low beam INFINITI M35 2006 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 73 of 5621

![INFINITI M35 2006 Factory User Guide ACS-64

[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

Symptom 3: ICC System Cannot Be Operated by CANCEL Switch, RESUME/

ACCELERATE Switch or DISTANCE Switch

NKS004DM

RESUME d INFINITI M35 2006 Factory User Guide ACS-64

[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

Symptom 3: ICC System Cannot Be Operated by CANCEL Switch, RESUME/

ACCELERATE Switch or DISTANCE Switch

NKS004DM

RESUME d](/img/42/57023/w960_57023-72.png)

ACS-64

[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

Symptom 3: ICC System Cannot Be Operated by CANCEL Switch, RESUME/

ACCELERATE Switch or DISTANCE Switch

NKS004DM

RESUME does not function in the following cases.

When MAIN switch is turned off once.

When the vehicle speed is less than 25 MPH (40 km/h).

1. CHECK SWITCHES

With CONSULT-II

With “ICC” “DATA MONITOR”, check if switches operate normally.

“RESUME/ACC SW”

“CANCEL SW”

“DISTANCE SW”

OK or NG

OK >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> GO TO 2.

2. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

With CONSULT-II

1. Perform self-diagnosis.

2. Check if “DTC 100 CAN COMM CIRCUIT” is indicated.

Is it indicated?

YES >> CAN communication inspection. Refer to ACS-60, "DTC 100 CAN COMM CIRCUIT" .

NO >> ICC steering switch inspection. Refer to ACS-47, "

DTC 6 OPERATION SW CIRC" .

Symptom 4: ICC System Is Not Cancelled When the A/T Selector Lever Is In

Other Than “D” and “M”

NKS004DN

1. CHECK D RANGE SWITCH

With CONSULT-II

With “ICC” “DATA MONITOR”, check if “D RANGE SW” and “NP RANGE SW” operate normally.

OK or NG

OK >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> GO TO 2.

2. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

With CONSULT-II

1. Perform self-diagnosis.

2. Check if “DTC 100 CAN COMM CIRCUIT” is indicated.

Is it indicated?

YES >> CAN communication inspection. Refer to ACS-60, "DTC 100 CAN COMM CIRCUIT" .

NO >> GO TO 3.

Page 74 of 5621

![INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-65

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

3. CHECK D RANGE SWITCH

With CONSULT-II

With “A/T” “DATA MONITOR”, check if “SLCT L INFINITI M35 2006 Factory User Guide TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-65

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

3. CHECK D RANGE SWITCH

With CONSULT-II

With “A/T” “DATA MONITOR”, check if “SLCT L](/img/42/57023/w960_57023-73.png)

TROUBLE DIAGNOSIS FOR SYMPTOMS

ACS-65

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

3. CHECK D RANGE SWITCH

With CONSULT-II

With “A/T” “DATA MONITOR”, check if “SLCT LVR POSI” operates normally.

OK or NG

OK >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NG >> 1. Perform “A/T” self-diagnosis. Refer to AT- 9 0 , "

CONSULT-II Function (A/T)" .

2. After repairing or replacing applicable item, erase DTC and perform ICC system running test.

Then perform self-diagnosis of ICC system again.

Symptom 5: Chime Does Not SoundNKS004DO

The chime may not sound occasionally in the following cases even if the distance from the vehicle ahead is

short:

When the speed difference from that of the vehicle ahead is small (both vehicles driving at similar speed).

When the vehicle ahead drives at faster speed (the actual distance is increasing).

When depressing the accelerator pedal.

Chime does not sound when the vehicle is not driving.

Chime does not sound when the system does not detect any vehicle ahead. (Diagnose the conditions

under which the system is detecting the vehicle ahead and when the system is malfunctioning. If there is

any malfunction in detecting the vehicle ahead, check the system following the ACS-66, "

Symptom 7: ICC

System Frequently Cannot Detect the Vehicle Ahead/ Detection Zone Is Short" ).

1. CHECK ICC WARNING CHIME

With CONSULT-II

With “ICC” “ACTIVE TEST”, check if “ICC BUZZER” operates normally.

OK or NG

OK >> 1. Determine preceding vehicle detection status when malfunction occurred. If chime should have

sounded: after replacing ICC sensor integrated unit and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test, and then perform self-diagnosis of ICC sys-

tem again.

NG >> GO TO 2.

2. PERFORM ICC SENSOR INTEGRATED UNIT SELF-DIAGNOSIS

With CONSULT-II

1. Perform self-diagnosis.

2. Check if “DTC 100 CAN COMM CIRCUIT” is indicated.

Is it indicated?

YES >> CAN communication inspection. Refer to ACS-60, "DTC 100 CAN COMM CIRCUIT" .

NO >> GO TO 3.

3. CHECK UNIFIED METER AND A/C AMP.

With CONSULT-II

Perform “METRE A/C AMP” self-diagnosis. Refer to DI-31, "

CONSULT-II Function (METER A/C AMP)" .

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 4.

Page 75 of 5621

![INFINITI M35 2006 Factory User Guide ACS-66

[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

4. CHECK CHIME OPERATION

With CONSULT-II

1. Select “BUZZER” on “BCM”.

2. With “BUZZER” “ACTIVE TEST”, che INFINITI M35 2006 Factory User Guide ACS-66

[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

4. CHECK CHIME OPERATION

With CONSULT-II

1. Select “BUZZER” on “BCM”.

2. With “BUZZER” “ACTIVE TEST”, che](/img/42/57023/w960_57023-74.png)

ACS-66

[ICC]

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

4. CHECK CHIME OPERATION

With CONSULT-II

1. Select “BUZZER” on “BCM”.

2. With “BUZZER” “ACTIVE TEST”, check if “IGN KEY WARN ALM” and “LIGHT WARN ALM” operate nor-

mally.

Does chime sound?

YES >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> 1. Replace combination meter.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

Symptom 6: Driving Force Is HuntingNKS004DP

1. PERFORM ECM SELF-DIAGNOSIS

With CONSULT-II

Perform “ENGINE” self-diagnosis. Refer to EC-133, "

CONSULT-II Function (ENGINE)" (for VQ35DE) or EC-

846, "CONSULT-II Function (ENGINE)" (for VK45DE).

Is malfunction indicated?

YES >> 1. Repair or replace applicable item.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> Refer to ACS-66, "

Symptom 7: ICC System Frequently Cannot Detect the Vehicle Ahead/ Detec-

tion Zone Is Short" .

Symptom 7: ICC System Frequently Cannot Detect the Vehicle Ahead/ Detection

Zone Is Short

NKS004DQ

The detection function may become unstable in the following cases.

When the reflector of the vehicle ahead is deficient/ not clean enough to reflect the radar.

When driving a road with extremely sharp corners.

When the sensor cannot detect the reflector of the vehicle ahead as the vehicle ahead is passing a hill or

passing the peak.

1. VISUAL CHECK 1

Check ICC sensor integrated unit body window for contamination and foreign materials.

Is it found?

YES >> 1. If any, remove them.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 2.

2. VISUAL CHECK 2

Check ICC sensor integrated unit body window for cracks and scratches.

Is it found?

YES >> 1. Replace ICC sensor integrated unit, and adjust laser beam aiming.

2. Erase DTC and perform ICC system running test. Then perform self-diagnosis of ICC system

again.

NO >> GO TO 3.

Page 1442 of 5621

COMBINATION METERS

DI-9

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

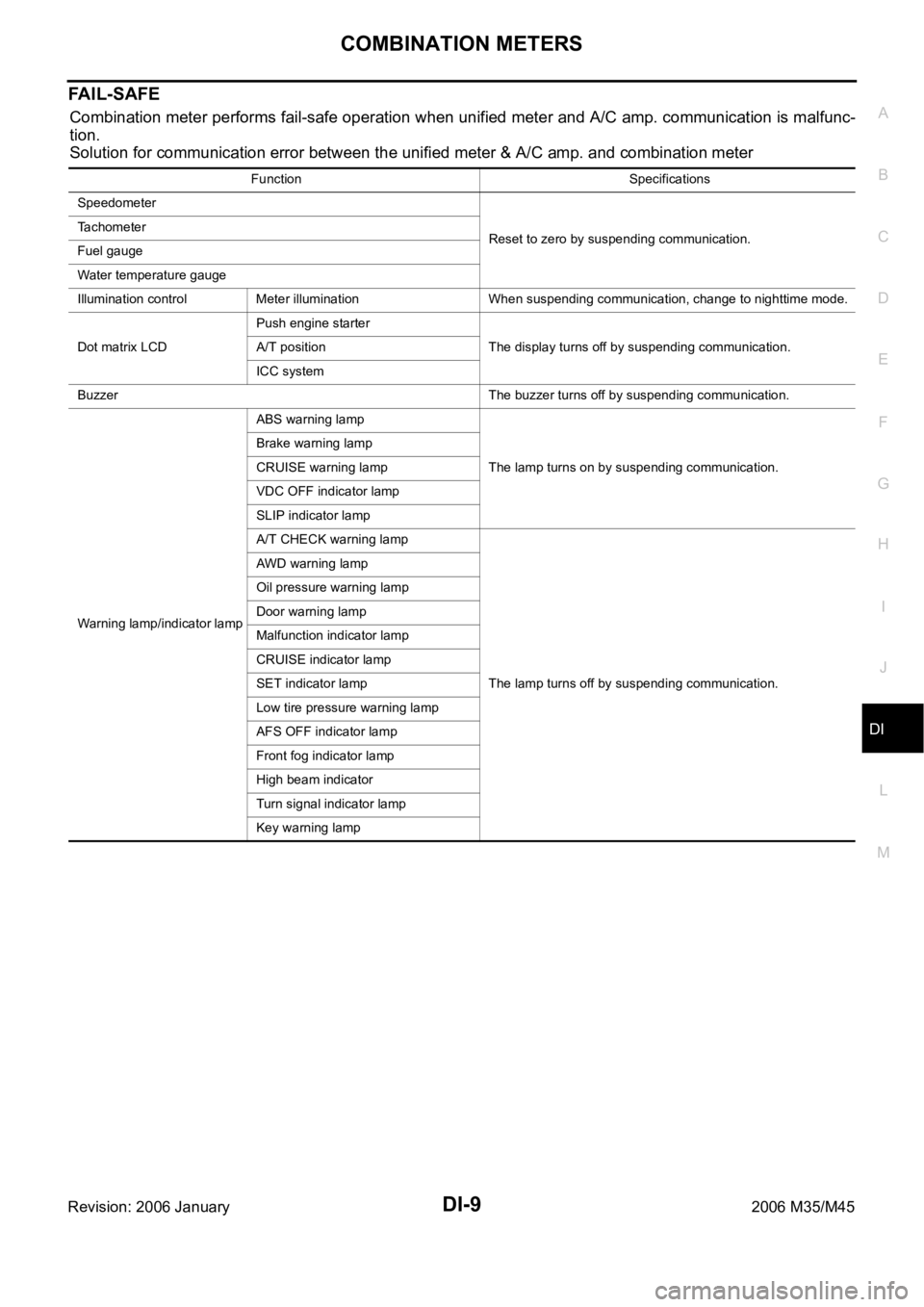

FA I L - S A F E

Combination meter performs fail-safe operation when unified meter and A/C amp. communication is malfunc-

tion.

Solution for communication error between the unified meter & A/C amp. and combination meter

Function Specifications

Speedometer

Reset to zero by suspending communication. Tachometer

Fuel gauge

Water temperature gauge

Illumination control Meter illumination When suspending communication, change to nighttime mode.

Dot matrix LCDPush engine starter

The display turns off by suspending communication. A/T position

ICC system

Buzzer The buzzer turns off by suspending communication.

Warning lamp/indicator lampABS warning lamp

The lamp turns on by suspending communication. Brake warning lamp

CRUISE warning lamp

VDC OFF indicator lamp

SLIP indicator lamp

A/T CHECK warning lamp

The lamp turns off by suspending communication. AWD warning lamp

Oil pressure warning lamp

Door warning lamp

Malfunction indicator lamp

CRUISE indicator lamp

SET indicator lamp

Low tire pressure warning lamp

AFS OFF indicator lamp

Front fog indicator lamp

High beam indicator

Turn signal indicator lamp

Key warning lamp

Page 1461 of 5621

DI-28

UNIFIED METER AND A/C AMP

Revision: 2006 January2006 M35/M45

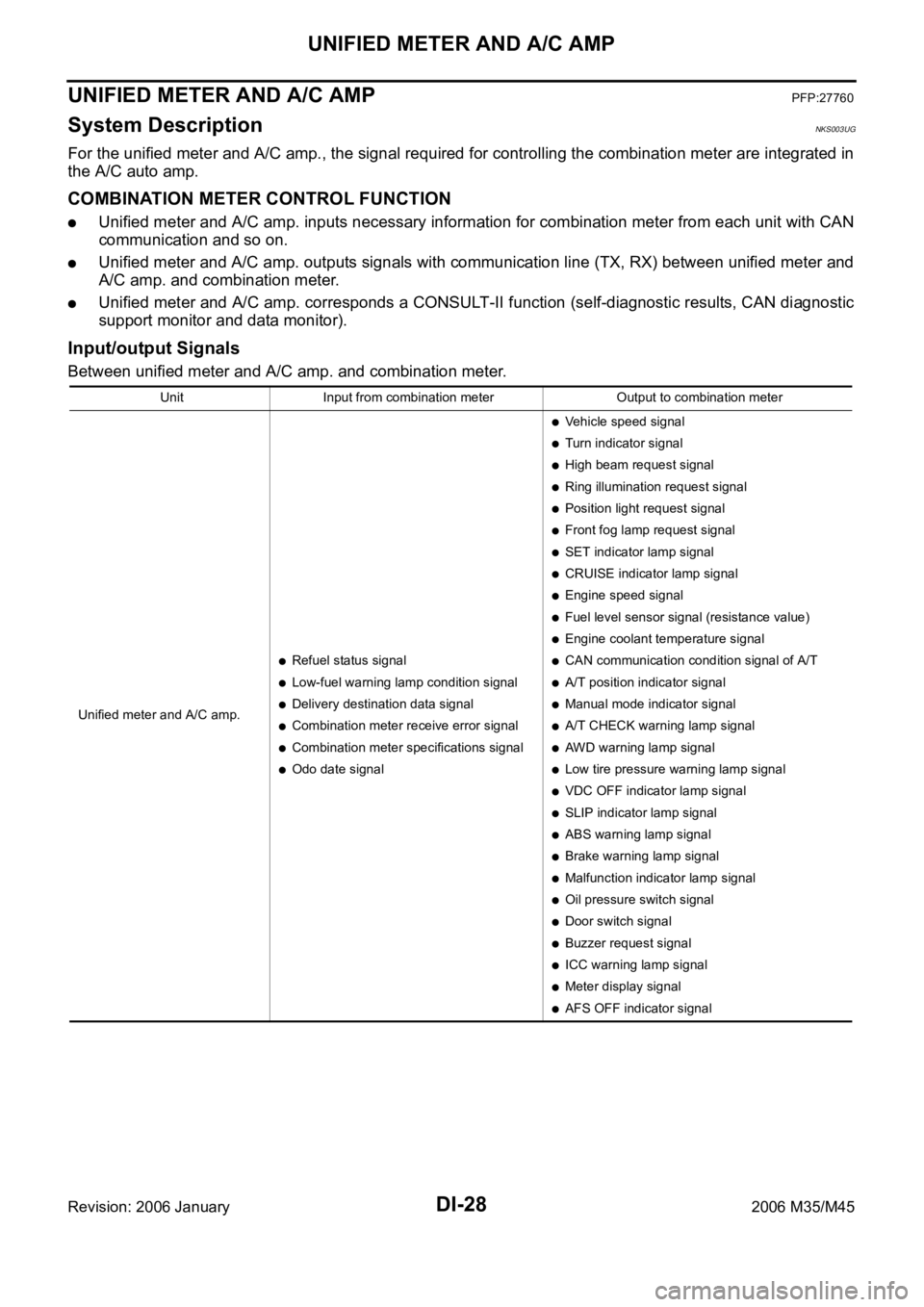

UNIFIED METER AND A/C AMPPFP:27760

System DescriptionNKS003UG

For the unified meter and A/C amp., the signal required for controlling the combination meter are integrated in

the A/C auto amp.

COMBINATION METER CONTROL FUNCTION

Unified meter and A/C amp. inputs necessary information for combination meter from each unit with CAN

communication and so on.

Unified meter and A/C amp. outputs signals with communication line (TX, RX) between unified meter and

A/C amp. and combination meter.

Unified meter and A/C amp. corresponds a CONSULT-II function (self-diagnostic results, CAN diagnostic

support monitor and data monitor).

Input/output Signals

Between unified meter and A/C amp. and combination meter.

Unit Input from combination meter Output to combination meter

Unified meter and A/C amp.

Refuel status signal

Low-fuel warning lamp condition signal

Delivery destination data signal

Combination meter receive error signal

Combination meter specifications signal

Odo date signal

Vehicle speed signal

Turn indicator signal

High beam request signal

Ring illumination request signal

Position light request signal

Front fog lamp request signal

SET indicator lamp signal

CRUISE indicator lamp signal

Engine speed signal

Fuel level sensor signal (resistance value)

Engine coolant temperature signal

CAN communication condition signal of A/T

A/T position indicator signal

Manual mode indicator signal

A/T CHECK warning lamp signal

AWD warning lamp signal

Low tire pressure warning lamp signal

VDC OFF indicator lamp signal

SLIP indicator lamp signal

ABS warning lamp signal

Brake warning lamp signal

Malfunction indicator lamp signal

Oil pressure switch signal

Door switch signal

Buzzer request signal

ICC warning lamp signal

Meter display signal

AFS OFF indicator signal

Page 1466 of 5621

UNIFIED METER AND A/C AMP

DI-33

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

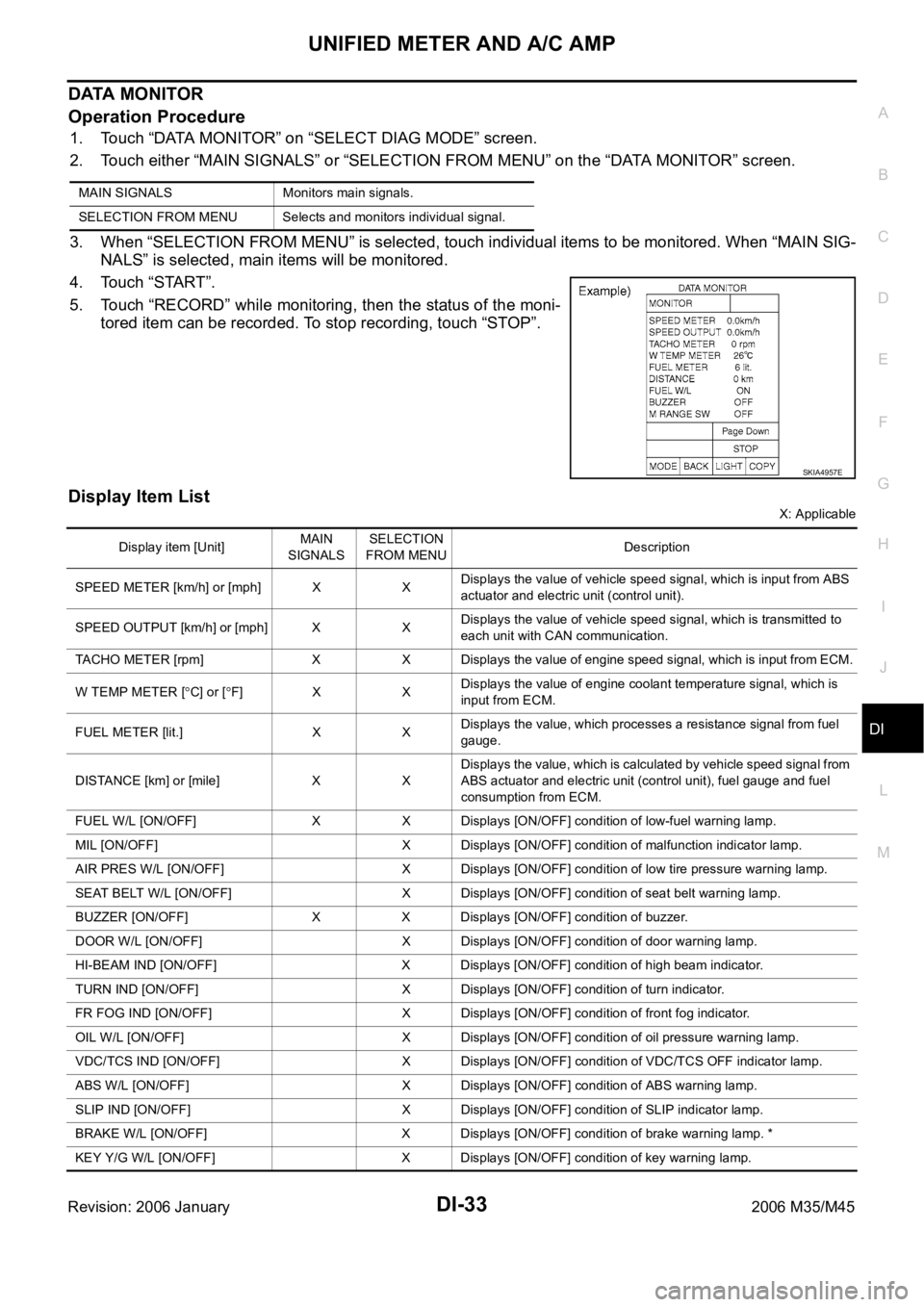

DATA MONITOR

Operation Procedure

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch either “MAIN SIGNALS” or “SELECTION FROM MENU” on the “DATA MONITOR” screen.

3. When “SELECTION FROM MENU” is selected, touch individual items to be monitored. When “MAIN SIG-

NALS” is selected, main items will be monitored.

4. Touch “START”.

5. Touch “RECORD” while monitoring, then the status of the moni-

tored item can be recorded. To stop recording, touch “STOP”.

Display Item List

X: Applicable MAIN SIGNALS Monitors main signals.

SELECTION FROM MENU Selects and monitors individual signal.

SKIA4957E

Display item [Unit]MAIN

SIGNALSSELECTION

FROM MENUDescription

SPEED METER [km/h] or [mph] X XDisplays the value of vehicle speed signal, which is input from ABS

actuator and electric unit (control unit).

SPEED OUTPUT [km/h] or [mph] X XDisplays the value of vehicle speed signal, which is transmitted to

each unit with CAN communication.

TACHO METER [rpm] X X Displays the value of engine speed signal, which is input from ECM.

W TEMP METER [

C] or [F] X XDisplays the value of engine coolant temperature signal, which is

input from ECM.

FUEL METER [lit.] X XDisplays the value, which processes a resistance signal from fuel

gauge.

DISTANCE [km] or [mile] X XDisplays the value, which is calculated by vehicle speed signal from

ABS actuator and electric unit (control unit), fuel gauge and fuel

consumption from ECM.

FUEL W/L [ON/OFF] X X Displays [ON/OFF] condition of low-fuel warning lamp.

MIL [ON/OFF] X Displays [ON/OFF] condition of malfunction indicator lamp.

AIR PRES W/L [ON/OFF] X Displays [ON/OFF] condition of low tire pressure warning lamp.

SEAT BELT W/L [ON/OFF] X Displays [ON/OFF] condition of seat belt warning lamp.

BUZZER [ON/OFF] X X Displays [ON/OFF] condition of buzzer.

DOOR W/L [ON/OFF] X Displays [ON/OFF] condition of door warning lamp.

HI-BEAM IND [ON/OFF] X Displays [ON/OFF] condition of high beam indicator.

TURN IND [ON/OFF] X Displays [ON/OFF] condition of turn indicator.

FR FOG IND [ON/OFF] X Displays [ON/OFF] condition of front fog indicator.

OIL W/L [ON/OFF] X Displays [ON/OFF] condition of oil pressure warning lamp.

VDC/TCS IND [ON/OFF] X Displays [ON/OFF] condition of VDC/TCS OFF indicator lamp.

ABS W/L [ON/OFF] X Displays [ON/OFF] condition of ABS warning lamp.

SLIP IND [ON/OFF] X Displays [ON/OFF] condition of SLIP indicator lamp.

BRAKE W/L [ON/OFF] X Displays [ON/OFF] condition of brake warning lamp. *

KEY Y/G W/L [ON/OFF] X Displays [ON/OFF] condition of key warning lamp.

Page 3189 of 5621

![INFINITI M35 2006 Factory User Guide EM-126

[VQ35DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

5. Drain engine coolant by removing water drain plugs from cylin-

der block both sides at “B” and “C” and cylinder bl INFINITI M35 2006 Factory User Guide EM-126

[VQ35DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

5. Drain engine coolant by removing water drain plugs from cylin-

der block both sides at “B” and “C” and cylinder bl](/img/42/57023/w960_57023-3188.png)

EM-126

[VQ35DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

5. Drain engine coolant by removing water drain plugs from cylin-

der block both sides at “B” and “C” and cylinder block front side

at “A” as shown in the figure.

6. Remove the following parts:

Oil pans (lower and upper); Refer to EM-29, "OIL PAN AND OIL STRAINER" .

Front and rear timing chain case; Refer to EM-64, "TIMING CHAIN" .

Cylinder head; Refer to EM-101, "CYLINDER HEAD" .

7. Remove knock sensor.

CAUTION:

Carefully handle sensor avoiding shocks.

8. Remove pilot converter using the pilot bushing puller (SST) as

necessary.

9. Remove rear oil seal retainer.

Remove by inserting a screwdriver between main bearing cap and rear oil seal retainer.

CAUTION:

If rear oil seal retainer is removed, replace it with new one.

NOTE:

Regard both rear oil seal and retainer as an assembly.

10. Remove baffle plate from main bearing beam (2WD models).

11. Remove piston and connecting rod assembly with the following procedure:

Before removing piston and connecting rod assembly, check the connecting rod side clearance. Refer

to EM-140, "

CONNECTING ROD SIDE CLEARANCE" .

CAUTION:

Be careful not to drop connecting rod bearing, and to scratch the surface.

a. Position crankshaft pin corresponding to connecting rod to be removed onto the bottom dead center.

PBIC2610E

SEM005G

Page 3191 of 5621

![INFINITI M35 2006 Factory User Guide EM-128

[VQ35DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

c. Push out piston pin with stick of outer diameter approximately 20

mm (0.79 in).

15. Remove main bearing cap bolts.

NOTE:

Use TORX s INFINITI M35 2006 Factory User Guide EM-128

[VQ35DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

c. Push out piston pin with stick of outer diameter approximately 20

mm (0.79 in).

15. Remove main bearing cap bolts.

NOTE:

Use TORX s](/img/42/57023/w960_57023-3190.png)

EM-128

[VQ35DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

c. Push out piston pin with stick of outer diameter approximately 20

mm (0.79 in).

15. Remove main bearing cap bolts.

NOTE:

Use TORX socket (size E14).

Before loosening main bearing cap bolts, measure the crankshaft end play. Refer to EM-140, "CRANK-

SHAFT END PLAY" .

Loosen main bearing cap bolts in the reverse order shown in

the figure in several different steps.

16. Remove main bearing beam.

17. Remove main bearing caps.

CAUTION:

Be careful not to drop main bearing, and to scratch the sur-

face.

Using main bearing cap bolts, remove main bearing cap while

shaking it back-and-forth.

18. Remove crankshaft.

19. Remove main bearings and thrust bearings from cylinder block and main bearing caps.

CAUTION:

Be careful not to drop main bearing, and to scratch the surface.

Identify installation positions, and store them without mixing them up.

20. Remove oil jet.

ASSEMBLY

1. Fully air-blow engine coolant and engine oil passages in cylinder block, cylinder bore and crankcase to

remove any foreign material.

CAUTION:

Use a goggles to protect your eye.

PBIC0262E

PBIC1800E

EMQ0195D

Page 3196 of 5621

![INFINITI M35 2006 Factory User Guide CYLINDER BLOCK

EM-133

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

13. Install connecting rod bearing cap.

Match the stamped cylinder number marks on connecting rod

with those INFINITI M35 2006 Factory User Guide CYLINDER BLOCK

EM-133

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

13. Install connecting rod bearing cap.

Match the stamped cylinder number marks on connecting rod

with those](/img/42/57023/w960_57023-3195.png)

CYLINDER BLOCK

EM-133

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

13. Install connecting rod bearing cap.

Match the stamped cylinder number marks on connecting rod

with those on connecting rod bearing cap to install.

Be sure that front mark on connecting rod bearing cap is fac-

ing front of the engine.

14. Tighten connecting rod bolt as follows:

a. Inspect the outer diameter of connecting rod bolt. Refer to EM-149, "

CONNECTING ROD BOLT OUTER

DIAMETER" .

b. Apply engine oil to the threads and seats of connecting rod bolts.

c. Tighten connecting rod bolts.

d. Then tighten all connecting rod bolts 90 degrees clockwise

(Angle tightening).

CAUTION:

Always use the angle wrench [SST: KV10112100 (BT8653-

A)]. Avoid tightening based on visual check alone.

After tightening connecting rod bolts, make sure that crank-

shaft rotates smoothly.

Check the connecting rod side clearance. Refer to EM-140,

"CONNECTING ROD SIDE CLEARANCE" .

15. Install baffle plate to main bearing beam (2WD models).

16. Install new rear oil seal retainer to cylinder block.

Apply new engine oil to both oil seal lip and dust seal lip.

Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000 ( — )] to rear oil seal retainer as

shown in the figure.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-48, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

CAUTION:

Replace with a new parts.

Attaching should be done within 5 minutes after coating.

Make sure the garter spring is in position and seal lips

not inverted.

NOTE:

Regard both rear oil seal and retainer as an assembly.

PBIC0809E

: 19.6 Nꞏm (2.0 kg-m, 14 ft-lb)

SEM953E

PBIC2661E

Page 3208 of 5621

![INFINITI M35 2006 Factory User Guide CYLINDER BLOCK

EM-145

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Piston Skirt Diameter

Measure the outer diameter of piston skirt with a micrometer.

Piston-to-Cylinder Bore INFINITI M35 2006 Factory User Guide CYLINDER BLOCK

EM-145

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Piston Skirt Diameter

Measure the outer diameter of piston skirt with a micrometer.

Piston-to-Cylinder Bore](/img/42/57023/w960_57023-3207.png)

CYLINDER BLOCK

EM-145

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Piston Skirt Diameter

Measure the outer diameter of piston skirt with a micrometer.

Piston-to-Cylinder Bore Clearance

Calculate by piston skirt diameter and cylinder bore inner diameter (direction “Y”, position “B”).

(Clearance) = (Cylinder bore inner diameter) – (Piston skirt diameter).

If the calculated value exceeds the limit, replace piston and piston pin assembly. Refer to EM-135, "HOW

TO SELECT PISTON" .

Re-boring Cylinder Bore

1. Cylinder bore size is determined by adding piston to cylinder bore clearance to piston skirt diameter.

2. Install main bearing caps and main bearing beam, and tighten to the specified torque. Otherwise, cylinder

bores may be distorted in final assembly.

3. Cut cylinder bores.

NOTE:

When any cylinder needs boring, all other cylinders must also be bored.

Do not cut too much out of cylinder bore at a time. Cut only 0.05 mm (0.0020 in) or so in diameter at a

time.

4. Hone cylinders to obtain the specified piston to cylinder bore clearance.

5. Measure finished cylinder bore for the out-of-round and taper.

NOTE:

Measurement should be done after cylinder bore cools down.

CRANKSHAFT MAIN JOURNAL DIAMETER

Measure the outer diameter of crankshaft main journals with a micrometer.

If out of the standard, measure the main bearing oil clearance. Then use undersize bearing. Refer to EM-

147, "MAIN BEARING OIL CLEARANCE" . Measure point

: Distance from the top 41.0 mm (1.614 in)

Standard

: 95.480 - 95.510 mm (3.7590 - 3.7602 in)

PBIC0125E

Standard : 0.010 - 0.030 mm (0.0004 - 0.0012 in)

Limit : 0.08 mm (0.0031 in)

Re-bored size calculation: D = A + B – C

where,

D: Bored diameter

A: Piston skirt diameter as measured

B: Piston to cylinder bore clearance (standard value)

C: Honing allowance 0.02 mm (0.0008 in)

Standard : 59.951 - 59.975 mm (2.3603 - 2.3612 in) dia.