turn signal INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1335 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-24

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DISPLAY ITEM LIST

Code Display item Malfunction detecting condition Check item

C1101 RR RH SENSOR-1Circuit of rear RH wheel se INFINITI M35 2006 Factory Service Manual BRC-24

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DISPLAY ITEM LIST

Code Display item Malfunction detecting condition Check item

C1101 RR RH SENSOR-1Circuit of rear RH wheel se](/img/42/57023/w960_57023-1334.png)

BRC-24

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DISPLAY ITEM LIST

Code Display item Malfunction detecting condition Check item

C1101 RR RH SENSOR-1Circuit of rear RH wheel sensor is open. Or when the sensor

power voltage is outside the standard.

BRC-34,

"Inspection 1:

Wheel Sensor

Circuit"

(Note 1) C1102 RR LH SENSOR-1Circuit of rear LH wheel sensor is open. Or when the sensor

power voltage is outside the standard.

C1103 FR RH SENSOR-1Circuit of front RH wheel sensor is open. Or when the sensor

power voltage is outside the standard.

C1104 FR LH SENSOR-1Circuit of front LH wheel sensor is open. Or when the sensor

power voltage is outside the standard.

C1105 RR RH SENSOR-2When the circuit in the rear RH wheel sensor is short-circuited.

Or when the distance between the wheel sensor and sensor rotor

is too large and the sensor pulse cannot be recognized by the

control unit.

C1106 RR LH SENSOR-2When the circuit in the rear LH wheel sensor is short-circuited. Or

when the distance between the wheel sensor and sensor rotor is

too large and the sensor pulse cannot be recognized by the con-

trol unit.

C1107 FR RH SENSOR-2When the circuit in the front RH wheel sensor is short-circuited.

Or when the distance between the wheel sensor and sensor rotor

is too large and the sensor pulse cannot be recognized by the

control unit.

C1108 FR LH SENSOR- 2When the circuit in the front LH wheel sensor is short-circuited.

Or when the distance between the wheel sensor and sensor rotor

is too large and the sensor pulse cannot be recognized by the

control unit.

C1109BATTERY VOLTAGE

[ABNORMAL]When the ABS actuator and electric unit (control unit) power sup-

ply voltage is lower than normal.BRC-37,

"Inspection 4:

ABS Actuator

and Electric Unit

(Control Unit)

Power Supply

and Ground Cir-

cuit"

C1110 CONTROLLER FAILUREWhen there is an internal malfunction in the ABS actuator and

electric unit (control unit).BRC-36,

"Inspection 3:

ABS Actuator

and Electric Unit

(Control Unit)"

C 1111 P U M P M O T O RDuring the actuator motor operating with ON, when the actuator

motor turns OFF, or when the control line for actuator motor relay

is open.BRC-38,

"Inspection 5:

ABS Motor and

Motor Relay Cir-

cuit"

During the actuator motor operating with OFF, when the actuator

motor turns ON, or when the control line for relay is shorted to

ground.

C1114 MAIN RELAYDuring the actuator relay operating with OFF, when the actuator

relay turns ON. Or when the control line for the relay is shorted to

the ground.BRC-40,

"Inspection 6:

Solenoid, VDC

Change-Over

Valve and Actua-

tor Relay Circuit"

During the actuator relay operating with ON, when the actuator

relay turns OFF, or when the control line for the relay is open.

C 111 5ABS SENSOR

[ABNORMAL SIGNAL]When wheel sensor input signal is malfunctioning.BRC-34,

"Inspection 1:

Wheel Sensor

Circuit"

(Note 1)

Page 1338 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-27

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Data MonitorNFS000QH

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DA INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-27

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Data MonitorNFS000QH

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DA](/img/42/57023/w960_57023-1337.png)

TROUBLE DIAGNOSIS

BRC-27

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

Data MonitorNFS000QH

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “DATA MONITOR” in order on CONSULT-II screen.

CAUTION:

When “START (NISSAN BASED VHCL)” is touched immediately after starting engine or turning on

the ignition switch, “ABS” might not be displayed in the system selection screen. In this case,

repeat the operation from step 1.

2. At the monitor item selection screen, touch one of the items “ECU INPUT SIGNALS”, “MAIN SIGNALS” or

“SELECTION FROM MENU”.

3. Touch “START” to proceed to the data monitor screen.

DISPLAY ITEM LIST

CAUTION:

The display shows the control unit calculation data, so a normal value might be displayed even in the

event the output circuit (harness) is open or short - circuited.

E: ECU INPUT SIGNALS M: MAIN SIGNALS S: SELECTION FROM MENU

SELECT

MONITOR

ITEM Monitor item Display contentData monitor

ConditionReference value in

normal operation

E, M, SFR LH SENSOR

FR RH SENSOR

RR LH SENSOR

RR RH SENSORWheel speed0 [km/h] Vehicle stopped

Nearly matches the speed

meter display (

10 % or

less)Vehicle running

(Note 1)

E, M, S STOP LAMP SW Brake pedal operationWhen brake pedal is

depressedON

When brake pedal is not

depressedOFF

E, M, S BATTERY VOLTBattery voltage supplied to the ABS

actuator and electric unit (control

unit)Ignition switch ON 10 – 16 V

E, M, S GEAR Gear position determined by TCM1st gear

2nd gear

3rd gear

4th gear

5th gear1

2

3

4

5

E, M, S SLCT LVR POSI A/T shift positionP position

R position

N position

D positionP

R

N

D

E, M, S OFF SW VDC OFF switch ON/OFFVDC OFF switch ON

(When VDC OFF indicator

lamp is ON)ON

VDC OFF switch OFF

(When VDC OFF indicator

lamp is OFF)OFF

E, M, S YAW RATE SENYaw rate detected by yaw rate/side

G sensorWhen vehicle stop Approx. 0 d/s

When vehicle turning (-75 to 75 d/s)

E, M, S4WD MODE MON

(Note 2)AWD activated Engine running AUTO

E, S ACCEL POS SIG Throttle actuator opening/closing is

displayed (linked with accelerator

pedal)Accelerator pedal not

depressed (ignition switch

is ON)0 %

Depress accelerator pedal

(ignition switch is ON)0 - 100 %

Page 1339 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-28

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

E, S SIDE G-SENSORTransverse G detected by side G

sensorVehicle stopped

Approx. 0 m/s

2

Vehicle turning rightNegative value

INFINITI M35 2006 Factory Service Manual BRC-28

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

E, S SIDE G-SENSORTransverse G detected by side G

sensorVehicle stopped

Approx. 0 m/s

2

Vehicle turning rightNegative value](/img/42/57023/w960_57023-1338.png)

BRC-28

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

E, S SIDE G-SENSORTransverse G detected by side G

sensorVehicle stopped

Approx. 0 m/s

2

Vehicle turning rightNegative value

(m/s2 )

Vehicle turning leftPositive value

(m/s

2 )

E, S STR ANGLE SIGSteering angle detected by steering

angle sensorStraight-ahead Approx. 0

Steering wheel turned –720 to 720

E, S PRESS SENSORBrake fluid pressure detected by

pressure sensorWith ignition switch turned

ON and brake pedal

releasedApprox. 0 bar

With ignition switch turned

ON and brake pedal

depressed–40 to 300 bar

E, S ENGINE RPM With engine runningWith engine stopped 0 rpm

Engine runningAlmost in accor-

dance with tachom-

eter display

E, S FLUID LEV SW Brake fluid level switchWhen brake fluid level

switch ONON

When brake fluid level

switch OFF OFF

E, S PARK BRAKE SW Parking brake switchParking brake switch is

activeON

Parking brake switch is

inactiveOFF

M, SFR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR RH IN SOL

RR RH OUT SOL

RR LH IN SOL

RR LH OUT SOLOperation status of all solenoid

valve Actuator (solenoid valve) is

active (“ACTIVE TEST”

with CONSULT-II) or actua-

tor relay is inactive (in fail-

safe mode)ON

When the actuator (sole-

noid valve) is not active

and actuator relay is active

(ignition switch ON)OFF

M, S MOTOR RELAY Motor and motor relay operationWhen the motor relay and

motor are operatingON

When the motor relay and

motor are not operatingOFF

M, SACTUATOR RLY

(Note 3)Actuator relay operationWhen the actuator relay is

operatingON

When the actuator relay is

not operatingOFF

M, S ABS WARN LAMPABS warning lamp

(Note 4)When ABS warning lamp is

ONON

When ABS warning lamp is

OFFOFF

M, S OFF LAMPVDC OFF indicator lamp

(Note 4)When VDC OFF indicator

lamp is ONON

When VDC OFF indicator

lamp is OFFOFF E: ECU INPUT SIGNALS M: MAIN SIGNALS S: SELECTION FROM MENU

SELECT

MONITOR

ITEM Monitor item Display contentData monitor

ConditionReference value in

normal operation

Page 1341 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-30

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Note 1: Confirm tire pressure is normal.

Note 2: Only AWD model.

Note 3: A brief moment of ON/OFF condition occurs every 20 se INFINITI M35 2006 Factory Service Manual BRC-30

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Note 1: Confirm tire pressure is normal.

Note 2: Only AWD model.

Note 3: A brief moment of ON/OFF condition occurs every 20 se](/img/42/57023/w960_57023-1340.png)

BRC-30

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Note 1: Confirm tire pressure is normal.

Note 2: Only AWD model.

Note 3: A brief moment of ON/OFF condition occurs every 20 seconds after ignition switch turned ON. This is not malfunction because it

is an operation for checking.

Note 4: On and off timing for warning lamp and indicator lanp.Refer to BRC-33, "

ON and OFF Timing for Warning Lamp and Indicator

Lamp" .

Active TestNFS000QI

CAUTION:

Do not perform active test while driving vehicle.

Make sure to completely bleed air from brake system.

The active test cannot be performed with the ABS warning lamp, VDC indicator lamp, SLIP indica-

tor lamp and brake warning lamp are on.

ABS warning lamp, VDC OFF indicator lamp, SLIP indicator lamp and brake warning lamp are on

during active test.

Erase memory of ICC system after implementing active test. Refer to ACS-34, "Self-Diagnostic

Function" .

OPERATION PROCEDURE

1. Touch “START (NISSAN BASED VHCL)”, “ABS”, “ACTIVE TEST” in order on the CONSULT-II screen.

CAUTION:

When “START (NISSAN BASED VHCL)” is touched immediately after starting engine or turning on

ignition switch, “ABS” might not be displayed in the "SELECT SYSTEM" screen. In this case,

repeat the operation from step 1.

2. Touch “SELECT TEST ITEM” is displayed.

3. Touch necessary test item.

4. While “MAIN SIGNALS” indication is inverted, touch “START”.

5. “ACTIVE TEST” screen will be displayed so perform the following test.

SV/R OUTPUT

(Note 3)Solenoid valve relay activatedWhen the solenoid valve

relay is active (When igni-

tion switch OFF)ON

When the solenoid valve

relay is not active (in the

fail-safe mode)OFF

S M/R OUTPUTActuator motor and motor relay acti-

vatedWhen the actuator motor

and motor relay are active

(

ACTIVE TEST” with

CONSULT-II)ON

When the actuator motor

and motor relay are inac-

tiveOFF E: ECU INPUT SIGNALS M: MAIN SIGNALS S: SELECTION FROM MENU

SELECT

MONITOR

ITEM Monitor item Display contentData monitor

ConditionReference value in

normal operation

SFIA0591E

Page 1342 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-31

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

NOTE:

When active test is performed while depressing the pedal, the pedal depression am INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-31

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

NOTE:

When active test is performed while depressing the pedal, the pedal depression am](/img/42/57023/w960_57023-1341.png)

TROUBLE DIAGNOSIS

BRC-31

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

NOTE:

When active test is performed while depressing the pedal, the pedal depression amount will change.

This is normal. (Only solenoid valve and ABS motor)

“TEST IS STOPPED” is displayed 10 seconds after operation start.

After “TEST IS STOPPED” is displayed, to perform test again, touch “BACK” and repeat step 3.

TEST ITEMS

Solenoid Valve

NOTE:

The example shown is for front right wheel. The procedure for the other wheels is the same as given below.

When performing an active test of the ABS function, select the

"MAIN SIGNALS" for each test item.In addition, when perform-

ing an active test of the VDC/TCS function, select the item menu

for each test item.

For ABS solenoid valve, touch “UP”, “KEEP”, and “DOWN” on

the display screen. For ABS solenoid valve (ACT), touch “UP”,

“ACT UP”, “ACT KEEP” and confirm that solenoid valves (IN,

OUT, USV, HSV) operate as shown in the table below.

*: ON for 1 to 2 seconds after the touch, and then OFF

Note: A brief moment of ON/OFF condition occurs every 20 seconds after ignition switch turned ON. This is not malfunction because it is

an operation for checking.

ABS Motor

Touch “ON” and “OFF” on screen. Make sure motor relay and actua-

tor relay operates as shown in table below.

Note: A brief moment of ON/OFF condition occurs every 20 seconds after ignition

switch turned ON. This is not malfunction because it is an operation for checking.

SFIA0678E

Operation

(Note)ABS solenoid valve ABS solenoid valve (ACT)

UP KEEP DOWN UP ACT UP ACT KEEP

FR RH IN SOL OFF ON ON OFF OFF OFF

FR RH OUT SOL OFF OFF ON* OFF OFF OFF

USV [FR-RL] OFF OFF OFF OFF ON ON

HSV [FR-RL] OFF OFF OFF OFF ON* OFF

Operation ON OFF

MOTOR RELAY ON OFF

ACTUATOR RLY

(Note)ON ON

SFIA0593E

Page 1345 of 5621

![INFINITI M35 2006 Factory Service Manual BRC-34

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Inspection 1: Wheel Sensor CircuitNFS000QL

CAUTION:

Do not check between wheel sensor terminals.

INSPECTION PROCEDURE

1. CHECK INFINITI M35 2006 Factory Service Manual BRC-34

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Inspection 1: Wheel Sensor CircuitNFS000QL

CAUTION:

Do not check between wheel sensor terminals.

INSPECTION PROCEDURE

1. CHECK](/img/42/57023/w960_57023-1344.png)

BRC-34

[VDC/TCS/ABS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Inspection 1: Wheel Sensor CircuitNFS000QL

CAUTION:

Do not check between wheel sensor terminals.

INSPECTION PROCEDURE

1. CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES >> GO TO 2.

NO >> INSPECTION END

2. CHECK TIRE

Check air pressure, wear and size.

Are air pressure, wear and size within standard?

YES >> GO TO 3.

NO >>

Adjust air pressure, or replace tire.

Perform the self-diagnosis, and make sure that the result shows “NO DTC IS DETECTED”.

3. CHECK SENSOR AND SENSOR ROTOR

Check sensor rotor for damage.

Check wheel sensor for damage, disconnection or looseness.

OK or NG

OK >> GO TO 4.

NG >>

Repair wheel sensor mount or replace sensor rotor. Then perform the self-diagnosis.

Perform the self-diagnosis, and make sure that the result shows “NO DTC IS DETECTED”.

4. CHECK CONNECTOR

1. Turn ignition switch OFF and disconnect ABS actuator and electric unit (control unit) connector E30 and

malfunctioning wheel sensor connector E41(FR-RH), E59(FR-LH), B101(RR-RH), B102(RR-LH). Check

terminal to see if it is deformed, disconnected, loose, etc., Repair or replace it if any malfunction condition

is found.

2. Reconnect connectors and then perform the self-diagnosis. Refer to BRC-23, "

OPERATION PROCE-

DURE" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 5.

Self-diagnosis results

FR RH SENSOR-1, -2

FR LH SENSOR-1, -2

RR RH SENSOR-1, -2

RR LH SENSOR-1, -2

ABS SENSOR [ABNORMAL SIGNAL]

Page 1346 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-35

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

5. CHECK WHEEL SENSOR HARNESS

1. Turn ignition switch OFF and disconnect malfunctioning whee INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-35

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

5. CHECK WHEEL SENSOR HARNESS

1. Turn ignition switch OFF and disconnect malfunctioning whee](/img/42/57023/w960_57023-1345.png)

TROUBLE DIAGNOSIS

BRC-35

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

5. CHECK WHEEL SENSOR HARNESS

1. Turn ignition switch OFF and disconnect malfunctioning wheel

sensor connector E41(FR-RH), E59(FR-LH), B101(RR-RH),

B102(RR-LH) and ABS actuator and electric unit (control unit)

connector E30.

2. Check continuity between terminals. (Also check continuity

when steering wheel is turned right and left and when sensor

harness inside the wheel house is moved.)

OK or NG

OK >> GO TO 6.

NG >>

Repair or replace malfunctioning components.

Perform the self-diagnosis, and make sure that the result shows “NO DTC IS DETECTED”.

6. CHECK WHEEL SENSOR

1. Replace wheel sensor that resulted in malfunction by self-diagnosis.

2. Reconnect connectors, drive vehicle at 30 km/h (19 MPH) or more for approximately 1 minute, and then

perform self-diagnosis.

Is above displayed on the self-diagnosis display?

OK >> INSPECTION END

NG >>

Replace ABS actuator and electric unit (control unit).

Perform the self-diagnosis, and make sure that the result shows “NO DTC IS DETECTED”.

SFIA3030E

Power supply circuit Signal circuit Ground circuit

WheelABS actuator

and electric

unit (control

unit)Wheel sensorABS actua-

tor and elec-

tric unit

(control unit)Wheel sensorABS actua-

tor and elec-

tric unit

(control

unit)

(signal)Ground

Front RH 9 1 10 2 9, 10

— Front LH 26 1 5 2 26, 5

Rear RH 7 1 29 2 7, 29

Rear LH 6 1 27 2 6, 27

Power supply circuit : Yes

Signal circuit : Yes

Ground circuit : No

Page 1354 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-43

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

4. CHECK DATA MONITOR

1. Turn ignition switch OFF and connect the steering angle sensor connector a INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-43

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

4. CHECK DATA MONITOR

1. Turn ignition switch OFF and connect the steering angle sensor connector a](/img/42/57023/w960_57023-1353.png)

TROUBLE DIAGNOSIS

BRC-43

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

4. CHECK DATA MONITOR

1. Turn ignition switch OFF and connect the steering angle sensor connector and ABS actuator and electric

unit (control unit) connector.

2. Select “STR ANGLE SIG” in “Data Monitor” and check steering angle sensor signal.

OK or NG

OK >> Perform self-diagnosis.

NG >>

Replace spiral cable (steering angle sensor) and adjust neutral position of steering angle sen-

sor. Refer to BRC-6, "

Adjustment of Steering Angle Sensor Neutral Position" .

Perform the self-diagnosis, and make sure that the result shows NO DTC IS DETECTED.

Inspection 9: Park/Neutral Position (PNP) Switch CircuitNFS000QT

INSPECTION PROCEDURE

1. CHECK SELF-DIAGNOSIS RESULTS

Check self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES >> GO TO 2.

NO >> INSPECTION END

2. CHECK DATA MONITOR

Select “SLCT LVR POSI” in “Data Monitor” and check Park/Neutral position switch signal.

OK or NG

OK >>Replace ABS actuator and electric unit (control unit).

Perform the self-diagnosis, and make sure that the result shows NO DTC IS DETECTED.

NG >> GO TO 3.Steering conditionSTR ANGLE SIG

(Data monitor)

Driving straight – 2.5

to + 2.5

Tu r n 9 0 to right Approx.+ 90

Tu r n 9 0 to left Approx.– 90

Self-diagnosis results

PNP POSI SIG

Selector lever positionSLCT LVR POSI

(Data monitor)

P position P

R position R

N position N

D position D

Page 1358 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-47

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

4. CHECK YAW RATE/SIDE G SENSOR HARNESS

1. Turn ignition switch OFF and disconnect Yaw rate/side G INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

BRC-47

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

4. CHECK YAW RATE/SIDE G SENSOR HARNESS

1. Turn ignition switch OFF and disconnect Yaw rate/side G](/img/42/57023/w960_57023-1357.png)

TROUBLE DIAGNOSIS

BRC-47

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

Revision: 2006 January2006 M35/M45

4. CHECK YAW RATE/SIDE G SENSOR HARNESS

1. Turn ignition switch OFF and disconnect Yaw rate/side G sensor connector M145 and ABS actuator and

electric unit (control unit) connector E30.

2. Check continuity between Yaw rate/side G sensor harness con-

nector M145 and ABS actuator and electric unit (control unit)

harness connector E30.

OK or NG

OK >> GO TO 5.

NG >>

Repair or replace malfunctioning components.

Perform the self-diagnosis, and make sure that the result shows NO DTC IS DETECTED.

5. CHECK DATA MONITOR

1. Connect the Yaw rate/side G sensor connector and ABS actuator and electric unit (control unit) connector.

2. Select “YAW RATE SEN”, “SIDE G-SENSOR” in “Data Monitor” and check Yaw rate/side G sensor

signal.

OK or NG

OK >>Replace ABS actuator and electric unit (control unit).

Perform the self-diagnosis, and make sure that the result shows NO DTC IS DETECTED.

NG >>

Replace Yaw rate/side G sensor.

Perform the self-diagnosis, and make sure that the result shows NO DTC IS DETECTED.

SFIA3045E

ABS actuator and electric unit (control unit) Yaw rate/side G sensor Continuity

18 1

Yes 37 2

16 4

20 5

15 6

Vehicle conditionYAW RATE SEN

(Data monitor)SIDE G-SENSOR

(Data monitor)

Stopped Approx. 0 d/s

Approx. 0 m/s

2

Turning right Negative value Negative value

Turning left Positive value Positive value

Page 1434 of 5621

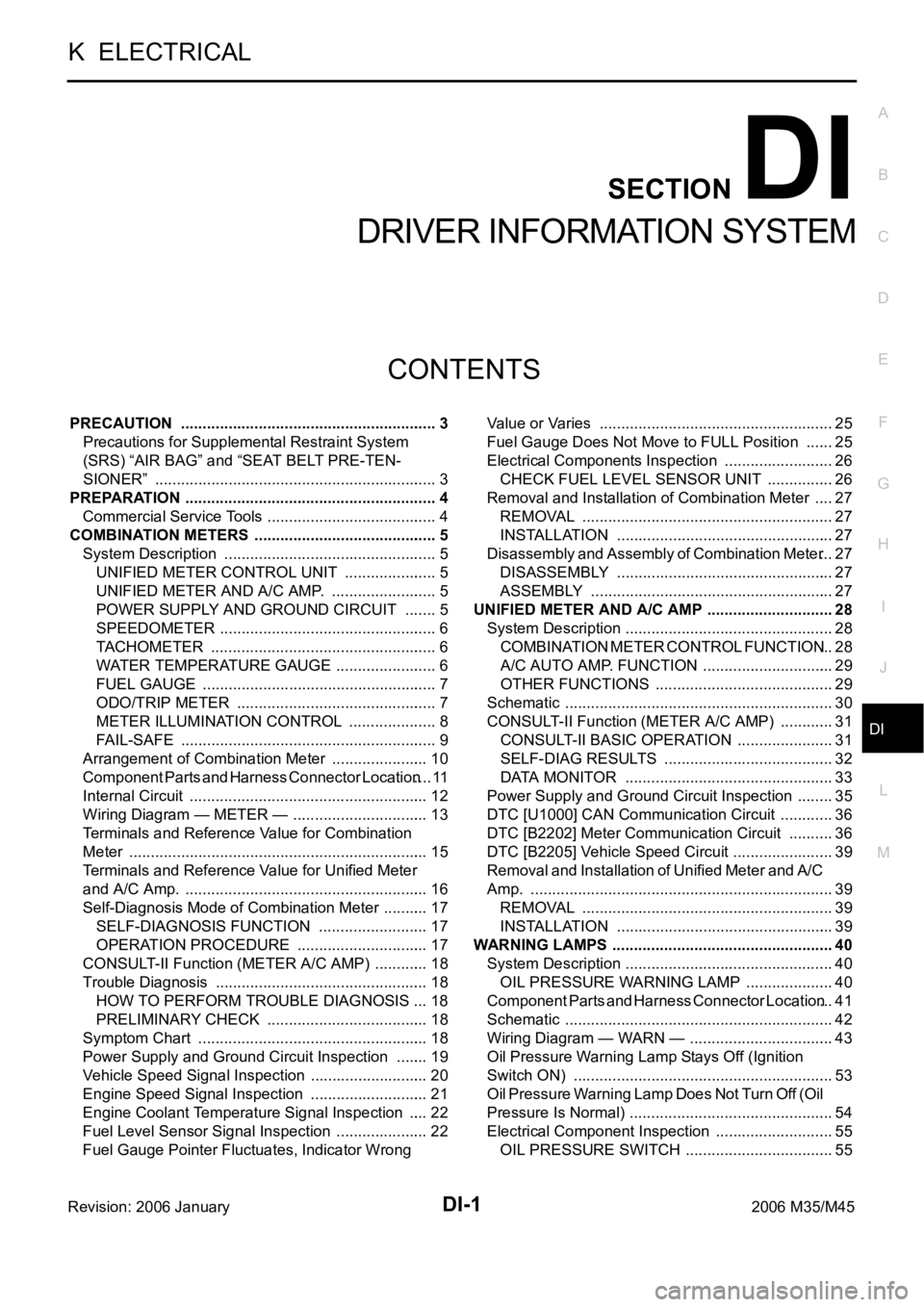

DI-1

DRIVER INFORMATION SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION DI

A

B

DI

Revision: 2006 January2006 M35/M45

DRIVER INFORMATION SYSTEM

PRECAUTION ............................................................ 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

PREPARATION ........................................................... 4

Commercial Service Tools ........................................ 4

COMBINATION METERS ........................................... 5

System Description .................................................. 5

UNIFIED METER CONTROL UNIT ...................... 5

UNIFIED METER AND A/C AMP. ......................... 5

POWER SUPPLY AND GROUND CIRCUIT ........ 5

SPEEDOMETER ................................................... 6

TACHOMETER ..................................................... 6

WATER TEMPERATURE GAUGE ........................ 6

FUEL GAUGE ....................................................... 7

ODO/TRIP METER ............................................... 7

METER ILLUMINATION CONTROL ..................... 8

FAIL-SAFE ............................................................ 9

Arrangement of Combination Meter ....................... 10

Component Parts and Harness Connector Location .... 11

Internal Circuit ........................................................ 12

Wiring Diagram — METER — ................................ 13

Terminals and Reference Value for Combination

Meter ...................................................................... 15

Terminals and Reference Value for Unified Meter

and A/C Amp. ......................................................... 16

Self-Diagnosis Mode of Combination Meter ........... 17

SELF-DIAGNOSIS FUNCTION .......................... 17

OPERATION PROCEDURE ............................... 17

CONSULT-II Function (METER A/C AMP) ............. 18

Trouble Diagnosis .................................................. 18

HOW TO PERFORM TROUBLE DIAGNOSIS ... 18

PRELIMINARY CHECK ...................................... 18

Symptom Chart ...................................................... 18

Power Supply and Ground Circuit Inspection ........ 19

Vehicle Speed Signal Inspection ............................ 20

Engine Speed Signal Inspection ............................ 21

Engine Coolant Temperature Signal Inspection ..... 22

Fuel Level Sensor Signal Inspection ...................... 22

Fuel Gauge Pointer Fluctuates, Indicator Wrong Value or Varies ....................................................... 25

Fuel Gauge Does Not Move to FULL Position ....... 25

Electrical Components Inspection .......................... 26

CHECK FUEL LEVEL SENSOR UNIT ................ 26

Removal and Installation of Combination Meter ..... 27

REMOVAL ........................................................

... 27

INSTALLATION ................................................... 27

Disassembly and Assembly of Combination Meter ... 27

DISASSEMBLY ................................................... 27

ASSEMBLY ......................................................... 27

UNIFIED METER AND A/C AMP ...........................

... 28

System Description ................................................. 28

COMBINATION METER CONTROL FUNCTION ... 28

A/C AUTO AMP. FUNCTION ............................... 29

OTHER FUNCTIONS .......................................... 29

Schematic ............................................................... 30

CONSULT-II Function (METER A/C AMP) ............. 31

CONSULT-II BASIC OPERATION ....................... 31

SELF-DIAG RESULTS ........................................ 32

DATA MONITOR ................................................. 33

Power Supply and Ground Circuit Inspection ......... 35

DTC [U1000] CAN Communication Circuit ............. 36

DTC [B2202] Meter Communication Circuit ........... 36

DTC [B2205] Vehicle Speed Circuit ........................ 39

Removal and Installation of Unified Meter and A/C

Amp. ....................................................................... 39

REMOVAL ........................................................

... 39

INSTALLATION ................................................... 39

WARNING LAMPS .................................................... 40

System Description ................................................. 40

OIL PRESSURE WARNING LAMP ..................... 40

Component Parts and Harness Connector Location ... 41

Schematic ............................................................... 42

Wiring Diagram — WARN — .................................. 43

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) ............................................................. 53

Oil Pressure Warning Lamp Does Not Turn Off (Oil

Pressure Is Normal) ................................................ 54

Electrical Component Inspection ............................ 55

OIL PRESSURE SWITCH ................................... 55