Fuse INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5116 of 5621

![INFINITI M35 2006 Factory Service Manual PRE-CRASH SEAT BELT

SB-17

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Ignition Power Supply Circuit CheckNHS00089

1. CHECK FUSE

Check 10A fuse [No.15, located in fuse block (J/B)].

NO INFINITI M35 2006 Factory Service Manual PRE-CRASH SEAT BELT

SB-17

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Ignition Power Supply Circuit CheckNHS00089

1. CHECK FUSE

Check 10A fuse [No.15, located in fuse block (J/B)].

NO](/img/42/57023/w960_57023-5115.png)

PRE-CRASH SEAT BELT

SB-17

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Ignition Power Supply Circuit CheckNHS00089

1. CHECK FUSE

Check 10A fuse [No.15, located in fuse block (J/B)].

NOTE:

Refer to SB-3, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown out, be sure to eliminate cause of malfunction before installing new fuse. Refer to

PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK IGNITION POWER SUPPLY CIRCUIT

1. Disconnect pre-crash seat belt control unit connector.

2. Turn ignition switch ON.

3. Check voltage between pre-crash seat belt control unit harness

connector and ground.

OK or NG

OK >> Ignition power supply circuit is OK.

NG >> Check pre-crash seat belt control unit ignition power supply circuit harness.

Motor Power Supply and Ground Circuit Check [B2454]NHS0008A

1. CHECK FUSE

Check 30A fusible link (letter G , located in the fuse and fusible link box).

NOTE:

Refer to SB-3, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown out, be sure to eliminate cause of malfunction before installing new fuse. Refer to

PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

Terminal

Voltage (V)

(Approx.) (+)

(–) Pre-crash seat

belt control unit

connectorTerminal

B142 13 Ground Battery voltage

PHIA1126E

Page 5147 of 5621

SC-10

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

STARTING SYSTEM PFP:00011

System Description NKS003NI

Power is supplied at all times

through 15A fuse (No. 78, located in the IPDM E/R)

to CPU of IPDM E/R,

through 15A fuse (No. 71, located in the IPDM E/R)

to CPU of IPDM E/R.

Ground is supplied

to IPDM E/R terminals 38 and 51

from grounds E22 and E43.

When the selector lever in the P or N position, power is supplied

from TCM, and through A/T assembly terminal 9

to IPDM E/R terminal 53.

And then provided that IPDM E/R receives a starter relay ON signal with CAN communication, starter relay is

energized.

With the ignition switch in the START position, power is supplied

through IPDM E/R terminal 3

to starter motor terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

Page 5152 of 5621

STARTING SYSTEM

SC-15

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

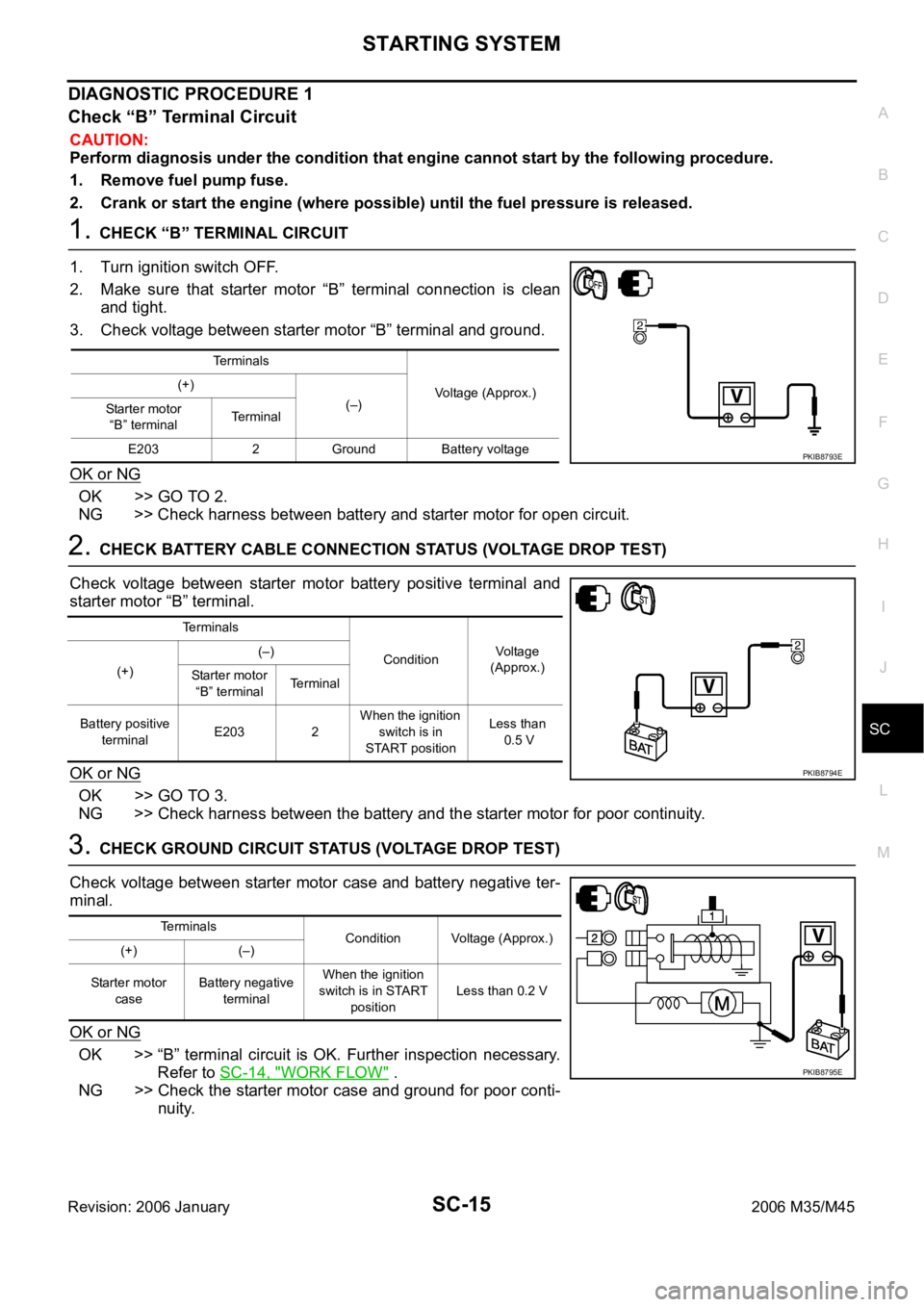

DIAGNOSTIC PROCEDURE 1

Check “B” Terminal Circuit

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1. CHECK “B” TERMINAL CIRCUIT

1. Turn ignition switch OFF.

2. Make sure that starter motor “B” terminal connection is clean

and tight.

3. Check voltage between starter motor “B” terminal and ground.

OK or NG

OK >> GO TO 2.

NG >> Check harness between battery and starter motor for open circuit.

2. CHECK BATTERY CABLE CONNECTION STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor battery positive terminal and

starter motor “B” terminal.

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter motor for poor continuity.

3. CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor case and battery negative ter-

minal.

OK or NG

OK >> “B” terminal circuit is OK. Further inspection necessary.

Refer to SC-14, "

WORK FLOW" .

NG >> Check the starter motor case and ground for poor conti-

nuity.

Terminals

Voltage (Approx.) (+)

(–)

Starter motor

“B” terminalTerminal

E203 2 Ground Battery voltage

PKIB8793E

Terminals

ConditionVoltage

(Approx.)

(+)(–)

Starter motor

“B” terminalTerminal

Battery positive

terminalE203 2 When the ignition

switch is in

START positionLess than

0.5 V

PKIB8794E

Terminals

Condition Voltage (Approx.)

(+) (–)

Starter motor

caseBattery negative

terminalWhen the ignition

switch is in START

positionLess than 0.2 V

PKIB8795E

Page 5153 of 5621

SC-16

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

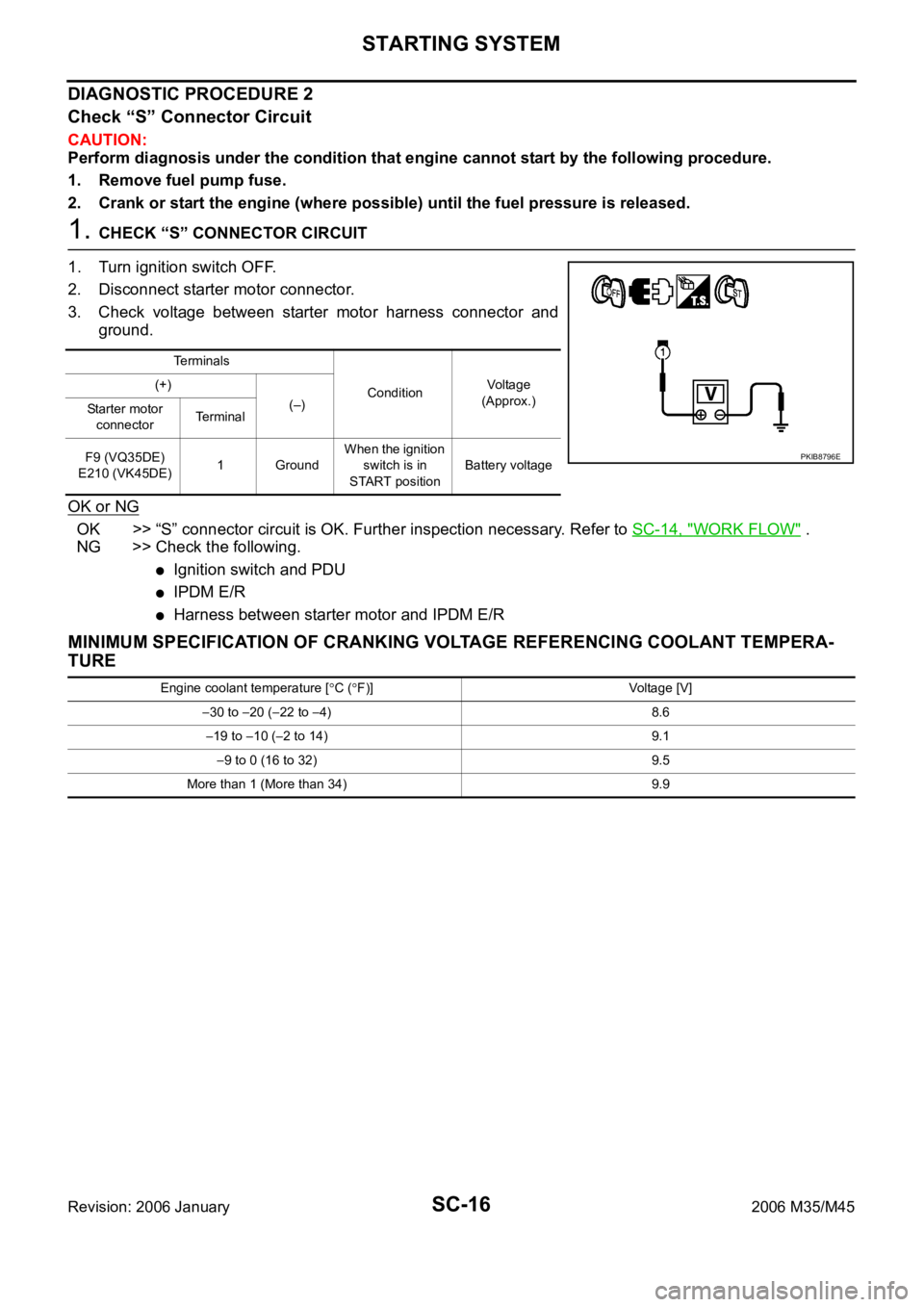

DIAGNOSTIC PROCEDURE 2

Check “S” Connector Circuit

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1. CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector.

3. Check voltage between starter motor harness connector and

ground.

OK or NG

OK >> “S” connector circuit is OK. Further inspection necessary. Refer to SC-14, "WORK FLOW" .

NG >> Check the following.

Ignition switch and PDU

IPDM E/R

Harness between starter motor and IPDM E/R

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

Te r m i n a l s

ConditionVoltage

(Approx.) (+)

(–)

Starter motor

connectorTe r m i n a l

F9 (VQ35DE)

E210 (VK45DE)1 GroundWhen the ignition

switch is in

START positionBattery voltage

PKIB8796E

Engine coolant temperature [C (F)] Voltage [V]

30 to 20 (22 to 4) 8.6

19 to 10 (2 to 14) 9.1

9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Page 5160 of 5621

CHARGING SYSTEM

SC-23

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

CHARGING SYSTEM PFP:00011

System Description NKS003NN

DESCRIPTION

The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times

through 10A fuse [No. 36, located in the fuse, fusible link and relay block (J/B)]

to alternator terminal 4 (“S” terminal).

“B” terminal supplies power to charge the battery and operate the vehicle's electrical system. Output voltage is

controlled by the IC regulator at terminal 4 (“S” terminal) detecting the input voltage.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 14, located in the fuse block (J/B)]

to combination meter terminal 12 for the charge warning lamp.

Ground is supplied at signal

to combination meter terminal 22

through alternator terminal 3 (“L” terminal).

Then power and ground are supplied, the charge warning lamp will illuminate.

When the alternator is providing sufficient voltage with the engine running, the ground is opened and the

charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

Ground is supplied

to alternator terminal 2 (“E” terminal)

through grounds E222, E223 and E224. (VQ35DE)

through ground E212. (VK45DE)

MALFUNCTION INDICATOR

The IC regulator warning function activates to illuminate the charge warning lamp, if any of the following symp-

toms occur while alternator is operating:

Excessive voltage is produced.

No voltage is produced.

Page 5169 of 5621

SC-32

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

PRELIMINARY INSPECTION

1. CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair battery terminals connection.

2. CHECK FUSE AND FUSIBLE LINK

Check for blown fuse and fusible link.

OK or NG

OK >> GO TO 3.

NG >> Be sure to eliminate cause of malfunction before installing new fuse.

3. CHECK “E” TERMINAL CONNECTION

Check if “E” terminal (alternator ground harness) is clean and tight.

OK or NG

OK >> GO TO 4.

NG >> Repair “E” terminal connection.

4. CHECK ALTERNATOR DRIVE BELT TENSION

Check alternator drive belt tension. Refer to EM-15, "

Checking Drive Belts" (VQ35DE) or EM-174, "Checking

Drive Belts" (VK45DE).

OK or NG

OK >> INSPECTION END

NG >> Repair as needed.

DIAGNOSTIC PROCEDURE 1

Check “L” Terminal Circuit (Open)

1. CHECK “L” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “L” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “L” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test. Refer to SC-28, "

Trouble Diagnoses with Battery/Starting/Charging System Tester

(Charging)" .

Unit Power source (Power supply terminals) Fuse and fusible link No.

Alternator Battery (“S” terminal) 36

Combination meter Ignition switch ON (“L” terminal) 14

Page 5170 of 5621

CHARGING SYSTEM

SC-33

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

2. CHECK “L” TERMINAL CIRCUIT (OPEN)

1. Disconnect alternator connector.

2. Apply ground to alternator harness connector terminal.

3. Check condition the charge warning lamp with the ignition

switch in the ON position.

OK or NG

OK >> Go to SC-31, "WORK FLOW" .

NG >> Check the following.

Harness for open between combination meter and alternator

Harness for open between combination meter and fuse

Charge warning lamp (Combination meter)

DIAGNOSTIC PROCEDURE 2

Check “L” Terminal Circuit (Short)

1. CHECK “L” TERMINAL CIRCUIT (SHORT)

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

Charge warning lamp should illuminate?

YES >> Check the following.

Harness for short between combination meter and alternator

Charge warning lamp (Combination meter)

NO >> Go to SC-31, "

WORK FLOW" .

DIAGNOSTIC PROCEDURE 3

Check “S” Terminal Circuit

1. CHECK “S” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “S” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “S” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test. Refer to SC-28, "

Trouble Diagnoses with Battery/Starting/Charging System Tester

(Charging)" .

Alternator

connectorTerminal

GroundCondition

Ignition switch

positionCharge warning

lamp

F20 (VQ35DE)

E209 (VK45DE)3 ON illuminate

PKIB8807E

Page 5171 of 5621

SC-34

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

2. CHECK “S” TERMINAL CIRCUIT

Check voltage between alternator harness connector and ground.

OK or NG

OK >> Go to SC-31, "WORK FLOW" .

NG >> Check harness for open between alternator and fuse.

DIAGNOSTIC PROCEDURE 4

Check “B” Terminal Circuit

1. CHECK “B” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “B” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “B” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test. Refer to SC-28, "

Trouble Diagnoses with Battery/Starting/Charging System Tester

(Charging)" .

2. CHECK “B” TERMINAL CIRCUIT

Check voltage between alternator “B” terminal and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open between alternator and fusible

link.

3. CHECK “B” TERMINAL CONNECTION (VOLTAGE DROP TEST)

1. Start engine, then engine running at idle and warm.

2. Check voltage between battery positive terminal and alternator

“B” terminal.

OK or NG

OK >> Go to SC-31, "WORK FLOW" .

NG >> Check harness between battery and alternator for poor continuity.

Terminals

Voltage (Approx.) (+)

(–)

Alternator connector Terminal

F20 (VQ35DE)

E209 (VK45DE)4 Ground Battery voltage

PKIB8808E

Terminals

Voltage (Approx.) (+)

(–)

Alternator “B” terminal Terminal

E205 [VQ35DE (2WD)]

E202 [VQ35DE (AWD)/VK45DE]1 Ground Battery voltage

PKIB8809E

Te r m i n a l s

Voltage

(Approx.)

(+)(–)

Alternator “B” terminal Terminal

Battery positive

terminalE205 [VQ35DE (2WD)]

E202 [VQ35DE (AWD)/VK45DE]1 Less than 0.2 V

PKIB8810E

Page 5192 of 5621

AUTOMATIC DRIVE POSITIONER

SE-11

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

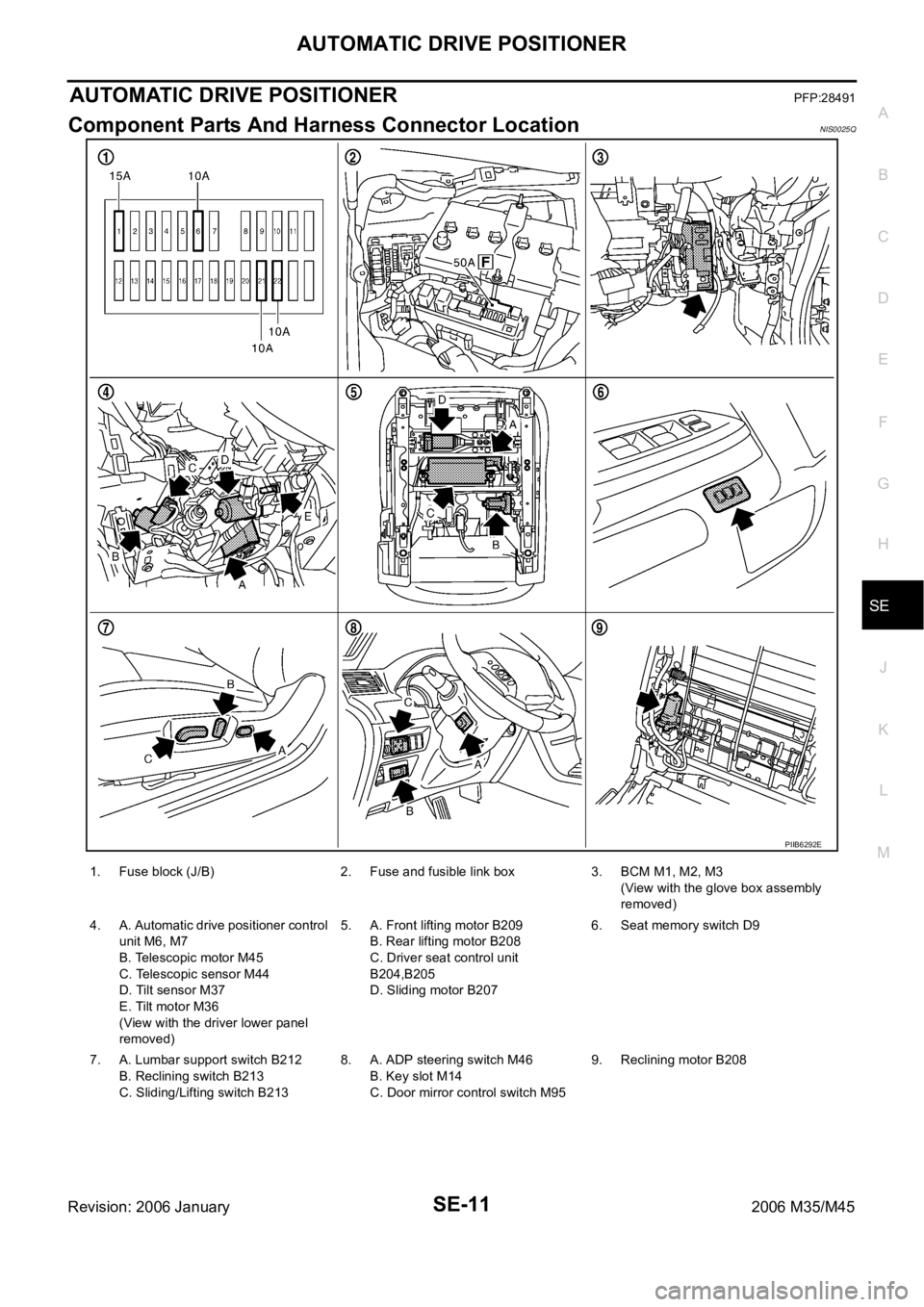

AUTOMATIC DRIVE POSITIONERPFP:28491

Component Parts And Harness Connector LocationNIS0025Q

PIIB6292E

1. Fuse block (J/B) 2. Fuse and fusible link box 3. BCM M1, M2, M3

(View with the glove box assembly

removed)

4. A. Automatic drive positioner control

unit M6, M7

B. Telescopic motor M45

C. Telescopic sensor M44

D. Tilt sensor M37

E. Tilt motor M36

(View with the driver lower panel

removed)5. A. Front lifting motor B209

B. Rear lifting motor B208

C. Driver seat control unit

B204,B205

D. Sliding motor B2076. Seat memory switch D9

7. A. Lumbar support switch B212

B. Reclining switch B213

C. Sliding/Lifting switch B2138. A. ADP steering switch M46

B. Key slot M14

C. Door mirror control switch M959. Reclining motor B208

Page 5211 of 5621

SE-30

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

Terminals and Reference Values for BCMNIS0025W

Terminals and Reference Value for Intelligent Key UnitNIS0025X

Termi-

nal Wire

colorItem ConditionVoltage (V)

(Approx)

11 V Power source (ACC)Ignition switch

(ACC or ON position)Battery voltage

37 LG Key switch signalKey switch ON (Key is inserted in key

slot)Battery voltage

Key switch OFF (Key is remove from

key slot)0

38 W Power source (IGN)Ignition switch

(ON or START position)Battery voltage

39 L CAN-H — —

40 P CAN-L — —

42 P Power source (Fuse) — Battery voltage

52 B Ground — 0

55 W Power source (Fusible link) — Battery voltage

62 V Drive side door switch ON (Open)

OFF (Closed) 0 Battery voltage

Te r m i -

nalWire

ColorItemCondition

Voltage (V)

Approx. Ignition

Switch

PositionOperation or Conditions

1 SB Power source (Fuse) — — Battery voltage

19 BR/Y Key switch signal LOCKInsert Intelligent Key into key slot. Battery voltage

Remove Intelligent Key from key slot. 0

20 B Ground ON — 0

27 V P range switch —Selector lever is in “P” position. 0

Other than above Battery voltage

37 P CAN-L — — —

38 L CAN-H — — —

40 B Ground ON — 0

41 Y Power source (Fuse) — — Battery voltage

56 B Ground ON — 0

57 L Power source (Fuse) — — Battery voltage

58 OA/T device power

supply —Wake up state Battery voltage

Sleep state 0

72 B Ground ON 0