fuse INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3616 of 5621

![INFINITI M35 2006 Factory Service Manual REVERSE INTERLOCK DOOR MIRROR SYSTEM

GW-97

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

through 10A fuse [No.21, located in the fuse block (J/B)]

to automatic drive positioner control INFINITI M35 2006 Factory Service Manual REVERSE INTERLOCK DOOR MIRROR SYSTEM

GW-97

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

through 10A fuse [No.21, located in the fuse block (J/B)]

to automatic drive positioner control](/img/42/57023/w960_57023-3615.png)

REVERSE INTERLOCK DOOR MIRROR SYSTEM

GW-97

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

through 10A fuse [No.21, located in the fuse block (J/B)]

to automatic drive positioner control unit terminal 34 and

to driver seat control unit terminal 40.

Ground is supplied

to automatic drive positioner control unit terminals 40 and 48.

through body grounds M16 and M70.

to driver seat control unit terminals 32 and 48.

through body grounds B5, B40 and B131.

to door mirror remote control switch terminal 13

through body grounds M16 and M70.

REVERSE INTERLOCK DOOR MIRROR SYSTEM OPERATION

When the ignition switch is in ON position, A/T control device into R position. Then TCM (in A/T assembly)

detects it and sends the A/T shift position signal to the driver seat control unit via DATA LINE (CAN H,

CAN L).

When selecting either left and right changeover switch, the automatic drive position control unit judges

which door mirror is selected according to the voltage of terminals 2 and 18. And then, it sends the signal

to driver seat control unit via communication signal.

When the driver seat control unit receives the A/T shift position signal and changeover switch signal, it

sends the operation signal to the automatic drive positioner control unit using the communication signal so

that the each mirror sensor voltage stays in a specified value.

Door mirror (RH) selected

Supply the power from terminals 14, 15 and 30 to door mirror (RH) terminals 5, 6 and 7 so that the voltage

of terminals 5 and 21 stays in a specified value. Then, adjust the mirror angle.

Door mirror (LH) selected

Supply the power from terminals 16, 31 and 32 to door mirror (LH) terminals 5, 6 and 7 do that the voltage

of terminals 6 and 22 is the specified value. Then, adjust the mirror angle.

CAN Communication System DescriptionNIS00232

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitNIS00233

Refer to LAN-34, "CAN Communication Unit" .

Page 3624 of 5621

REVERSE INTERLOCK DOOR MIRROR SYSTEM

GW-105

C

D

E

F

G

H

J

K

L

MA

B

GW

Revision: 2006 January2006 M35/M45

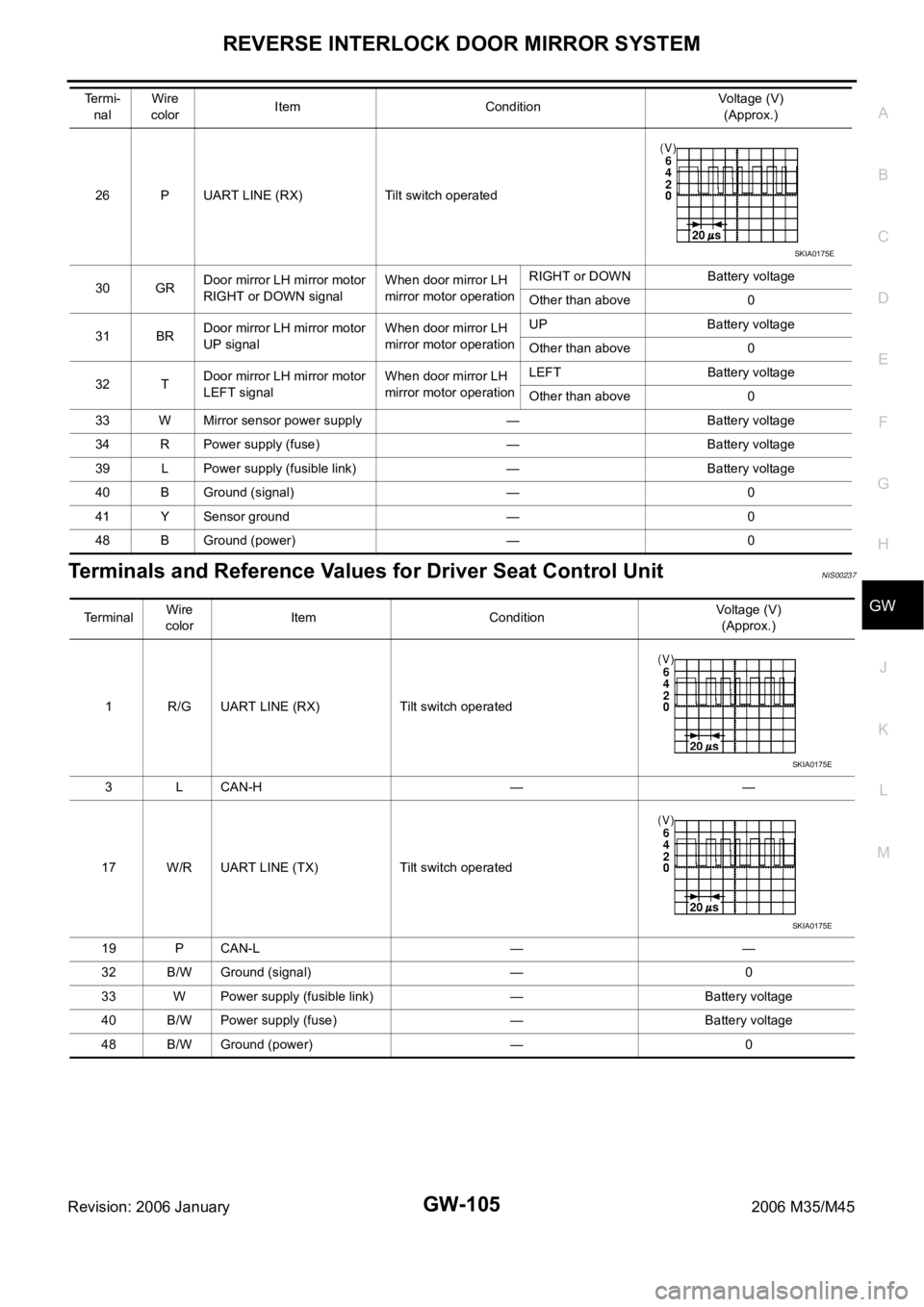

Terminals and Reference Values for Driver Seat Control UnitNIS00237

26 P UART LINE (RX) Tilt switch operated

30 GRDoor mirror LH mirror motor

RIGHT or DOWN signalWhen door mirror LH

mirror motor operationRIGHT or DOWN Battery voltage

Other than above 0

31 BRDoor mirror LH mirror motor

UP signalWhen door mirror LH

mirror motor operationUP Battery voltage

Other than above 0

32 TDoor mirror LH mirror motor

LEFT signalWhen door mirror LH

mirror motor operationLEFT Battery voltage

Other than above 0

33 W Mirror sensor power supply — Battery voltage

34 R Power supply (fuse) — Battery voltage

39 L Power supply (fusible link) — Battery voltage

40 B Ground (signal) — 0

41 Y Sensor ground — 0

48 B Ground (power) — 0 Termi-

nalWire

colorItem ConditionVoltage (V)

(Approx.)

SKIA0175E

Terminal Wire

colorItem ConditionVoltage (V)

(Approx.)

1 R/G UART LINE (RX) Tilt switch operated

3 L CAN-H — —

17 W/R UART LINE (TX) Tilt switch operated

19 P CAN-L — —

32 B/W Ground (signal) — 0

33 W Power supply (fusible link) — Battery voltage

40 B/W Power supply (fuse) — Battery voltage

48 B/W Ground (power) — 0

SKIA0175E

SKIA0175E

Page 3645 of 5621

IDX-4

ALPHABETICAL INDEX

Electronic ignition (EI) system ............. EC-33, EC-743

Engine control module (ECM) .......... EC-496, EC-1215

Engine control system diagram ........... EC-30, EC-740

Engine coolant temperature sensor (ECTS) ... EC-226,

EC-238

, EC-948, EC-961

Engine coolant(VK45DE) .................................. CO-40

Engine coolant(VQ35DE) ................................. CO-11

Engine oil filter replacement ............................. MA-26

Engine oil filter replacement(VQ35DE) ............. MA-19

Engine oil precautions .......................................... GI-8

Engine oil replacement(VQ35DE) ..................... MA-18

Engine oil(VK45DE) ........................................... LU-26

Engine oil(VQ35DE) ............................................ LU-7

Engine removal(VK45DE) ............................... EM-244

Engine removal(VQ35DE) .............................. EM-113

Engine room cover ............................................ EM-14

Engine room cover(VK45DE) ......................... EM-173

ETC1 - Wiring diagram .................... EC-614, EC-1345

ETC2 - Wiring diagram .................... EC-609, EC-1340

ETC3 - Wiring diagram .................... EC-620, EC-1352

EVAP canister ...................................... EC-42, EC-752

EVAP canister purge volume control solenoid valve ....

EC-412

, EC-420, EC-1132, EC-1140

EVAP canister vent control valve ...... EC-427, EC-434,

EC-1147

, EC-1154

EVAP control system (small leak) diagnosis .. EC-403,

EC-466

, EC-1124, EC-1185

EVAP control system pressure sensor ........... EC-440,

EC-443

, EC-450, EC-1160, EC-1163, EC-1170

EVAP control system purge flow monitoring diagnosis

EC-398

, EC-1119

EVAP vapor lines inspection ................. MA-21, MA-28

Evaporative emission (EVAP) system . EC-39, EC-749

Evaporator ..................................................... ATC-168

Exhaust manifold(VK45DE) ............................ EM-183

Exhaust system ................................................... EX-3

Exhaust system inspection ..................... EX-3, MA-29

Expansion valve ............................................. ATC-169

F

F/FOG - Wiring diagram ................................... LT-197

F/PUMP - Wiring diagram ................ EC-686, EC-1428

Final drive pre-inspection .................. FFD-16, RFD-19

Final drive removal and installation .. FFD-13, RFD-16

Floor trim ............................................................. EI-50

Flow charts ......................................................... GI-28

Fluid temperature sensor (A/T) ........................ AT-135

Fluorescent leak detector .............................. ATC-170

FPCM - Wiring diagram ................... EC-527, EC-1253

Freeze frame data ............................... EC-59, EC-770

Front brake solenoid valve ................. AT-151, AT-153

Front bumper ...................................................... EI-11

Front combination lamp removal and installation LT-76

Front door ............................. BL-190, BL-196, GW-63

Front passenger air bag .................................. SRS-42

Front seat belt .................................................... SB-30

Front seat belt pre-tensioner ..... SB-2, SRS-3, SRS-47

Front washer ...................................................... WW-4

Front wiper ......................................................... WW-4

FTS - Wiring diagram ....................................... AT-136

FTTS - Wiring diagram .... EC-345, EC-350, EC-1068,

EC-1073

Fuel cut control (at no load high engine speed) EC-34,

EC-744

Fuel filter replacement ......................................... FL-4

Fuel gauge ............................................................ DI-5

Fuel injection system (Bank 1) ......... EC-321, EC-332,

EC-1044

, EC-1055

Fuel injection system (Bank 2) ......... EC-321, EC-332,

EC-1044

, EC-1055

Fuel injector ................................................... EC-1420

Fuel injector and fuel tube(VK45DE) .............. EM-193

Fuel injector and fuel tube(VQ35DE) ................ EM-45

Fuel level sensor EC-475, EC-477, EC-479, EC-1194,

EC-1196

, EC-1198

Fuel line inspection .................................. FL-3, MA-25

Fuel line inspection(VQ35DE) .......................... MA-18

Fuel precautions ................................................... GI-6

Fuel pressure check ........................... EC-98, EC-809

Fuel pressure release ......................... EC-98, EC-809

Fuel pump ....................................... EC-685, EC-1427

Fuel pump and gauge .......................................... FL-4

Fuel pump control module .............. EC-525, EC-1251

Fuel pump dropping resistor ........... EC-525, EC-1251

Fuel system ......................................................... FL-3

Fuel tank ............................................................ FL-10

Fuel tank temperature sensor .......... EC-343, EC-349,

EC-1066

, EC-1072

Fuel tank vacuum relief valve ............. EC-42, EC-752

FUELB1 - Wiring diagram EC-323, EC-334, EC-1046,

EC-1057

FUELB2 - Wiring diagram EC-325, EC-336, EC-1048,

EC-1059

Fuse .................................................................. PG-17

Fuse and fusible link box ................................ PG-112

Fusible link ........................................................ PG-17

G

Gauges ................................................................. DI-5

Generator ........................................................... SC-23

Generator - See Alternator ................................ SC-23

Glass ........................ GW-11, GW-61, GW-63, GW-67

Grille - See Exterior ............................................ EI-16

Ground distribution ........................................... PG-46

H

H/LAMP - Wiring diagram ....................... LT-13

, LT-48

Harness connector .......................................... PG-102

Harness layout .................................................. PG-63

Hazard warning lamp ....................................... LT-211

Headlamp removal and installation .................... LT-76

Headlining - See Roof trim .................................. EI-52

Heated oxygen sensor 2 (bank 1) .... EC-286, EC-297,

EC-310

, EC-1009, EC-1020, EC-1033

Heated oxygen sensor 2 (bank 2) .... EC-286, EC-297,

Page 3678 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN](/img/42/57023/w960_57023-3677.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-9

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSES WORK FLOWPFP:00004

When Displaying CAN Communication System ErrorsNKS003XS

WHEN A MALFUNCTION IS DETECTED BY CAN COMMUNICATION SYSTEM

CAN communication line is open. (CAN H, CAN L, or both)

CAN communication line is shorted. (Ground, between CAN lines, or other harnesses)

The areas related to CAN communication of unit is malfunctioning.

WHEN A MALFUNCTION IS DETECTED EXCEPT CAN COMMUNICATION SYSTEM

Removal and installation of parts: When the units that perform CAN communication or the sensors related

to CAN communication are removed and installed, malfunction may be detected (or DTC other than CAN

communication may be detected).

Fuse blown out (removed): CAN communication of the unit may be stopped at such time.

Low voltage: If the voltage decreases because of battery discharge when IGN is ON, malfunction may be

detected by self-diagnosis according to the units.

Page 3756 of 5621

![INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-87

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

16. CHECK ECM AND IPDM E/R INTERNAL CIRCUIT

1. Remove ECM and IPDM E/R from vehicle.

2. Check resistance INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 1)

LAN-87

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

16. CHECK ECM AND IPDM E/R INTERNAL CIRCUIT

1. Remove ECM and IPDM E/R from vehicle.

2. Check resistance](/img/42/57023/w960_57023-3755.png)

CAN SYSTEM (TYPE 1)

LAN-87

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

16. CHECK ECM AND IPDM E/R INTERNAL CIRCUIT

1. Remove ECM and IPDM E/R from vehicle.

2. Check resistance between ECM terminals.

3. Check resistance between IPDM E/R terminals.

OK or NG

OK >> GO TO 17.

NG >> Replace ECM and/or IPDM E/R.

17. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then make sure that the symptom is reproduced.

OK or NG

OK >> GO TO 18.

NG >> Refer to LAN-18, "

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced"

.

18. CHECK UNIT REPRODUCIBILITY

Performs the following procedure for each unit, and then perform reproducibility test.

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the unit connector.

4. Connect the battery cable to the negative terminal.

5. Make sure that the symptom filled in the “Symptom” of the check sheet is reproduced. (Do not confuse it

with the symptom related to removed unit.)

6. Make sure that the same symptom is reproduced.

–A/T assembly

–BCM

–Low tire pressure warning control unit

–Steering angle sensor

–Intelligent Key unit

–Unified meter and A/C amp.

–AV control unit

–Driver seat control unit

–ABS actuator and electric unit (control unit)

–ECM

–IPDM E/R

Check results

Reproduce>>Install removed unit, and then check the other unit.

Not reproduced>>Replace removed unit.

TerminalResistance

(Approx.)

94 86 108 – 132

TerminalResistance

(Approx.)

49 50 108 – 132

LKIA0037E

Page 3797 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-128

[CAN]

CAN SYSTEM (TYPE 2)

Revision: 2006 January2006 M35/M45

16. CHECK ECM AND IPDM E/R INTERNAL CIRCUIT

1. Remove ECM and IPDM E/R from vehicle.

2. Check resistance between ECM terminals.

3. INFINITI M35 2006 Factory Service Manual LAN-128

[CAN]

CAN SYSTEM (TYPE 2)

Revision: 2006 January2006 M35/M45

16. CHECK ECM AND IPDM E/R INTERNAL CIRCUIT

1. Remove ECM and IPDM E/R from vehicle.

2. Check resistance between ECM terminals.

3.](/img/42/57023/w960_57023-3796.png)

LAN-128

[CAN]

CAN SYSTEM (TYPE 2)

Revision: 2006 January2006 M35/M45

16. CHECK ECM AND IPDM E/R INTERNAL CIRCUIT

1. Remove ECM and IPDM E/R from vehicle.

2. Check resistance between ECM terminals.

3. Check resistance between IPDM E/R terminals.

OK or NG

OK >> GO TO 17.

NG >> Replace ECM and/or IPDM E/R.

17. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then make sure that the symptom is reproduced.

OK or NG

OK >> GO TO 18.

NG >> Refer to LAN-18, "

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced"

.

18. CHECK UNIT REPRODUCIBILITY

Performs the following procedure for each unit, and then perform reproducibility test.

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the unit connector.

4. Connect the battery cable to the negative terminal.

5. Make sure that the symptom filled in the “Symptom” of the check sheet is reproduced. (Do not confuse it

with the symptom related to removed unit.)

6. Make sure that the same symptom is reproduced.

–A/T assembly

–BCM

–Low tire pressure warning control unit

–Steering angle sensor

–Intelligent Key unit

–Unified meter and A/C amp.

–NAVI control unit

–Driver seat control unit

–ABS actuator and electric unit (control unit)

–ECM

–IPDM E/R

Check results

Reproduce>>Install removed unit, and then check the other unit.

Not reproduced>>Replace removed unit.

TerminalResistance

(Approx.)

94 86 108 – 132

TerminalResistance

(Approx.)

49 50 108 – 132

LKIA0037E

Page 3845 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-176

[CAN]

CAN SYSTEM (TYPE 3)

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then INFINITI M35 2006 Factory Service Manual LAN-176

[CAN]

CAN SYSTEM (TYPE 3)

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then](/img/42/57023/w960_57023-3844.png)

LAN-176

[CAN]

CAN SYSTEM (TYPE 3)

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then make sure that the symptom is reproduced.

OK or NG

OK >> GO TO 20.

NG >> Refer to LAN-18, "

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced"

.

20. CHECK UNIT REPRODUCIBILITY

Performs the following procedure for each unit, and then perform reproducibility test.

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the unit connector.

4. Connect the battery cable to the negative terminal.

5. Make sure that the symptom filled in the “Symptom” of the check sheet is reproduced. (Do not confuse it

with the symptom related to removed unit.)

6. Make sure that the same symptom is reproduced.

–A/T assembly

–AFS control unit

–BCM

–Low tire pressure warning control unit

–Steering angle sensor

–Intelligent Key unit

–Unified meter and A/C amp.

–AV control unit

–Pre-crash seat belt control unit

–Driver seat control unit

–ABS actuator and electric unit (control unit)

–ECM

–IPDM E/R

Check results

Reproduce>>Install removed unit, and then check the other unit.

Not reproduced>>Replace removed unit.

IPDM E/R Ignition Relay Circuit InspectionNKS003ZQ

Check the following. If no malfunction is found, replace the IPDM E/R.

IPDM E/R power supply circuit. Refer to PG-30, "Check IPDM E/R Power Supply and Ground Circuit" .

Ignition power supply circuit. Refer to PG-12, "IGNITION POWER SUPPLY — IGNITION SW. IN “ON”

AND/OR “START”" .

Page 3892 of 5621

![INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 4)

LAN-223

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Conne INFINITI M35 2006 Factory Service Manual CAN SYSTEM (TYPE 4)

LAN-223

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Conne](/img/42/57023/w960_57023-3891.png)

CAN SYSTEM (TYPE 4)

LAN-223

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then make sure that the symptom is reproduced.

OK or NG

OK >> GO TO 20.

NG >> Refer to LAN-18, "

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced"

.

20. CHECK UNIT REPRODUCIBILITY

Performs the following procedure for each unit, and then perform reproducibility test.

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the unit connector.

4. Connect the battery cable to the negative terminal.

5. Make sure that the symptom filled in the “Symptom” of the check sheet is reproduced. (Do not confuse it

with the symptom related to removed unit.)

6. Make sure that the same symptom is reproduced.

–A/T assembly

–AFS control unit

–BCM

–Low tire pressure warning control unit

–Steering angle sensor

–Intelligent Key unit

–Unified meter and A/C amp.

–NAVI control unit

–Pre-crash seat belt control unit

–Driver seat control unit

–ABS actuator and electric unit (control unit)

–ECM

–IPDM E/R

Check results

Reproduce>>Install removed unit, and then check the other unit.

Not reproduced>>Replace removed unit.

IPDM E/R Ignition Relay Circuit InspectionNKS0040E

Check the following. If no malfunction is found, replace the IPDM E/R.

IPDM E/R power supply circuit. Refer to PG-30, "Check IPDM E/R Power Supply and Ground Circuit" .

Ignition power supply circuit. Refer to PG-12, "IGNITION POWER SUPPLY — IGNITION SW. IN “ON”

AND/OR “START”" .

Page 3943 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-274

[CAN]

CAN SYSTEM (TYPE 5)

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then INFINITI M35 2006 Factory Service Manual LAN-274

[CAN]

CAN SYSTEM (TYPE 5)

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then](/img/42/57023/w960_57023-3942.png)

LAN-274

[CAN]

CAN SYSTEM (TYPE 5)

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then make sure that the symptom is reproduced.

OK or NG

OK >> GO TO 20.

NG >> Refer to LAN-18, "

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced"

.

20. CHECK UNIT REPRODUCIBILITY

Performs the following procedure for each unit, and then perform reproducibility test.

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the unit connector.

4. Connect the battery cable to the negative terminal.

5. Make sure that the symptom filled in the “Symptom” of the check sheet is reproduced. (Do not confuse it

with the symptom related to removed unit.)

6. Make sure that the same symptom is reproduced.

–A/T assembly

–AFS control unit

–BCM

–LDW camera unit

–Low tire pressure warning control unit

–Steering angle sensor

–Intelligent Key unit

–Unified meter and A/C amp.

–NAVI control unit

–Pre-crash seat belt control unit

–Driver seat control unit

–ABS actuator and electric unit (control unit)

–ICC sensor integrated unit

–ECM

–IPDM E/R

Check results

Reproduce>>Install removed unit, and then check the other unit.

Not reproduced>>Replace removed unit.

IPDM E/R Ignition Relay Circuit InspectionNKS00415

Check the following. If no malfunction is found, replace the IPDM E/R.

IPDM E/R power supply circuit. Refer to PG-30, "Check IPDM E/R Power Supply and Ground Circuit" .

Ignition power supply circuit. Refer to PG-12, "IGNITION POWER SUPPLY — IGNITION SW. IN “ON”

AND/OR “START”" .

Page 3989 of 5621

![INFINITI M35 2006 Factory Service Manual LAN-320

[CAN]

CAN SYSTEM (TYPE 6)

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then INFINITI M35 2006 Factory Service Manual LAN-320

[CAN]

CAN SYSTEM (TYPE 6)

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then](/img/42/57023/w960_57023-3988.png)

LAN-320

[CAN]

CAN SYSTEM (TYPE 6)

Revision: 2006 January2006 M35/M45

19. CHECK SYMPTOM

1. Fill in described symptoms on the column “Symptom” in the check sheet.

2. Connect all connectors, and then make sure that the symptom is reproduced.

OK or NG

OK >> GO TO 20.

NG >> Refer to LAN-18, "

Example of Filling in Check Sheet When Initial Conditions Are Not Reproduced"

.

20. CHECK UNIT REPRODUCIBILITY

Performs the following procedure for each unit, and then perform reproducibility test.

1. Turn ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the unit connector.

4. Connect the battery cable to the negative terminal.

5. Make sure that the symptom filled in the “Symptom” of the check sheet is reproduced. (Do not confuse it

with the symptom related to removed unit.)

6. Make sure that the same symptom is reproduced.

–A/T assembly

–AFS control unit

–BCM

–Low tire pressure warning control unit

–Steering angle sensor

–Intelligent Key unit

–Unified meter and A/C amp.

–AV control unit

–RAS control unit

–Driver seat control unit

–ABS actuator and electric unit (control unit)

–ECM

–IPDM E/R

Check results

Reproduce>>Install removed unit, and then check the other unit.

Not reproduced>>Replace removed unit.

IPDM E/R Ignition Relay Circuit InspectionNKS0041T

Check the following. If no malfunction is found, replace the IPDM E/R.

IPDM E/R power supply circuit. Refer to PG-30, "Check IPDM E/R Power Supply and Ground Circuit" .

Ignition power supply circuit. Refer to PG-12, "IGNITION POWER SUPPLY — IGNITION SW. IN “ON”

AND/OR “START”" .