Fuse INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5284 of 5621

POWER SEAT(REAR)

SE-103

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

Work FlowNIS00277

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to SE-95, "

System Description" .

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to SE-103,

"Trouble Diagnoses Symptom Chart" .

4. Does rear power seat operate normally? YES: GO TO 5, NO: GO TO 4.

5. INSPECTION END.

Trouble Diagnoses Symptom ChartNIS00278

Check that other systems using the signal of the following systems operate normally.

Rear Power Seat Power Supply Circuit InspectionNIS00279

1. CHECK FUSIBLE LINK

Check 50A fusible link (letter F located in the fuse and fusible link box).

NOTE:

Refer to SE-95, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse, refer to PG-

3, "POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK CIRCUIT BREAKER

Check circuit breaker.

NOTE:

Refer to PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace the circuit breaker.

Symptom Diagnoses / service procedure Refer to page

Rear power seat LH, RH do not operate. Rear power seat power supply circuit inspectionSE-103

Rear power seat LH or RH sliding switch does not operate

moreover, retreat function does not operate if the door is

opened1. Rear seat control unit power supply and

ground circuit inspectionSE-104

2. Rear seat sliding motor circuit inspectionSE-105

Rear power seat LH or RH does not operate, but retreat func-

tion operates when the door is openedRear power seat switch circuit inspectionSE-106

Rear power seat LH and RH retreat function does not operate,

but operates by sliding switchAutomatic return cancel switch inspectionSE-109

Rear power seat LH or RH retreat function does not operate,

but operates by a sliding switch1. Rear door switch circuit inspectionSE-1102. Automatic return cancel switch circuit inspec-

tionSE-108

3. Rear seat sliding sensor circuit inspectionSE-111

Page 5294 of 5621

CLIMATE CONTROLLED SEAT

SE-113

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

CLIMATE CONTROLLED SEATPFP:870U6

Component Parts and Harness Connector LocationNIS0027H

System DescriptionNIS0027I

The climate controlled seat system is controlled by climate controlled seat control unit.

Heating and cooling are possible for a thermal electric device (heat conversion machine).

NOTE:

The climate controlled seat system is downed when the temperature sensor set as the seat cushion and

the seat back's thermal electric device machine detects 20

C (68 F)or more of mutual differences of tem-

perature.

In this case, by turning off ignition switch, system down is canceled and it can be reused by turning on

ignition switch again.

The climate controlled seat blower keep low speed for approximately 60 seconds after turning the climate

controlled seat switch.

CAUTION:

The thermal electric device has the character in which, as for an opposite side. one side becomes

high temperature at the time of low temperature.

PIIB5891E

1. Fuse block (J/B) 2. Climate controlled seat relay E16 3.a: Climate controlled seat switch

driver side B20

b: Climate controlled seat switch

passenger side B19

4.a: Seat cushion thermal electric

device B285 (driver side)

B295 (passenger side)

b: Climate controlled seat control

unit B283, B284 (driver side)

B293, B294 (passenger side)

c: Climate controlled seat blower

motor B282 (driver side)

B292 (passenger side)5.Seatback thermal electric device

B220 (driver side)

B258 (passenger side)

Page 5295 of 5621

SE-114

CLIMATE CONTROLLED SEAT

Revision: 2006 January2006 M35/M45

At the time of work, please turn OFF a switch, and carry it out after checking that the thermal elec-

tric device has got cold.

Power is at all times supplied

through 15A fuse [No. 41 located in the fuse fusible link and relay unit]

to climate controlled seat relay terminals 5.

through 15A fuse [No. 42 located in the fuse fusible link and relay unit]

to climate controlled seat relay terminals 7.

When the ignition switch turned to ON or START position,

Power is supplied

through 10A fuse [No. 12, located in the fuse block (J/B)]

to climate controlled seat relay terminal 2.

Then ground is supplied

to climate controlled seat relay terminal 1,

through body grounds E22 and E43.

Then climate controlled seat relay is energized.

When climate controlled seat relay is turned to ON,

Power is supplied,

through climate controlled seat relay terminal 3,

to climate controlled seat control unit (passenger side) terminal 2 and 4.

through climate controlled seat relay terminal 6,

to climate controlled seat control unit (driver side) terminal 2 and 4.

When climate controlled switch select HEAT, ground is supplied

through climate controlled seat switch terminal 1 and 3,

to climate controlled seat control unit terminal 10.

Then, the climate controlled seat control unit receives climate controlled seat switch HEAT signal.

When climate controlled seat switch select COOL, ground is supplied

through climate controlled seat switch terminal 1 and 2,

to climate controlled seat control unit terminal 20,

Then, the climate controlled seat control unit receives climate controlled switch COOL signal.

When blower motor rotates, signal is transmitted

to climate controlled seat control unit terminal 18,

through climate controlled seat blower motor terminal 1.

This is climate controlled seat blower motor tachometer signal.

When climate controlled seat control unit receives climate controlled seat switch signal and tachometer signal,

Power is supplied

to climate controlled seat blower motor terminal 4,

through climate controlled seat control unit terminal 17.

This is blower motor revolution control signal.

When blower motor receivers blower motor revolution control signal,

Power is supplied

through climate controlled seat control unit terminal 14,

to climate controlled seat blower motor terminal 2.

When number of rotations correspond signal,

Ground is supplied

to climate controlled seat blower motor terminal 3,

through climate controlled seat control unit terminal 7,

through climate controlled seat control unit terminal 3,

through body grounds B5, B40 and B131.

Then motor revolution is controlled.

When the ignition switch turned to ON or START position,

Power is supplied

Page 5307 of 5621

SE-126

CLIMATE CONTROLLED SEAT

Revision: 2006 January2006 M35/M45

Climate Controlled Seat Control Unit Power Supply Circuit CheckNIS0027P

1. CHECK FUSE

Check 10A fuse [No. 12, located in fuse block (J/B)]

NOTE:

Refer to SE-113, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse, refer to PG-

3, "POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK CLIMATE CONTROLLED SEAT RELAY POWER SUPPLY CIRCUIT

1. Disconnect climate controlled seat relay connector.

2. Turn ignition switch ON.

3. Check voltage between climate controlled seat relay harness

connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between fuse block (J/B) and

climate controlled seat relay.

3. CHECK CLIMATE CONTROLLED SEAT RELAY

Check continuity climate controlled seat relay.

OK or NG

OK >> GO TO 4.

NG >> Replace climate controlled seat relay.

Terminal

Voltage (V)

(Approx.) (+)

(–)

Climate controlled

seat relay connectorTerminal

E16 2 Ground Battery voltage

PIIB6067E

Climate controlled

seat relay connectorTerminal Condition Continuity

E163512V direct current

supply between

terminals 1and 2Ye s

No current supply No

6712V direct current

supply between

terminals 1and 2Ye s

No current supply No

SEC202B

Page 5308 of 5621

CLIMATE CONTROLLED SEAT

SE-127

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

4. CHECK CLIMATE CONTROLLED SEAT RELAY GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between climate controlled seat relay connec-

tor and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between climate controlled

seat relay and ground.

Climate Controlled Seat Control Unit Power Supply and Ground Circuit Inspec-

tion

NIS0027Q

1. CHECK CLIMATE CONTROLLED SEAT CONTROL UNIT POWER SUPPLY CIRCUIT

1. Disconnect climate controlled seat control unit connector.

2. Turn ignition switch ON.

3. Check voltage between climate controlled seat control unit con-

nector and ground.

OK or NG

OK >> GO TO 6.

NG >> GO TO 2.

2. CHECK FUSE

Check 15A fuse [No. 42, located in fuse, fusible link and relay unit] (Driver side)

Check 15A fuse [No. 41, located in fuse, fusible link and relay unit] (Passenger side)

NOTE:

Refer to SE-113, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 3.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse, refer to PG-

3, "POWER SUPPLY ROUTING CIRCUIT" .

Terminal

Continuity

Climate controlled

seat relay connectorTerminal

Ground

E16 1 Yes

PIIB6068E

Terminal

Voltage (V)

(Approx.) (+)

(–)

Climate controlled seat

control unit connectorTerminal

B284

(driver side)

B294

(passenger side)2

Ground Battery voltage

4

PIIB6069E

Page 5324 of 5621

HEATED SEAT

SE-143

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

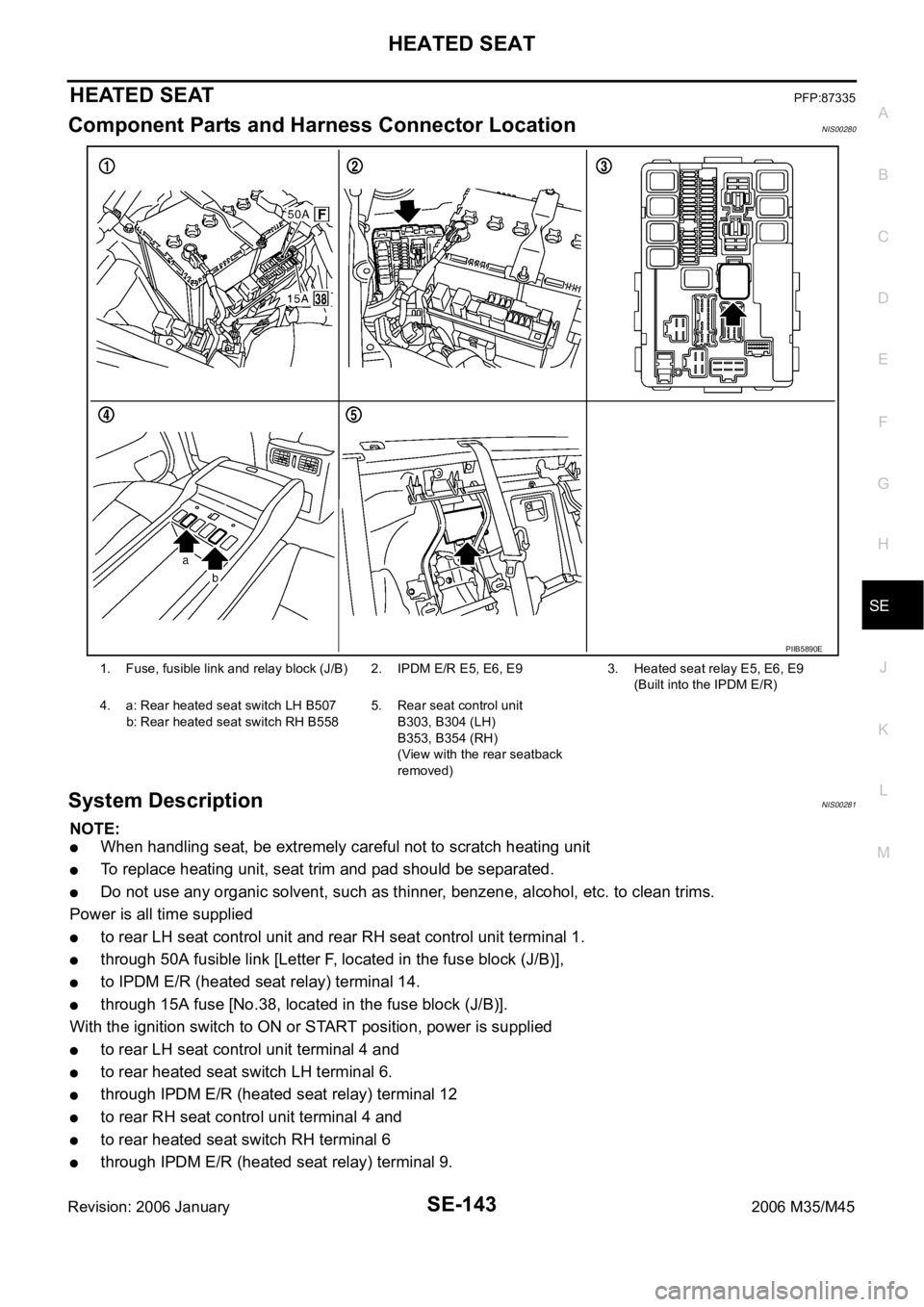

HEATED SEATPFP:87335

Component Parts and Harness Connector LocationNIS00280

System Description NIS00281

NOTE:

When handling seat, be extremely careful not to scratch heating unit

To replace heating unit, seat trim and pad should be separated.

Do not use any organic solvent, such as thinner, benzene, alcohol, etc. to clean trims.

Power is all time supplied

to rear LH seat control unit and rear RH seat control unit terminal 1.

through 50A fusible link [Letter F, located in the fuse block (J/B)],

to IPDM E/R (heated seat relay) terminal 14.

through 15A fuse [No.38, located in the fuse block (J/B)].

With the ignition switch to ON or START position, power is supplied

to rear LH seat control unit terminal 4 and

to rear heated seat switch LH terminal 6.

through IPDM E/R (heated seat relay) terminal 12

to rear RH seat control unit terminal 4 and

to rear heated seat switch RH terminal 6

through IPDM E/R (heated seat relay) terminal 9.

1. Fuse, fusible link and relay block (J/B) 2. IPDM E/R E5, E6, E93. Heated seat relay E5, E6, E9

(Built into the IPDM E/R)

4. a: Rear heated seat switch LH B507

b: Rear heated seat switch RH B5585. Rear seat control unit

B303, B304 (LH)

B353, B354 (RH)

(View with the rear seatback

removed)

PIIB5890E

Page 5333 of 5621

SE-152

HEATED SEAT

Revision: 2006 January2006 M35/M45

Rear Heated Seat Power Supply and Ground Circuit InspectionNIS00287

1. CHECK FUSIBLE LINK AND FUSE

Check 50A fusible link (letter F located in the fuse and fusible link box).

Check 15A fuse (No.38, located in fuse block).

Check circuit breaker.

NOTE:

Refer to SE-143, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse or circuit breaker is blown, be sure to eliminate cause of malfunction before installing new

fuse or new circuit breaker, refer to PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK HEATED SEAT RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Check voltage between IPDM E/R (heated seat relay) connector

and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between fuse block (J/B) and IPDM E/R (heated seat relay).

3. CHECK HEATED SEAT RELAY GROUND CIRCUIT

1. Disconnect IPDM E/R (heated seat relay) connector.

2. Check continuity between IPDM E/R (heated seat relay) con-

nector and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between IPDM E/R (heated

seat relay) and ground.

Terminal

Voltage (V)

(Approx.) (+)

(–) IPDM E/R

(heated seat relay)

connectorTerminal

E6 14 Ground Battery voltage

PIIB5995E

Te r m i n a l

Continuity IPDM E/R

(heated seat relay)

connectorTerminal

Ground

E9 54 Yes

PIIB5996E

Page 5352 of 5621

FRONT SEAT

SE-171

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

Remove driver's seat control unit. (Driver's seat only)

Remove the driver seat control switch.

Remove seat cushion finisher B and seat cushion finisher C.

Remove seat harnesses.

Assembly

Assemble in the reverse order of disassembly. Be careful of the following two points.

Install the hog rings of seat cushion trim in position, and then

securely connect the trim or trim code with the pad side wire.

Clamp the harness in position.

CLIMATE CONTROLLED SEAT

Blower Filter Replacement

Put your hand behind front seat cushion, pull filter downward and

remove it. Replace filter with a new one.

NOTE:

When replacing, be sure to set the front seat lifter to the top

position.

When installing, do not confuse up-down direction of the filter.

PIIB3357J

PIIB3356J

PIIB6502E

Page 5369 of 5621

SRS-8

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSISPFP:00004

Trouble Diagnosis IntroductionNHS00090

CAUTION:

Do not use electrical test equipment on any circuit related to the SRS unless instructed in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Do not repair, splice or modify the SRS wiring harness. If the harness is damaged, replace it with a

new one.

Keep ground portion clean.

DIAGNOSIS FUNCTION

The SRS self-diagnosis results can be read by using “AIR BAG” warning lamp and/or CONSULT-II.

The User mode is exclusively prepared for the customer (driver). This mode warns the driver of a system mal-

function through the operation of the “AIR BAG” warning lamp.

The Diagnosis mode allows the technician to locate and inspect the malfunctioning part.

The mode applications for the “AIR BAG” warning lamp and CONSULT-II are as follows:

HOW TO PERFORM TROUBLE DIAGNOSIS FOR QUICK AND ACCURATE REPAIR

A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malfunction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

Information from Customer

WHAT..... Vehicle model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Preliminary Check

Make sure the following parts are in good order.

Battery (Refer to SC-4, "How to Handle Battery" .)

Fuse (Refer to SRS-12, "Wiring Diagram — SRS —" .)

System component-to-harness connections

User mode Diagnosis mode Display type

“AIR BAG” warning lamp X X ON-OFF operation

CONSULT-II — X Monitoring

Page 5397 of 5621

SRS-36

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Trouble Diagnosis: “AIR BAG” Warning Lamp Does Not Turn OFFNHS00099

DIAGNOSTIC PROCEDURE 7

1. CHECK THE DEPLOYMENT OF AIR BAG MODULE

Is air bag module deployed?

YES or NO

YES >> Refer to SRS-50, "COLLISION DIAGNOSIS" .

NO >> GO TO 2.

2. CHECK THE AIR BAG FUSE

Check 10A fuse [No.13, located in fuse block (J/B)].

Refer to PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3. CHECK AIR BAG FUSE AGAIN

Replace “AIR BAG” fuse and turn ignition switch ON.

Does the

“AIR BAG” fuse blow again?

YES >> Repair or replace main harness.

NO >>INSPECTION END

4. CHECK DIAGNOSIS SENSOR UNIT

Connect CONSULT-II and touch “START”.

Is “AIR BAG” displayed on CONSULT-II?

YES or NO

YES >> GO TO 5.

NO >> Visually check the wiring harness connection of diagno-

sis sensor unit. If the harness connection check result is

OK, replace diagnosis sensor unit.

5. CHECK HARNESS CONNECTION

Is harness connection between warning lamp and diagnosis sensor unit OK?

OK or NG

OK >> Replace diagnosis sensor unit.

NG >> Connect “AIR BAG” warning lamp and diagnosis sensor unit connector properly. If “AIR BAG”

warning lamp still does not go off, replace harness.

BCIA0030E