check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4948 of 5621

REAR PROPELLER SHAFT

PR-9

C

E

F

G

H

I

J

K

L

MA

B

PR

Revision: 2006 January2006 M35/M45

5. Loosen mounting nuts of center bearing mounting brackets.

CAUTION:

Tighten mounting nuts temporarily.

6. Remove propeller shaft fixing bolts and nuts.

7. Remove center bearing mounting bracket fixing nuts.

8. Remove propeller shaft.

CAUTION:

If constant velocity joint was bent during propeller shaft

assembly removal, installation, or transportation, its boot

may be damaged. Wrap boot interference area to metal part

with shop cloth or rubber to protect boot from breakage.

INSPECTION

Inspect propeller shaft runout at measuring points. If runout

exceeds specifications, replace propeller shaft assembly. For

measuring point, refer to PR-6, "

Propeller Shaft Runout Measur-

ing Point" .

As shown in the figure, while fixing yoke on one side, check axial

play of joint. If outside the standard, replace relevant propeller

shaft.

Check propeller shaft for bend and damage. If damage is

detected, replace relevant propeller shaft assembly.

CAUTION:

Do not disassemble joints.

Check center bearing for noise and damage. If noise or damage

is detected, replace center bearing. Refer to PR-11, "

Disassem-

bly and Assembly of Center Bearing (For 3S80A-1VL107 and

3F80A-1VL107 Type)" .

PDIA0402E

Propeller shaft runout limit : 0.8 mm (0.031 in)

SDIA2071E

Journal axial play : 0 mm (0 in)

SPD874

Page 4949 of 5621

PR-10

REAR PROPELLER SHAFT

Revision: 2006 January2006 M35/M45

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

Avoid damaging the rebro joint boot, protect it with a shop towel or equivalent.

Align matching marks to install propeller shaft to final drive and transfer (AWD models only) companion

flanges, and then tighten to specified torque. Refer to PR-7, "

Components" .

Install center bearing mounting bracket (Upper) with its arrow

mark facing forward.

Adjust position of mounting bracket sliding back and forth to pre-

vent play in thrust direction of center bearing insulator. Install

bracket to vehicle.

After assembly, perform a driving test to check propeller shaft

vibration. If vibration occurred, separate propeller shaft from

final drive. Reinstall companion flange after rotating it by 60,

120, 180, 240, 300 degrees. Then perform driving test and

check propeller shaft vibration again at each point.

If propeller shaft or final drive has been replaced, connect them

as follows:

1. Install the propeller shaft while aligning its matching mark A with

the matching mark B on the joint as close as possible.

2. Tighten the joint bolts to the specified torque. Refer to PR-7,

"Components" .

CAUTION:

Do not reuse the bolts, nuts and washers.

PDIA0017E

SDIA2049E

Page 4954 of 5621

PS-1

POWER STEERING SYSTEM

G STEERING

CONTENTS

C

D

E

F

H

I

J

K

L

M

SECTION PS

A

B

PS

Revision: 2006 January2006 M35/M45

POWER STEERING SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions Necessary for Steering Wheel Rotation

after Battery Disconnect ........................................... 3

OPERATION PROCEDURE ................................. 3

Precautions for Steering System .............................. 4

PREPARATION ........................................................... 5

Special Service Tools [SST] ..................................... 5

Commercial Service Tools ........................................ 6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Trouble Shooting Chart .................................... 7

POWER STEERING FLUID ........................................ 8

Checking Fluid Level ...........................................

..... 8

Checking Fluid Leakage ........................................... 8

Air Bleeding Hydraulic System ................................. 8

STEERING WHEEL .................................................. 10

On-Vehicle Inspection and Service ........................ 10

CHECKING CONDITION OF INSTALLATION .... 10

CHECKING STEERING WHEEL PLAY .............. 10

CHECKING NEUTRAL POSITION STEERING

WHEEL ............................................................... 10

CHECKING STEERING WHEEL TURNING

FORCE ................................................................ 10

CHECKING FRONT WHEEL TURNING ANGLE .... 11

Removal and Installation ........................................ 12

REMOVAL ........................................................

... 12

INSTALLATION ................................................... 12

STEERING COLUMN ............................................... 13

Removal and Installation ........................................ 13

COMPONENTS .................................................. 13

REMOVAL OF UPPER JOINT, COLLAR, HOLE

COVER SEAL, HOLE COVER, LOWER SHAFT

AND LOWER JOINT ........................................... 14

INSPECTION AFTER REMOVAL ....................... 14INSTALLATION OF UPPER JOINT, COLLAR,

HOLE COVER SEAL, HOLE COVER, LOWER

SHAFT AND LOWER JOINT .............................. 14

REMOVAL OF STEERING COLUMN ASSEM-

BLY ...................................................................... 15

INSPECTION AFTER REMOVAL ....................... 16

INSTALLATION OF STEERING COLUMN

ASSEMBLY ......................................................... 16

INSPECTION AFTER INSTALLATION ................ 16

Disassembly and Assembly .................................... 17

COMPONENTS ................................................... 17

DISASSEMBLY ................................................... 17

INSPECTION AFTER DISASSEMBLY ................ 17

ASSEMBLY ......................................................... 17

INSPECTION AFTER ASSEMBLY ...................... 17

POWER STEERING GEAR ...................................... 18

Removal and Installation ........................................ 18

COMPONENTS ................................................... 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ................ 19

Disassembly and Assembly .................................

... 20

COMPONENTS ................................................... 20

DISASSEMBLY ................................................... 21

INSPECTION AFTER DISASSEMBLY ................ 22

ASSEMBLY ......................................................... 24

POWER STEERING OIL PUMP ............................... 29

On-Vehicle Inspection and Service ......................... 29

CHECKING RELIEF OIL PRESSURE ................ 29

Removal and Installation ........................................ 29

REMOVAL ........................................................

... 29

INSTALLATION ................................................... 29

Disassembly and Assembly (Models with VK45DE) ... 30

COMPONENTS ................................................... 30

INSPECTION BEFORE DISASSEMBLY ............. 30

DISASSEMBLY ................................................... 31

INSPECTION AFTER DISASSEMBLY ................ 31

Page 4956 of 5621

PRECAUTIONS

PS-3

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NGS000CZ

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions Necessary for Steering Wheel Rotation after Battery DisconnectNGS000D0

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK

position, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Carry the Intelligent Key or insert it to the key slot and turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-II.

Page 4957 of 5621

PS-4

PRECAUTIONS

Revision: 2006 January2006 M35/M45

Precautions for Steering SystemNGS000D1

In case of removing steering gear assembly, make the final tightening with grounded and unloaded vehi-

cle condition, and then check wheel alignment.

Observe the following precautions when disassembling.

–Before disassembly, thoroughly clean the outside of the unit.

–Disassembly should be done in a clean work area. It is important to prevent the internal parts from becom-

ing contaminated by dirt or other foreign matter.

–For easier and proper assembly, place disassembled parts in order on a parts rack.

–Use nylon cloth or paper towels to clean the parts; common shop rags can leave lint that might interfere

with their operation.

–Do not reuse non-reusable parts.

–Before assembling, apply the specified grease to the directed parts.

Page 4961 of 5621

PS-8

POWER STEERING FLUID

Revision: 2006 January2006 M35/M45

POWER STEERING FLUIDPFP:KLF20

Checking Fluid LevelNGS000D5

Check fluid level with engine stopped.

Make sure that fluid level is between MIN and MAX.

Fluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

The fluid level should not exceed the MAX line. Excessive

fluid will cause fluid leakage from the cap.

Do not reuse drained power steering fluid.

Recommended fluid is Genuine Nissan PSF or equiva-

lent.

Checking Fluid LeakageNGS000D6

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80

C (122

to 176

F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right

stop.

3. Hold steering wheel at each lock position for five seconds and

carefully, check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not overtighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to PS-29, "

POWER STEERING OIL

PUMP" .

6. Check steering gear boots for accumulation of fluid indicating from steering gear.

Air Bleeding Hydraulic SystemNGS000D7

If air bleeding is not complete, the following symptoms can be observed.

Bubbles are created in reservoir tank.

Clicking noise can be heard from oil pump.

Excessive buzzing in the oil pump.

NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of

the system.

1. Turn steering wheel several times from full left stop to full right stop with engine off.

CAUTION:

Turn steering wheel while filling reservoir tank with fluid so as not to lower fluid level below the

MIN line.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

3. Repeat step 2 above several times at approximately 3 second intervals.

CAUTION:

Do not hold the steering wheel in a locked position for more than 10 seconds. (There is the possi-

bility that oil pump may be damaged.)

4. Check fluid for bubbles and while contamination.HOT : Fluid temperature 50 - 80

C (122 - 176F)

COLD : Fluid temperature 0 - 30

C (32 - 86F)

PGIA0007J

SGIA0506E

Page 4962 of 5621

POWER STEERING FLUID

PS-9

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

5. Stop engine if bubbles and white contamination do not drain out. Perform step 2 and 3 above after waiting

until bubbles and white contamination drain out.

6. Stop the engine, and then check fluid level.

Page 4963 of 5621

PS-10

STEERING WHEEL

Revision: 2006 January2006 M35/M45

STEERING WHEELPFP:48430

On-Vehicle Inspection and ServiceNGS000D8

CHECKING CONDITION OF INSTALLATION

Check installation conditions of steering gear assembly, front suspension assembly, axle and steering col-

umn assembly.

Check if movement exists when steering wheel is moved up and down, to the left and right and to the axial

direction.

Check steering gear assembly mounting bolts and nut for looseness. Refer to PS-18, "COMPONENTS" .

CHECKING STEERING WHEEL PLAY

Turn steering wheel so that front wheels come to the straight-ahead position. Start engine and lightly turn

steering wheel to the left and right until front wheels start to move. Measure steering wheel movement on

the outer circumference.

When the measurement value is outside the standard value, check backlash for each joint of steering col-

umn assembly and installation condition of steering gear assembly.

CHECKING NEUTRAL POSITION STEERING WHEEL

Make sure that steering gear assembly, steering column assembly and steering wheel are installed in the

correct position.

Perform neutral position inspection after wheel alignment. Refer to FSU-6, "Wheel Alignment Inspection"

(2WD), FSU-23, "Wheel Alignment Inspection" (AWD).

Set vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

Loosen outer socket lock nut and turn inner socket to left and right equally to make fine adjustments if

steering wheel is not in the neutral position.

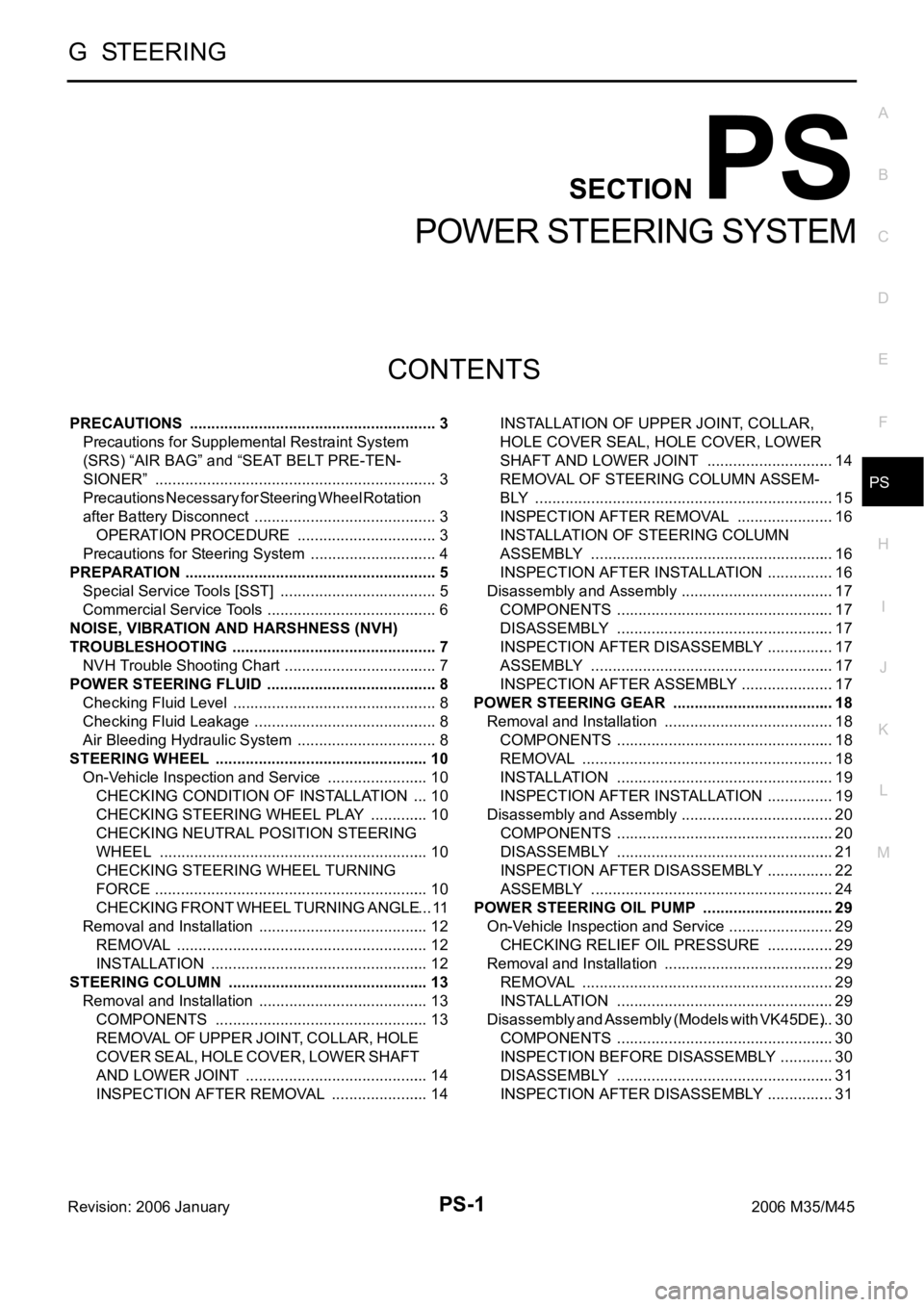

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level and dry surface, set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating temperature. [Make sure temperature of fluid is

approximately 50 to 80

C (122 to 176F).]

4. Check steering wheel turning force when steering wheel has

been turned 540

from neutral position.

NOTE:

Multiply the distance (L) from the hook of spring scale to the

center of steering wheel by the measurement value with a spring

scale.

5. If steering wheel turning force is out of the specification, check

rack sliding force and relief hydraulic pressure of oil pump.

Regarding relief hydraulic pressure of oil pump, refer to PS-29,

"CHECKING RELIEF OIL PRESSURE" .

a. Disconnect lower joint and steering knuckle from steering gear assembly. Refer to PS-13, "

COMPO-

NENTS" , FAX-5, "COMPONENT" .

b. Start and run engine at idle to make sure steering fluid has reached normal operating temperature. Steering wheel axial end play : 0 mm (0 in)

Steering wheel play : 0 - 35 mm (0 - 1.38 in)

Steering wheel turning

force: 7.45 Nꞏm (0.76 kg-m, 66 in-lb)

SGIA1025J

Page 4964 of 5621

STEERING WHEEL

PS-11

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

c. While pulling outer socket slowly in 11 . 5 m m (0.453 in) range

from neutral position, make sure rack sliding force is within

specification.

d. If rack sliding force is not within specification, overhaul steering

gear assembly.

CHECKING FRONT WHEEL TURNING ANGLE

Check front wheel turning angle after toe-in inspection. Place

front wheels on turning radius gauges and rear wheels on

stands. Check the maximum inner and outer wheel turning

angles for LH and RH road wheels.

With the engine at idle, turn steering wheel from full left stop to

full right stop and measure the turning angles.

Measure rack stroke if angles are outside the specified value.

Disassemble steering gear assembly to check the cause that

rack stroke is outside of the standard.

Steering angles are not adjustable. Check steering gear assem-

bly, steering column assembly and front suspension compo-

nents for wear or damage if any of the turning angles are

different from the specified value. Replace any of them, if any

non-standard condition exists.

Rack sliding force2WD 195 - 258 N (19.9 - 26.3 kg, 44 - 58 lb)

AWD 227 - 305 N (23.2 - 31.1 kg, 51 - 69 lb)

SST090B

FAA0016D

SGIA0055E

Drive type 2WD AWD

Tire size P245/45R18 245/40R19 245/45R18

Inner wheel (Angle: A)Minimum 36

20 (36.3)3945 (39.8)

Nominal 39

20 (39.3)4245 (42.8)

Maximum 40

20 (40.3)4345 (43.8)

Outer wheel (Angle: B) Nominal 33

25 (33.4)3320 (33.3)3230 (32.5)

Drive type 2WD AWD

Rack stroke “L” 68.5 mm (2.697 in) 67.0 mm (2.638 in)

SGIA0629J

Page 4967 of 5621

PS-14

STEERING COLUMN

Revision: 2006 January2006 M35/M45

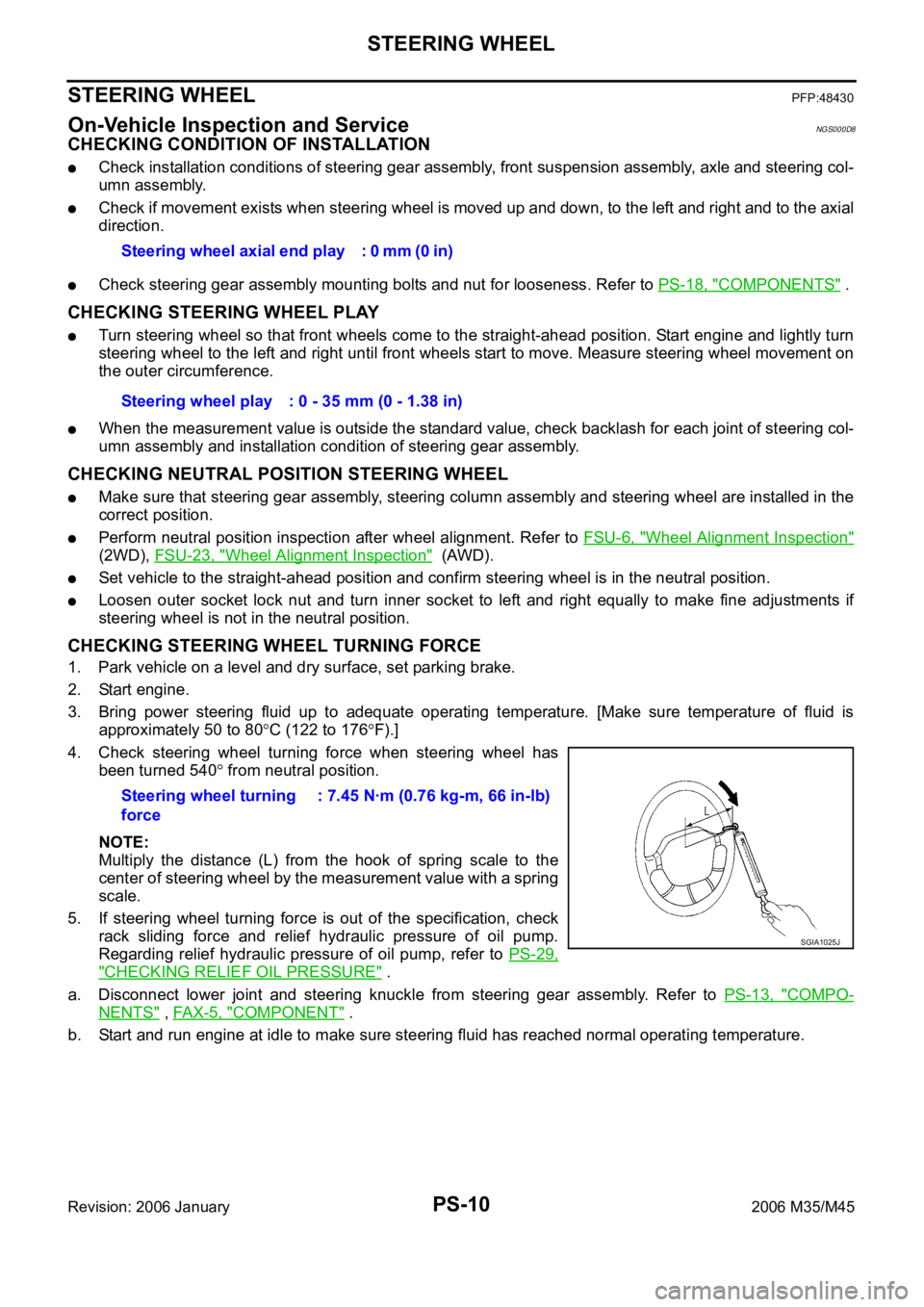

REMOVAL OF UPPER JOINT, COLLAR, HOLE COVER SEAL, HOLE COVER, LOWER SHAFT

AND LOWER JOINT

1. Set vehicle to the straight ahead-position.

2. Remove fixing bolts and nut of upper joint (1), then remove

upper joint (1), collar (2) from lower shaft and steering column

assembly.

3. Raise vehicle.

4. Remove lower side fixing bolt of lower joint.

5. Remove upper side fixing bolt of lower joint, then remove lower

joint from lower shaft and steering gear assembly.

6. Remove lower shaft from vehicle.

7. Lowering vehicle.

8. Loosen clamp, and then remove hole cover seal from hole

cover.

9. Remove mounting nuts of hole cover, and then remove clamp

and hole cover from dash panel.

INSPECTION AFTER REMOVAL

Check each part of upper joint, collar, hole cover seal, hole cover, lower shaft and lower joint for damage or

other malfunctions. Replace if there are.

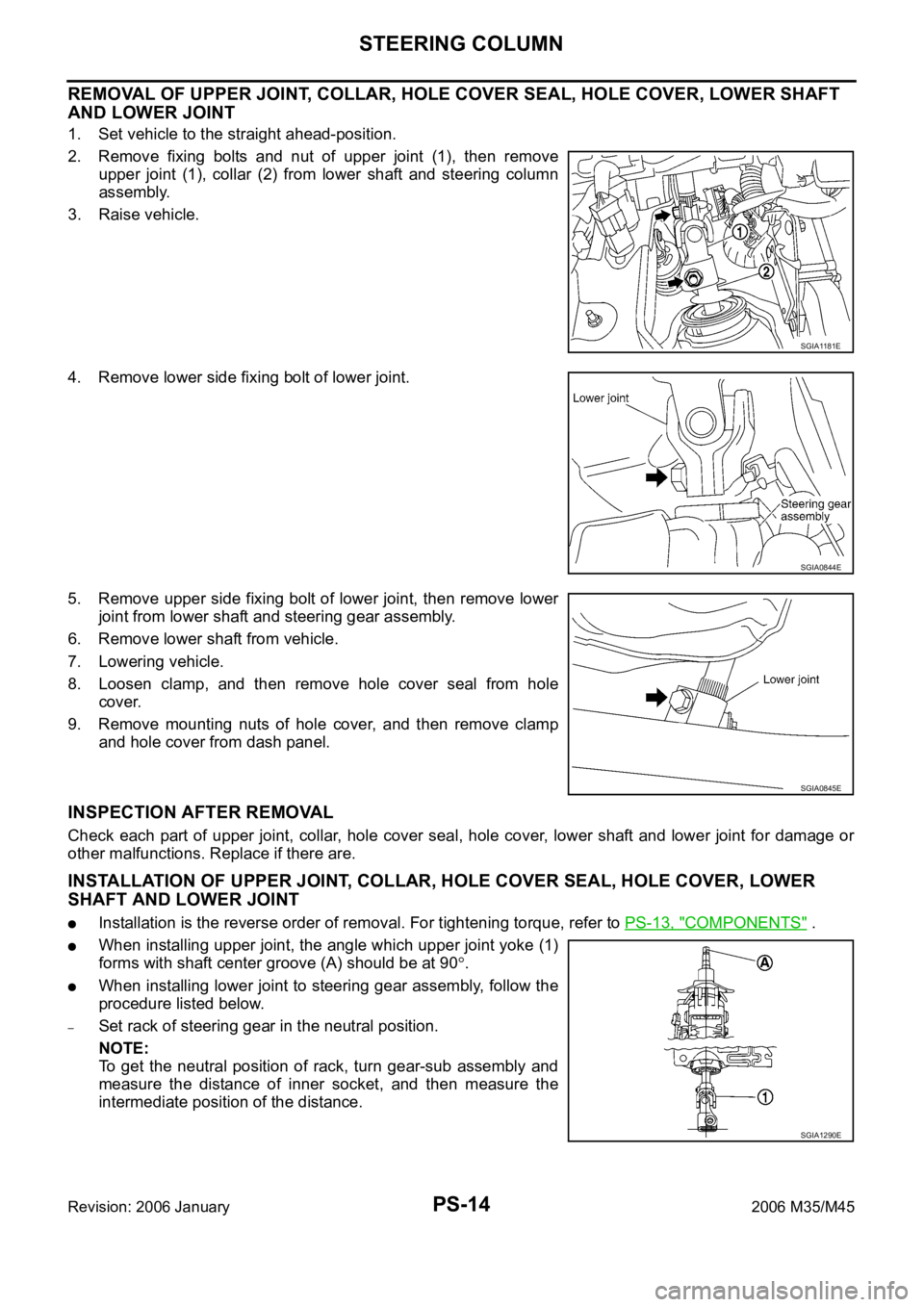

INSTALLATION OF UPPER JOINT, COLLAR, HOLE COVER SEAL, HOLE COVER, LOWER

SHAFT AND LOWER JOINT

Installation is the reverse order of removal. For tightening torque, refer to PS-13, "COMPONENTS" .

When installing upper joint, the angle which upper joint yoke (1)

forms with shaft center groove (A) should be at 90

.

When installing lower joint to steering gear assembly, follow the

procedure listed below.

–Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn gear-sub assembly and

measure the distance of inner socket, and then measure the

intermediate position of the distance.

SGIA1181E

SGIA0844E

SGIA0845E

SGIA1290E