wheel INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5000 of 5621

RAX-1

REAR AXLE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION RAX

A

B

RAX

Revision: 2006 January2006 M35/M45

REAR AXLE

PRECAUTIONS .......................................................... 2

Caution ..................................................................... 2

PREPARATION ........................................................... 3

Special Service Tools [SST] ..................................... 3

Commercial Service Tools ........................................ 3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH Troubleshooting Chart ..................................... 4

WHEEL HUB .............................................................. 5

On-Vehicle Inspection and Service .......................... 5

WHEEL BEARING INSPECTION ......................... 5

Removal and Installation .......................................... 5

COMPONENT ....................................................... 5

REMOVAL ........................................................

..... 5

INSPECTION AFTER REMOVAL ......................... 6

INSTALLATION ..................................................... 7REAR DRIVE SHAFT ................................................. 8

Removal and Installation .......................................... 8

COMPONENT ....................................................... 8

REMOVAL ........................................................

..... 8

INSPECTION AFTER REMOVAL ......................... 8

INSTALLATION ..................................................... 9

Disassembly and Assembly ...................................... 9

COMPONENT ....................................................... 9

DISASSEMBLY ..................................................... 9

INSPECTION AFTER DISASSEMBLY ................ 10

ASSEMBLY ......................................................... 11

SERVICE DATA ........................................................ 14

Wheel Bearing ........................................................ 14

Drive Shaft .............................................................. 14

Page 5002 of 5621

![INFINITI M35 2006 Factory Service Manual PREPARATION

RAX-3

C

E

F

G

H

I

J

K

L

MA

B

RAX

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NDS000FN

The actual shapes of Kent-Moore tools may differ from those of INFINITI M35 2006 Factory Service Manual PREPARATION

RAX-3

C

E

F

G

H

I

J

K

L

MA

B

RAX

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NDS000FN

The actual shapes of Kent-Moore tools may differ from those of](/img/42/57023/w960_57023-5001.png)

PREPARATION

RAX-3

C

E

F

G

H

I

J

K

L

MA

B

RAX

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NDS000FN

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsNDS000FO

Tool number

(Kent-Moore No.)

Tool nameDescription

KV38100500

(—)

Drift

a: 80 mm (3.15 in) dia.

b: 60 mm (2.36 in) dia.Installing drive shaft plug

KV38102200

(—)

Drift

a: 90 mm (3.54 in) dia.

b: 31 mm (1.22 in) dia.Installing drive shaft plug

ZZA0701D

ZZA0920D

Tool nameDescription

Power tool

Removing wheel nuts

Removing brake caliper assembly

Removing suspension links

Removing drive shaft

PBIC0190E

Page 5003 of 5621

RAX-4

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNDS000FP

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: ApplicableReference page

—

RAX-10—

RAX-8—

NVH in PR section.

NVH in RFD section.

NVH in RAX and RSU sections.

Refer to REAR AXLE in this chart.

NVH in WT section.

NVH in WT section.

Refer to DRIVE SHAFT in this chart.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

PROPELLER SHAFT

DIFFERENTIAL

REAR AXLE AND REAR SUSPENSION

REAR AXLE

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomDRIVE

SHAFTNoise

Shake

REAR

AXLENoise

Shake

Vibration

Shimmy

Judder

Poor quality ride or handling

Page 5004 of 5621

WHEEL HUB

RAX-5

C

E

F

G

H

I

J

K

L

MA

B

RAX

Revision: 2006 January2006 M35/M45

WHEEL HUBPFP:43202

On-Vehicle Inspection and ServiceNDS000FQ

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

WHEEL BEARING INSPECTION

Move wheel hub and bearing assembly in the axial direction by hand. Make sure there is no looseness of

wheel bearing.

Rotate wheel hub, and make sure that is no unusual noise or other irregular conditions. If there is any of

irregular conditions, replace wheel hub and bearing assembly.

Removal and InstallationNDS000FR

COMPONENT

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

REMOVAL

Wheel Hub and Bearing Assembly

1. Remove tire from vehicle with a power tool.

2. Remove rear brake caliper with a power tool. Hang it in a place where it will not interfere with work. Refer

to BR-31, "

Removal and Installation of Brake Caliper Assembly" .

CAUTION:

Do not depress brake pedal while brake caliper is removed. Axial end play : 0.05 mm (0.002 in) or less

1. Axle housing 2. Ball seat 3. Bushing

4. Back plate 5. Anchor block 6. Wheel hub and bearing assembly

7. Cotter pin

SDIA3251E

Page 5005 of 5621

RAX-6

WHEEL HUB

Revision: 2006 January2006 M35/M45

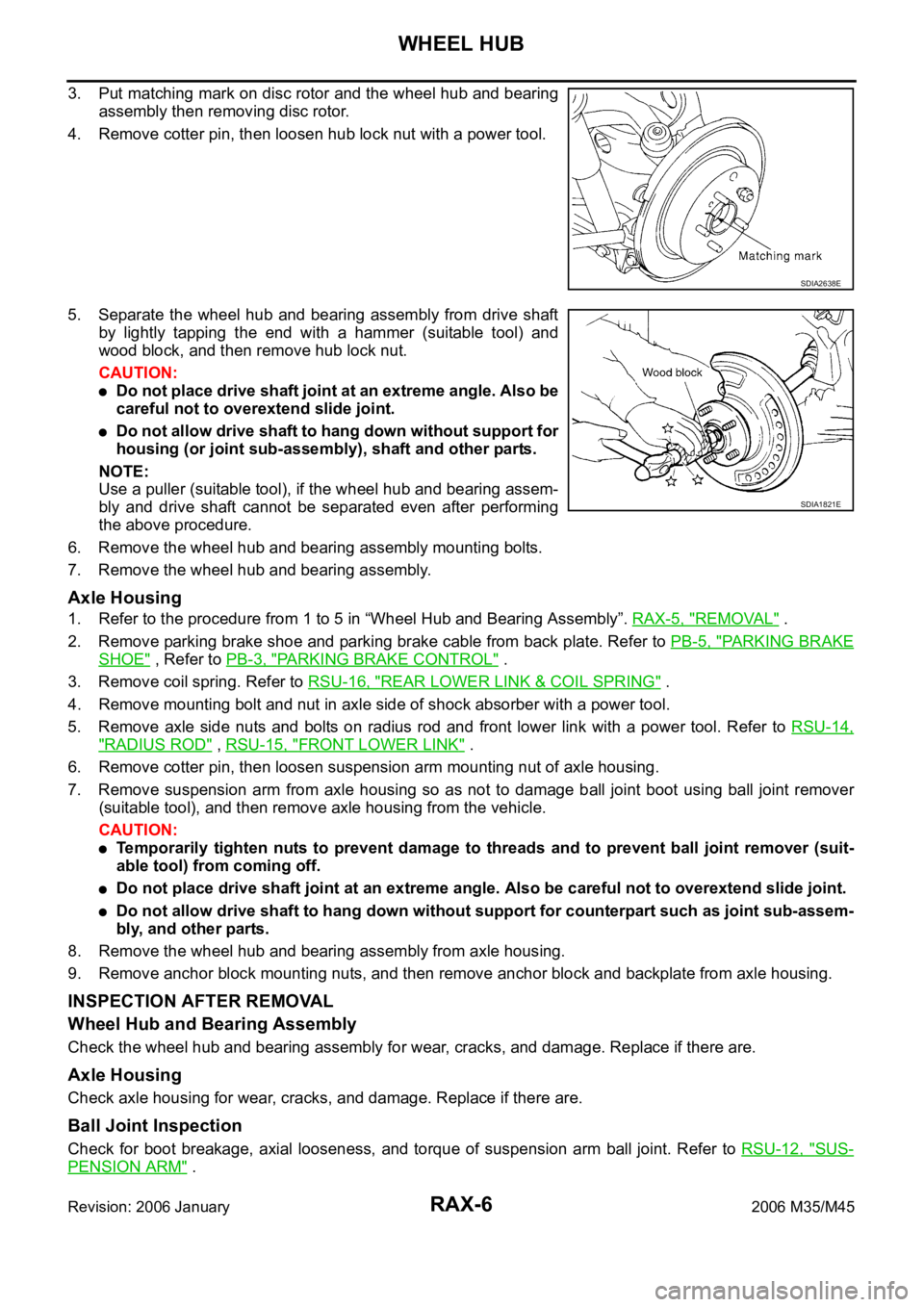

3. Put matching mark on disc rotor and the wheel hub and bearing

assembly then removing disc rotor.

4. Remove cotter pin, then loosen hub lock nut with a power tool.

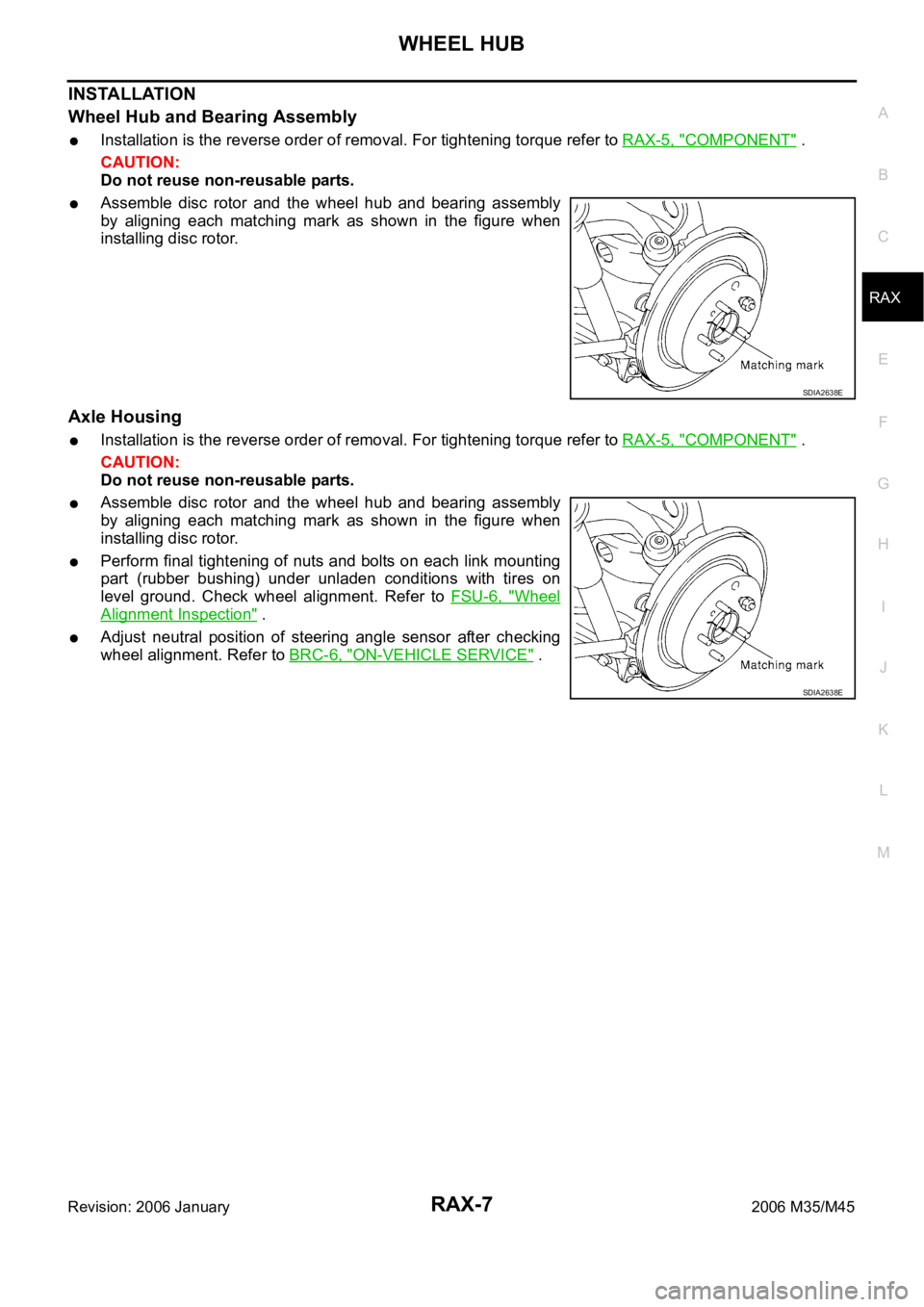

5. Separate the wheel hub and bearing assembly from drive shaft

by lightly tapping the end with a hammer (suitable tool) and

wood block, and then remove hub lock nut.

CAUTION:

Do not place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Do not allow drive shaft to hang down without support for

housing (or joint sub-assembly), shaft and other parts.

NOTE:

Use a puller (suitable tool), if the wheel hub and bearing assem-

bly and drive shaft cannot be separated even after performing

the above procedure.

6. Remove the wheel hub and bearing assembly mounting bolts.

7. Remove the wheel hub and bearing assembly.

Axle Housing

1. Refer to the procedure from 1 to 5 in “Wheel Hub and Bearing Assembly”. RAX-5, "REMOVAL" .

2. Remove parking brake shoe and parking brake cable from back plate. Refer to PB-5, "

PA R K I N G B R A K E

SHOE" , Refer to PB-3, "PARKING BRAKE CONTROL" .

3. Remove coil spring. Refer to RSU-16, "

REAR LOWER LINK & COIL SPRING" .

4. Remove mounting bolt and nut in axle side of shock absorber with a power tool.

5. Remove axle side nuts and bolts on radius rod and front lower link with a power tool. Refer to RSU-14,

"RADIUS ROD" , RSU-15, "FRONT LOWER LINK" .

6. Remove cotter pin, then loosen suspension arm mounting nut of axle housing.

7. Remove suspension arm from axle housing so as not to damage ball joint boot using ball joint remover

(suitable tool), and then remove axle housing from the vehicle.

CAUTION:

Temporarily tighten nuts to prevent damage to threads and to prevent ball joint remover (suit-

able tool) from coming off.

Do not place drive shaft joint at an extreme angle. Also be careful not to overextend slide joint.

Do not allow drive shaft to hang down without support for counterpart such as joint sub-assem-

bly, and other parts.

8. Remove the wheel hub and bearing assembly from axle housing.

9. Remove anchor block mounting nuts, and then remove anchor block and backplate from axle housing.

INSPECTION AFTER REMOVAL

Wheel Hub and Bearing Assembly

Check the wheel hub and bearing assembly for wear, cracks, and damage. Replace if there are.

Axle Housing

Check axle housing for wear, cracks, and damage. Replace if there are.

Ball Joint Inspection

Check for boot breakage, axial looseness, and torque of suspension arm ball joint. Refer to RSU-12, "SUS-

PENSION ARM" .

SDIA2638E

SDIA1821E

Page 5006 of 5621

WHEEL HUB

RAX-7

C

E

F

G

H

I

J

K

L

MA

B

RAX

Revision: 2006 January2006 M35/M45

INSTALLATION

Wheel Hub and Bearing Assembly

Installation is the reverse order of removal. For tightening torque refer to RAX-5, "COMPONENT" .

CAUTION:

Do not reuse non-reusable parts.

Assemble disc rotor and the wheel hub and bearing assembly

by aligning each matching mark as shown in the figure when

installing disc rotor.

Axle Housing

Installation is the reverse order of removal. For tightening torque refer to RAX-5, "COMPONENT" .

CAUTION:

Do not reuse non-reusable parts.

Assemble disc rotor and the wheel hub and bearing assembly

by aligning each matching mark as shown in the figure when

installing disc rotor.

Perform final tightening of nuts and bolts on each link mounting

part (rubber bushing) under unladen conditions with tires on

level ground. Check wheel alignment. Refer to FSU-6, "

Wheel

Alignment Inspection" .

Adjust neutral position of steering angle sensor after checking

wheel alignment. Refer to BRC-6, "

ON-VEHICLE SERVICE" .

SDIA2638E

SDIA2638E

Page 5007 of 5621

RAX-8

REAR DRIVE SHAFT

Revision: 2006 January2006 M35/M45

REAR DRIVE SHAFTPFP:39600

Removal and InstallationNDS000FS

COMPONENT

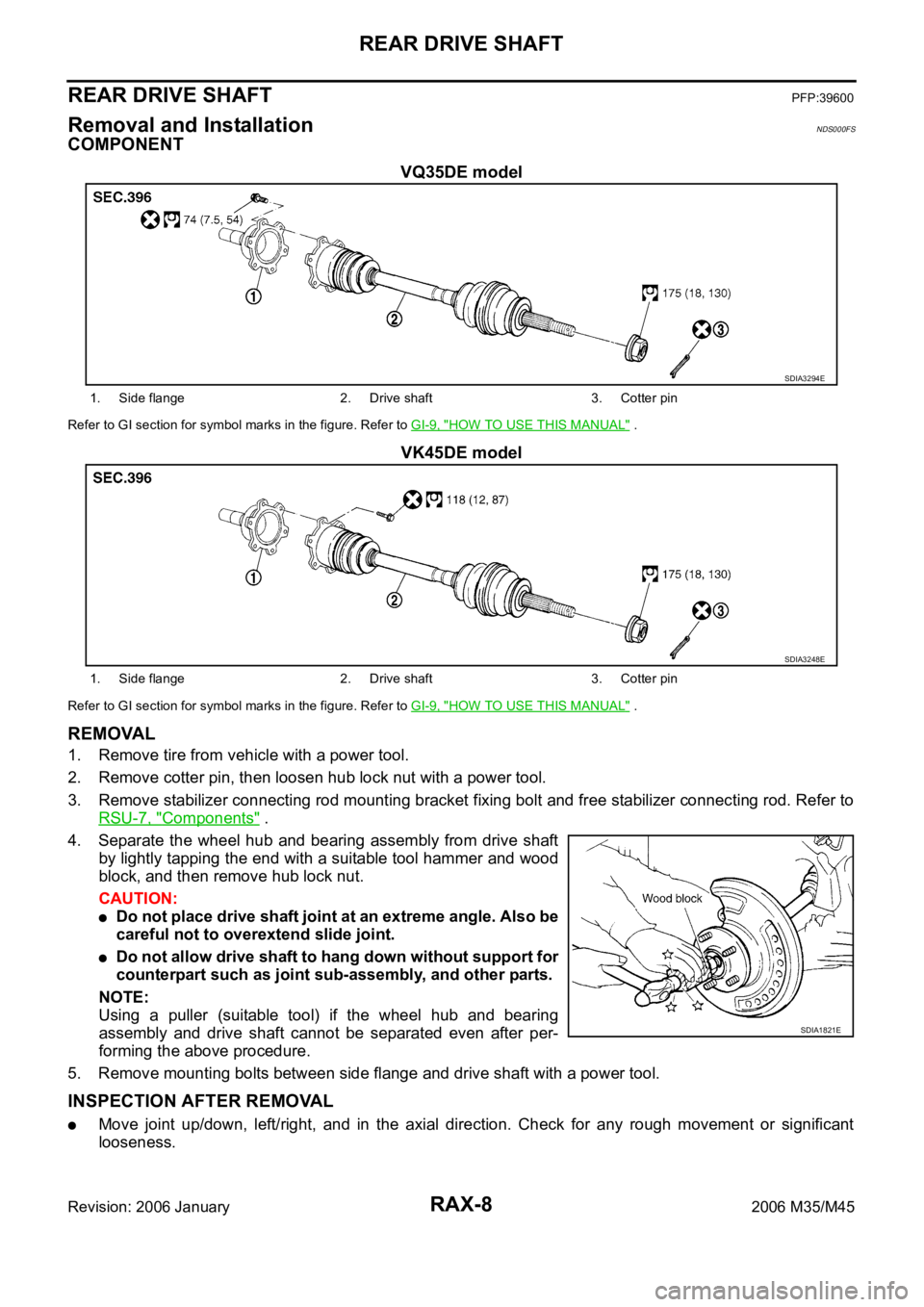

VQ35DE model

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

VK45DE model

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

REMOVAL

1. Remove tire from vehicle with a power tool.

2. Remove cotter pin, then loosen hub lock nut with a power tool.

3. Remove stabilizer connecting rod mounting bracket fixing bolt and free stabilizer connecting rod. Refer to

RSU-7, "

Components" .

4. Separate the wheel hub and bearing assembly from drive shaft

by lightly tapping the end with a suitable tool hammer and wood

block, and then remove hub lock nut.

CAUTION:

Do not place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Do not allow drive shaft to hang down without support for

counterpart such as joint sub-assembly, and other parts.

NOTE:

Using a puller (suitable tool) if the wheel hub and bearing

assembly and drive shaft cannot be separated even after per-

forming the above procedure.

5. Remove mounting bolts between side flange and drive shaft with a power tool.

INSPECTION AFTER REMOVAL

Move joint up/down, left/right, and in the axial direction. Check for any rough movement or significant

looseness.

SDIA3294E

1. Side flange 2. Drive shaft 3. Cotter pin

SDIA3248E

1. Side flange 2. Drive shaft 3. Cotter pin

SDIA1821E

Page 5008 of 5621

REAR DRIVE SHAFT

RAX-9

C

E

F

G

H

I

J

K

L

MA

B

RAX

Revision: 2006 January2006 M35/M45

Check boot for cracks or other damage, and also for grease

leakage.

If a malfunction is found, disassemble drive shaft, and then

replace with new one.

INSTALLATION

Installation is the reverse order of removal. For tightening torque. Refer to RAX-8, "COMPONENT" .

CAUTION:

Do not reuse non-reusable parts.

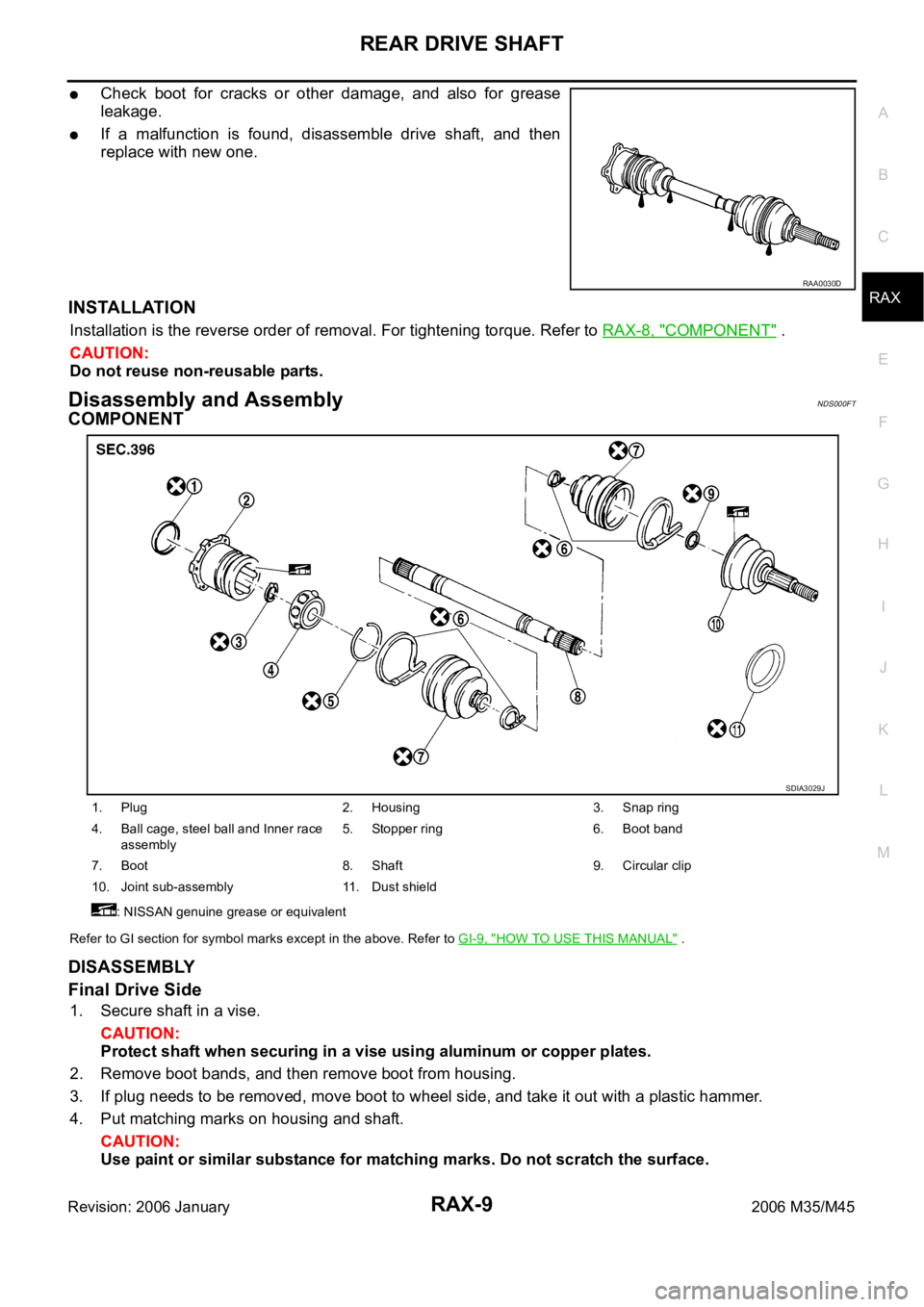

Disassembly and AssemblyNDS000FT

COMPONENT

Refer to GI section for symbol marks except in the above. Refer to GI-9, "HOW TO USE THIS MANUAL" .

DISASSEMBLY

Final Drive Side

1. Secure shaft in a vise.

CAUTION:

Protect shaft when securing in a vise using aluminum or copper plates.

2. Remove boot bands, and then remove boot from housing.

3. If plug needs to be removed, move boot to wheel side, and take it out with a plastic hammer.

4. Put matching marks on housing and shaft.

CAUTION:

Use paint or similar substance for matching marks. Do not scratch the surface.

RAA0030D

1. Plug 2. Housing 3. Snap ring

4. Ball cage, steel ball and Inner race

assembly5. Stopper ring 6. Boot band

7. Boot 8. Shaft 9. Circular clip

10. Joint sub-assembly 11. Dust shield

: NISSAN genuine grease or equivalent

SDIA3029J

Page 5009 of 5621

RAX-10

REAR DRIVE SHAFT

Revision: 2006 January2006 M35/M45

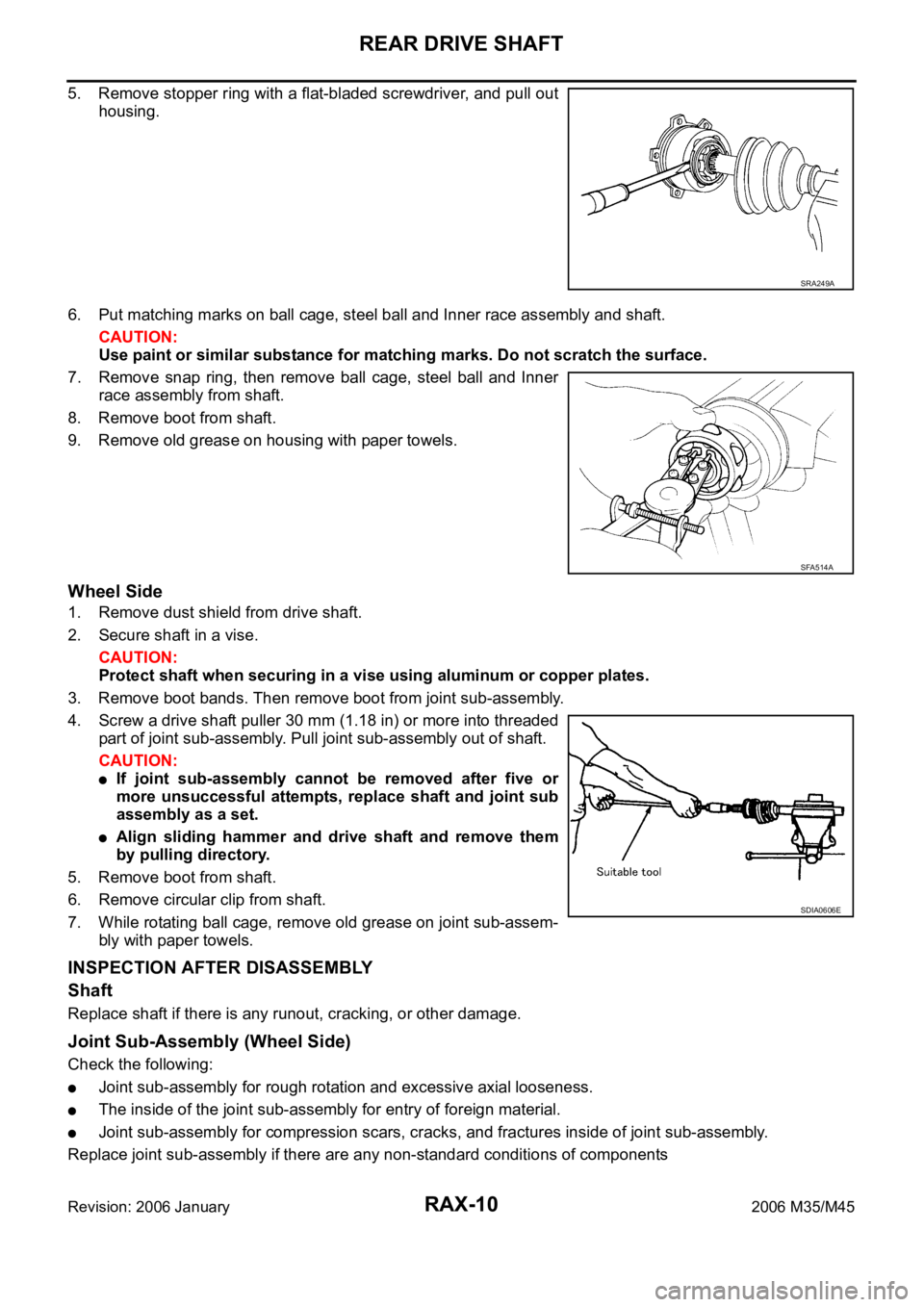

5. Remove stopper ring with a flat-bladed screwdriver, and pull out

housing.

6. Put matching marks on ball cage, steel ball and Inner race assembly and shaft.

CAUTION:

Use paint or similar substance for matching marks. Do not scratch the surface.

7. Remove snap ring, then remove ball cage, steel ball and Inner

race assembly from shaft.

8. Remove boot from shaft.

9. Remove old grease on housing with paper towels.

Wheel Side

1. Remove dust shield from drive shaft.

2. Secure shaft in a vise.

CAUTION:

Protect shaft when securing in a vise using aluminum or copper plates.

3. Remove boot bands. Then remove boot from joint sub-assembly.

4. Screw a drive shaft puller 30 mm (1.18 in) or more into threaded

part of joint sub-assembly. Pull joint sub-assembly out of shaft.

CAUTION:

If joint sub-assembly cannot be removed after five or

more unsuccessful attempts, replace shaft and joint sub

assembly as a set.

Align sliding hammer and drive shaft and remove them

by pulling directory.

5. Remove boot from shaft.

6. Remove circular clip from shaft.

7. While rotating ball cage, remove old grease on joint sub-assem-

bly with paper towels.

INSPECTION AFTER DISASSEMBLY

Shaft

Replace shaft if there is any runout, cracking, or other damage.

Joint Sub-Assembly (Wheel Side)

Check the following:

Joint sub-assembly for rough rotation and excessive axial looseness.

The inside of the joint sub-assembly for entry of foreign material.

Joint sub-assembly for compression scars, cracks, and fractures inside of joint sub-assembly.

Replace joint sub-assembly if there are any non-standard conditions of components

SRA249A

SFA514A

SDIA0606E

Page 5011 of 5621

RAX-12

REAR DRIVE SHAFT

Revision: 2006 January2006 M35/M45

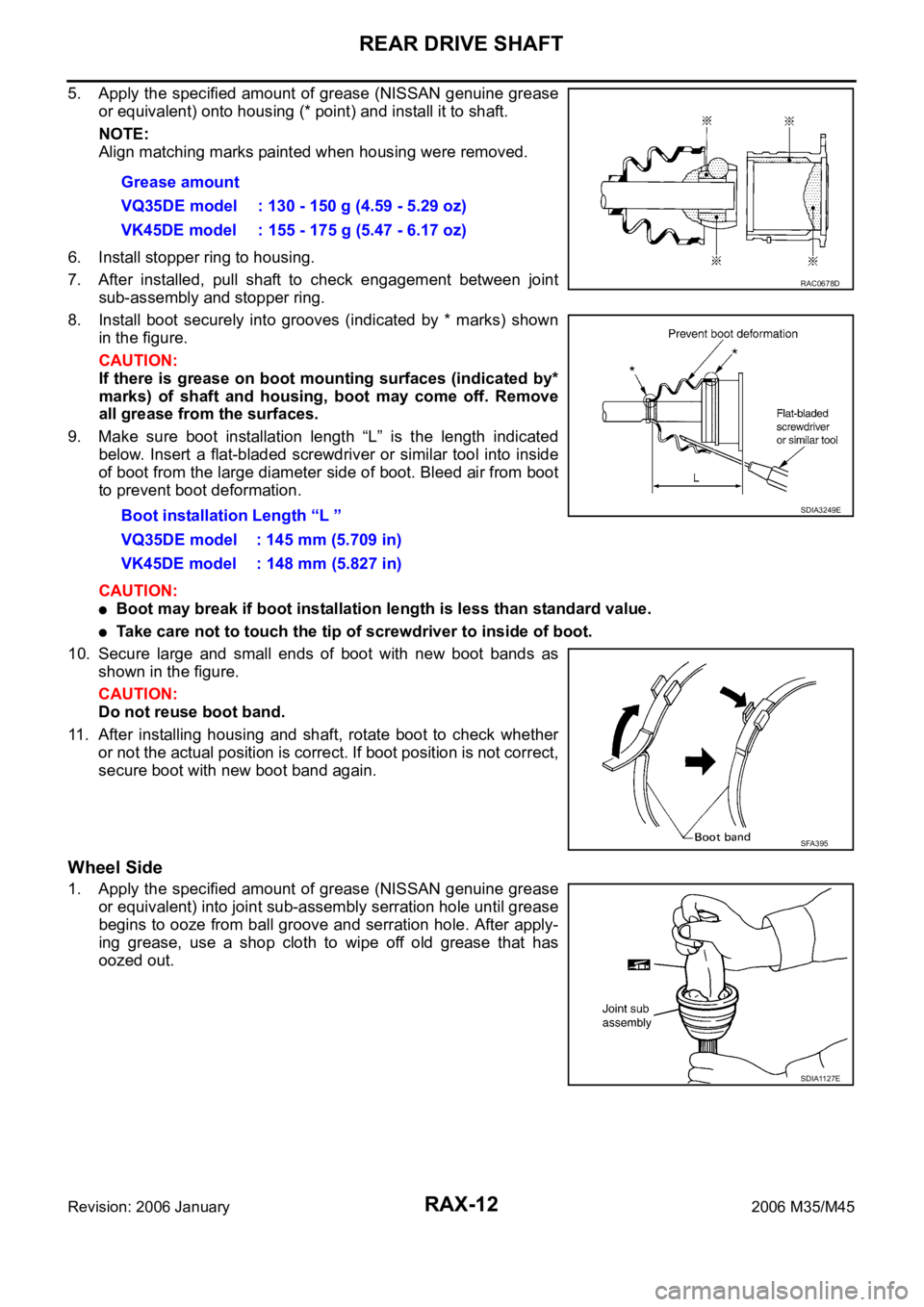

5. Apply the specified amount of grease (NISSAN genuine grease

or equivalent) onto housing (* point) and install it to shaft.

NOTE:

Align matching marks painted when housing were removed.

6. Install stopper ring to housing.

7. After installed, pull shaft to check engagement between joint

sub-assembly and stopper ring.

8. Install boot securely into grooves (indicated by * marks) shown

in the figure.

CAUTION:

If there is grease on boot mounting surfaces (indicated by*

marks) of shaft and housing, boot may come off. Remove

all grease from the surfaces.

9. Make sure boot installation length “L” is the length indicated

below. Insert a flat-bladed screwdriver or similar tool into inside

of boot from the large diameter side of boot. Bleed air from boot

to prevent boot deformation.

CAUTION:

Boot may break if boot installation length is less than standard value.

Take care not to touch the tip of screwdriver to inside of boot.

10. Secure large and small ends of boot with new boot bands as

shown in the figure.

CAUTION:

Do not reuse boot band.

11. After installing housing and shaft, rotate boot to check whether

or not the actual position is correct. If boot position is not correct,

secure boot with new boot band again.

Wheel Side

1. Apply the specified amount of grease (NISSAN genuine grease

or equivalent) into joint sub-assembly serration hole until grease

begins to ooze from ball groove and serration hole. After apply-

ing grease, use a shop cloth to wipe off old grease that has

oozed out.Grease amount

VQ35DE model : 130 - 150 g (4.59 - 5.29 oz)

VK45DE model : 155 - 175 g (5.47 - 6.17 oz)

Boot installation Length “L ”

VQ35DE model : 145 mm (5.709 in)

VK45DE model : 148 mm (5.827 in)

RAC0678D

SDIA3249E

SFA395

SDIA1127E