wheel INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5013 of 5621

RAX-14

SERVICE DATA

Revision: 2006 January2006 M35/M45

SERVICE DATAPFP:00030

Wheel BearingNDS000FU

Drive ShaftNDS000FV

Axial end play 0.05 mm (0.002 in) or less

Joint typeWheel side Final drive side

VQ35DE model VK45DE model VQ35DE model VK45DE model

Grease quantity115 - 135 g

(4.06 - 4.76 oz)155 - 175 g

(5.47 - 6.17 oz)130 - 150 g

(4.59 - 5.29 oz)155 - 175 g

(5.47 - 6.17 oz)

Boots installed length 136 mm (5.354 in) 145 mm (5.709 in) 145 mm (5.709 in) 148 mm (5.827 in)

Page 5050 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-7

C

E

F

G

H

I

J

K

L

MA

B

RFD

Revision: 2006 January2006 M35/M45

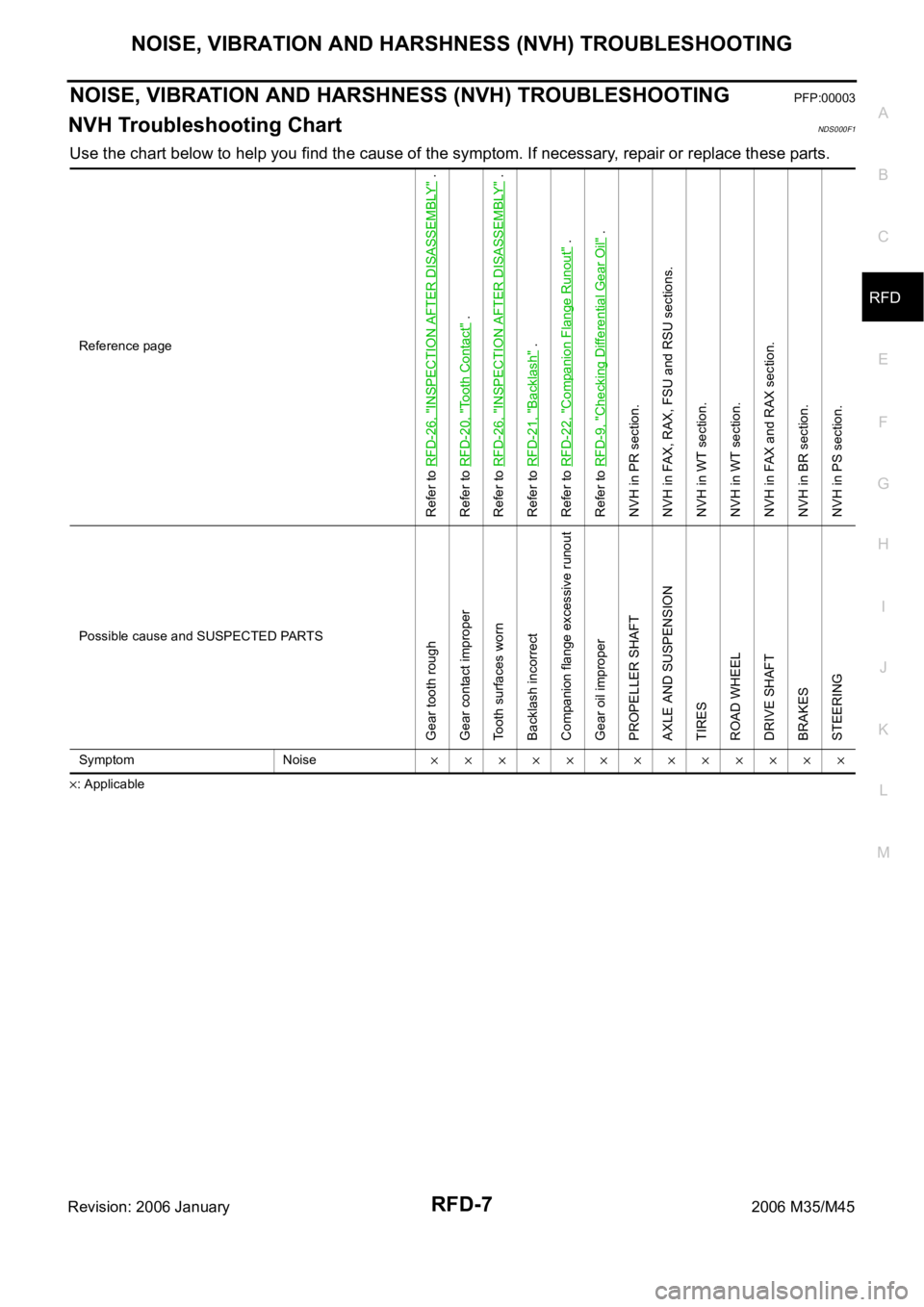

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNDS000F1

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: ApplicableReference page

Refer to RFD-26, "

INSPECTION AFTER DISASSEMBLY

" .

Refer to RFD-20, "

Tooth Contact

" .

Refer to RFD-26, "

INSPECTION AFTER DISASSEMBLY

" .

Refer to RFD-21, "

Backlash

" .

Refer to RFD-22, "

Companion Flange Runout

" .

Refer to RFD-9, "

Checking Differential Gear Oil

" .

NVH in PR section.

NVH in FAX, RAX, FSU and RSU sections.

NVH in WT section.

NVH in WT section.

NVH in FAX and RAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom Noise

Page 5053 of 5621

RFD-10

FRONT OIL SEAL

Revision: 2006 January2006 M35/M45

FRONT OIL SEALPFP:38189

Removal and InstallationNDS000F5

CAUTION:

Verify identification stamp of replacement frequency put in the lower part of gear carrier to determine

replacement for collapsible spacer when replacing front oil seal. Refer to RFD-10, "

IDENTIFICATION

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL" . If necessary collapsible spacer

replacement, remove final drive assembly and disassemble it to replace front oil seal and collapsible

spacer. Refer to RFD-16, "

Removal and Installation" and RFD-18, "Disassembly and Assembly" .

NOTE:

The reuse of collapsible spacer is prohibited in principle. However, it is reusable on a one-time basis

only in cases when replacing front oil seal.

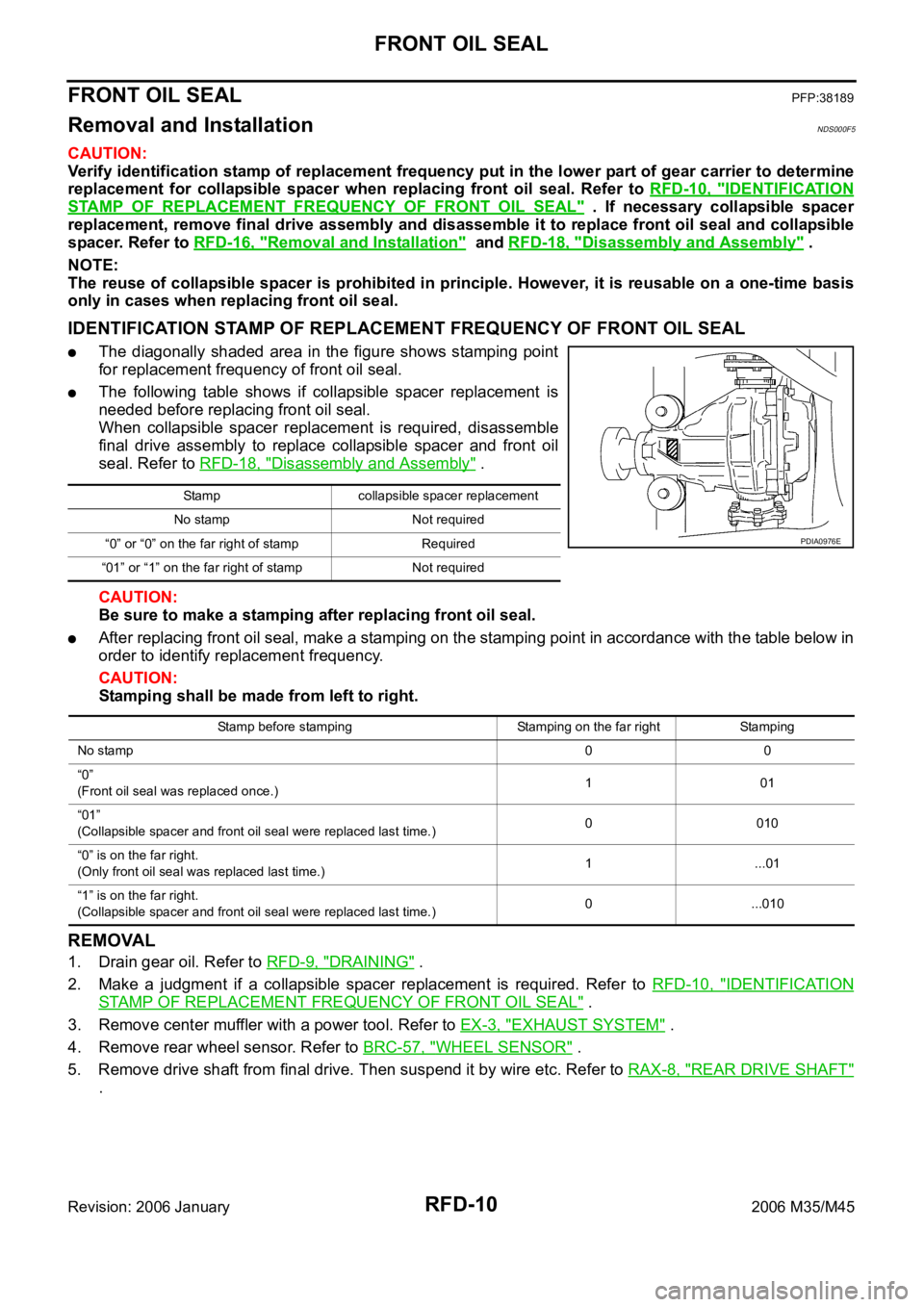

IDENTIFICATION STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL

The diagonally shaded area in the figure shows stamping point

for replacement frequency of front oil seal.

The following table shows if collapsible spacer replacement is

needed before replacing front oil seal.

When collapsible spacer replacement is required, disassemble

final drive assembly to replace collapsible spacer and front oil

seal. Refer to RFD-18, "

Disassembly and Assembly" .

CAUTION:

Be sure to make a stamping after replacing front oil seal.

After replacing front oil seal, make a stamping on the stamping point in accordance with the table below in

order to identify replacement frequency.

CAUTION:

Stamping shall be made from left to right.

REMOVAL

1. Drain gear oil. Refer to RFD-9, "DRAINING" .

2. Make a judgment if a collapsible spacer replacement is required. Refer to RFD-10, "

IDENTIFICATION

STAMP OF REPLACEMENT FREQUENCY OF FRONT OIL SEAL" .

3. Remove center muffler with a power tool. Refer to EX-3, "

EXHAUST SYSTEM" .

4. Remove rear wheel sensor. Refer to BRC-57, "

WHEEL SENSOR" .

5. Remove drive shaft from final drive. Then suspend it by wire etc. Refer to RAX-8, "

REAR DRIVE SHAFT"

.

Stamp collapsible spacer replacement

No stamp Not required

“0” or “0” on the far right of stamp Required

“01” or “1” on the far right of stamp Not required

PDIA0976E

Stamp before stamping Stamping on the far right Stamping

No stamp00

“0”

(Front oil seal was replaced once.)101

“01”

(Collapsible spacer and front oil seal were replaced last time.)0 010

“0” is on the far right.

(Only front oil seal was replaced last time.)1...01

“1” is on the far right.

(Collapsible spacer and front oil seal were replaced last time.)0 ...010

Page 5056 of 5621

FRONT OIL SEAL

RFD-13

C

E

F

G

H

I

J

K

L

MA

B

RFD

Revision: 2006 January2006 M35/M45

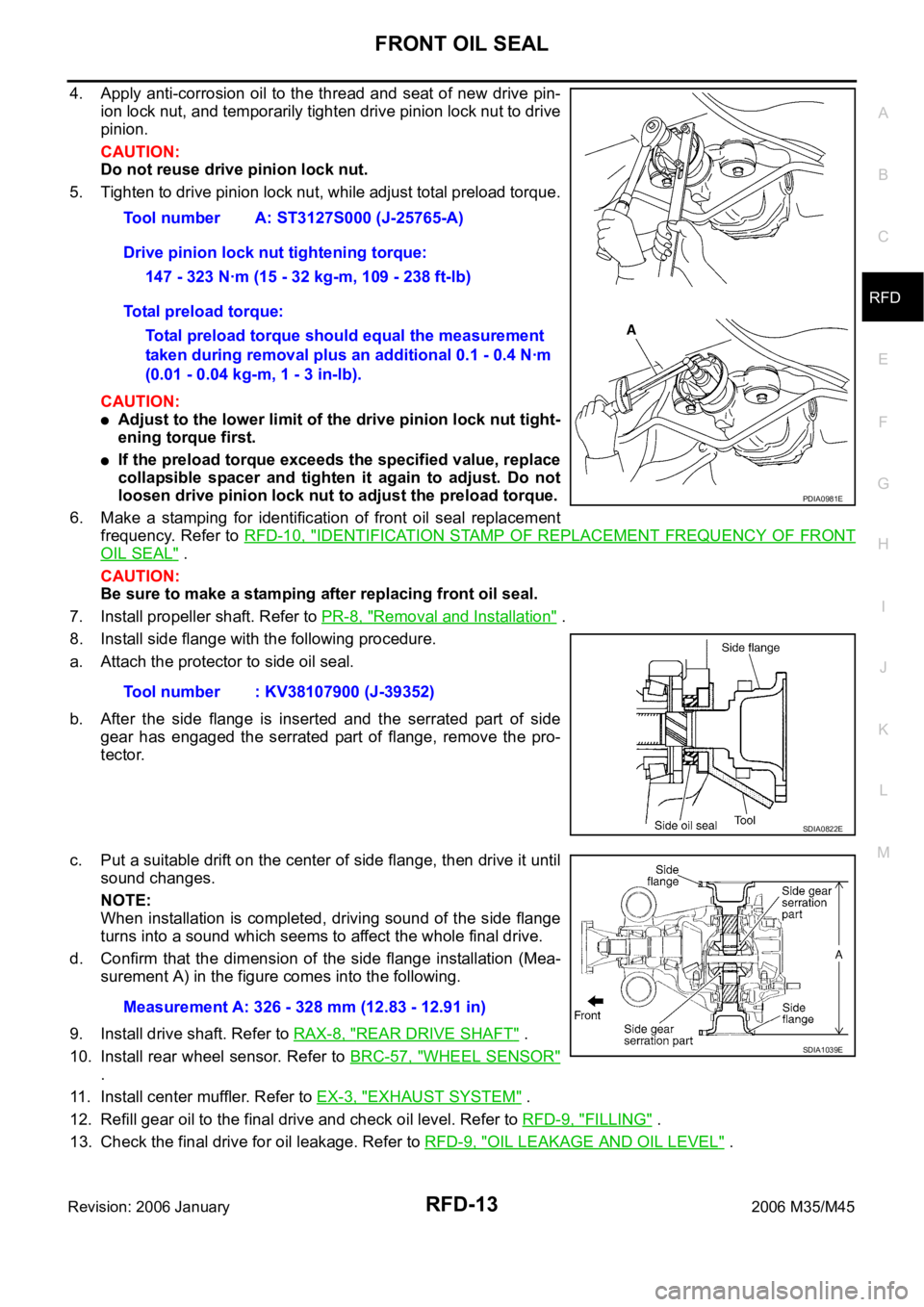

4. Apply anti-corrosion oil to the thread and seat of new drive pin-

ion lock nut, and temporarily tighten drive pinion lock nut to drive

pinion.

CAUTION:

Do not reuse drive pinion lock nut.

5. Tighten to drive pinion lock nut, while adjust total preload torque.

CAUTION:

Adjust to the lower limit of the drive pinion lock nut tight-

ening torque first.

If the preload torque exceeds the specified value, replace

collapsible spacer and tighten it again to adjust. Do not

loosen drive pinion lock nut to adjust the preload torque.

6. Make a stamping for identification of front oil seal replacement

frequency. Refer to RFD-10, "

IDENTIFICATION STAMP OF REPLACEMENT FREQUENCY OF FRONT

OIL SEAL" .

CAUTION:

Be sure to make a stamping after replacing front oil seal.

7. Install propeller shaft. Refer to PR-8, "

Removal and Installation" .

8. Install side flange with the following procedure.

a. Attach the protector to side oil seal.

b. After the side flange is inserted and the serrated part of side

gear has engaged the serrated part of flange, remove the pro-

tector.

c. Put a suitable drift on the center of side flange, then drive it until

sound changes.

NOTE:

When installation is completed, driving sound of the side flange

turns into a sound which seems to affect the whole final drive.

d. Confirm that the dimension of the side flange installation (Mea-

surement A) in the figure comes into the following.

9. Install drive shaft. Refer to RAX-8, "

REAR DRIVE SHAFT" .

10. Install rear wheel sensor. Refer to BRC-57, "

WHEEL SENSOR"

.

11. Install center muffler. Refer to EX-3, "

EXHAUST SYSTEM" .

12. Refill gear oil to the final drive and check oil level. Refer to RFD-9, "

FILLING" .

13. Check the final drive for oil leakage. Refer to RFD-9, "

OIL LEAKAGE AND OIL LEVEL" . Tool number A: ST3127S000 (J-25765-A)

Drive pinion lock nut tightening torque:

147 - 323 Nꞏm (15 - 32 kg-m, 109 - 238 ft-lb)

Total preload torque:

Total preload torque should equal the measurement

taken during removal plus an additional 0.1 - 0.4 Nꞏm

(0.01 - 0.04 kg-m, 1 - 3 in-lb).

Tool number : KV38107900 (J-39352)

PDIA0981E

SDIA0822E

Measurement A: 326 - 328 mm (12.83 - 12.91 in)

SDIA1039E

Page 5057 of 5621

RFD-14

SIDE OIL SEAL

Revision: 2006 January2006 M35/M45

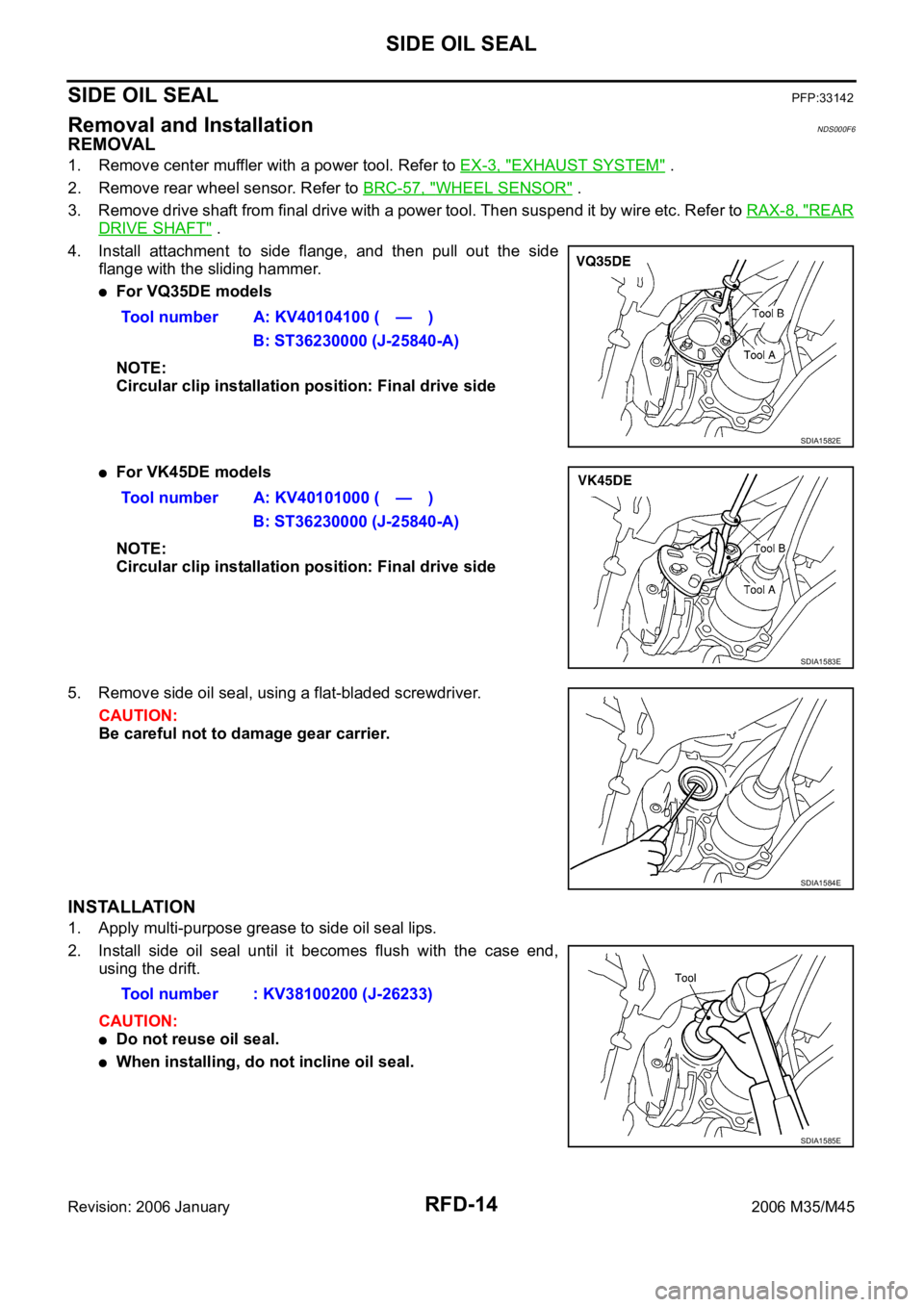

SIDE OIL SEALPFP:33142

Removal and InstallationNDS000F6

REMOVAL

1. Remove center muffler with a power tool. Refer to EX-3, "EXHAUST SYSTEM" .

2. Remove rear wheel sensor. Refer to BRC-57, "

WHEEL SENSOR" .

3. Remove drive shaft from final drive with a power tool. Then suspend it by wire etc. Refer to RAX-8, "

REAR

DRIVE SHAFT" .

4. Install attachment to side flange, and then pull out the side

flange with the sliding hammer.

For VQ35DE models

NOTE:

Circular clip installation position: Final drive side

For VK45DE models

NOTE:

Circular clip installation position: Final drive side

5. Remove side oil seal, using a flat-bladed screwdriver.

CAUTION:

Be careful not to damage gear carrier.

INSTALLATION

1. Apply multi-purpose grease to side oil seal lips.

2. Install side oil seal until it becomes flush with the case end,

using the drift.

CAUTION:

Do not reuse oil seal.

When installing, do not incline oil seal.Tool number A: KV40104100 ( — )

B: ST36230000 (J-25840-A)

SDIA1582E

Tool number A: KV40101000 ( — )

B: ST36230000 (J-25840-A)

SDIA1583E

SDIA1584E

Tool number : KV38100200 (J-26233)

SDIA1585E

Page 5058 of 5621

SIDE OIL SEAL

RFD-15

C

E

F

G

H

I

J

K

L

MA

B

RFD

Revision: 2006 January2006 M35/M45

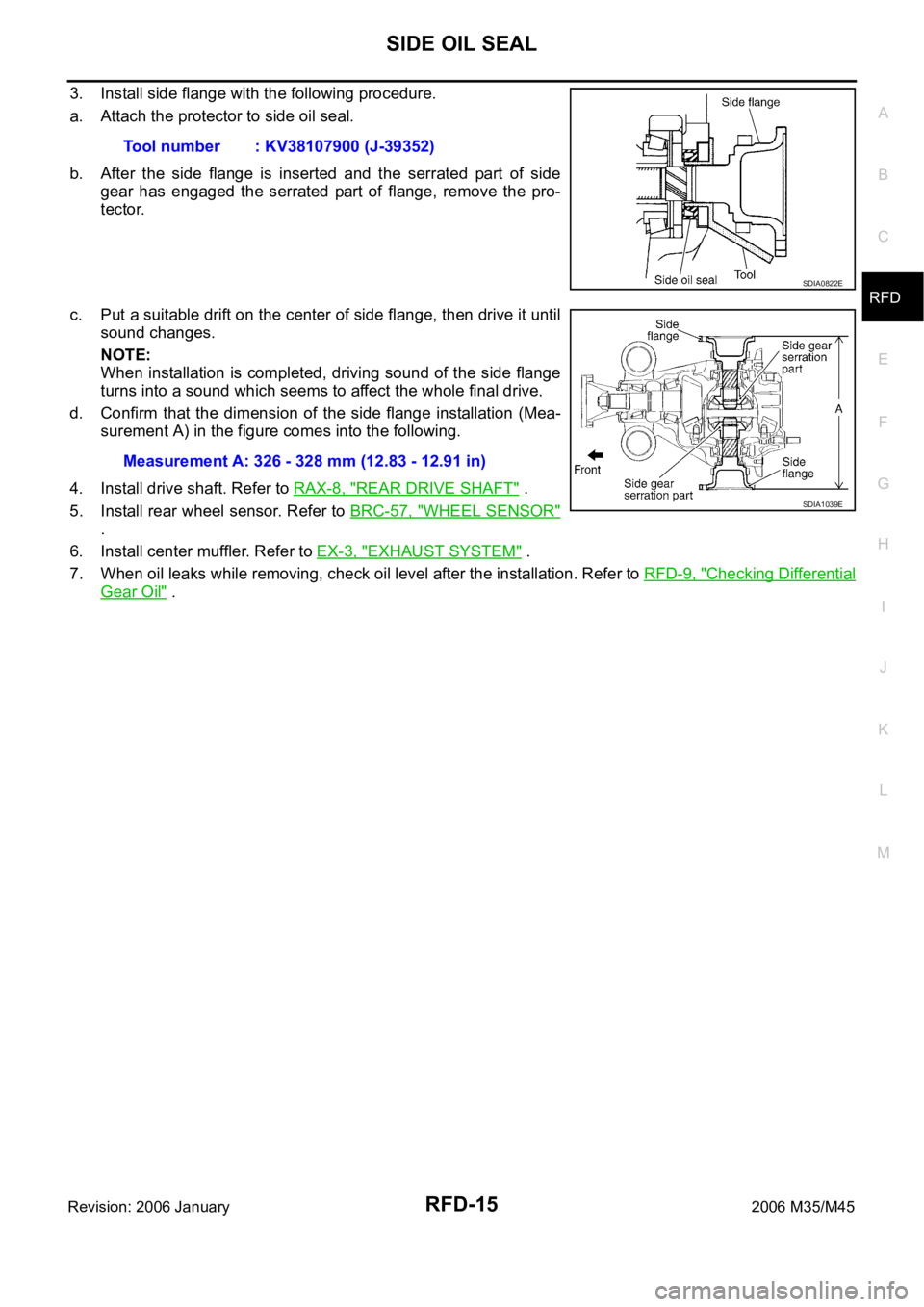

3. Install side flange with the following procedure.

a. Attach the protector to side oil seal.

b. After the side flange is inserted and the serrated part of side

gear has engaged the serrated part of flange, remove the pro-

tector.

c. Put a suitable drift on the center of side flange, then drive it until

sound changes.

NOTE:

When installation is completed, driving sound of the side flange

turns into a sound which seems to affect the whole final drive.

d. Confirm that the dimension of the side flange installation (Mea-

surement A) in the figure comes into the following.

4. Install drive shaft. Refer to RAX-8, "

REAR DRIVE SHAFT" .

5. Install rear wheel sensor. Refer to BRC-57, "

WHEEL SENSOR"

.

6. Install center muffler. Refer to EX-3, "

EXHAUST SYSTEM" .

7. When oil leaks while removing, check oil level after the installation. Refer to RFD-9, "

Checking Differential

Gear Oil" . Tool number : KV38107900 (J-39352)

SDIA0822E

Measurement A: 326 - 328 mm (12.83 - 12.91 in)

SDIA1039E

Page 5059 of 5621

RFD-16

REAR FINAL DRIVE ASSEMBLY

Revision: 2006 January2006 M35/M45

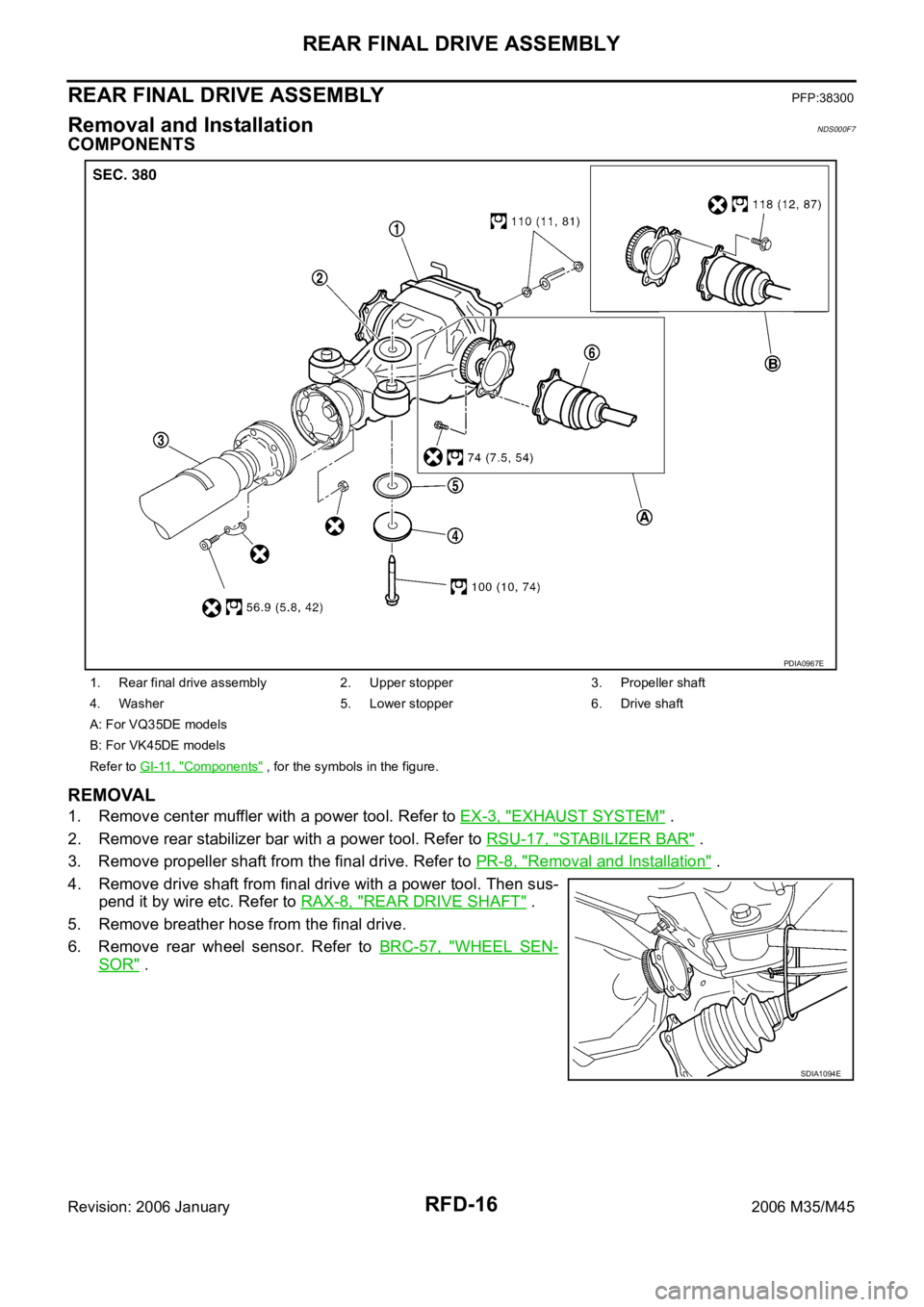

REAR FINAL DRIVE ASSEMBLYPFP:38300

Removal and InstallationNDS000F7

COMPONENTS

REMOVAL

1. Remove center muffler with a power tool. Refer to EX-3, "EXHAUST SYSTEM" .

2. Remove rear stabilizer bar with a power tool. Refer to RSU-17, "

STABILIZER BAR" .

3. Remove propeller shaft from the final drive. Refer to PR-8, "

Removal and Installation" .

4. Remove drive shaft from final drive with a power tool. Then sus-

pend it by wire etc. Refer to RAX-8, "

REAR DRIVE SHAFT" .

5. Remove breather hose from the final drive.

6. Remove rear wheel sensor. Refer to BRC-57, "

WHEEL SEN-

SOR" .

1. Rear final drive assembly 2. Upper stopper 3. Propeller shaft

4. Washer 5. Lower stopper 6. Drive shaft

A: For VQ35DE models

B: For VK45DE models

Refer to GI-11, "

Components" , for the symbols in the figure.

PDIA0967E

SDIA1094E

Page 5082 of 5621

RSU-1

REAR SUSPENSION

E SUSPENSION

CONTENTS

C

D

F

G

H

I

J

K

L

M

SECTION RSU

A

B

RSU

Revision: 2006 January2006 M35/M45

REAR SUSPENSION

PRECAUTIONS .......................................................... 2

Precautions .............................................................. 2

PREPARATION ........................................................... 3

Special Service Tools [SST] ..................................... 3

Commercial Service Tools ........................................ 3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH Troubleshooting Chart ..................................... 4

REAR SUSPENSION ASSEMBLY ............................. 5

On-Vehicle Inspection and Service .......................... 5

SUSPENSION ARM BALL JOINT AXIAL END

PLAY INSPECTION .............................................. 5

SHOCK ABSORBER INSPECTION ..................... 5

Wheel Alignment Inspection ..................................... 5

DESCRIPTION ...................................................... 5

PRELIMINARY INSPECTION ............................... 5

GENERAL INFORMATION AND RECOMMEN-

DATIONS .............................................................. 5

THE ALIGNMENT PROCESS .............................. 6

CAMBER INSPECTION ........................................ 6

TOE-IN .................................................................. 6

Components ............................................................. 7

Removal and Installation .......................................... 8

REMOVAL ........................................................

..... 8

INSTALLATION ..................................................... 8

SHOCK ABSORBER ................................................ 10

Removal and Installation ........................................ 10

REMOVAL ........................................................

... 10

INSPECTION AFTER REMOVAL ....................... 10

INSTALLATION ................................................... 10

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ............... 10

ASSEMBLY .......................................................... 11SUSPENSION ARM .................................................. 12

Removal and Installation ........................................ 12

REMOVAL ........................................................

... 12

INSPECTION AFTER REMOVAL ....................... 12

INSTALLATION ................................................... 13

RADIUS ROD ............................................................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................

... 14

INSPECTION AFTER REMOVAL ....................... 14

INSTALLATION ................................................... 14

FRONT LOWER LINK .............................................. 15

Removal and Installation ........................................ 15

REMOVAL ........................................................

... 15

INSPECTION AFTER REMOVAL ....................... 15

INSTALLATION ................................................... 15

REAR LOWER LINK & COIL SPRING ..................

... 16

Removal and Installation ........................................ 16

REMOVAL ........................................................

... 16

INSPECTION AFTER REMOVAL ....................... 16

INSTALLATION ................................................... 16

STABILIZER BAR ..................................................... 17

Removal and Installation ........................................ 17

REMOVAL ........................................................

... 17

INSPECTION AFTER REMOVAL ....................... 17

INSTALLATION ................................................... 17

SERVICE DATA ........................................................ 18

Wheel Alignment (Unladen)* .................................. 18

Ball Joint ................................................................. 18

Wheelarch Height (Unladen*) ................................. 18

Page 5083 of 5621

RSU-2

PRECAUTIONS

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

PrecautionsNES000J2

When installing rubber bushings, final tightening must be carried out under unladen conditions with tires

on ground. Oil will shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

–Unladen conditions mean that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

After servicing suspension parts, be sure to check wheel alignment.

Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-

oiled, tighten as they are.

Page 5084 of 5621

![INFINITI M35 2006 Factory Service Manual PREPARATION

RSU-3

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NES000J3

The actual shapes of Kent-Moore tools may differ from those of INFINITI M35 2006 Factory Service Manual PREPARATION

RSU-3

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NES000J3

The actual shapes of Kent-Moore tools may differ from those of](/img/42/57023/w960_57023-5083.png)

PREPARATION

RSU-3

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

PREPARATIONPFP:00002

Special Service Tools [SST]NES000J3

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsNES000J4

Tool number

(Kent-Moore No.)

Tool nameDescription

ST3127S000

(See J25742-1)

Preload Gauge

1. GG91030000

(J25765)

Torque wrench

2. HT62940000

(—)

Socket adapter

3. HT62900000

(—)

Socket adapterMeasuring rotating torque of ball joint

NT124

Tool nameDescription

Power tool

Removing wheel nuts

Removing brake caliper assembly

Removing rear suspension component

parts

PBIC0190E