator.

AT CHECK W/L X Indicates [On/Off] cond ition of AT CHECK warning lamp.

CRUISE IND [On/Off] X Indicates [On/Off] condition of CRUISE indicator lamp.

SET IND [On/Off] X Indicates [On/Off] condition of SET indicator lamp.

CRUISE W/L [On/Off] X Indicates [On/Of f] condition of ICC warning lamp.

4WD LOCK SW [On/Off] X This item is not used for this model. “off” is always displayed.

4WD LOCK IND [On/Off] X This item is not used for this model. “off” is always displayed.

4WD W/L [On/Off] X Indicates [On/Off] condition of AWD warning lamp.

RR COMB STATE [OK/NG] X Indicates [OK/NG] condition of rear combination lamp circuit. Display item [Unit]

MAIN

SIGNALS SELECTION

FROM MENU Contents

Power source Fuse No.

Battery power supply 19 ACC power supply 10, 11

Ignition power supply 12

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C