check oil INFINITI FX35 2008 Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: FX35, Model: INFINITI FX35 2008Pages: 3924, PDF Size: 81.37 MB

Page 538 of 3924

REFRIGERANT LINESATC-133

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

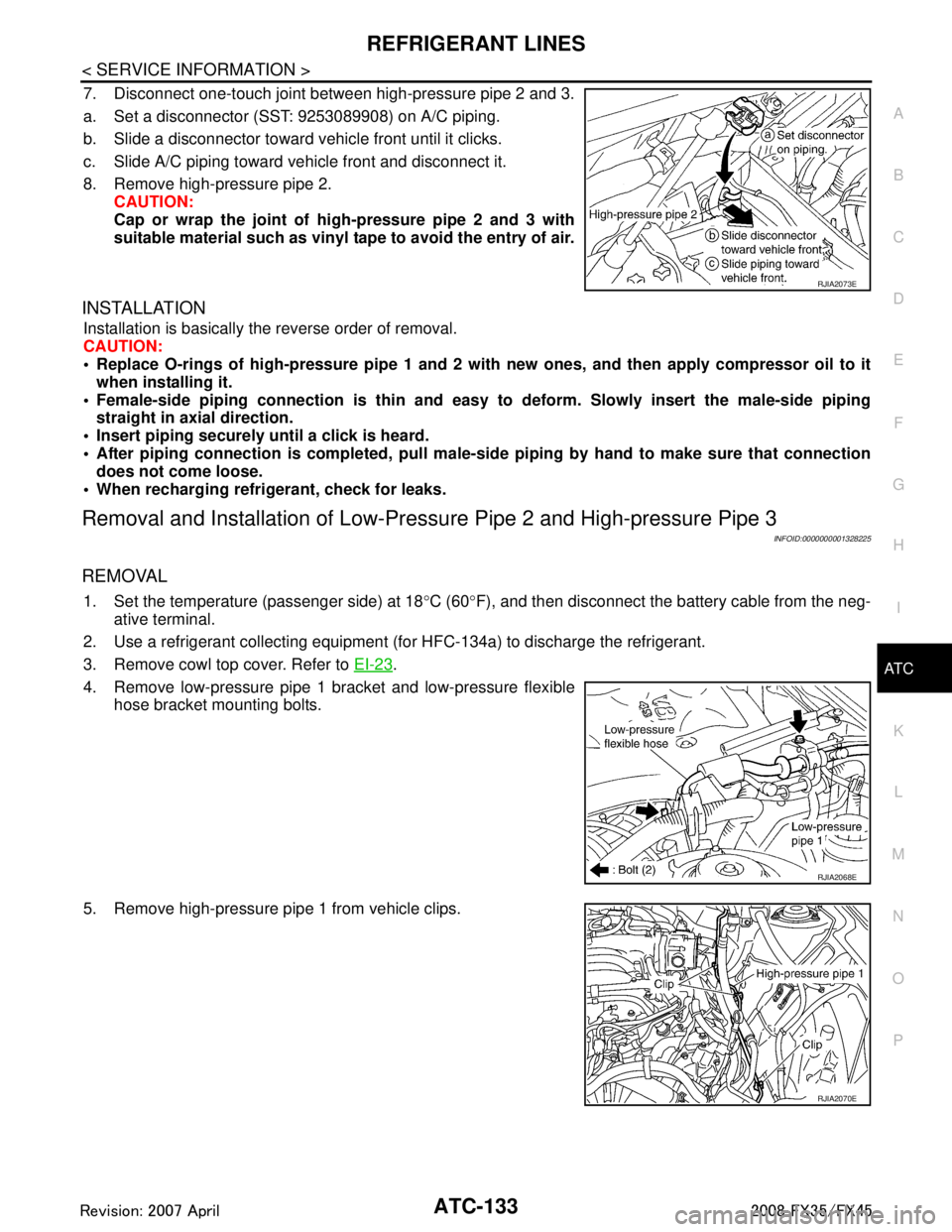

7. Disconnect one-touch joint between high-pressure pipe 2 and 3.

a. Set a disconnector (SST: 9253089908) on A/C piping.

b. Slide a disconnector toward vehicle front until it clicks.

c. Slide A/C piping toward vehicle front and disconnect it.

8. Remove high-pressure pipe 2. CAUTION:

Cap or wrap the joint of hi gh-pressure pipe 2 and 3 with

suitable material such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings of high-pressure pipe 1 and 2 wit h new ones, and then apply compressor oil to it

when installing it.

Female-side piping c onnection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

Insert piping securely until a click is heard.

After piping connection is comple ted, pull male-side piping by hand to make sure that connection

does not come loose.

When recharging refrigerant, check for leaks.

Removal and Installation of Low-Pressu re Pipe 2 and High-pressure Pipe 3

INFOID:0000000001328225

REMOVAL

1. Set the temperature (passenger side) at 18 °C (60 °F), and then disconnect the battery cable from the neg-

ative terminal.

2. Use a refrigerant collecting equipment (f or HFC-134a) to discharge the refrigerant.

3. Remove cowl top cover. Refer to EI-23

.

4. Remove low-pressure pipe 1 bracket and low-pressure flexible hose bracket mounting bolts.

5. Remove high-pressure pipe 1 from vehicle clips.

RJIA2073E

RJIA2068E

RJIA2070E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 539 of 3924

![INFINITI FX35 2008 Workshop Manual

ATC-134

< SERVICE INFORMATION >

REFRIGERANT LINES

6. Disconnect one-touch joints.

a. Set a disconnector [high-pressure side (SST: 9253089908), low-pressure side (SST: 9253089916)] on A/C piping.

b. S INFINITI FX35 2008 Workshop Manual

ATC-134

< SERVICE INFORMATION >

REFRIGERANT LINES

6. Disconnect one-touch joints.

a. Set a disconnector [high-pressure side (SST: 9253089908), low-pressure side (SST: 9253089916)] on A/C piping.

b. S](/img/42/57017/w960_57017-538.png)

ATC-134

< SERVICE INFORMATION >

REFRIGERANT LINES

6. Disconnect one-touch joints.

a. Set a disconnector [high-pressure side (SST: 9253089908), low-pressure side (SST: 9253089916)] on A/C piping.

b. Slide a disconnector toward vehicle front until it clicks.

c. Slide A/C piping toward vehicle front and disconnect it. CAUTION:

Cap or wrap the joint of low-pressure pipe 1 and high-pres-

sure pipe 2 with suitable material such as vinyl tape to

avoid the entry of air.

7. Remove blower unit. Refer to ATC-103

.

8. Remove mounting screws, and then remove air mix door motor (passenger side), mode door motor and evaporator cover.

9. Remove mounting bolt, and then remove low-pressure pipe 2 and high-pressure pipe 3.

CAUTION:

Cap or wrap the joint of expan sion valve with suitable mate-

rial such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings of low-pressure pipe 1, 2 and high-p ressure pipe 2, 3 with new ones, and then apply

compressor oil to it when installing it.

Female-side piping connection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

Insert piping securely until a click is heard.

After piping connection is comp leted, pull male-side piping by hand to make sure that connection

does not come loose.

When recharging refrigerant, check for leaks.

Removal and Installation of Liquid TankINFOID:0000000001328226

REMOVAL

1. Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant.

2. Remove front grille. Refer to EI-22

.

3. Clean liquid tank and its surrounding area, and remove dust and rust from liquid tank. CAUTION:

RJIA2037E

RJIA0940E

RJIA2038E

Low-pressure pipe 1 bracket and low-pressure flexible hose bracket mounting bolts

: 5.5 N·m (0.56 kg-m, 49 in-lb)

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 540 of 3924

REFRIGERANT LINESATC-135

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

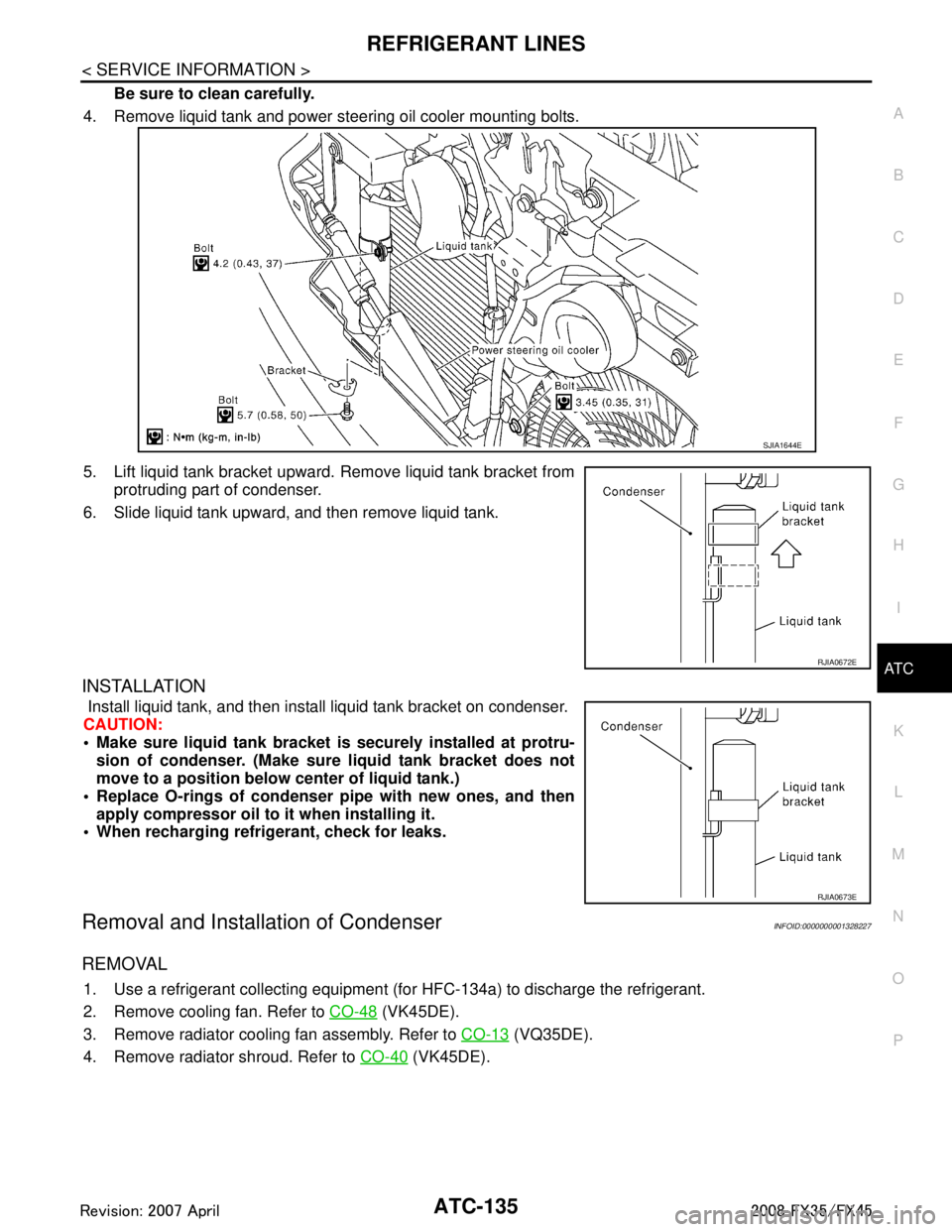

Be sure to clean carefully.

4. Remove liquid tank and power steering oil cooler mounting bolts.

5. Lift liquid tank bracket upward. Remove liquid tank bracket from protruding part of condenser.

6. Slide liquid tank upward, and then remove liquid tank.

INSTALLATION

Install liquid tank, and then install liquid tank bracket on condenser.

CAUTION:

Make sure liquid tank bracket is securely installed at protru- sion of condenser. (Make sure liquid tank bracket does not

move to a position below center of liquid tank.)

Replace O-rings of condenser pipe with new ones, and then

apply compressor oil to it when installing it.

When recharging refrigerant, check for leaks.

Removal and Installation of CondenserINFOID:0000000001328227

REMOVAL

1. Use a refrigerant collecting equipment (f or HFC-134a) to discharge the refrigerant.

2. Remove cooling fan. Refer to CO-48

(VK45DE).

3. Remove radiator cooling fan assembly. Refer to CO-13

(VQ35DE).

4. Remove radiator shroud. Refer to CO-40

(VK45DE).

SJIA1644E

RJIA0672E

RJIA0673E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 542 of 3924

REFRIGERANT LINESATC-137

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

After piping connection is comple ted, pull male-side piping by hand to make sure that connection

does not come loose.

When recharging refrigerant, check for leaks.

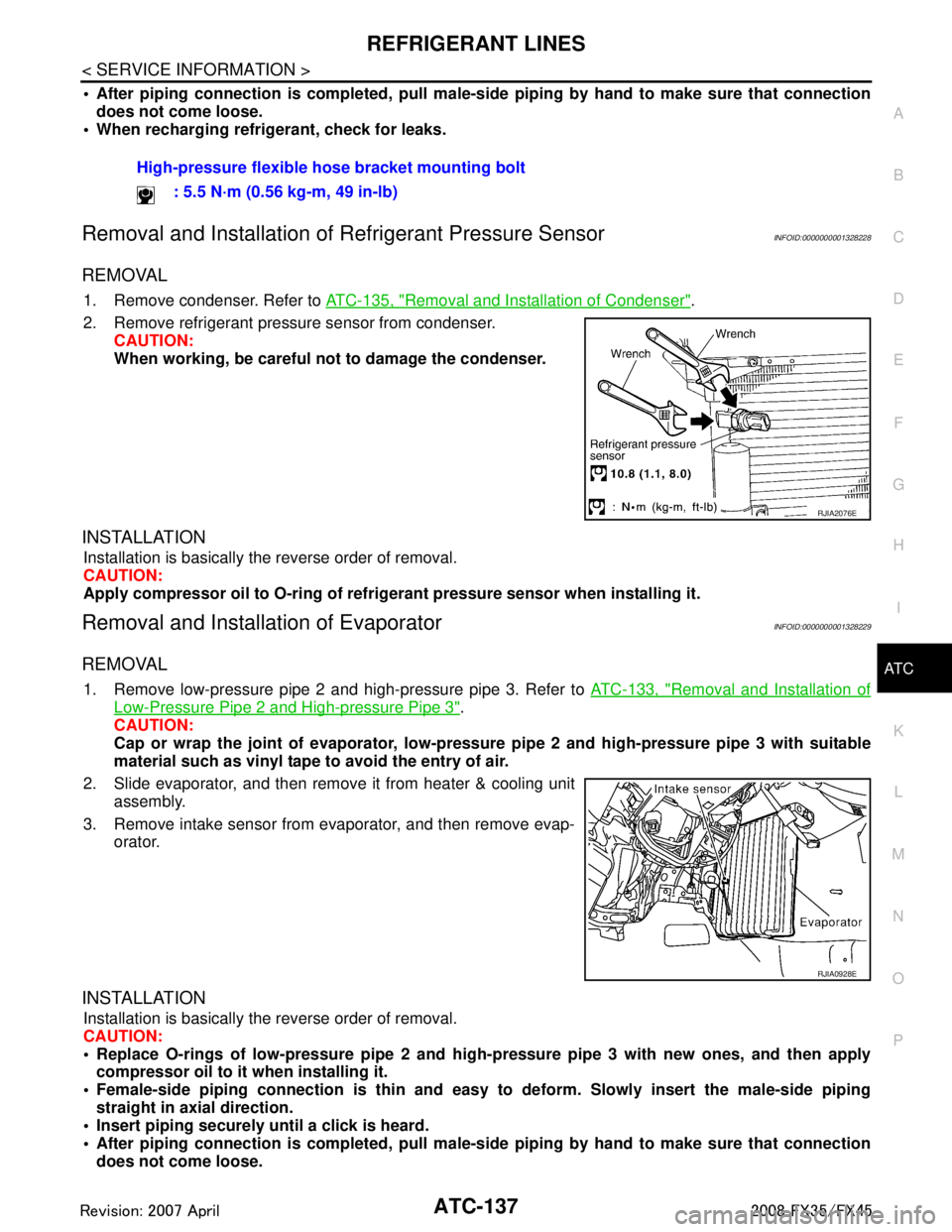

Removal and Installation of Refrigerant Pressure SensorINFOID:0000000001328228

REMOVAL

1. Remove condenser. Refer to ATC-135, "Removal and Installation of Condenser".

2. Remove refrigerant pressure sensor from condenser. CAUTION:

When working, be careful no t to damage the condenser.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Apply compressor oil to O-ring of refrig erant pressure sensor when installing it.

Removal and Installation of EvaporatorINFOID:0000000001328229

REMOVAL

1. Remove low-pressure pipe 2 and high-pressure pipe 3. Refer to ATC-133, "Removal and Installation of

Low-Pressure Pipe 2 and High-pressure Pipe 3".

CAUTION:

Cap or wrap the joint of evaporator, low-pressure pipe 2 and high-pressure pipe 3 with suitable

material such as vinyl tape to avoid the entry of air.

2. Slide evaporator, and then remove it from heater & cooling unit assembly.

3. Remove intake sensor from evaporator, and then remove evap- orator.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings of low-pressure pipe 2 and high- pressure pipe 3 with new ones, and then apply

compressor oil to it when installing it.

Female-side piping c onnection is thin and easy to deform. Slowly insert the male-side piping

straight in axial direction.

Insert piping securely until a click is heard.

After piping connection is comple ted, pull male-side piping by hand to make sure that connection

does not come loose. High-pressure flexible hose bracket mounting bolt

: 5.5 N·m (0.56 kg-m, 49 in-lb)

RJIA2076E

RJIA0928E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 543 of 3924

ATC-138

< SERVICE INFORMATION >

REFRIGERANT LINES

O-rings are different from low-pressure pipe 1 (high-pressure pipe 2) and low-pressure pipe 2 (high-

pressure pipe 3).

Mark the mounting position of intake sensor bracket prior to removal so that the reinstalled sensor

can be located in the same position.

When recharging refrigerant, check for leaks.

Removal and Installation of Expansion ValveINFOID:0000000001328230

REMOVAL

1. Remove evaporator. Refer to ATC-137, "Removal and Installation of Evaporator".

2. Remove mounting bolts, and then remove expansion valve. CAUTION:

Cap or wrap the joint of evaporator with suitable material

such as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is basically the reverse order of removal.

CAUTION:

Replace O-rings of evaporator with new ones, and then apply compressor oil to it when installing it.

O-rings are different from low-pressure pipe 1 (h igh-pressure pipe 2) and low-pressure pipe 2 (high-

pressure pipe 3).

When recharging refrigerant, check for leaks.

Checking of Refrigerant LeaksINFOID:0000000001328231

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage ma y indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electrical leak detector or fluorescent dye leak

detector (SST: J-42220).

If dye is observed, c onfirm the leak with an electrical leak detector. It is possible a prior leak was repaired and

not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electric al leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

CAUTION:

Moving the electrical leak detector probe slower and closer to the suspected leak area will improve the

chances of finding a leak.

Checking System for Leaks Using the Fluore scent Leak DetectorINFOID:0000000001328232

1. Check A/C system for leaks using the UV lamp and safety goggles (SST: J-42220) in a low sunlight area

(area without windows preferable). Illuminate all co mponents, fittings and lines. The dye will appear as a

bright green/yellow area at the point of leakage. Fluorescent dye observed at the evaporator drain open-

ing indicates an evaporator core assembly (tubes, core or expansion valve) leak.

2. If the suspected area is difficult to see, use an adjustable mirror or wipe the area with a clean shop rag or

cloth, with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye cleaner (SST: J-43872) to prevent future

misdiagnosis. Low-pressure pipe 1 bracket mounting bolt

: 5.5 N·m (0.56 kg-m, 49 in-lb)

RJIA1864E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 544 of 3924

REFRIGERANT LINESATC-139

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

4. Perform a system performance check and verify the l eak repair with an approved electrical leak detector.

NOTE:

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and lubricants, may falsely trigger the leak detector. Make sure the surfaces to be

checked are clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionINFOID:0000000001328233

(This procedure is only necessary when recharging t he system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pressure must be at least 345 kPa (3.52 kg/cm

2, 50 psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refr igerant dye into the injector tool (SST: J-41459).

3. Connect the injector tool to the A/C low-pressure side service valve.

4. Start the engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye inje ctor tool (SST: J-41459) (refer to the manufacture’s

operating instructions).

6. With the engine still running, disconnect the injector tool from the service valve. CAUTION:

Be careful the A/C system or replacing a componen t, pour the dye directly into the open system

connection and proceed wi th the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak , it may take from minutes to days for the dye to

penetrate a leak and become visible.

8. Attach a blue label as necessary.

Electrical Leak DetectorINFOID:0000000001328234

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C electrical leak

detector (SST) or equivalent. Ensure that the instrument is calibrated

and set properly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

1. Position probe approximately 5 mm (3/16 in) away from point to

be checked.

SHA196FA

SHA707EA

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 732 of 3924

BCS-12

< SERVICE INFORMATION >

BCM (BODY CONTROL MODULE)

ITEMS OF EACH PART

BCM can perform the following functions for each system.

NOTE:

CONSULT-III displays systems equipped in the vehicle.

×:Applicable

NOTE:

*1: Vehicle with remote keyless entry system display this item.

*2: Vehicle with Intelligent Key system display this item.

*3: This item is displayed, but does not function.

WORK SUPPORT

Display Item List

BCM Diagnostic test item Check item, diagnostic test mode Content

Inspection by part WORK SUPPORT Changes setting of each function.

SELF-DIAG RESULTS BCM performs self-diagnosis of CAN communication.

DATA MONITOR Displays the input data of BCM in real time.

CAN DIAG SUPPORT MNTR

The transmit/receive diagnosis result of CAN communication can be

read.

ACTIVE TEST Gives a drive signal to a load to check the operation.

ECU PART NUMBER ECM part number can be read.

CONFIGURATION (Not be used)

System and item CONSULT-III display Diagnostic test mode (Inspection by part)

WORK SUPPORT DATA MONITOR ACTIVE TEST

BCM BCM ×

Power door lock system DOOR LOCK ×××

Rear window defogger REAR DEFOGGER ××

Warning chime BUZZER ××

Room lamp timer INT LAMP ×××

Remote keyless entry system*

1MULTI REMOTE ENT ×××

Headlamp HEAD LAMP ×××

Wiper WIPER ×××

Turn signal lamp

Hazard lamp FLASHER

××

Blower fan switch signal

A/C switch signal AIR CONDITONER

×

Intelligent Key system*

2INTELLIGENT KEY ×

Combination switch COMB SW ×

NVIS IMMU ××

Room lamp battery saver BATTERY SAVER ×× ×

Trunk lid TRUNK*

3××

Vehicle security system THEFT ALM ×××

Retained power control RETAINED PWR ×××

Oil pressure swit ch SIGNAL BUFFER ××

Low tire pressure warning system AIR PRESSURE MONITOR ×××

Panic system PANIC ALARM ×

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 986 of 3924

BR-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001612918

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the “SUPPLEMENTAL RESTRAINT SYS-

TEM” and “SEAT BELTS” of this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISS AN/INFINITI dealer.

Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the “SUPPLEMEN TAL RESTRAINT SYSTEM”.

Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Procedure without Cowl Top CoverINFOID:0000000001612920

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precaution for Brake SystemINFOID:0000000001327604

Clean dust on front brake and rear brake with a vacuum dust collector. Do not blow with compressed air.

Recommended fluid is brake fluid “DOT 3”. MA-9, "

Fluids and Lubricants".

Do not reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas.

To clean or wash all parts of master cylinder, disc brake caliper and wheel cylinder, use new brake fluid.

Do not use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

Use a flare nut crowfoot and torque wrench when installing brake

tube.

When installing brake piping, be sure to check torque.

Before working, turn ignition switch OFF and disconnect connec- tors for ABS actuator and electric unit (control unit) or battery neg-

ative terminal.

Burnish the brake contact surfaces after refinishing or replacing drums or rotors, after replacing pads or linings, or if a soft pedal

occurs at very low mileage.

Refer to BR-23, "

Brake Burnishing Procedure" (Front disc brake),

BR-29, "

Brake Burnishing Procedure" (Rear disc brake).

WARNING:

Clean brake pads and shoes with a waste cl oth, then clean with a dust collector.

PIIB3706J

SBR686C

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1000 of 3924

BR-16

< SERVICE INFORMATION >

VACUUM LINES

VACUUM LINES

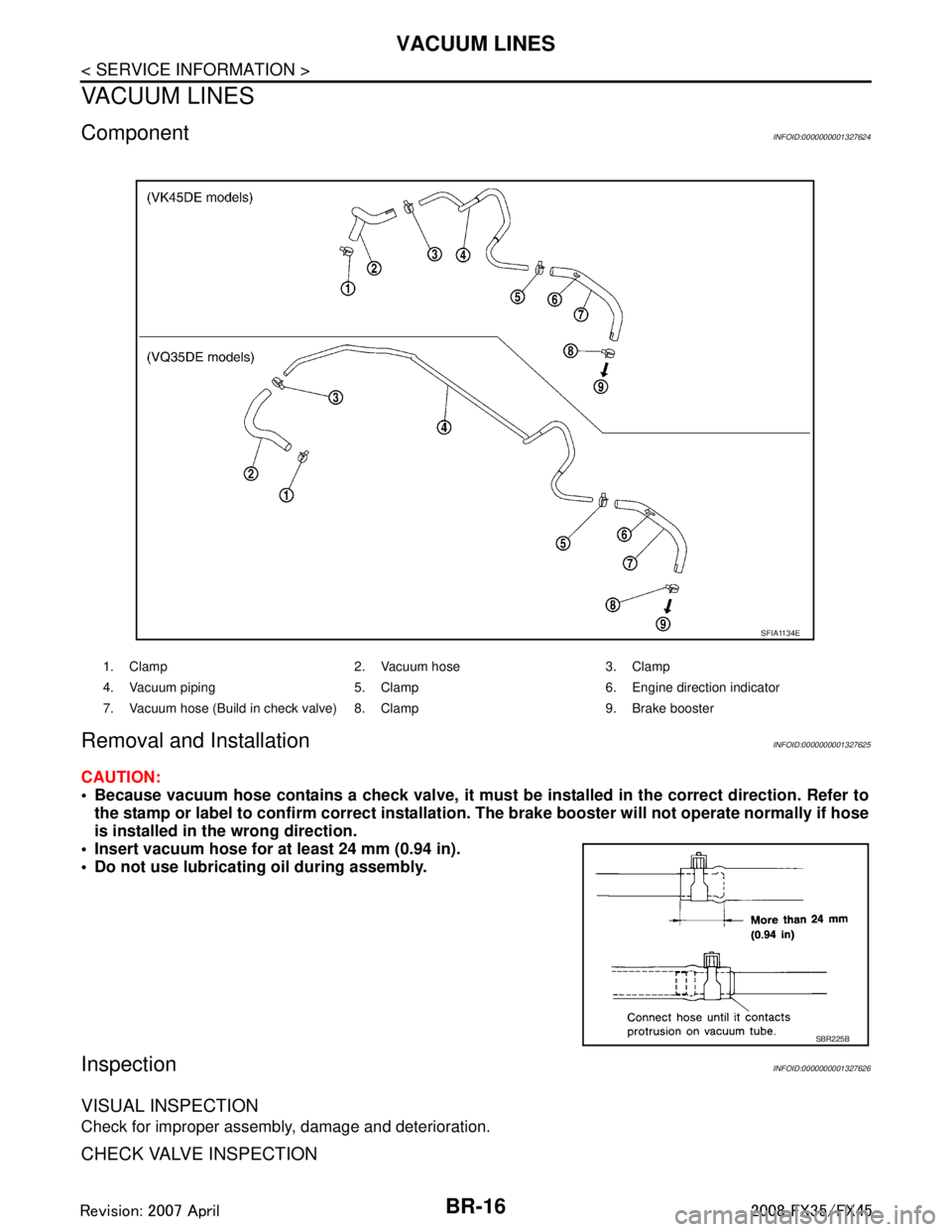

ComponentINFOID:0000000001327624

Removal and InstallationINFOID:0000000001327625

CAUTION:

Because vacuum hose contains a check valve, it must be installed in the correct direction. Refer to

the stamp or label to confirm co rrect installation. The brake booster will not ope rate normally if hose

is installed in the wrong direction.

Insert vacuum hose for at least 24 mm (0.94 in).

Do not use lubricating oil during assembly.

InspectionINFOID:0000000001327626

VISUAL INSPECTION

Check for improper assembly, damage and deterioration.

CHECK VALVE INSPECTION

1. Clamp 2. Vacuum hose 3. Clamp

4. Vacuum piping 5. Clamp 6. Engine direction indicator

7. Vacuum hose (Build in check valve) 8. Clamp 9. Brake booster

SFIA1134E

SBR225B

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C

Page 1005 of 3924

FRONT DISC BRAKEBR-21

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

3. Remove sliding pins and sliding pin boots from torque member.

4. Place a wooden block as shown in the figure, and blow air from union bolt mounting hole to remove pistons and piston boots.

CAUTION:

Do not get your fingers caught in piston.

5. Using a flat-bladed screwdriver, remove piston seal from cylin- der body.

CAUTION:

Be careful not to damage cylinder inner wall.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

CAUTION:

Use new brake fluid to clean. Do not use mi neral oils such as gasoline or kerosene.

Check the inner wall of cylinder for corrosion, wear, and damage. If a malfunction is detected, replace cylin-

der body.

Minor flaws caused by corrosion or a foreign material can be removed by polishing a surface of the inner wall with a fine sandpaper. Replace cylinder body, if necessary.

Torque Member

Check for wear, cracks, and damage. If a malfunc tion is detected, replace the torque member.

Piston

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Check piston surface for corrosion, wear, and damage. If a malfunction is detected, replace applicable part.

Sliding Pin, Sliding Pin Bolt, and Sliding Pin Boot

Check sliding pins, sliding pin bolts and sliding pin boots for wear, damage, and cracks. If a malfunction is

detected, replace applicable part.

ASSEMBLY

1. Apply polyglycol ether based lubricant to the piston seal, and

install them to the cylinder body.

CAUTION:

Do not reuse piston seal.

BRB0032D

SFIA0141E

SFIA2920E

3AA93ABC3ACD3AC03ACA3AC03AC63AC53A913A773A893A873A873A8E3A773A983AC73AC93AC03AC3

3A893A873A873A8F3A773A9D3AAF3A8A3A8C3A863A9D3AAF3A8B3A8C