Body INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1274 of 5621

BODY REPAIR

BL-335

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

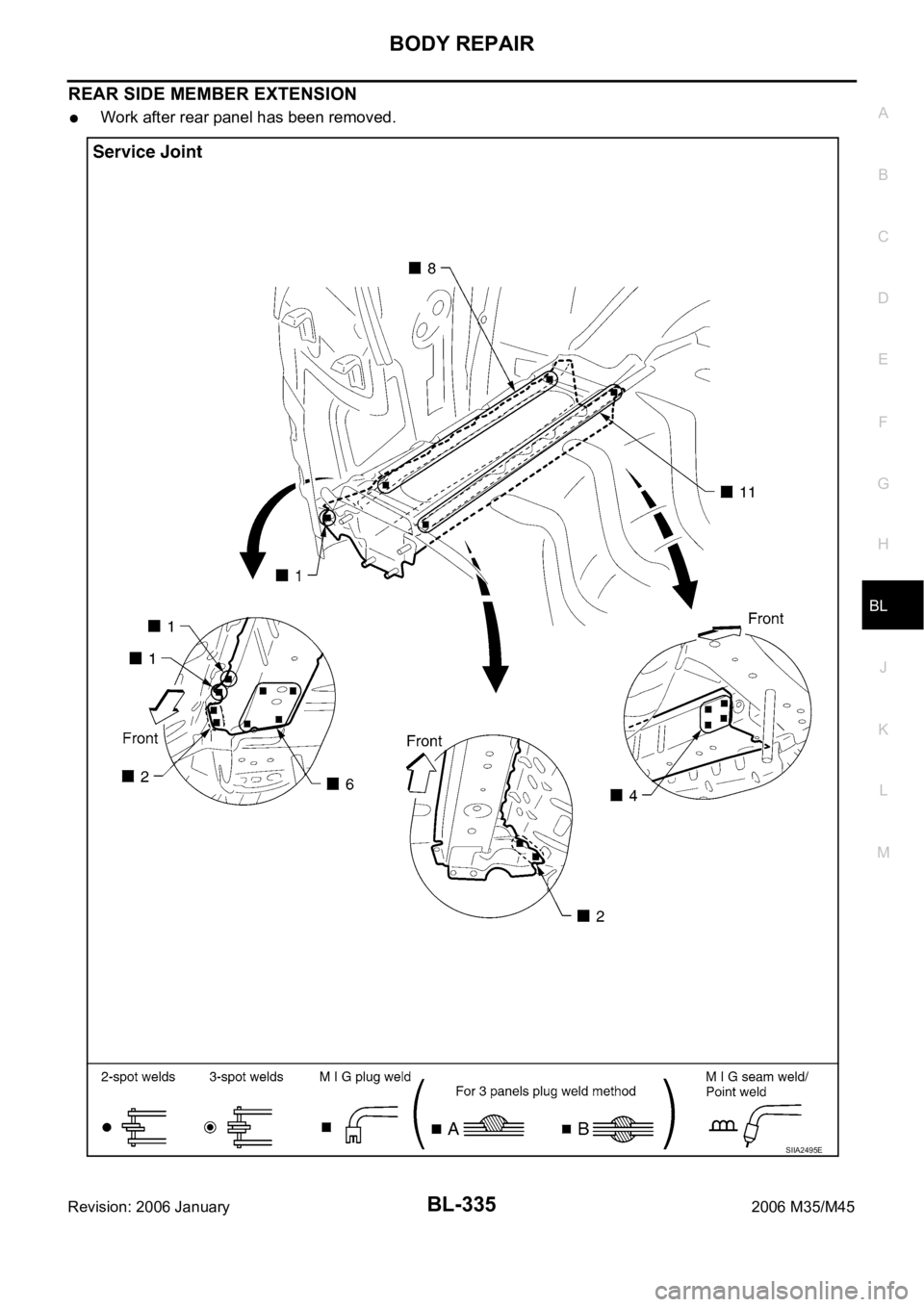

REAR SIDE MEMBER EXTENSION

Work after rear panel has been removed.

SIIA2495E

Page 1275 of 5621

BL-336

BODY REPAIR

Revision: 2006 January2006 M35/M45

Change parts

Rear side member extension (LH)

Page 1290 of 5621

BRAKE MASTER CYLINDER

BR-15

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

BRAKE MASTER CYLINDERPFP:46010

On-Board InspectionNFS000P2

LEAK INSPECTION

Check for leaking in a master cylinder installation surface, a reservoir tank installation surface, and brake

tube connections.

Removal and InstallationNFS000P3

CAUTION:

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, wash it away with water immediately.

Never scratch the piston of master cylinder when installing/removing because the piston is

exposed. Check if any dust is not on the piston, and wash with brake fluid if needed.

Hold cylinder body when handing master cylinder. Never hold the piston because the piston might

be detached if pulled strongly.

REMOVAL

1. Drain brake fluid. Refer to BR-10, "Drain and Refill" .

2. Disconnect brake fluid level switch harness connector.

3. Disconnect master cylinder brake tubes, using a flare nut wrench.

4. Remove master cylinder mounting nuts and remove master cylinder assembly from vehicle.

INSTALLATION

CAUTION:

Refill with new brake fluid “DOT 3”.

Never reuse drained brake fluid.

1. Installation is in the reverse order of removal.

CAUTION:

Apply silicone grease to brake booster (to “A” position in

the figure) when installing master cylinder to brake booster.

2. Tighten brake tube flare nut to the specified torque using a flare

nut torque wrench. Refer to BR-12, "

Hydraulic Circuit" .

3. Refill with new brake fluid and bleed air. Refer to BR-11, "

Bleed-

ing Brake System" .

SFIA2847J

Page 1291 of 5621

BR-16

BRAKE MASTER CYLINDER

Revision: 2006 January2006 M35/M45

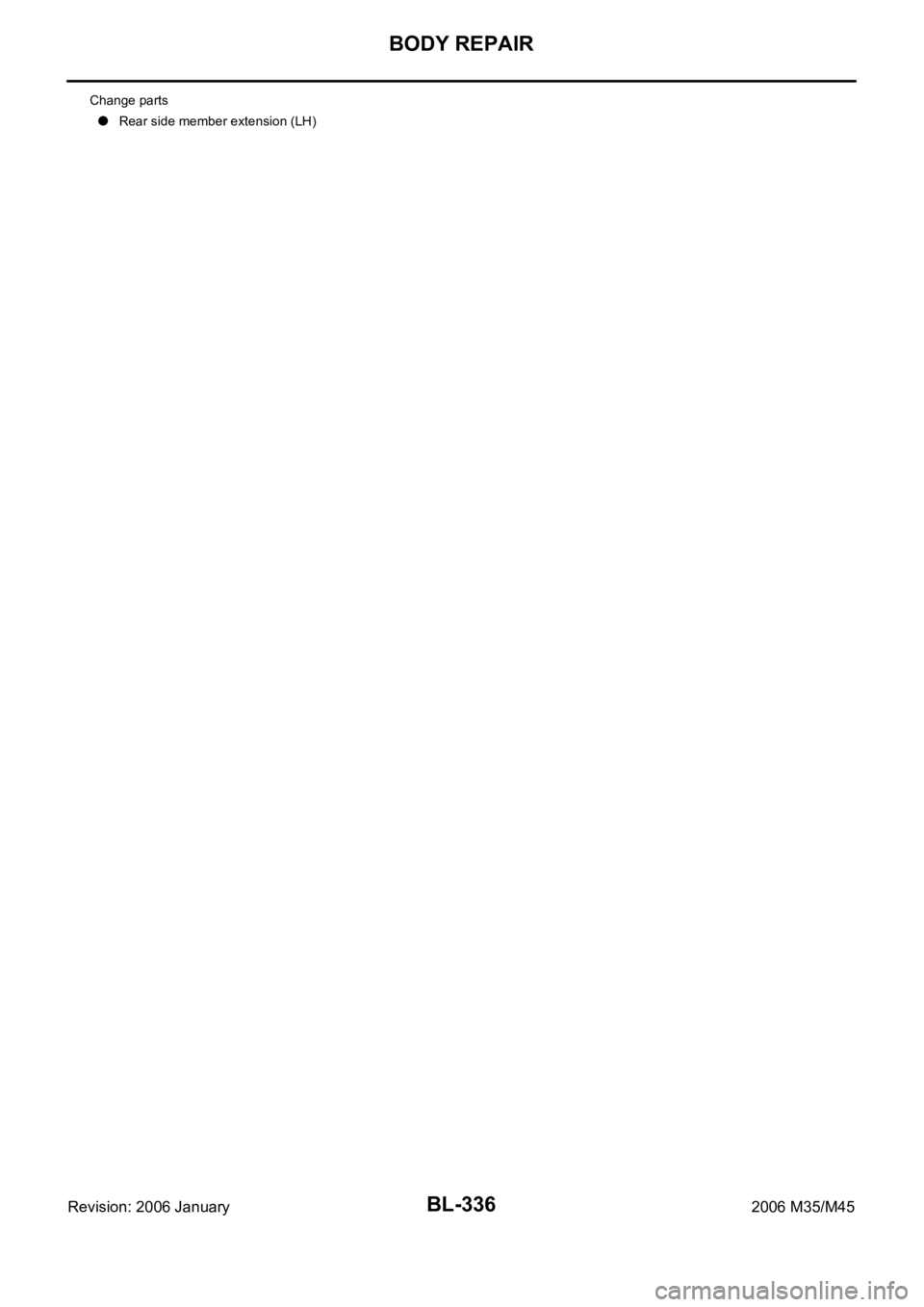

Disassembly and AssemblyNFS000P4

COMPONENTS

Disassembly and AssemblyNFS000P5

DISASSEMBLY

CAUTION:

Master cylinder cannot be disassembled.

Remove reservoir tank only when absolutely necessary.

When securing master cylinder assembly in a vise, be sure not to over-tighten.

When securing in a vise use copper plates or cloth to protect the flange.

1. Using a pin punch [commercial service tool: diameter approxi-

mately 4 mm (0.16 in)], remove mounting pin on reservoir tank.

2. Remove reservoir tank and grommet from cylinder body.

1. Reservoir cap 2. Oil strainer 3. Reservoir tank

4. Grommet 5. Pin 6. Master cylinder assembly

7. O-ring 8. Brake fluid level switch connector

: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease: Brake fluid

Refer to GI section for symbol marks except in the above.

SFIA2955E

BRA0559D

Page 1292 of 5621

BRAKE MASTER CYLINDER

BR-17

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

ASSEMBLY

CAUTION:

Never use mineral oils such as kerosene, gasoline during the cleaning and assembly process.

Do not drop parts. If a part is dropped, do not use it.

1. Apply brake fluid to the grommet and attach it to the cylinder body.

CAUTION:

Do not reuse grommet.

2. Install reservoir tank onto the cylinder body.

3. Secure master cylinder assembly into a vise with a chamfered

pin insert hole on cylinder body facing upward.

4. Tilt reservoir tank as shown in the figure and insert mounting pin.

Return reservoir tank to a upright position when mounting pin

passes through the pinhole in the cylinder body. Push the

mounting pin to the opposite pinhole of the reservoir tank so that

it is the same conditions as the insertion side.

CAUTION:

Be sure to fix the flange part with the brake tube installa-

tion side of cylinder body up.

Do not reuse mounting pin.

PFIA0505J

BRA0559D

Page 1298 of 5621

FRONT DISC BRAKE

BR-23

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

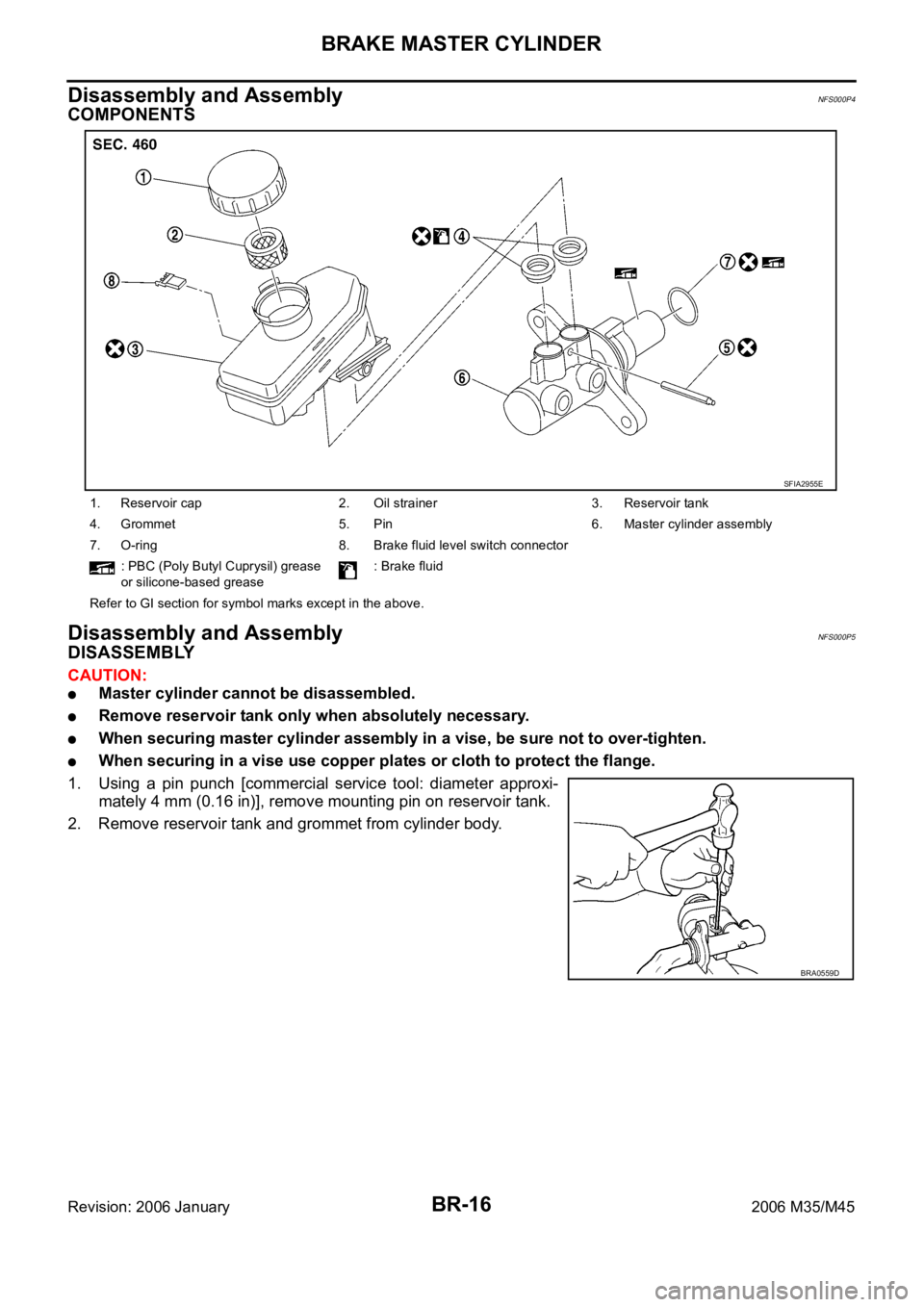

FRONT DISC BRAKEPFP:41000

On-Board InspectionNFS000PB

PAD WEAR INSPECTION

Check pad thickness from an inspection hole on cylinder body.

Check using a scale if necessary.

ComponentsNFS000PC

WAR NING :

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

While removing cylinder body, do not depress brake pedal because piston will pop out. Standard thickness : 11.0 mm (0.433 in)

Repair limit thickness : 2.0 mm (0.079 in)

MAA0439D

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover

Refer to GI-11, "

Components" and the followings for the symbols in the figure.

1: Apply rubber grease.

2: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

3: Apply polyglycol ether based lubricant.

: Apply brake fluid.

PFIA0820E

Page 1299 of 5621

BR-24

FRONT DISC BRAKE

Revision: 2006 January2006 M35/M45

It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

Do not damage piston boot.

If any shim is subject to serious corrosion, replace it with a new one.

Always replace shim and shim cover as a set when replacing brake pads.

Keep rotor free from brake fluid.

Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low mileage. Refer to BR-28, "

BRAKE

BURNISHING PROCEDURE" .

Removal and Installation of Brake PadNFS000PD

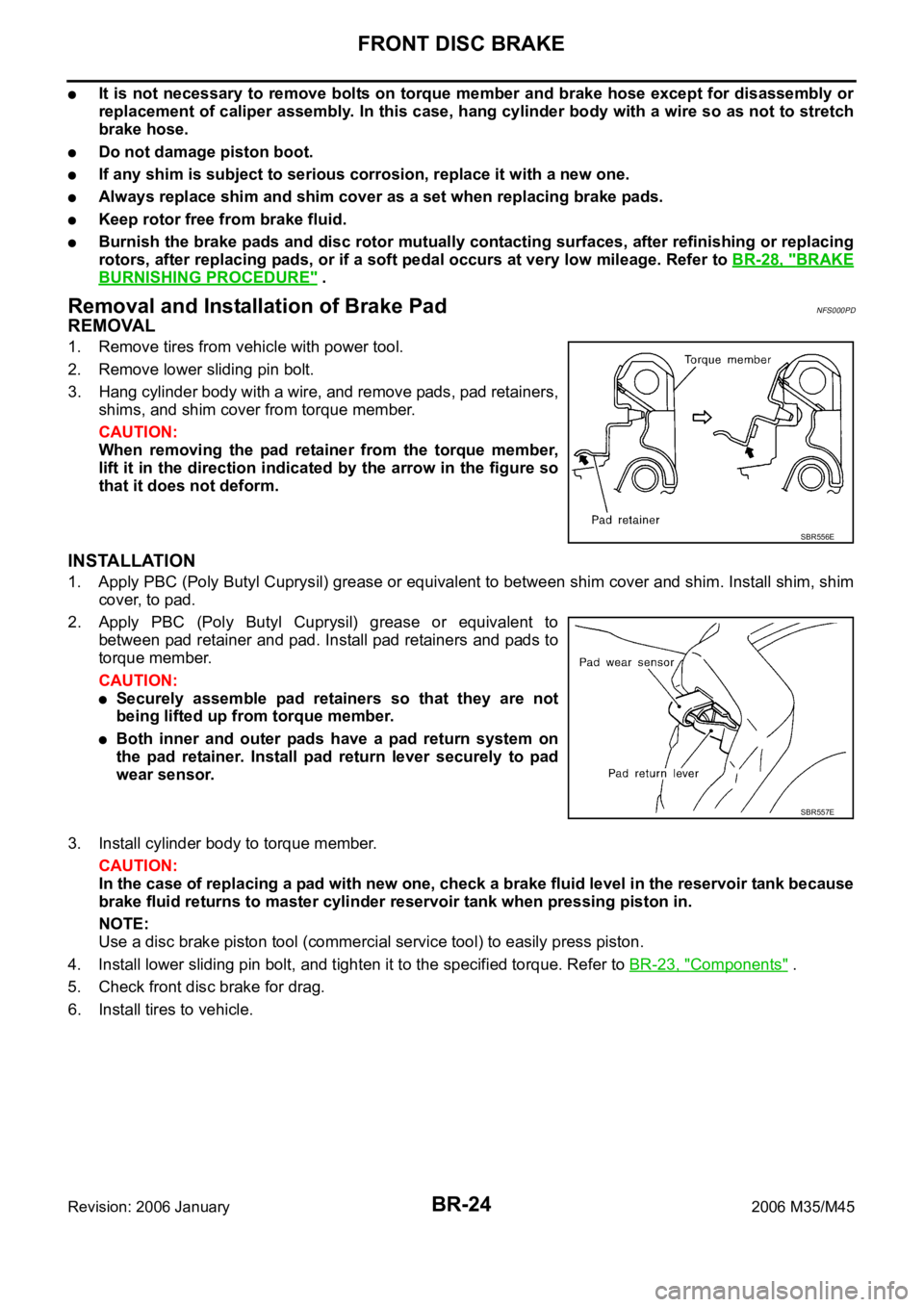

REMOVAL

1. Remove tires from vehicle with power tool.

2. Remove lower sliding pin bolt.

3. Hang cylinder body with a wire, and remove pads, pad retainers,

shims, and shim cover from torque member.

CAUTION:

When removing the pad retainer from the torque member,

lift it in the direction indicated by the arrow in the figure so

that it does not deform.

INSTALLATION

1. Apply PBC (Poly Butyl Cuprysil) grease or equivalent to between shim cover and shim. Install shim, shim

cover, to pad.

2. Apply PBC (Poly Butyl Cuprysil) grease or equivalent to

between pad retainer and pad. Install pad retainers and pads to

torque member.

CAUTION:

Securely assemble pad retainers so that they are not

being lifted up from torque member.

Both inner and outer pads have a pad return system on

the pad retainer. Install pad return lever securely to pad

wear sensor.

3. Install cylinder body to torque member.

CAUTION:

In the case of replacing a pad with new one, check a brake fluid level in the reservoir tank because

brake fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool (commercial service tool) to easily press piston.

4. Install lower sliding pin bolt, and tighten it to the specified torque. Refer to BR-23, "

Components" .

5. Check front disc brake for drag.

6. Install tires to vehicle.

SBR556E

SBR557E

Page 1301 of 5621

BR-26

FRONT DISC BRAKE

Revision: 2006 January2006 M35/M45

Disassembly and Assembly of Brake Caliper AssemblyNFS000PF

NOTE:

Do not remove torque member, pads, shims, shim covers, and pad retainers when disassembling and assem-

bling cylinder body assembly.

DISASSEMBLY

1. Remove sliding pin bolt, and then remove cylinder body from torque member.

CAUTION:

Do not drop pads, shims, shim cover and pad retainers from torque member.

2. Remove sliding pins and sliding pin boots from torque member.

3. Place a wooden block as shown in the figure, and blow air from

union bolt mounting hole to remove pistons and piston boots.

CAUTION:

Do not get fingers caught in the pistons.

4. Remove piston seal from cylinder body using a flat-bladed

screwdriver.

CAUTION:

Be careful not to damage a cylinder inner wall.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for corrosion, wear, and damage. If a malfunction is detected, replace cylinder

body.

CAUTION:

Clean cylinder body using new brake fluid. Never use mineral oils such as gasoline or kerosene.

Torque Member

Check torque member for wear, cracks, and damage. Replace if there are.

Piston

Check the piston surface for corrosion, wear, and damage. If a malfunction is detected, replace applicable

part.

CAUTION:

A piston sliding surface is plated. Do not polish with sandpaper.

Sliding Pin, Sliding Pin Bolt, and Sliding Pin Boot

Check sliding pin, sliding pin bolt, and sliding pin boot for wear, damage, and cracks. Replace if there are.

BRB0032D

SFIA0141E

Page 1302 of 5621

FRONT DISC BRAKE

BR-27

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

ASSEMBLY

1. Apply polyglycol ether based lubricant to piston seal, and install

them to cylinder body.

CAUTION:

Do not reuse piston seal.

2. Apply rubber grease to piston boot. Cover the piston end with

piston boot, and then install cylinder side lip on piston boot

securely into a groove on cylinder body.

CAUTION:

Do not reuse piston boot.

3. Apply brake fluid to piston. Push piston into cylinder body by

hand and push piston boot piston-side lip into the piston groove.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

4. Install sliding pins and sliding pin boots to torque member.

5. Install torque member to steering knuckle, and tighten mounting bolts to the specified torque. Refer to BR-

23, "Components" .

CAUTION:

Do not allow oil or any moisture on all contact surfaces between steering knuckle and brake cali-

per assembly.

6. Press in piston until pads can be installed, and then install cylinder body to torque member.

7. Tighten sliding pin bolts to the specified torque. Refer to BR-23, "

Components" .

SFIA2399E

SFIA2432E

SFIA2279E

Page 1304 of 5621

REAR DISC BRAKE

BR-29

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

REAR DISC BRAKEPFP:44000

On-Board InspectionNFS000PG

PAD WEAR INSPECTION

Check pad thickness from an inspection hole on cylinder body.

Check using a scale if necessary.

ComponentsNFS000PH

Standard

Standard thickness : 8.5 mm (0.335 in)

Repair limit thickness : 2.0 mm (0.079 in)

BRA0010D

1. Union bolt 2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Retaining ring 12. Inner shim cover

13. Inner shim 14. Inner pad 15. Pad retainer

16. Outer pad 17. Outer shim 18. Sliding pin boot

19. Bushing 20. Torque member mounting bolt 21. Washer

22. Torque member 23. Pad wear sensor 24. Inner pad (RH)

Refer to GI-11, "

Components" and the followings for the symbols in the figure.

1: Apply rubber grease.

2: Apply PBC (Poly Butyl Cuprysil) grease or silicone-based grease.

PFIA0705J