Fuse INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4865 of 5621

PG-38

PDU (POWER DISTRIBUTION UNIT)

Revision: 2006 January2006 M35/M45

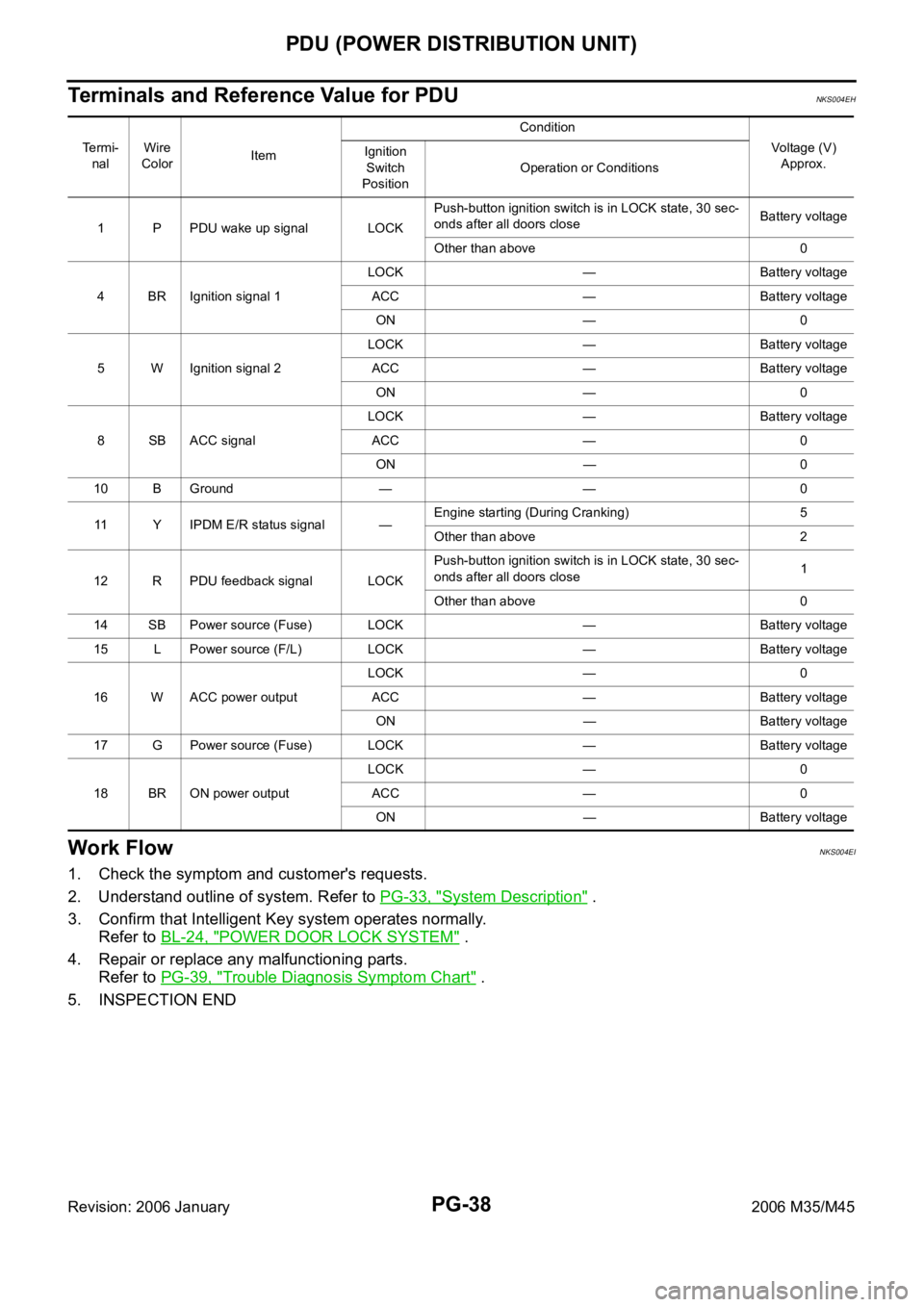

Terminals and Reference Value for PDUNKS004EH

Work FlowNKS004EI

1. Check the symptom and customer's requests.

2. Understand outline of system. Refer to PG-33, "

System Description" .

3. Confirm that Intelligent Key system operates normally.

Refer to BL-24, "

POWER DOOR LOCK SYSTEM" .

4. Repair or replace any malfunctioning parts.

Refer to PG-39, "

Trouble Diagnosis Symptom Chart" .

5. INSPECTION END

Te r m i -

nalWire

ColorItemCondition

Voltage (V)

Approx. Ignition

Switch

PositionOperation or Conditions

1 P PDU wake up signal LOCKPush-button ignition switch is in LOCK state, 30 sec-

onds after all doors closeBattery voltage

Other than above 0

4 BR Ignition signal 1LOCK — Battery voltage

ACC — Battery voltage

ON — 0

5 W Ignition signal 2LOCK — Battery voltage

ACC — Battery voltage

ON — 0

8 SB ACC signalLOCK — Battery voltage

ACC — 0

ON — 0

10 B Ground — — 0

11 Y IPDM E/R status signal —Engine starting (During Cranking) 5

Other than above 2

12 R PDU feedback signal LOCKPush-button ignition switch is in LOCK state, 30 sec-

onds after all doors close1

Other than above 0

14 SB Power source (Fuse) LOCK — Battery voltage

15 L Power source (F/L) LOCK — Battery voltage

16 W ACC power outputLOCK — 0

ACC — Battery voltage

ON — Battery voltage

17 G Power source (Fuse) LOCK — Battery voltage

18 BR ON power outputLOCK — 0

ACC — 0

ON — Battery voltage

Page 4938 of 5621

FUSE BLOCK - JUNCTION BOX (J/B)

PG-111

C

D

E

F

G

H

I

J

L

MA

B

PG

Revision: 2006 January2006 M35/M45

FUSE BLOCK - JUNCTION BOX (J/B)PFP:24350

Terminal ArrangementNKS004EZ

CKIT0663E

Page 4939 of 5621

PG-112

FUSE, FUSIBLE LINK AND RELAY BOX

Revision: 2006 January2006 M35/M45

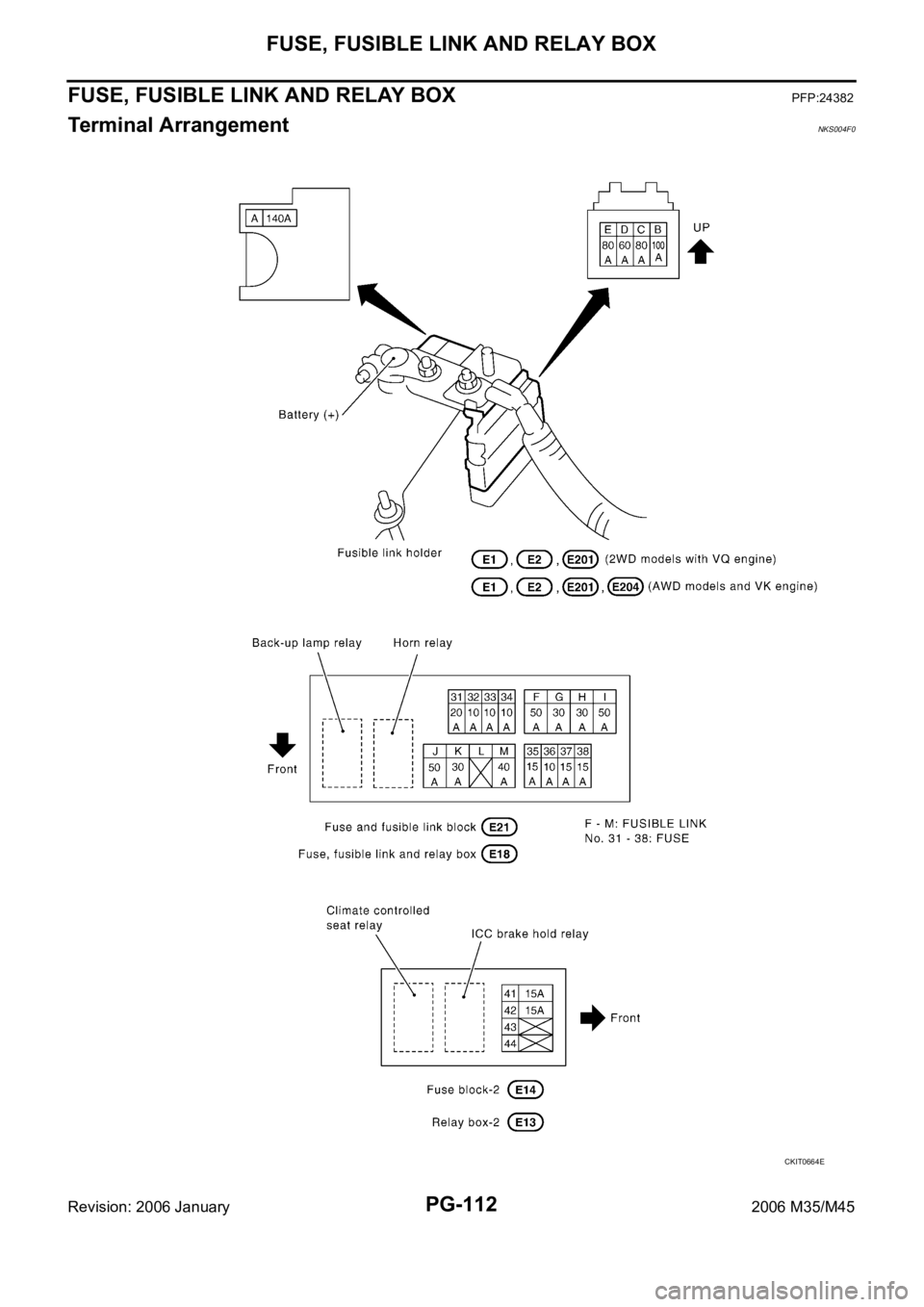

FUSE, FUSIBLE LINK AND RELAY BOXPFP:24382

Terminal ArrangementNKS004F0

CKIT0664E

Page 4961 of 5621

PS-8

POWER STEERING FLUID

Revision: 2006 January2006 M35/M45

POWER STEERING FLUIDPFP:KLF20

Checking Fluid LevelNGS000D5

Check fluid level with engine stopped.

Make sure that fluid level is between MIN and MAX.

Fluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

The fluid level should not exceed the MAX line. Excessive

fluid will cause fluid leakage from the cap.

Do not reuse drained power steering fluid.

Recommended fluid is Genuine Nissan PSF or equiva-

lent.

Checking Fluid LeakageNGS000D6

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80

C (122

to 176

F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right

stop.

3. Hold steering wheel at each lock position for five seconds and

carefully, check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not overtighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to PS-29, "

POWER STEERING OIL

PUMP" .

6. Check steering gear boots for accumulation of fluid indicating from steering gear.

Air Bleeding Hydraulic SystemNGS000D7

If air bleeding is not complete, the following symptoms can be observed.

Bubbles are created in reservoir tank.

Clicking noise can be heard from oil pump.

Excessive buzzing in the oil pump.

NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of

the system.

1. Turn steering wheel several times from full left stop to full right stop with engine off.

CAUTION:

Turn steering wheel while filling reservoir tank with fluid so as not to lower fluid level below the

MIN line.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

3. Repeat step 2 above several times at approximately 3 second intervals.

CAUTION:

Do not hold the steering wheel in a locked position for more than 10 seconds. (There is the possi-

bility that oil pump may be damaged.)

4. Check fluid for bubbles and while contamination.HOT : Fluid temperature 50 - 80

C (122 - 176F)

COLD : Fluid temperature 0 - 30

C (32 - 86F)

PGIA0007J

SGIA0506E

Page 4985 of 5621

PS-32

POWER STEERING OIL PUMP

Revision: 2006 January2006 M35/M45

ASSEMBLY

NOTE:

Secure oil pump in a vise if necessary.

CAUTION:

Use copper plates when securing in a vise.

1. Apply multi purpose grease to oil seal lips (1). Apply power

steering fluid around oil seal, and then install oil seal to body

assembly.

2. Apply power steering fluid to drive shaft, and press drive shaft

into body assembly, then install snap ring.

3. Apply power steering fluid to O-ring, and install O-ring into body

assembly.

4. Install side plate to body assembly.

5. Install dowel pin (3) into dowel pin hole (A), and install cam ring

(2) pointing it's D

1 side toward the body assembly (1) side as

shown in the figure.

When installing cam ring, turn carved face with a letter E (B)

of it to rear cover.

CAUTION:

Do not confuse the assembling direction of cam ring. If

cam ring is installed facing the incorrect direction, it may

cause oil pump operation malfunction.

6. Install rotor to body assembly.

SGIA1150E

SGIA0422E

SGIA1166E

Page 5023 of 5621

RF-10

SUNROOF

Revision: 2006 January2006 M35/M45

SUNROOFPFP:91210

Component Parts and Harness Connector LocationNIS0023Q

PIIB6291E

1. Fuse block (J/B) 2. Fuse and fusible link box 3. BCM M1, M2, M3

(View with the glove box assembly

removed)

4. Sunroof motor assembly M186 5. Sunroof switch R53 6. Front door switch (driver side) B11

Page 5024 of 5621

SUNROOF

RF-11

C

D

E

F

G

H

J

K

L

MA

B

RF

Revision: 2006 January2006 M35/M45

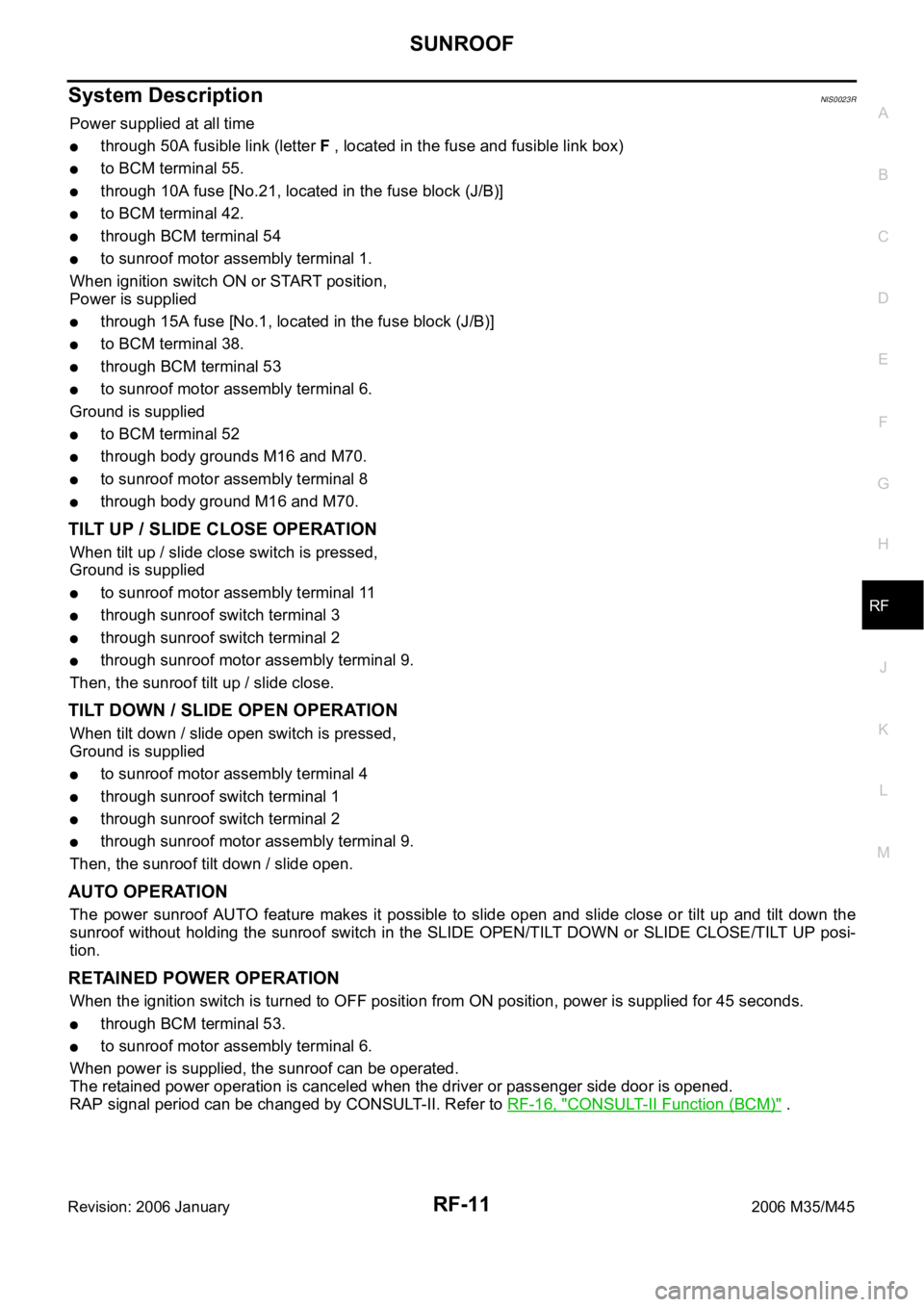

System DescriptionNIS0023R

Power supplied at all time

through 50A fusible link (letter F , located in the fuse and fusible link box)

to BCM terminal 55.

through 10A fuse [No.21, located in the fuse block (J/B)]

to BCM terminal 42.

through BCM terminal 54

to sunroof motor assembly terminal 1.

When ignition switch ON or START position,

Power is supplied

through 15A fuse [No.1, located in the fuse block (J/B)]

to BCM terminal 38.

through BCM terminal 53

to sunroof motor assembly terminal 6.

Ground is supplied

to BCM terminal 52

through body grounds M16 and M70.

to sunroof motor assembly terminal 8

through body ground M16 and M70.

TILT UP / SLIDE CLOSE OPERATION

When tilt up / slide close switch is pressed,

Ground is supplied

to sunroof motor assembly terminal 11

through sunroof switch terminal 3

through sunroof switch terminal 2

through sunroof motor assembly terminal 9.

Then, the sunroof tilt up / slide close.

TILT DOWN / SLIDE OPEN OPERATION

When tilt down / slide open switch is pressed,

Ground is supplied

to sunroof motor assembly terminal 4

through sunroof switch terminal 1

through sunroof switch terminal 2

through sunroof motor assembly terminal 9.

Then, the sunroof tilt down / slide open.

AUTO OPERATION

The power sunroof AUTO feature makes it possible to slide open and slide close or tilt up and tilt down the

sunroof without holding the sunroof switch in the SLIDE OPEN/TILT DOWN or SLIDE CLOSE/TILT UP posi-

tion.

RETAINED POWER OPERATION

When the ignition switch is turned to OFF position from ON position, power is supplied for 45 seconds.

through BCM terminal 53.

to sunroof motor assembly terminal 6.

When power is supplied, the sunroof can be operated.

The retained power operation is canceled when the driver or passenger side door is opened.

RAP signal period can be changed by CONSULT-II. Refer to RF-16, "

CONSULT-II Function (BCM)" .

Page 5028 of 5621

SUNROOF

RF-15

C

D

E

F

G

H

J

K

L

MA

B

RF

Revision: 2006 January2006 M35/M45

Terminals and Reference Value for BCMNIS0023T

Terminals and Reference Value for Sunroof Motor AssemblyNIS0023U

Te r m i -

nalWire

colorItem ConditionVoltage (V)

(Approx.)

12 P Front door switch (passenger side)OPEN (ON) 0

CLOSE (OFF) Battery voltage

38 W Power source (IGN) Ignition switch (ON or START) position Battery voltage

42 P Power source (Fuse) — Battery voltage

52 B Ground (power) — 0

53 BR RAP signalIgnition switch ON Battery voltage

Within 45 seconds after ignition switch is turned to

OFF positionBattery voltage

When driver side or passenger side door is opened

during retained power operation.0

54 O Power window power supply (BAT) — Battery voltage

55 W Power source (Fusible link) — Battery voltage

62 V Front door switch (driver side)OPEN (ON) 0

CLOSE (OFF) Battery voltage

Te r m i -

nalWire

colorItem ConditionVoltage (V)

(Approx.)

1 O BAT power supply (BCM) — Battery voltage

4LGSunroof (TILT DOWN/SLIDE

OPEN) switch signalIgnition switch ON and sunroof switch in

TILT DOWN / SLIDE OPEN position0

Other than above Battery voltage

6YRAP signalIgnition switch ON Battery voltage

Within 45 seconds after ignition switch is turned to

OFF positionBattery voltage

When driver side or passenger side door is opened

during retained power operation.0

8 B Ground — 0

9 Y Sunroof switch ground — 0

11 LSunroof (TILT UP/SLIDE CLOSE)

switch signalIgnition switch ON and sunroof switch in

TILT UP / SLIDE CLOSE position0

Other than above Battery voltage

Page 5031 of 5621

RF-18

SUNROOF

Revision: 2006 January2006 M35/M45

Work FlowNIS0023W

1. Check the symptom and customer's requests.

2. Understand the outline of system. Refer to RF-11, "

System Description" .

3. According to the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to RF-18,

"Diagnosis Symptom Chart" .

4. Does sunroof system operate normally? If Yes, GO TO 5. If No, GO TO 3.

5. INSPECTION END.

Diagnosis Symptom ChartNIS0023X

BCM Power Supply and Ground Circuit CheckNIS0023Y

1. CHECK FUSE

Check 50A fusible link (letter F, located in the fuse and fusible link box).

Check 15A fuse [No.1, located in the fuse block (J/B)]

Check 10A fuse [No.21, located in the fuse block (J/B)]

NOTE:

Refer to RF-10, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown out, be sure to eliminate cause of malfunction before installing new fuse. Refer to

PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

Symptom Diagnostic procedure and repair order Refer to page

Sunroof does not operate properly.1. Power supply and ground circuit check of BCMRF-18

2. Sunroof motor assembly power supply and ground

circuit checkRF-19

3. Sunroof switch system checkRF-21

4. Replace sunroof motor assembly.RF-25

Automatic operation dose not operate.1. Initialization procedure check.RF-122. Replace sunroof motor assembly.RF-25

Motor does not stop at sunroof fully -open or fully- closed

position.1. Initialization procedure check.RF-12

2. Replace sunroof motor assembly.RF-25

Retained power operation does not operate properly.1. Check the retained power operation mode setting.RF-172. Door switch check.RF-23

3. Replace sunroof motor assembly.RF-25

Sunroof does not operate anti-pinch function.1. Initialization procedure check.RF-122. Replace sunroof motor assembly.RF-25

Page 5102 of 5621

PRE-CRASH SEAT BELT

SB-3

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

PRE-CRASH SEAT BELTPFP:98845

Component Parts and Harness Connector LocationNHS0007X

System DescriptionNHS0007Y

Pre-crash seat belt system is adapted to front seat belts RH/LH.

When the pre-crash seat belt control unit judges the emergency braking operation, it gives the sense of

security by the motor built into the pre-crash seat belt retracting the shoulder belt and suppressing the

crew's posture change. Also, it eases the damage of the collision.

PHIA1123E

1. Fuse block (J/B) 2.Fuse, fusible link and relay block

(J/B)3.Pre-crash seat belt control unit B142

(View with the trunk side finisher LH

removed)

4.Brake pedal stroke sensor E125

(View with the instrument driver

lower panel removed)5.Pre-crash seat belt motor B32 (LH),

B8 (RH)

(View with the center pillar lower

garnish removed)6.Seat belt buckle switch B203 (driver

seat) B253 (passenger seat)