battery INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5197 of 5621

SE-16

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

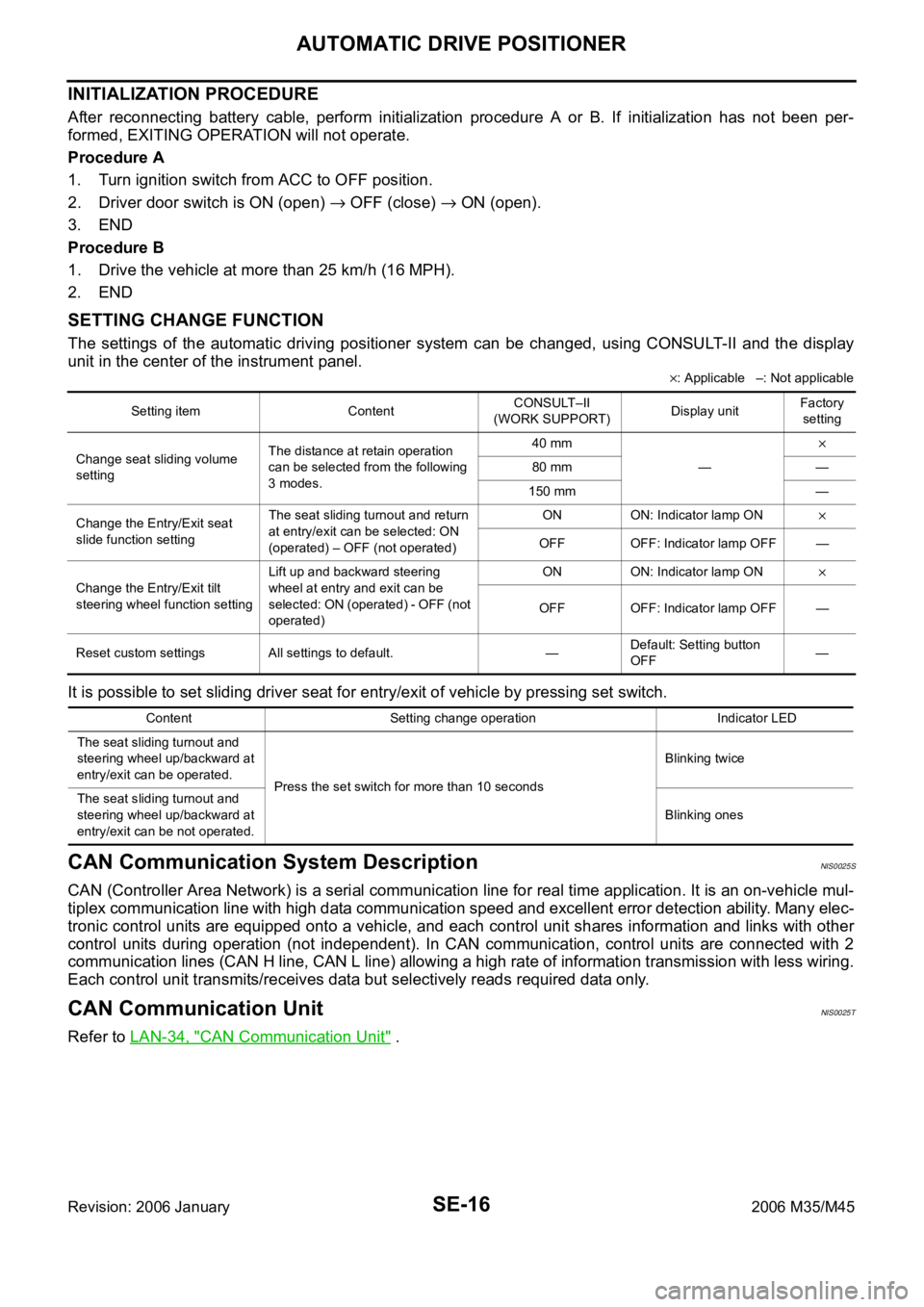

INITIALIZATION PROCEDURE

After reconnecting battery cable, perform initialization procedure A or B. If initialization has not been per-

formed, EXITING OPERATION will not operate.

Procedure A

1. Turn ignition switch from ACC to OFF position.

2. Driver door switch is ON (open)

OFF (close) ON (open).

3. END

Procedure B

1. Drive the vehicle at more than 25 km/h (16 MPH).

2. END

SETTING CHANGE FUNCTION

The settings of the automatic driving positioner system can be changed, using CONSULT-II and the display

unit in the center of the instrument panel.

: Applicable –: Not applicable

It is possible to set sliding driver seat for entry/exit of vehicle by pressing set switch.

CAN Communication System DescriptionNIS0025S

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitNIS0025T

Refer to LAN-34, "CAN Communication Unit" .

Setting item ContentCONSULT–II

(WORK SUPPORT)Display unitFactory

setting

Change seat sliding volume

settingThe distance at retain operation

can be selected from the following

3 modes.40 mm

—

80 mm —

150 mm —

Change the Entry/Exit seat

slide function settingThe seat sliding turnout and return

at entry/exit can be selected: ON

(operated) – OFF (not operated)ON ON: Indicator lamp ON

OFF OFF: Indicator lamp OFF —

Change the Entry/Exit tilt

steering wheel function settingLift up and backward steering

wheel at entry and exit can be

selected: ON (operated) - OFF (not

operated)ON ON: Indicator lamp ON

OFF OFF: Indicator lamp OFF —

Reset custom settings All settings to default. —Default: Setting button

OFF—

Content Setting change operation Indicator LED

The seat sliding turnout and

steering wheel up/backward at

entry/exit can be operated.

Press the set switch for more than 10 secondsBlinking twice

The seat sliding turnout and

steering wheel up/backward at

entry/exit can be not operated.Blinking ones

Page 5211 of 5621

SE-30

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

Terminals and Reference Values for BCMNIS0025W

Terminals and Reference Value for Intelligent Key UnitNIS0025X

Termi-

nal Wire

colorItem ConditionVoltage (V)

(Approx)

11 V Power source (ACC)Ignition switch

(ACC or ON position)Battery voltage

37 LG Key switch signalKey switch ON (Key is inserted in key

slot)Battery voltage

Key switch OFF (Key is remove from

key slot)0

38 W Power source (IGN)Ignition switch

(ON or START position)Battery voltage

39 L CAN-H — —

40 P CAN-L — —

42 P Power source (Fuse) — Battery voltage

52 B Ground — 0

55 W Power source (Fusible link) — Battery voltage

62 V Drive side door switch ON (Open)

OFF (Closed) 0 Battery voltage

Te r m i -

nalWire

ColorItemCondition

Voltage (V)

Approx. Ignition

Switch

PositionOperation or Conditions

1 SB Power source (Fuse) — — Battery voltage

19 BR/Y Key switch signal LOCKInsert Intelligent Key into key slot. Battery voltage

Remove Intelligent Key from key slot. 0

20 B Ground ON — 0

27 V P range switch —Selector lever is in “P” position. 0

Other than above Battery voltage

37 P CAN-L — — —

38 L CAN-H — — —

40 B Ground ON — 0

41 Y Power source (Fuse) — — Battery voltage

56 B Ground ON — 0

57 L Power source (Fuse) — — Battery voltage

58 OA/T device power

supply —Wake up state Battery voltage

Sleep state 0

72 B Ground ON 0

Page 5212 of 5621

AUTOMATIC DRIVE POSITIONER

SE-31

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

Terminals and Reference Values for Driver Seat Control UnitNIS0025Y

Te r m i -

nalWire

colorItem ConditionVoltage (V)

(Approx)

1 P/L UART LINE (RX) Tilt switch operated

3BR/WCAN-H — —

9 W/R Reclining sensor signalON (seat reclining motor operation)

Other than above 0 or 5

10 W/G Rear lifting sensor signalON (rear lifting motor operation)

Other than above 0 or 5

11 R/W Sliding switch backward signalON (seat sliding switch backward

operation)0

Other than above Battery voltage

12 G/W Reclining switch backward signalON (seat reclining switch backward

operation)0

Other than above Battery voltage

13 Y/W Front lifting switch DOWN signalON (front lifting switch DOWN opera-

tion)0

Other than above Battery voltage

14 L/W Rear lifting switch DOWN signalON (rear lifting switch DOWN opera-

tion)0

Other than above Battery voltage

17 P/B UART LINE (TX) Tilt switch operated

19 G/O CAN-L — —

21 G/R Detention switch signalA/T selector lever is in P position. 0

A/T selector lever is in other than P

position.Battery voltage

SKIA0175E

PIIB2807E

PIIB2809E

SKIA0175E

Page 5213 of 5621

SE-32

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

24 W Seat sliding sensor signalON (seat sliding motor operation)

Other than above 0 or 5

25 W/Y Front lifting sensor signalON (front lifting motor operation)

Other than above 0 or 5

26 R/B Seat sliding switch forward signalON (seat sliding switch forward oper-

ation)0

Other than above Battery voltage

27 G/BSeat reclining switch forward sig-

nalON (seat reclining switch forward

operation)0

Other than above Battery voltage

28 Y/B Front lifting switch UP signalON (front lifting switch UP operation) 0

Other than above Battery voltage

29 L/B Rear lifting switch UP signalON (rear lifting switch UP operation) 0

Other than above Battery voltage

31 B/W Sensor ground — 0

32 W/B Ground (signal) — 0

33 W Power source (C/B) — Battery voltage

35 R/WSliding motor forward output sig-

nalSliding switch forward operation

(Motor operated)Battery voltage

Other than above 0

36 G/WReclining motor forward output

signalReclining switch forward operation

(Motor operated)Battery voltage

Other than above 0

37 Y/WFront lifting motor DOWN output

signalFront lifting switch down operation

(Motor operated)Battery voltage

Other than above 0

38 L/BRear lifting motor UP output sig-

nalRear lifting switch up operation (Motor

operated)Battery voltage

Other than above 0

39 L/WRear lifting motor DOWN output

signalRear lifting switch down operation

(Motor operated)Battery voltage

Other than above 0

40 R/B Power source (Fuse) — Battery voltage

42 R/BSliding motor backward output

signalSliding switch backward operation

(Motor operated)Battery voltage

Other than above 0 Te r m i -

nalWire

colorItem ConditionVoltage (V)

(Approx)

SIIA0690J

SIIA0691J

Page 5214 of 5621

AUTOMATIC DRIVE POSITIONER

SE-33

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

Terminals and Reference Values for Automatic Drive Positioner Control UnitNIS0025Z

44 G/BReclining motor backward output

signalReclining switch backward operation

(Motor operated)Battery voltage

Other than above 0

45 Y/BFront lifting motor UP output sig-

nalFront lifting switch upward operation

(Motor operated)Battery voltage

Other than above 0

48 B Ground (power) — 0 Te r m i -

nalWire

colorItem ConditionVoltage (V)

(Approx)

Te r m i -

nal Wire

colorItem ConditionVoltage (V)

(Approx)

1 Y Tilt switch UP signalTilt switch is UP operation 0

Other than above 5

5L/RMirror sensor (RH vertical)

signalWhen mirror motor RH is UP or DOWN

operationChanges between 4.2 (close to perk)

0.5 (close to valley)

6LGMirror sensor (LH vertical)

signalWhen mirror motor LH is UP or DOWN

operationChanges between 4.2 (close to perk)

0.5 (close to valley)

7 L Tilt sensor signalTilt position : Top 1

Tilt position : Bottom 3.8

9 LG Memory switch 1 signalMemory switch 1 ON 0

Other than above 5

10 O UART LINE (TX) Tilt switch operated

11 RTelescopic switch forward

signalWhen telescopic switch is forward oper-

ation0

Other than above 5

12 R/GMemory switch indictor 1 sig-

nalWhen illuminate indictor 1 1

Other than above Battery voltage

13 PMemory switch indictor 2 sig-

nalWhen illuminate indictor 2 1

Other than above Battery voltage

14 L Mirror motor RH UP signalWhen mirror motor RH UP operation Battery voltage

Other than above 0

15 G Mirror motor RH LEFT signalWhen mirror motor RH LEFT operation Battery voltage

Other than above 0

16 W/LMirror motor LH DOWN sig-

nalWhen mirror motor LH DOWN opera-

tionBattery voltage

Other than above 0

Mirror motor LH RIGHT sig-

nalWhen mirror motor LH RIGHT opera-

tionBattery voltage

Other than above 0

17 LG Tilt switch DOWN signalWhen tilt switch is DOWN position 0

Other than above 5

SKIA0175E

Page 5215 of 5621

SE-34

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

21 SBMirror sensor (RH horizon-

tal) signalWhen mirror motor RH is LEFT or

RIGHT operationChanges between 3.5 (close to left

edge) 0.5 (close to right edge)

22 O/LMirror sensor (LH horizontal)

signalWhen mirror motor LH is LEFT or

RIGHT operationChanges between 0.5 (close to left

edge) 3.5 (close to right edge)

23 GR Telescopic sensor inputTelescopic position : Top 4.6

Telescopic position : Bottom 0.4

24 BR/W Set switch signalSet switch ON 0

Other than above 5

25 LG/B Memory switch 2 signalMemory switch 2 ON 0

Other than above 5

26 P UART LINE (RX) Tilt switch is operated

27 WTelescopic switch backward

signalTelescopic switch turned to backward 0

Other than above 5

30 GRMirror motor RH DOWN sig-

nalWhen mirror motor RH DOWN opera-

tionBattery voltage

Other than above 0

Mirror motor RH RIGTH sig-

nalWhen mirror motor RH RIGHT opera-

tionBattery voltage

Other than above 0

31 BR Mirror motor LH UP signalWhen mirror motor LH UP operation Battery voltage

Other than above 0

32 V Mirror motor LH LEFT signalWhen mirror motor LH LEFT operation Battery voltage

Other than above 0

33 W Sensor power supply — 5

34 R Power source (Fuse) — Battery voltage

35 LG Tilt motor UP signalTilt switch is UP operation Battery voltage

Other than above 0

36 PTelescopic motor forward sig-

nalTelescopic switch is forward operation Battery voltage

Other than above 0

39 L Power source (C/B) — Battery voltage

40 B Ground — 0

41 Y Sensor ground — 0

42 G Tilt motor DOWN signalTilt switch is DOWN operation Battery voltage

Other than above 0

44 GTelescopic motor backward

signalTelescopic switch is backward opera-

tionBattery voltage

Other than above 0

48 B Ground — 0 Termi-

nal Wire

colorItem ConditionVoltage (V)

(Approx)

SKIA0175E

Page 5219 of 5621

SE-38

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

ACTIVE TEST

CAUTION:

During vehicle driving, do not perform active test.

NOTE:

If active test is performed, reset seat memory and key fob interlock drive positioner after performing work.

DISPLAY ITEM LIST

WORK SUPPORT

The seat slide amount at entry/exit operation setting can be changed by CONSULT-II. Refer to SE-16, "SET-

TING CHANGE FUNCTION" .

DETENT SW “ON/OFF”The selector lever position “OFF (P position) / ON (other than P position)” judged

from the detention switch signal is displayed.

STARTER SW “ON/OFF”Ignition key switch ON (START, ON) /OFF (IGN, ACC, or OFF) status judged from

the ignition switch signal is displayed.

SLIDE PULSE —Value (32768) when battery connects is as standard. If it moves backward, the

value increases. If it moves forward, the value decreases.

RECLN PULSE —Value (32768) when battery connects is as standard. If it moves backward, the

value increases. If it moves forward, the value decreases.

LIFT FR PULSE —Value (32768) when battery connects is as standard. If it moves DOWN, the value

increases. If it moves UP, the value decreases.

LIFT RR PULSE —Value (32768) when battery connects is as standard. If it moves DOWN, the value

increases. If it moves UP, the value decreases.

MIR/SEN RH U–D “V” Voltage output from RH door mirror sensor (UP/DOWN) is displayed.

MIR/SEN RH R–L “V” Voltage output from RH door mirror sensor (LH/RH) is displayed.

MIR/SEN LH U–D “V” Voltage output from LH door mirror sensor (UP/DOWN) is displayed.

MIR/SEN LH R–L “V” Voltage output from LH door mirror sensor (LH/RH) is displayed. Monitor item [OPERATION or UNIT] Contents

Test item Description

TILT MOTOR The tilt motor is activated by receiving the drive signal.

TELESCO MOTOR The telescopic motor is activated by receiving the drive signal.

SEAT SLIDE The sliding motor is activated by receiving the drive signal.

SEAT RECLINING The reclining motor is activated by receiving the drive signal.

SEAT LIFTER FR The front lifting motor is activated by receiving the drive signal.

SEAT LIFTER RR The rear lifting motor is activated by receiving the drive signal.

MIRROR MOTOR RHThe RH mirror motor moves the mirror UP/DOWN and LEFT/RIGHT by receiving the drive

signal.

MIRROR MOTOR LHThe LH mirror motor moves the mirror UP/DOWN and LEFT/RIGHT by receiving the drive

signal.

MEMORY SW INDCTR The memory switch indicator is lit by receiving the drive signal.

Page 5222 of 5621

AUTOMATIC DRIVE POSITIONER

SE-41

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

CAN Communication Inspection Using CONSULT-II (Self-Diagnosis)NIS00263

1. SELF-DIAGNOSTIC RESULT CHECK

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Connect to CONSULT-II, and select “AUTO DRIVE POS.” on the “SELECT DIAG SYSTEM” screen.

2. Select “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

3. Check display content in self-diagnostic results.

Contents displayed

No malfunction>>Inspection End.

Malfunction in CAN communication system>>After printing the monitor items, go to “CAN System”. Refer to

LAN-7, "

Precautions When Using CONSULT-II" .

BCM Power Supply and Ground Circuit CheckNIS00264

1. CHECK FUSE

Check if any of the following fuses in the BCM are blown.

NOTE:

Refer to SE-11, "

Component Parts And Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-

3, "POWER SUPPLY ROUTING CIRCUIT" .

CONSULT-II display code Diagnosis item

U1000INITIAL DIAG

TRANSMIT DIAG

BCM/SEC

METER/M&A

TCM

Unit Power source Fuse No.

BCMBattery power supplyF (50A)

Battery power supply 21 (10A)

Ignition switch ON or STRAT signal 1 (15A)

Ignition switch ACC or ON signal 6 (10A)

Page 5223 of 5621

SE-42

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

2. CHECK POWER SUPPLY CIRCUIT (BCM)

1. Turn ignition switch OFF.

2. Disconnect BCM connector.

3. Check voltage between BCM connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace the harness between BCM and fuse.

3. CHECK GROUND CIRCUIT (BCM)

Check continuity between BCM connector and ground.

OK or NG

OK >> BCM power supply and ground circuit are OK.

NG >> Repair or replace the harness between BCM and

ground.

Driver Seat Control Unit Power Supply and Ground Circuit CheckNIS00265

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit connector.

3. Check voltage between driver seat control unit connector and

ground.

OK or NG

OK >> GO TO 2.

NG >> Check the following.

Repair or replace harness between driver seat control unit and fuse block (J/B).

Circuit breaker.

Terminals

Condition of ignition

switchVoltage (V)

(Approx.) (+)

(–)

BCM

connectorTerminal

M138

GroundON

Battery voltage 11 A C C

M242

OFF

55

PIIB6296E

BCM connector Terminal

GroundContinuity

M2 52 Yes

PIIB5935E

Terminals

Voltage (V)

(Approx.) (+)

(–)

Driver seat con-

trol unit connectorTerminal

B20533

Ground Battery voltage

40

PIIB6128E

Page 5224 of 5621

AUTOMATIC DRIVE POSITIONER

SE-43

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

2. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between the driver seat control unit connector and ground.

OK or NG

OK >> Driver seat control unit power supply and ground circuit

are OK.

NG >> Repair or replace harness between driver seat control

unit and ground.

Automatic Drive Positioner Power Supply and Ground Circuit CheckNIS00266

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit connector.

3. Check voltage between automatic drive positioner control unit connector and ground.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace harness between automatic drive

positioner control unit and fuse block (J/B).

2. CHECK GROUND CIRCUIT

Check continuity between the automatic drive positioner control unit connector and ground.

OK or NG

OK >> Automatic drive positioner control unit power supply and

ground circuit are OK.

NG >> Repair or replace harness between automatic drive

positioner control unit and ground.

Driver seat control

unit connectorTerminal

GroundContinuity

B204 32

Ye s

B205 48

PIIB6129E

Terminals

Voltage (V)

(Approx.) (+)

(–) Automatic drive

positioner control

unit connectorTerminal

M734

Ground Battery voltage

39

PIIB6130E

Automatic drive

positioner control

unit connectorTerminal

GroundContinuity

M740

Ye s

48

PIIB6131E