check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5152 of 5621

STARTING SYSTEM

SC-15

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

DIAGNOSTIC PROCEDURE 1

Check “B” Terminal Circuit

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

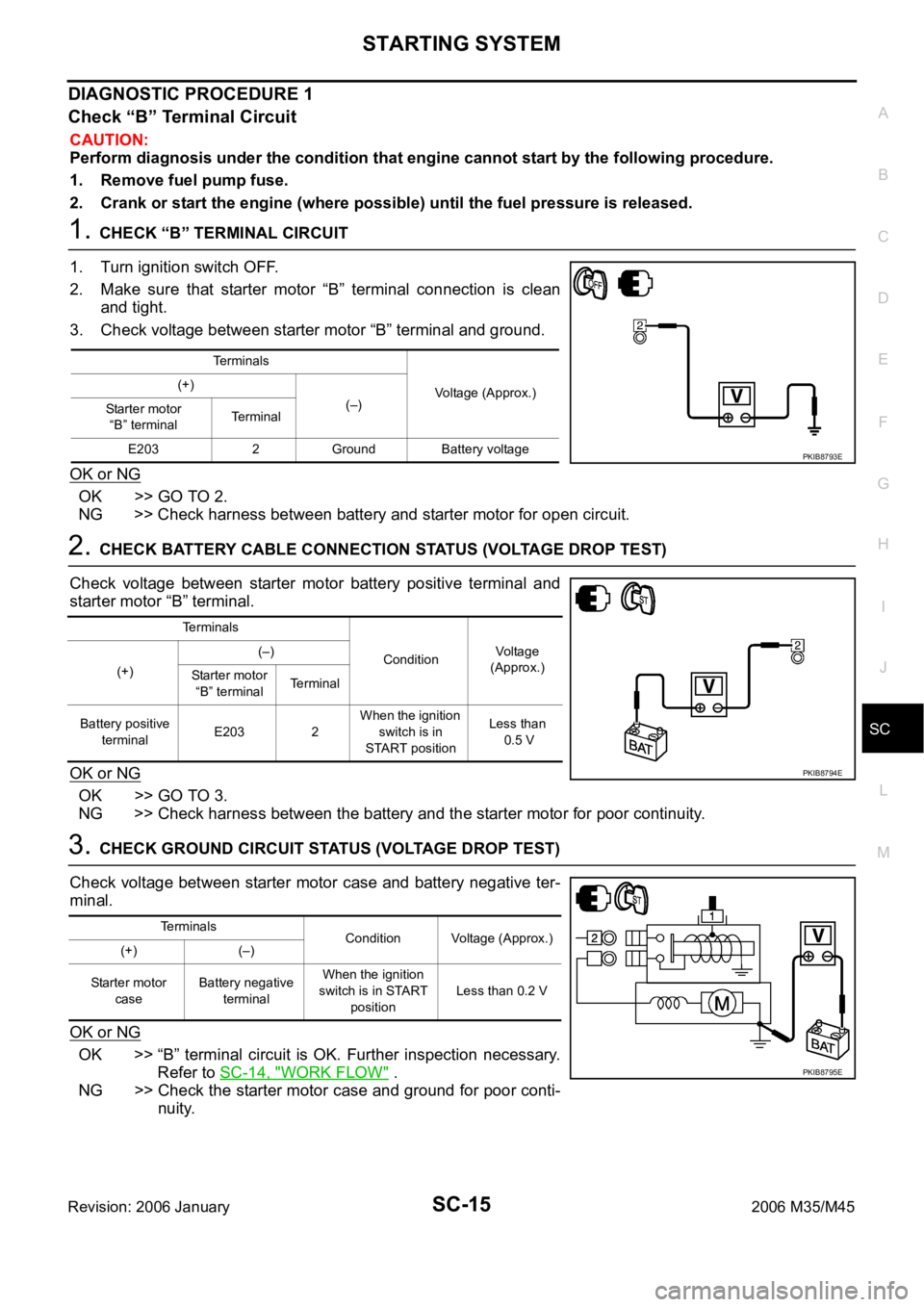

1. CHECK “B” TERMINAL CIRCUIT

1. Turn ignition switch OFF.

2. Make sure that starter motor “B” terminal connection is clean

and tight.

3. Check voltage between starter motor “B” terminal and ground.

OK or NG

OK >> GO TO 2.

NG >> Check harness between battery and starter motor for open circuit.

2. CHECK BATTERY CABLE CONNECTION STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor battery positive terminal and

starter motor “B” terminal.

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter motor for poor continuity.

3. CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor case and battery negative ter-

minal.

OK or NG

OK >> “B” terminal circuit is OK. Further inspection necessary.

Refer to SC-14, "

WORK FLOW" .

NG >> Check the starter motor case and ground for poor conti-

nuity.

Terminals

Voltage (Approx.) (+)

(–)

Starter motor

“B” terminalTerminal

E203 2 Ground Battery voltage

PKIB8793E

Terminals

ConditionVoltage

(Approx.)

(+)(–)

Starter motor

“B” terminalTerminal

Battery positive

terminalE203 2 When the ignition

switch is in

START positionLess than

0.5 V

PKIB8794E

Terminals

Condition Voltage (Approx.)

(+) (–)

Starter motor

caseBattery negative

terminalWhen the ignition

switch is in START

positionLess than 0.2 V

PKIB8795E

Page 5153 of 5621

SC-16

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

DIAGNOSTIC PROCEDURE 2

Check “S” Connector Circuit

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

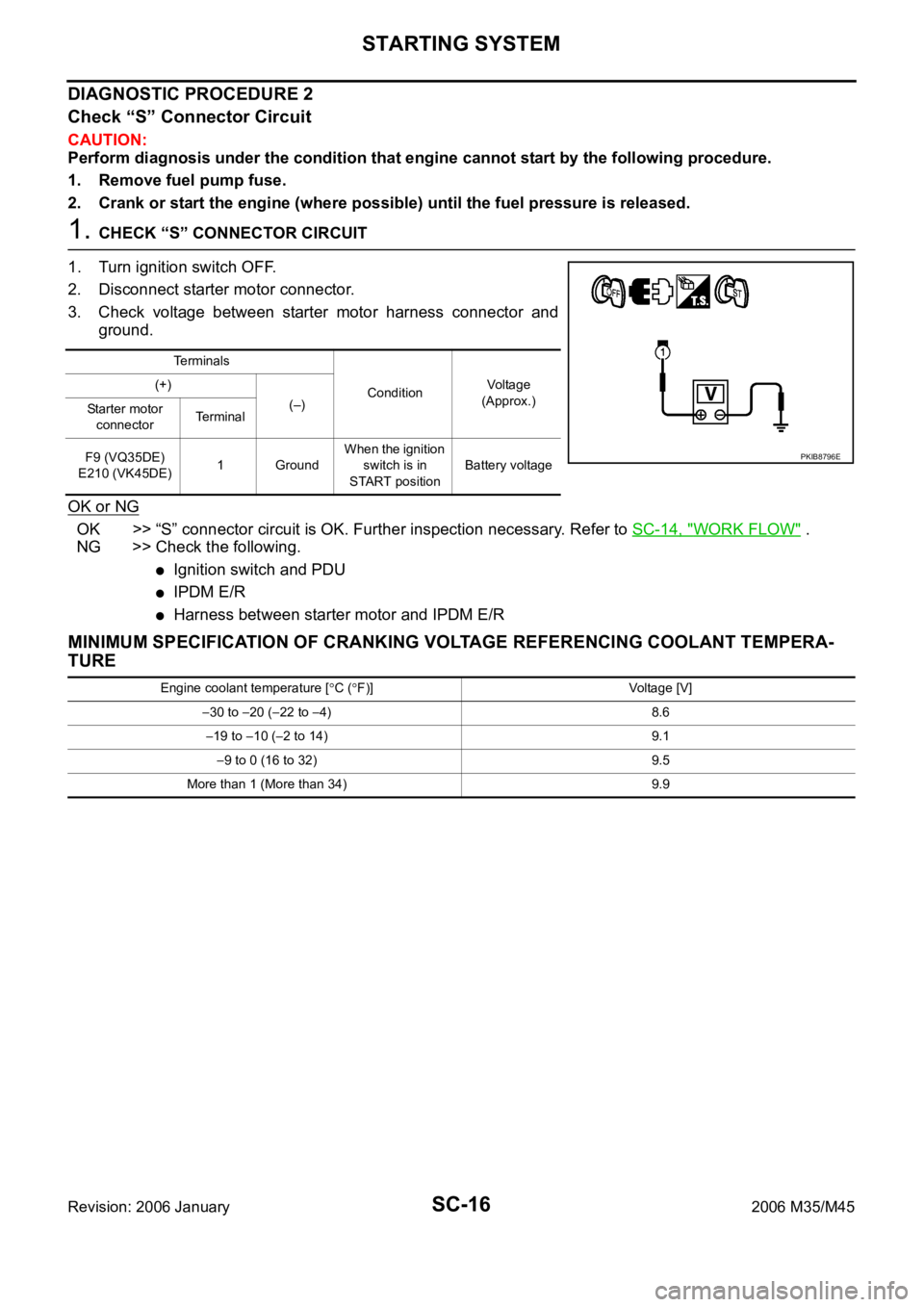

1. CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector.

3. Check voltage between starter motor harness connector and

ground.

OK or NG

OK >> “S” connector circuit is OK. Further inspection necessary. Refer to SC-14, "WORK FLOW" .

NG >> Check the following.

Ignition switch and PDU

IPDM E/R

Harness between starter motor and IPDM E/R

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

Te r m i n a l s

ConditionVoltage

(Approx.) (+)

(–)

Starter motor

connectorTe r m i n a l

F9 (VQ35DE)

E210 (VK45DE)1 GroundWhen the ignition

switch is in

START positionBattery voltage

PKIB8796E

Engine coolant temperature [C (F)] Voltage [V]

30 to 20 (22 to 4) 8.6

19 to 10 (2 to 14) 9.1

9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Page 5159 of 5621

SC-22

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

VK45DE ENGINE MODELS

INSPECTION AFTER DISASSEMBLY

Pinion/Clutch Check

1. Inspect pinion teeth.

Replace pinion if teeth are worn or damaged. (Also check condition of ring gear teeth.)

2. Inspect reduction gear teeth.

Replace reduction gear if teeth are worn or damaged. (Also check condition of armature shaft gear

teeth.)

3. Check to see if pinion locks in one direction and rotates smoothly in the opposite direction.

If it locks or rotates in both directions, or unusual resistance is evident, replace.

1. Magnetic switch assembly 2. Adjusting plate 3. Packing

4. Plate 5. Shift lever 6. Sleeve bearing

7. Front bracket assembly 8. Yoke assembly 9. Armature assembly

10. Washer 11. Rear bearing 12. Brush holder assembly

13. Rear bracket assembly 14. Cover 15. Packing

16. Ball 17. Shaft gear assembly 18. Clutch gear assembly

19. Pinion stopper 20. Stopper clip

: Nꞏm (kg-m, in-lb) (H): High-temperature grease point

PKIB8653E

Page 5165 of 5621

SC-28

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

Trouble Diagnoses with Battery/Starting/Charging System Tester (Charging)NKS003NP

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and alternator test segments must be done

as a set from start to finish.

Before starting, perform the preliminary inspection. Refer to SC-32, "

PRELIMINARY INSPECTION" .

1. Stop the operation of the power generation voltage variable control in either of the following procedures.

After selecting “ENGINE” of “SELECT SYSTEM” using CONSULT-II, set the DUTY value of “ALTERNA-

TOR DUTY” to 0% by selecting “ALTERNATOR DUTY” of “ACTIVE TEST”. Continue “ACTIVE TEST”

until the end of inspection. (When the DUTY value is 0 or 100%, the normal power generation is per-

formed according to the characteristic of the IC regulator of the alternator.)

Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC

(P1550 - P1554) of the engine might remain. After finishing the inspection, connect the battery current

sensor connector and erase the self-diagnostic results history of the engine using CONSULT-II.]

2. Turn off all loads on the vehicle electrical system.

3. Perform battery and starting system test with Battery/Starting/

Charging system tester.

4. Press “ENTER” to begin the charging system test.

5. Start engine.

6. Press “ENTER” until “LOADS OFF REV ENGINE 5 SEC” is dis-

played.

7. Raise and hold the engine speed at 1,500 to 2,000 rpm for about

5 seconds, then return the engine to idle.

Once the increase in engine rpm is detected, press “ENTER” to

continue.

NOTE:

If after 30 seconds an increase in engine idle speed is not

detected, “RPM NOT DETECTED” will display.

Some engines may have a higher idle initially after starting,

particularly when the engine is cold. The tester may detect

this without any other action being taken. If this occurs, con-

tinue on with the testing process. The final results will not be affected.

8. The tester now checks the engine at idle and performs the

DIODE/RIPPLE check.

9. When complete, the tester will prompt you to turn on the follow-

ing electrical loads.

Heater fan set to highest speed. Do not run the A/C or wind-

shield defroster.

Headlamp high beam

Rear window defogger

NOTE:

Do not run the windshield wipers or any other cyclical loads.

SEL417X

SEL418X

SEL419X

Page 5168 of 5621

CHARGING SYSTEM

SC-31

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

WORK FLOW

*1SC-32, "Check “L” Terminal Circuit

(Open)"

*2SC-33, "Check “L” Terminal Circuit

(Short)"

*3SC-33, "Check “S” Terminal Circuit"

*4SC-34, "Check “B” Terminal Circuit"*5SC-38, "Alternator Pulley Inspec-

tion" (VQ35DE)

SC-40, "

Alternator Pulley Inspec-

tion" (VK45DE)

SKIB0527E

Page 5169 of 5621

SC-32

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

PRELIMINARY INSPECTION

1. CHECK BATTERY TERMINALS CONNECTION

Check if battery terminals are clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair battery terminals connection.

2. CHECK FUSE AND FUSIBLE LINK

Check for blown fuse and fusible link.

OK or NG

OK >> GO TO 3.

NG >> Be sure to eliminate cause of malfunction before installing new fuse.

3. CHECK “E” TERMINAL CONNECTION

Check if “E” terminal (alternator ground harness) is clean and tight.

OK or NG

OK >> GO TO 4.

NG >> Repair “E” terminal connection.

4. CHECK ALTERNATOR DRIVE BELT TENSION

Check alternator drive belt tension. Refer to EM-15, "

Checking Drive Belts" (VQ35DE) or EM-174, "Checking

Drive Belts" (VK45DE).

OK or NG

OK >> INSPECTION END

NG >> Repair as needed.

DIAGNOSTIC PROCEDURE 1

Check “L” Terminal Circuit (Open)

1. CHECK “L” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “L” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “L” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test. Refer to SC-28, "

Trouble Diagnoses with Battery/Starting/Charging System Tester

(Charging)" .

Unit Power source (Power supply terminals) Fuse and fusible link No.

Alternator Battery (“S” terminal) 36

Combination meter Ignition switch ON (“L” terminal) 14

Page 5170 of 5621

CHARGING SYSTEM

SC-33

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

2. CHECK “L” TERMINAL CIRCUIT (OPEN)

1. Disconnect alternator connector.

2. Apply ground to alternator harness connector terminal.

3. Check condition the charge warning lamp with the ignition

switch in the ON position.

OK or NG

OK >> Go to SC-31, "WORK FLOW" .

NG >> Check the following.

Harness for open between combination meter and alternator

Harness for open between combination meter and fuse

Charge warning lamp (Combination meter)

DIAGNOSTIC PROCEDURE 2

Check “L” Terminal Circuit (Short)

1. CHECK “L” TERMINAL CIRCUIT (SHORT)

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

Charge warning lamp should illuminate?

YES >> Check the following.

Harness for short between combination meter and alternator

Charge warning lamp (Combination meter)

NO >> Go to SC-31, "

WORK FLOW" .

DIAGNOSTIC PROCEDURE 3

Check “S” Terminal Circuit

1. CHECK “S” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “S” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “S” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test. Refer to SC-28, "

Trouble Diagnoses with Battery/Starting/Charging System Tester

(Charging)" .

Alternator

connectorTerminal

GroundCondition

Ignition switch

positionCharge warning

lamp

F20 (VQ35DE)

E209 (VK45DE)3 ON illuminate

PKIB8807E

Page 5171 of 5621

SC-34

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

2. CHECK “S” TERMINAL CIRCUIT

Check voltage between alternator harness connector and ground.

OK or NG

OK >> Go to SC-31, "WORK FLOW" .

NG >> Check harness for open between alternator and fuse.

DIAGNOSTIC PROCEDURE 4

Check “B” Terminal Circuit

1. CHECK “B” TERMINAL CONNECTION

1. Turn ignition switch OFF.

2. Check if “B” terminal is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair “B” terminal connection. Confirm repair by performing complete Battery/Starting/Charging

system test. Refer to SC-28, "

Trouble Diagnoses with Battery/Starting/Charging System Tester

(Charging)" .

2. CHECK “B” TERMINAL CIRCUIT

Check voltage between alternator “B” terminal and ground.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open between alternator and fusible

link.

3. CHECK “B” TERMINAL CONNECTION (VOLTAGE DROP TEST)

1. Start engine, then engine running at idle and warm.

2. Check voltage between battery positive terminal and alternator

“B” terminal.

OK or NG

OK >> Go to SC-31, "WORK FLOW" .

NG >> Check harness between battery and alternator for poor continuity.

Terminals

Voltage (Approx.) (+)

(–)

Alternator connector Terminal

F20 (VQ35DE)

E209 (VK45DE)4 Ground Battery voltage

PKIB8808E

Terminals

Voltage (Approx.) (+)

(–)

Alternator “B” terminal Terminal

E205 [VQ35DE (2WD)]

E202 [VQ35DE (AWD)/VK45DE]1 Ground Battery voltage

PKIB8809E

Te r m i n a l s

Voltage

(Approx.)

(+)(–)

Alternator “B” terminal Terminal

Battery positive

terminalE205 [VQ35DE (2WD)]

E202 [VQ35DE (AWD)/VK45DE]1 Less than 0.2 V

PKIB8810E

Page 5172 of 5621

CHARGING SYSTEM

SC-35

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

Power Generation Voltage Variable Control System Operation InspectionNKS003NQ

CAUTION:

For this model, the battery current sensor that is installed to the battery cable at the negative ter-

minal measures the charging/discharging current of the battery, and performs various controls. If

the electrical component or the ground wire is connected directly to the battery terminal, the cur-

rent other than that being measured with the battery current sensor is charging to or discharging

from the battery. This condition causes the malfunction of the control, and then the battery dis-

charge may occur. Never connect the electrical component or the ground wire directly to the bat-

tery terminal.

When performing this inspection, always use the charged battery that completed the battery

inspection. (When the charging rate of the battery is low, the response speed of the voltage

change will become slow. This is a cause of an incorrect inspection.)

INSPECTION PROCEDURE

1. CHECK ECM (CONSULT-II)

Perform ECM self-diagnosis with CONSULT-II. Refer to EC-133, "

CONSULT-II Function (ENGINE)"

(VQ35DE) or EC-846, "CONSULT-II Function (ENGINE)" (VK45DE).

Self

-diagnostic results content

No malfunction detected>> GO TO 2.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts.

2. CHECK OPERATION OF POWER GENERATION VOLTAGE VARIABLE CONTROL SYSTEM

1. Connect CONSULT-II and start the engine.

2. The selector lever is in “P” or “N” position and all of the electric

loads and A/C, etc. are turned OFF.

3. Select “ALTERNATOR DUTY” at “ACTIVE TEST” of “ENGINE”,

and then check the value of “BATTERY VOLT” monitor when

DUTY value of “ALTERNATOR DUTY” is set to 40.0 %.

4. Check the value of “BATTERY VOLT” monitor when DUTY value

of “ALTERNATOR DUTY” is set to 80.0%.

OK or NG

OK >> INSPECTION END

NG >> GO TO 3. (The charging condition of the battery should

be normal.)

3. CHECK IPDM E/R (CONSULT-II)

Perform IPDM E/R self-diagnosis with CONSULT-II. Refer to PG-20, "

CONSULT-II Function (IPDM E/R)" .

Self

-diagnostic results content

No malfunction detected>> GO TO 4.

Malfunction detected>> Check applicable parts, and repair or replace corresponding parts. “BATTERY VOLT”

2 seconds after setting the

DUTY value of “ALTERNA-

TOR DUTY” to 40.0 %: 12 - 13.6 V

PKIB4503E

“BATTERY VOLT”

20 seconds after setting

the DUTY value of “ALTER-

NATOR DUTY” to 80.0 %: +0.5 V or more against

the value of “BATTERY

VOLT” monitor when

DUTY value is 40.0 %

PKIB4504E

Page 5173 of 5621

SC-36

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

4. CHECK HARNESS BETWEEN ALTERNATOR AND IPDM E/R

1. Turn ignition switch OFF.

2. Disconnect alternator connector and IPDM E/R connector.

3. Check continuity between alternator harness connector (A) and

IPDM E/R harness connector (B).

4. Check continuity between alternator harness connector (A) and

ground.

OK or NG

OK >> Replace IPDM E/R.

NG >> Repair harness or connector between IPDM E/R and alternator.

AB

Continuity

Connector Terminal Connector Terminal

F20 (VQ35DE)

E209 (VK45DE)5 E8 33 Yes

A

GroundCondition

Connector Terminal

F20 (VQ35DE)

E209 (VK45DE)5No

PKIB8811E