check INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5065 of 5621

RFD-22

REAR FINAL DRIVE ASSEMBLY

Revision: 2006 January2006 M35/M45

Companion Flange Runout

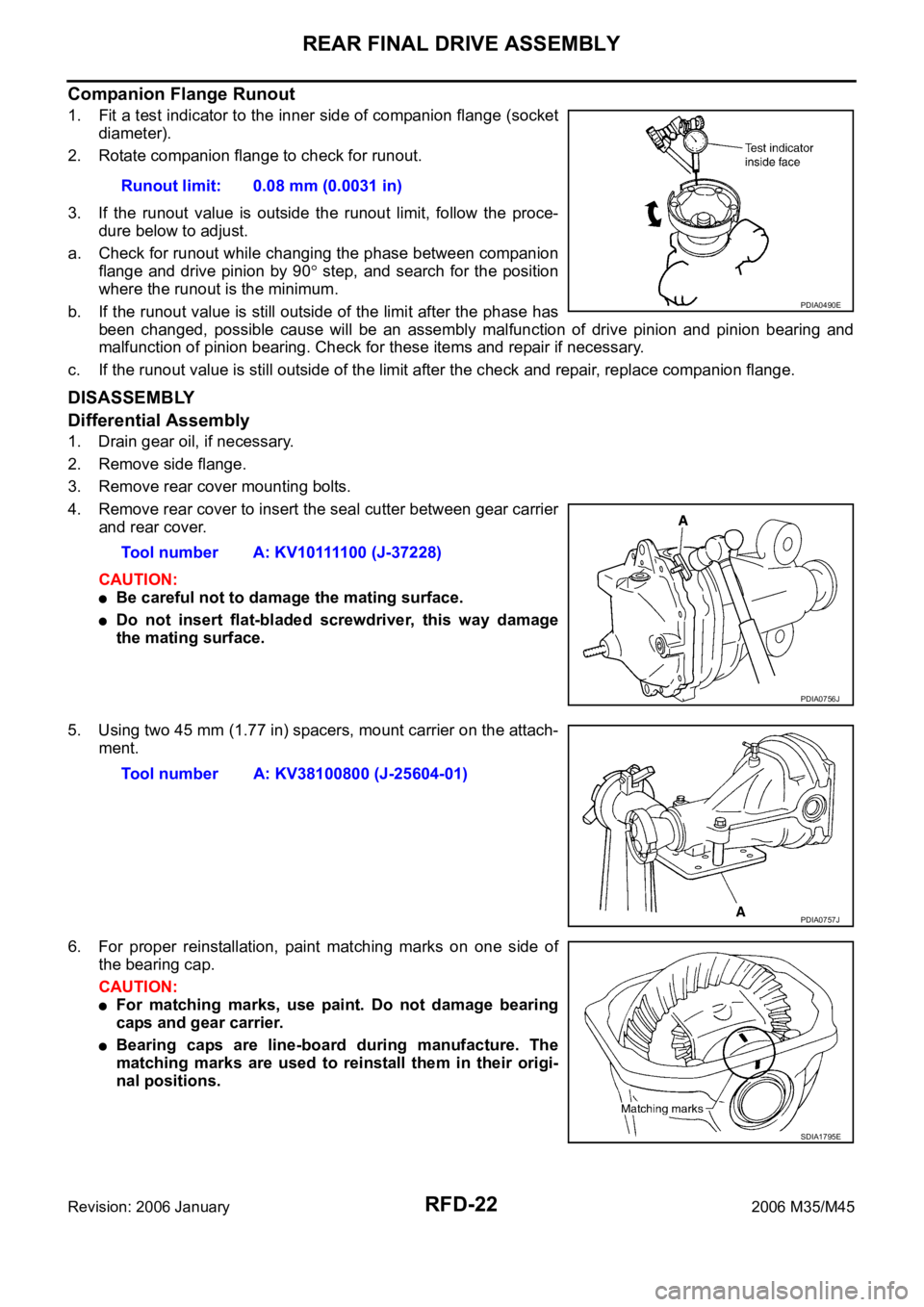

1. Fit a test indicator to the inner side of companion flange (socket

diameter).

2. Rotate companion flange to check for runout.

3. If the runout value is outside the runout limit, follow the proce-

dure below to adjust.

a. Check for runout while changing the phase between companion

flange and drive pinion by 90

step, and search for the position

where the runout is the minimum.

b. If the runout value is still outside of the limit after the phase has

been changed, possible cause will be an assembly malfunction of drive pinion and pinion bearing and

malfunction of pinion bearing. Check for these items and repair if necessary.

c. If the runout value is still outside of the limit after the check and repair, replace companion flange.

DISASSEMBLY

Differential Assembly

1. Drain gear oil, if necessary.

2. Remove side flange.

3. Remove rear cover mounting bolts.

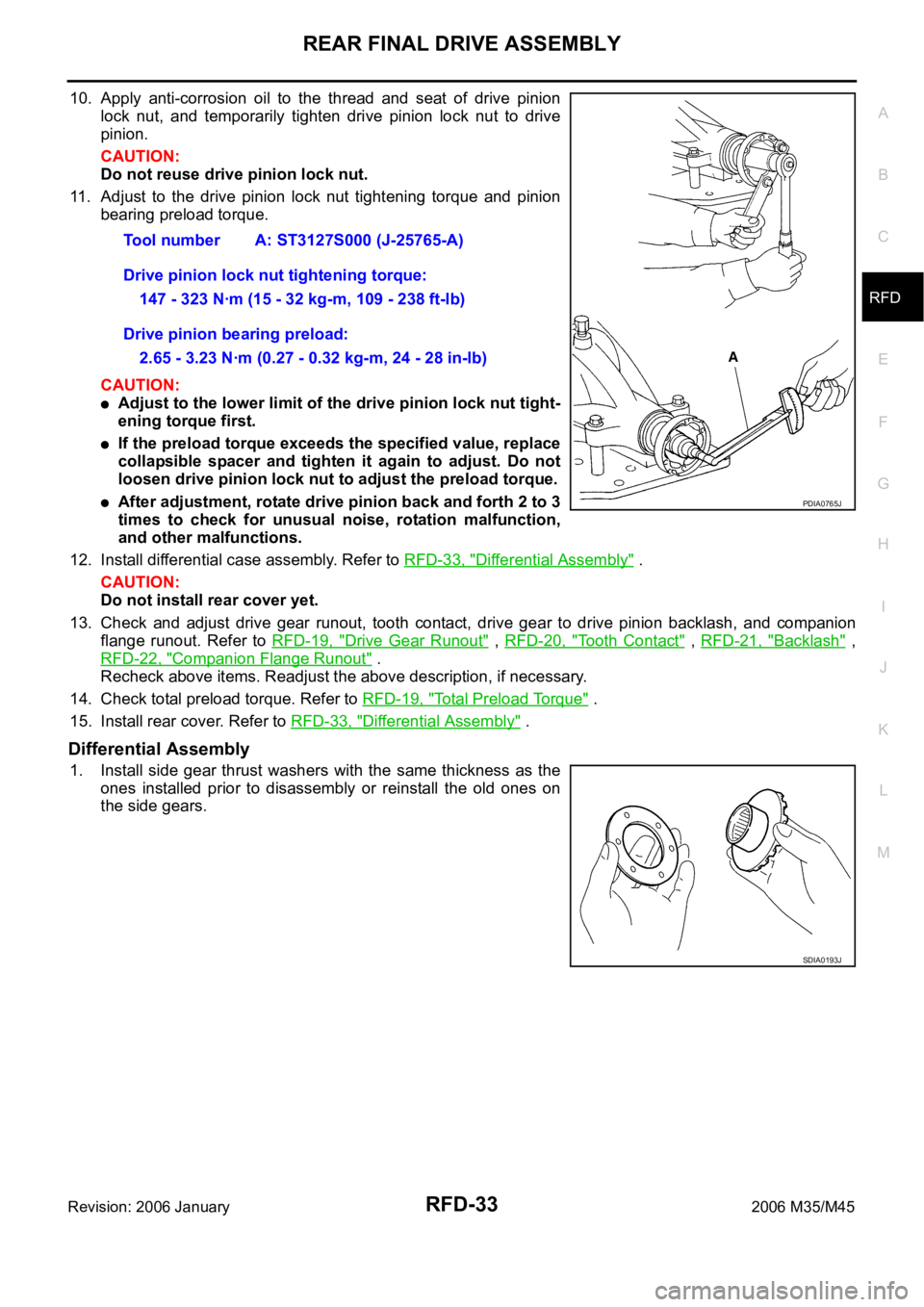

4. Remove rear cover to insert the seal cutter between gear carrier

and rear cover.

CAUTION:

Be careful not to damage the mating surface.

Do not insert flat-bladed screwdriver, this way damage

the mating surface.

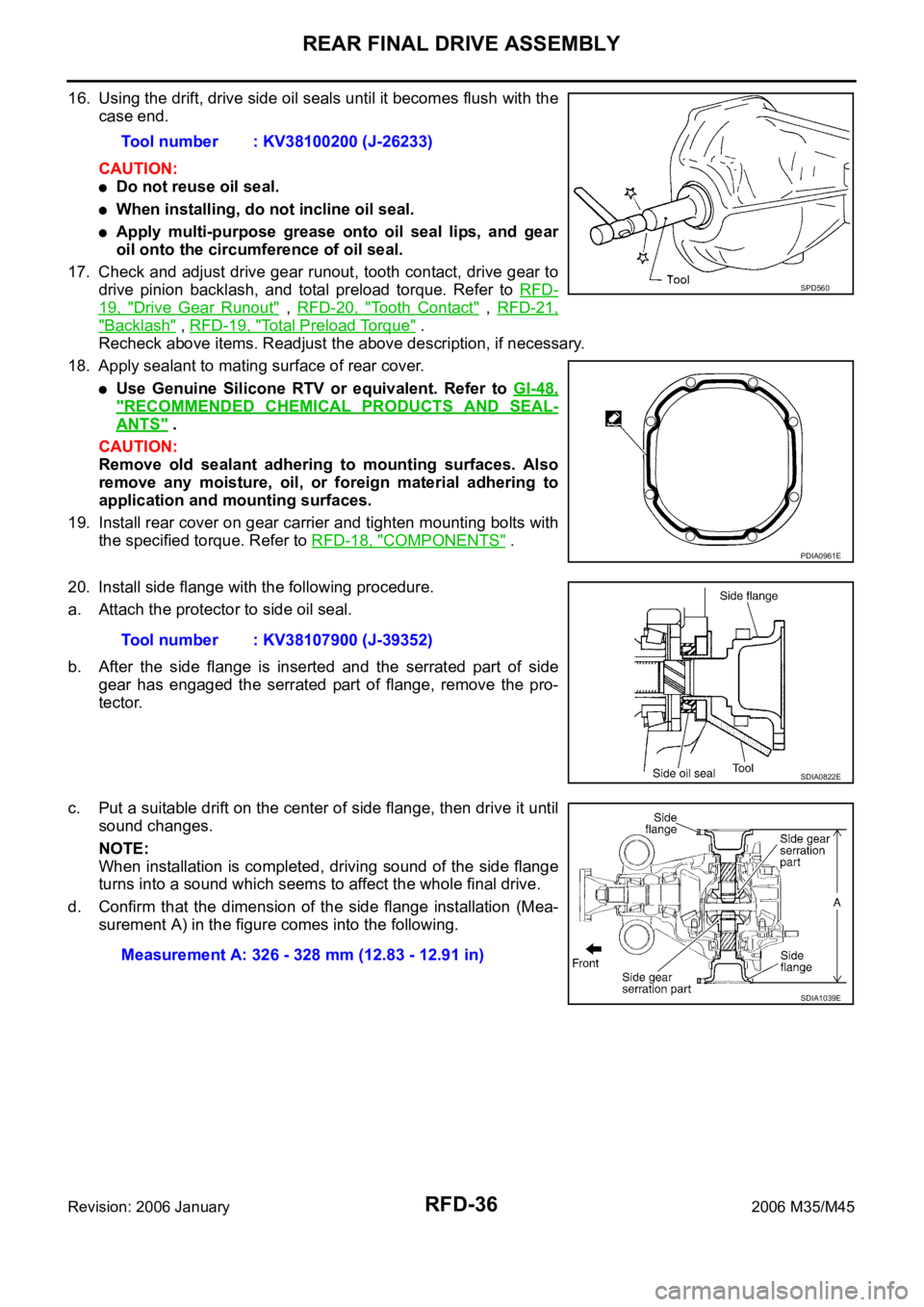

5. Using two 45 mm (1.77 in) spacers, mount carrier on the attach-

ment.

6. For proper reinstallation, paint matching marks on one side of

the bearing cap.

CAUTION:

For matching marks, use paint. Do not damage bearing

caps and gear carrier.

Bearing caps are line-board during manufacture. The

matching marks are used to reinstall them in their origi-

nal positions.Runout limit: 0.08 mm (0.0031 in)

PDIA0490E

Tool number A: KV10111100 (J-37228)

PDIA0756J

Tool number A: KV38100800 (J-25604-01)

PDIA0757J

SDIA1795E

Page 5076 of 5621

REAR FINAL DRIVE ASSEMBLY

RFD-33

C

E

F

G

H

I

J

K

L

MA

B

RFD

Revision: 2006 January2006 M35/M45

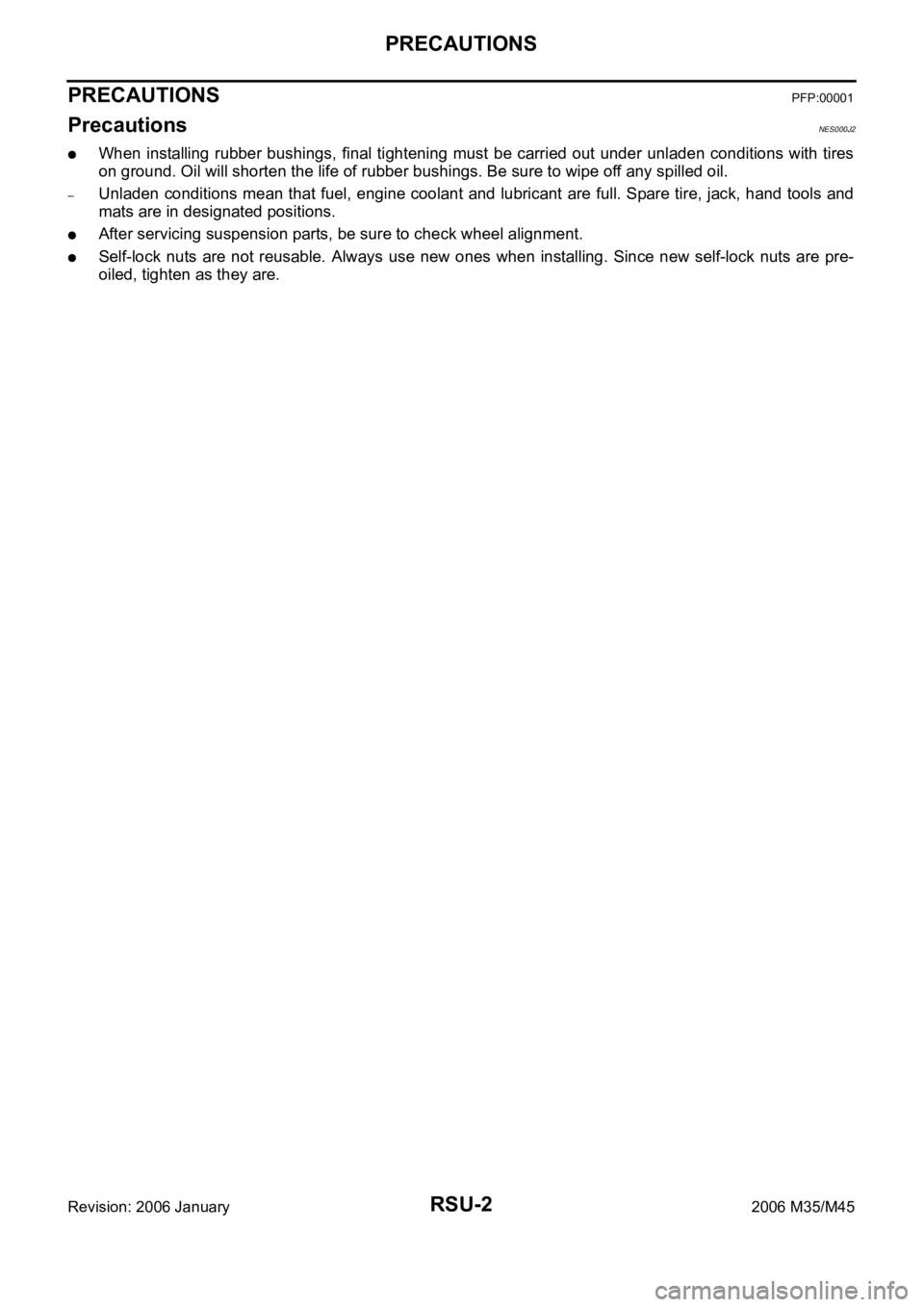

10. Apply anti-corrosion oil to the thread and seat of drive pinion

lock nut, and temporarily tighten drive pinion lock nut to drive

pinion.

CAUTION:

Do not reuse drive pinion lock nut.

11. Adjust to the drive pinion lock nut tightening torque and pinion

bearing preload torque.

CAUTION:

Adjust to the lower limit of the drive pinion lock nut tight-

ening torque first.

If the preload torque exceeds the specified value, replace

collapsible spacer and tighten it again to adjust. Do not

loosen drive pinion lock nut to adjust the preload torque.

After adjustment, rotate drive pinion back and forth 2 to 3

times to check for unusual noise, rotation malfunction,

and other malfunctions.

12. Install differential case assembly. Refer to RFD-33, "

Differential Assembly" .

CAUTION:

Do not install rear cover yet.

13. Check and adjust drive gear runout, tooth contact, drive gear to drive pinion backlash, and companion

flange runout. Refer to RFD-19, "

Drive Gear Runout" , RFD-20, "Tooth Contact" , RFD-21, "Backlash" ,

RFD-22, "

Companion Flange Runout" .

Recheck above items. Readjust the above description, if necessary.

14. Check total preload torque. Refer to RFD-19, "

Total Preload Torque" .

15. Install rear cover. Refer to RFD-33, "

Differential Assembly" .

Differential Assembly

1. Install side gear thrust washers with the same thickness as the

ones installed prior to disassembly or reinstall the old ones on

the side gears.Tool number A: ST3127S000 (J-25765-A)

Drive pinion lock nut tightening torque:

147 - 323 Nꞏm (15 - 32 kg-m, 109 - 238 ft-lb)

Drive pinion bearing preload:

2.65 - 3.23 Nꞏm (0.27 - 0.32 kg-m, 24 - 28 in-lb)

PDIA0765J

SDIA0193J

Page 5079 of 5621

RFD-36

REAR FINAL DRIVE ASSEMBLY

Revision: 2006 January2006 M35/M45

16. Using the drift, drive side oil seals until it becomes flush with the

case end.

CAUTION:

Do not reuse oil seal.

When installing, do not incline oil seal.

Apply multi-purpose grease onto oil seal lips, and gear

oil onto the circumference of oil seal.

17. Check and adjust drive gear runout, tooth contact, drive gear to

drive pinion backlash, and total preload torque. Refer to RFD-

19, "Drive Gear Runout" , RFD-20, "Tooth Contact" , RFD-21,

"Backlash" , RFD-19, "Total Preload Torque" .

Recheck above items. Readjust the above description, if necessary.

18. Apply sealant to mating surface of rear cover.

Use Genuine Silicone RTV or equivalent. Refer to GI-48,

"RECOMMENDED CHEMICAL PRODUCTS AND SEAL-

ANTS" .

CAUTION:

Remove old sealant adhering to mounting surfaces. Also

remove any moisture, oil, or foreign material adhering to

application and mounting surfaces.

19. Install rear cover on gear carrier and tighten mounting bolts with

the specified torque. Refer to RFD-18, "

COMPONENTS" .

20. Install side flange with the following procedure.

a. Attach the protector to side oil seal.

b. After the side flange is inserted and the serrated part of side

gear has engaged the serrated part of flange, remove the pro-

tector.

c. Put a suitable drift on the center of side flange, then drive it until

sound changes.

NOTE:

When installation is completed, driving sound of the side flange

turns into a sound which seems to affect the whole final drive.

d. Confirm that the dimension of the side flange installation (Mea-

surement A) in the figure comes into the following.Tool number : KV38100200 (J-26233)

SPD560

PDIA0961E

Tool number : KV38107900 (J-39352)

SDIA0822E

Measurement A: 326 - 328 mm (12.83 - 12.91 in)

SDIA1039E

Page 5081 of 5621

RFD-38

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

SELECTIVE PARTS

Side Gear Thrust Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Pinion Height Adjusting Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information.

Side Bearing Adjusting Washer

Unit: mm (in)

*: Always check with the Parts Department for the latest parts information. Thickness Part number* Thickness Part number*

0.75 (0.0295)

0.78 (0.0307)

0.81 (0.0319)

0.84 (0.0331)38424 EC000

38424 EC001

38424 EC002

38424 EC0030.87 (0.0343)

0.90 (0.0350)

0.93 (0.0366)38424 EC004

38424 EC005

38424 EC006

Thickness Part number* Thickness Part number*

3.05 (0.1201)

3.08 (0.1213)

3.11 (0.1224)

3.14 (0.1236)38154 0C000

38154 0C001

38154 0C002

38154 0C0033.17 (0.1248)

3.20 (0.1260)

3.23 (0.1272)

3.26 (0.1283)38154 0C004

38154 0C005

38154 0C006

38154 0C007

Thickness Part number* Thickness Part number*

2.00 (0.0787)

2.05 (0.0807)

2.10 (0.0827)

2.15 (0.0846)

2.20 (0.0866)

2.25 (0.0886)

2.30 (0.0906)38453 N3100

38453 N3101

38453 N3102

38453 N3103

38453 N3104

38453 N3105

38453 N31062.35 (0.0925)

2.40 (0.0945)

2.45 (0.0965)

2.50 (0.0984)

2.55 (0.1004)

2.60 (0.1024)

2.65 (0.1043)38453 N3107

38453 N3108

38453 N3109

38453 N3110

38453 N3111

38453 N3112

38453 N3113

Page 5083 of 5621

RSU-2

PRECAUTIONS

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

PrecautionsNES000J2

When installing rubber bushings, final tightening must be carried out under unladen conditions with tires

on ground. Oil will shorten the life of rubber bushings. Be sure to wipe off any spilled oil.

–Unladen conditions mean that fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

After servicing suspension parts, be sure to check wheel alignment.

Self-lock nuts are not reusable. Always use new ones when installing. Since new self-lock nuts are pre-

oiled, tighten as they are.

Page 5086 of 5621

REAR SUSPENSION ASSEMBLY

RSU-5

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

REAR SUSPENSION ASSEMBLYPFP:55020

On-Vehicle Inspection and ServiceNES000J6

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

SUSPENSION ARM BALL JOINT AXIAL END PLAY INSPECTION

Measure axial end play by placing and moving up/down with an iron pry bar or something similar between sus-

pension arm and axle.

CAUTION:

Be careful not to damage ball joint boot.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace if malfunction is detected.

Wheel Alignment InspectionNES000J7

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats in designated positions.

PRELIMINARY INSPECTION

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-6, "

ROAD WHEEL" .

3. Wheel bearing axial end play. Refer to RAX-5, "

WHEEL BEARING INSPECTION" .

4. Ball joint axial end play of suspension arm. Refer to RSU-5, "

SUSPENSION ARM BALL JOINT AXIAL

END PLAY INSPECTION" .

5. Shock absorber operation.

6. Each mounting point of axle and suspension for looseness and deformation.

7. Each of front lower link, rear lower link, radius rod, rear suspension member, suspension arm and shock

absorber for cracks, deformation, and other damage.

8. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

–This type of alignment is recommended for any NISSAN/INFINITI vehicle.

–The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel is

centered.

–The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

–The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

–Your alignment equipment should be regularly calibrated in order to give correct information.

–Check with the manufacturer of your specific equipment for their recommended Service/Calibration

Schedule.Standard value

Axial end play : 0 mm (0 in)

Page 5087 of 5621

RSU-6

REAR SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

THE ALIGNMENT PROCESS

IMPORTANT:

Use only the alignment specifications listed in this Service Manual.

When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

–The alignment specifications programmed into your machine that operate these indicators may not be cor-

rect.

–This may result in an ERROR.

Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). DO NOT use this “Rolling Compensation”

method.

–Use the “Jacking Compensation Method”. After installing the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

–See Instructions in the alignment machine you're using for more information on this.

CAMBER INSPECTION

Measure camber of both right and left wheels with a suitable alignment gauge.

Adjust in accordance with the following procedures.

If outside the standard value, adjust with adjusting bolt in front

lower link.

NOTE:

After adjusting camber, be sure to check toe-in.

TOE-IN

If toe-in is not within the specification, adjust with adjusting bolt in

rear lower link.

CAUTION:

Be sure to adjust equally on RH and LH side with adjusting bolt.

If toe-in is not still within the specification, inspect and replace any

damaged or worn rear suspension parts.Standard value

Camber : Refer to RSU-18, "

SERVICE DATA" .

SRA096A

SEIA0227E

SEIA0228E

Page 5089 of 5621

RSU-8

REAR SUSPENSION ASSEMBLY

Revision: 2006 January2006 M35/M45

Refer to GI section for symbol marks in the figure. Refer to GI-9, "HOW TO USE THIS MANUAL" .

Removal and InstallationNES000J9

REMOVAL

1. Remove tire with a power tool.

2. Remove brake caliper with a power tool. Hang it in a place where it will not interfere with work. Refer to

BR-29, "

REAR DISC BRAKE" .

CAUTION:

Do not depressing brake pedal while brake caliper is removed.

3. Put matching marks on both disc rotor and the wheel hub and

bearing assembly, then remove disc rotor.

4. Remove rear under cover.

5. Remove wheel sensor from rear final drive.

6. Remove harness from rear final drive and rear suspension

member.

7. Remove center muffler. Refer to EX-3, "

EXHAUST SYSTEM" .

8. Remove rear propeller shaft. Refer to PR-6, "

REAR PROPEL-

LER SHAFT" .

9. Remove stabilizer bar. Refer to RSU-17, "

STABILIZER BAR" .

10. Remove parking brake cable mounting bolt and separate park-

ing brake cable from vehicle and rear suspension member. Refer to PB-3, "

PARKING BRAKE CONTROL"

.

11. Remove rear lower link and coil spring. Refer to RSU-16, "

REAR LOWER LINK & COIL SPRING" .

12. Remove mounting bolt on lower side of shock absorber. Refer to RSU-10, "

SHOCK ABSORBER" .

13. Set jack under rear final drive.

14. Remove member stay from vehicle.

15. Remove rear pin stay mounting bolts and nuts.

16. Gradually lowering jack, remove rear pin stay and rear suspension assembly.

INSTALLATION

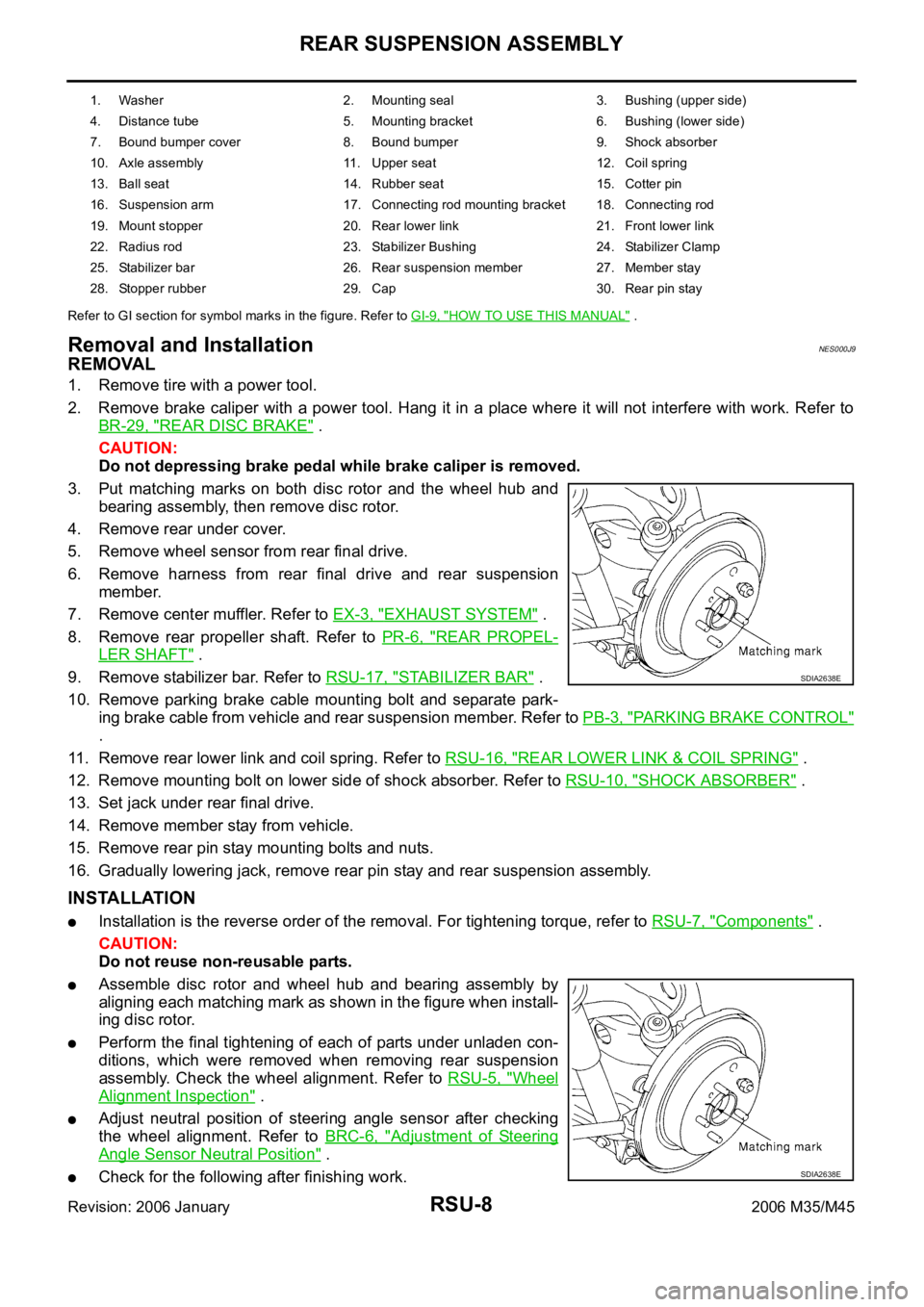

Installation is the reverse order of the removal. For tightening torque, refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

Assemble disc rotor and wheel hub and bearing assembly by

aligning each matching mark as shown in the figure when install-

ing disc rotor.

Perform the final tightening of each of parts under unladen con-

ditions, which were removed when removing rear suspension

assembly. Check the wheel alignment. Refer to RSU-5, "

Wheel

Alignment Inspection" .

Adjust neutral position of steering angle sensor after checking

the wheel alignment. Refer to BRC-6, "

Adjustment of Steering

Angle Sensor Neutral Position" .

Check for the following after finishing work.

1. Washer 2. Mounting seal 3. Bushing (upper side)

4. Distance tube 5. Mounting bracket 6. Bushing (lower side)

7. Bound bumper cover 8. Bound bumper 9. Shock absorber

10. Axle assembly 11. Upper seat 12. Coil spring

13. Ball seat 14. Rubber seat 15. Cotter pin

16. Suspension arm 17. Connecting rod mounting bracket 18. Connecting rod

19. Mount stopper 20. Rear lower link 21. Front lower link

22. Radius rod 23. Stabilizer Bushing 24. Stabilizer Clamp

25. Stabilizer bar 26. Rear suspension member 27. Member stay

28. Stopper rubber 29. Cap 30. Rear pin stay

SDIA2638E

SDIA2638E

Page 5091 of 5621

RSU-10

SHOCK ABSORBER

Revision: 2006 January2006 M35/M45

SHOCK ABSORBERPFP:56210

Removal and InstallationNES000JA

REMOVAL

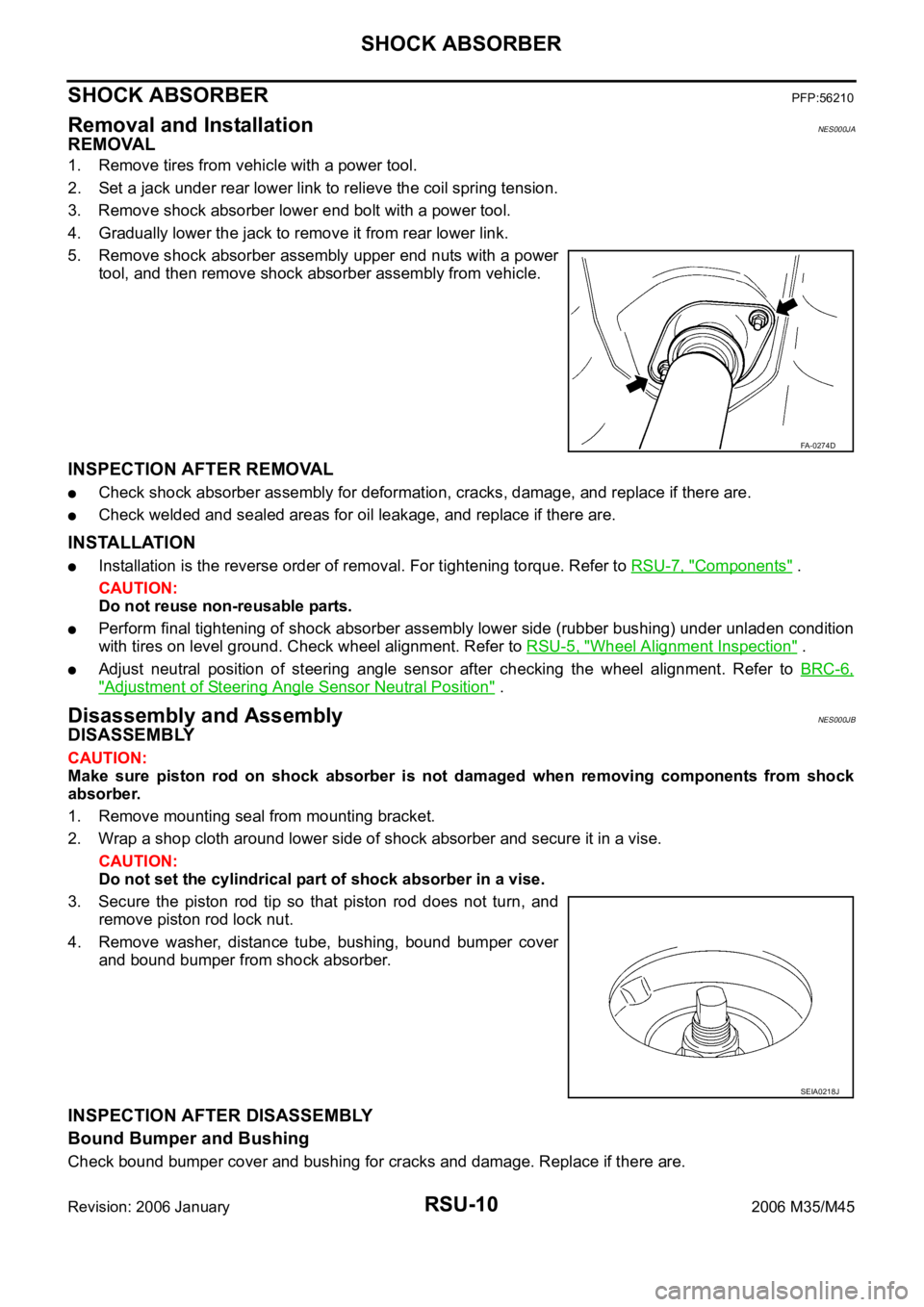

1. Remove tires from vehicle with a power tool.

2. Set a jack under rear lower link to relieve the coil spring tension.

3. Remove shock absorber lower end bolt with a power tool.

4. Gradually lower the jack to remove it from rear lower link.

5. Remove shock absorber assembly upper end nuts with a power

tool, and then remove shock absorber assembly from vehicle.

INSPECTION AFTER REMOVAL

Check shock absorber assembly for deformation, cracks, damage, and replace if there are.

Check welded and sealed areas for oil leakage, and replace if there are.

INSTALLATION

Installation is the reverse order of removal. For tightening torque. Refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

Perform final tightening of shock absorber assembly lower side (rubber bushing) under unladen condition

with tires on level ground. Check wheel alignment. Refer to RSU-5, "

Wheel Alignment Inspection" .

Adjust neutral position of steering angle sensor after checking the wheel alignment. Refer to BRC-6,

"Adjustment of Steering Angle Sensor Neutral Position" .

Disassembly and AssemblyNES000JB

DISASSEMBLY

CAUTION:

Make sure piston rod on shock absorber is not damaged when removing components from shock

absorber.

1. Remove mounting seal from mounting bracket.

2. Wrap a shop cloth around lower side of shock absorber and secure it in a vise.

CAUTION:

Do not set the cylindrical part of shock absorber in a vise.

3. Secure the piston rod tip so that piston rod does not turn, and

remove piston rod lock nut.

4. Remove washer, distance tube, bushing, bound bumper cover

and bound bumper from shock absorber.

INSPECTION AFTER DISASSEMBLY

Bound Bumper and Bushing

Check bound bumper cover and bushing for cracks and damage. Replace if there are.

FA-0274D

SEIA0218J

Page 5092 of 5621

SHOCK ABSORBER

RSU-11

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

Shock Absorber

Check the following:

Shock absorber for deformation, cracks, and other damage. Replace if there are.

Piston rod for damage, uneven wear, and distortion. Replace if there are.

ASSEMBLY

Installation is the reverse order of removal. For tightening torque. Refer to RSU-7, "Components" .

CAUTION:

Do not reuse non-reusable parts.

Make sure piston rod on shock absorber is not damaged when attaching components to shock absorber.