Body INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3178 of 5621

![INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-115

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Vehicle Underbody

1. Remove A/T fluid cooler hoses and power steering oil pump oil cooler hoses.

Install pl INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-115

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Vehicle Underbody

1. Remove A/T fluid cooler hoses and power steering oil pump oil cooler hoses.

Install pl](/img/42/57023/w960_57023-3177.png)

ENGINE ASSEMBLY

EM-115

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Vehicle Underbody

1. Remove A/T fluid cooler hoses and power steering oil pump oil cooler hoses.

Install plug to avoid leakage of A/T fluid and power steering fluid.

2. Disconnect heated oxygen sensor 2 harness.

3. Remove three way catalyst and exhaust front tube. Refer to EX-3, "

EXHAUST SYSTEM" .

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to PS-13, "

STEERING COLUMN" .

5. Remove rear propeller shaft. Refer to PR-6, "

REAR PROPELLER SHAFT" .

6. Disengage A/T control rod at control device assembly side. Then, temporarily secure it on the transmis-

sion assembly, so that it does not sag. Refer to AT- 2 2 2 , "

SHIFT CONTROL SYSTEM" .

7. Remove rear plate cover from oil pan (upper). Then remove bolts fixing drive plate to torque converter.

Refer to EM-29, "

OIL PAN AND OIL STRAINER" and AT- 2 7 1 , "TRANSMISSION ASSEMBLY" .

8. Remove transmission joint bolts which pierce at oil pan (upper) lower rear side. Refer to AT- 2 7 1 , "

TRANS-

MISSION ASSEMBLY" .

9. Remove front stabilizer at transverse link side. Refer to FSU-18, "

STABILIZER BAR" .

10. Remove lower ends of left and right strut from transverse link. Refer to FSU-6, "

FRONT SUSPENSION

ASSEMBLY" .

11. Separate steering outer sockets from steering knuckle. Refer to PS-18, "

POWER STEERING GEAR" .

12. Remove transverse links mounting bolts at knuckle side. Refer to FSU-14, "

TRANSVERSE LINK" .

Removal Work

1. Use a manual lift table caddy (commercial service tool) or equiv-

alently rigid tool such as a transmission jack. Securely support

bottom of suspension member and the transmission assembly.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove rear engine mounting member bolts.

3. Remove front suspension member mounting bolts and nuts. Refer to FSU-6, "

FRONT SUSPENSION

ASSEMBLY" .

4. Carefully lower jack, or raise lift to remove the engine, the transmission assembly and front suspension

member. When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with the vehicle.

Make sure that all connection points have been disconnected.

Keep in mind the center of vehicle gravity changes. If necessary, use jack(s) to support the vehi-

cle at rear jacking point(s) to prevent it from falling it off the lift.

Separation Work

1. Install engine slingers into front of cylinder head (right bank) and

rear of cylinder head (left bank).

PBIC0804E

Slinger bolts:

: 28.0 Nꞏm (2.9 kg-m, 21 ft-lb)

PBIC2061E

Page 3183 of 5621

![INFINITI M35 2006 Factory Service Manual EM-120

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "BODY SIDE

TRIM" and INFINITI M35 2006 Factory Service Manual EM-120

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "BODY SIDE

TRIM" and](/img/42/57023/w960_57023-3182.png)

EM-120

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "BODY SIDE

TRIM" and IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect engine room harness connectors at unit sides TCM, ECM and other.

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CAUTION:

When pulling out harnesses, take care not to damage harnesses and connectors.

After temporarily securing, cover connectors with vinyl or similar material to protect against for-

eign material adhesion.

Vehicle Underbody

1. Remove A/T fluid cooler hoses and power steering oil pump oil cooler hoses.

Install plug to avoid leakage of A/T fluid and power steering fluid.

2. Disconnect heated oxygen sensor 2 harness. Refer to EX-3, "

EXHAUST SYSTEM" .

3. Remove three way catalyst and exhaust front tube. Refer to EX-3, "

EXHAUST SYSTEM" .

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to PS-13, "

STEERING COLUMN" .

5. Remove rear propeller shaft. Refer to PR-6, "

REAR PROPELLER SHAFT" .

6. Remove front drive shaft (both side). Refer to FAX-8, "

FRONT DRIVE SHAFT" .

7. Disconnect harness connector from transmission assembly and transfer assembly.

8. Disengage A/T control rod at control device assembly side. Then, temporarily secure it on the transmis-

sion assembly, so that it does not sag. Refer to AT-222, "

SHIFT CONTROL SYSTEM" .

9. Remove rear plate cover from oil pan (upper). Then remove bolts fixing drive plate to torque converter.

Refer to EM-29, "

OIL PAN AND OIL STRAINER" and AT-271, "TRANSMISSION ASSEMBLY" .

10. Remove bolts fixing the transmission assembly to lower rear side of oil pan (upper). Refer to AT- 2 7 1 ,

"TRANSMISSION ASSEMBLY" .

11. Remove front stabilizer at transverse link side. Refer to FSU-18, "

STABILIZER BAR" .

12. Remove lower ends of left and right strut from transverse link. Refer to FSU-23, "

FRONT SUSPENSION

ASSEMBLY" .

13. Separate steering outer sockets from steering knuckle. Refer to PS-18, "

POWER STEERING GEAR" .

14. Remove transverse links mounting bolts at knuckle side. Refer to FSU-31, "

TRANSVERSE LINK" .

Removal Work

1. Use a manual lift table caddy (commercial service tool) or equiv-

alently rigid tool such as a transmission jack. Securely support

bottom of suspension member and transmission.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove rear engine mounting member bolts.

3. Remove front suspension member mounting bolts and nuts. Refer to FSU-23, "

FRONT SUSPENSION

ASSEMBLY" .

4. Carefully lower jack, or raise lift to remove the engine, transmission assembly, transfer, front final drive

assembly and front suspension member. When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with the vehicle.

Make sure that all connection points have been disconnected.

Keep in mind the center of the vehicle gravity changes. If necessary, use jack(s) to support the

vehicle at rear jacking point(s) to prevent it from falling it off the lift.

PBIC0804E

Page 3270 of 5621

![INFINITI M35 2006 Factory Service Manual TIMING CHAIN

EM-207

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

NOTE:

To remove timing chain and related parts, start with those on left bank. The procedure for removing part INFINITI M35 2006 Factory Service Manual TIMING CHAIN

EM-207

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

NOTE:

To remove timing chain and related parts, start with those on left bank. The procedure for removing part](/img/42/57023/w960_57023-3269.png)

TIMING CHAIN

EM-207

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

NOTE:

To remove timing chain and related parts, start with those on left bank. The procedure for removing parts

on right bank is omitted because it is the same as that for left bank.

a. Press tab in the direction of arrow (or turn lever in the direction

of arrow) to unlock the locking with the groove that stops ten-

sioner plunger from returning.

Lightly press tensioner plunger to release the tension of

spring for this operation.

b. Push in tensioner plunger to align the hole on lever and that on

pump main body.

Pushing in tensioner too far does not allow the holes to align.

Therefore, push in plunger to the degree at which the start of

stopper groove and tab engages.

c. Insert stopper pin [hard wire with approx. 0.5 mm (0.020 in)

diameter or similar tool] to fix plunger. With plunger fixed, remove chain tensioner.

17. Remove chain tension guide and timing chain slack guide.

18. Remove timing chain and crankshaft sprocket.

CAUTION:

After removing timing chain, do not turn crankshaft and camshaft separately, or valves will strike

the piston head.

19. With hexagonal part of camshaft locked with wrench, loosen

mounting bolts securing camshaft sprocket to remove camshaft

sprocket.

CAUTION:

Do not loosen mounting bolts with securing anything other

than the camshaft hexagonal portion or with tensioning the

timing chain.

20. Perform same procedure as for left bank, remove timing chain and related parts on right side.

21. Use scraper to remove all traces of old liquid gasket from front cover and opposite mating surfaces.

Remove oil liquid gasket from bolt hole and thread.

22. Use scraper to remove all trace of liquid gasket from chain tensioner cover and intake valve timing control

covers.

PBIC2343E

PBIC0030E

PBIC2084E

Page 3308 of 5621

![INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li INFINITI M35 2006 Factory Service Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li](/img/42/57023/w960_57023-3307.png)

ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for

unavoidable reasons, support at the rear axle jacking point with transmission jack or similar tool

before starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-42, "Garage Jack and

Safety Stand and 2-Pole Lift" .

REMOVAL

Outline

At first, remove engine, transmission assembly with front suspension member from vehicle downward. Then

separate engine from transmission.

Preparation

1. Release fuel pressure. Refer to EC-809, "FUEL PRESSURE RELEASE" .

2. Drain engine coolant from radiator. Refer to CO-40, "

Changing Engine Coolant" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery cables. Refer to SC-4, "

BATTERY" .

4. Remove crankshaft position sensor (POS) from transmission.

CAUTION:

Handle carefully to avoid dropping and shocks.

Do not disassemble.

Do not allow metal powder to adhere to magnetic part at sensor tip.

Do not place sensors in a location where they are exposed to magnetism.

5. Remove the following parts:

Front and rear engine undercover (power tool)

Air duct (inlet), air duct and air cleaner case assembly; Refer to EM-177, "AIR CLEANER AND AIR

DUCT" .

Front road wheels and tires (power tool)

Engine Room LH

1. Disconnect heater hoses, and install plugs to avoid leakage of engine coolant.

2. Disconnect wire bonding from exhaust manifold cover to vehicle.

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Discharge refrigerant from A/C circuit. Refer to ATC-151, "

REFRIGERANT LINES" .

5. Remove A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to AT C -

151, "REFRIGERANT LINES" .

Engine Room RH

1. Disconnect fuel feed hose and EVAP hose. Refer to EM-193, "FUEL INJECTOR AND FUEL TUBE" .

CAUTION:

Fit plugs onto disconnected hose to prevent fuel leak.

2. Disconnect ground cable (between vehicle and right bank cylinder head).

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Disconnect reservoir tank of power steering oil pump from engine, and move it aside for easier work.

CAUTION:

When temporarily securing, keep reservoir tank upright to avoid a fluid leak.

Ve h i c le i n s i d e

Follow procedure below to disconnect engine room harness connectors at passenger room side, and tempo-

rarily secure them on engine.

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "

BODY SIDE

TRIM" and IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect engine room harness connectors at unit sides TCM, ECM and other.

Page 3309 of 5621

![INFINITI M35 2006 Factory Service Manual EM-246

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CA INFINITI M35 2006 Factory Service Manual EM-246

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CA](/img/42/57023/w960_57023-3308.png)

EM-246

[VK45DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CAUTION:

When pulling out harnesses, take care not to damage harnesses and connectors.

After temporarily securing, cover connectors with vinyl or similar material to protect against for-

eign material adhesion.

Vehicle Underbody

1. Remove A/T fluid cooler hoses and power steering oil pump oil cooler hoses.

Install plug to avoid leakage of A/T fluid and power steering fluid.

2. Disconnect heated oxygen sensor 2 harness. Refer to EX-3, "

EXHAUST SYSTEM" .

3. Remove exhaust front tube with power tool. Refer to EX-3, "

EXHAUST SYSTEM" .

4. Disconnect steering lower joint at power steering gear assembly side, and release steering lower shaft.

Refer to PS-13, "

STEERING COLUMN" .

5. Separate steering outer sockets from steering knuckle. Refer to PS-18, "

POWER STEERING GEAR" .

6. Remove A/T control rod at control device assembly side. Then temporarily secure it on transmission, so

that it does not sag. Refer to AT-222, "

SHIFT CONTROL SYSTEM" .

7. Remove rear plate cover from oil pan. Then remove bolts fixing drive plate to torque converter. Refer to

EM-187, "

OIL PAN AND OIL STRAINER" and AT-271, "TRANSMISSION ASSEMBLY" .

8. Remove transmission joint bolts which pierce at oil pan lower rear side. Refer to AT- 2 7 1 , "

TRANSMIS-

SION ASSEMBLY" .

9. Remove lower ends of left and right strut from transverse link. Refer to FSU-6, "

FRONT SUSPENSION

ASSEMBLY" .

10. Remove transverse link mounting bolts at knuckle side. Refer to FSU-14, "

TRANSVERSE LINK" .

11. Remove front stabilizer at transverse link side. Refer to FSU-6, "

FRONT SUSPENSION ASSEMBLY" .

12. Remove rear propeller shaft. Refer to PR-6, "

REAR PROPELLER SHAFT" .

Removal Work

1. Use manual lift table caddy (commercial service tool) or equiva-

lently rigid tool such as transmission jack. Securely support bot-

tom of suspension member and transmission assembly.

CAUTION:

Put a piece of wood or something similar as the supporting

surface, secure a completely stable condition.

2. Remove engine rear member mounting bolts.

3. Remove front suspension member mounting nuts and bolts with power tool. Refer to FSU-6, "

FRONT

SUSPENSION ASSEMBLY" .

4. Carefully lower jack, or raise lift to remove engine, transmission and front suspension member assembly.

When performing work, observe the following caution:

CAUTION:

Confirm there is no interference with vehicle.

Make sure that all connection points have been disconnected.

Keep in mind the center of vehicle gravity changes. If necessary, use jack(s) to support vehicle

at rear jacking point(s) to prevent it from falling it off the lift.

PBIC0804E

Page 3474 of 5621

HOW TO USE THIS MANUAL

GI-11

C

D

E

F

G

H

I

J

K

L

MB

GI

Revision: 2006 January2006 M35/M45

ComponentsNAS0007L

THE LARGE ILLUSTRATIONS are exploded views (see the following) and contain tightening torques,

lubrication points, section number of the PARTS CATALOG (e.g. SEC. 440) and other information neces-

sary to perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriate PARTS CATALOG .

Components shown in an illustration may be identified by a circled number. When this style of illustration

is used, the text description of the components will follow the illustration.

SYMBOLS

1. Union bolt 2. Copper washer 3. Brake hose

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Piston seal 8. Piston 9. Piston boot

10. Cylinder body 11. Sliding pin 12. Torque member mounting bolt

13. Washer 14. Sliding pin boot 15. Bushing

16. Torque member 17. Inner shim cover 18. Inner shim

19. Inner pad 20. Pad retainer 21. Pad wear sensor

22. Outer pad 23. Outer shim 24. Outer shim cover

1: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease2: Rubber grease : Brake fluid

Refer to GI section for additional symbol definitions.

SFIA2959E

SAIA0749E

Page 3481 of 5621

GI-18

HOW TO USE THIS MANUAL

Revision: 2006 January2006 M35/M45

Optional Splice

DESCRIPTION

SGI942

Num-

berItem Description

1 Power condition

This shows the condition when the system receives battery positive voltage (can be oper-

ated).

2 Fusible link

The double line shows that this is a fusible link.

The open circle shows current flow in, and the shaded circle shows current flow out.

3Fusible link/fuse loca-

tion

This shows the location of the fusible link or fuse in the fusible link or fuse box. For arrange-

ment, refer to PG section, POWER SUPPLY ROUTING.

4Fuse

The single line shows that this is a fuse.

The open circle shows current flow in, and the shaded circle shows current flow out.

5 Current rating

This shows the current rating of the fusible link or fuse.

6 Connectors

This shows that connector E3 is female and connector M1 is male.

The G/R wire is located in the 1A terminal of both connectors.

Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is SMJ connec-

tor. Refer to PG section, SMJ (SUPER MULTIPLE JUNCTION).

7 Optional splice

The open circle shows that the splice is optional depending on vehicle application.

8 Splice

The shaded circle shows that the splice is always on the vehicle.

9 Page crossing

This arrow shows that the circuit continues to an adjacent page.

The A will match with the A on the preceding or next page.

10 Common connector

The dotted lines between terminals show that these terminals are part of the same connector.

11 Option abbreviation

This shows that the circuit is optional depending on vehicle application.

12 Relay

This shows an internal representation of the relay. For details, refer to PG section, STAN-

DARDIZED RELAY.

13 Connectors

This shows that the connector is connected to the body or a terminal with bolt or nut.

Page 3498 of 5621

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

GI-35

C

D

E

F

G

H

I

J

K

L

MB

GI

Revision: 2006 January2006 M35/M45

Control Unit Circuit Test

System Description:When the switch is ON, the control unit lights up the lamp.

INPUT-OUTPUT VOLTAGE CHART

The voltage value is based on the body ground.

*:If high resistance exists in the switch side circuit (caused by a single strand), terminal 1 does not detect battery voltage. Control unit

does not detect the switch is ON even if the switch does not turn ON. Therefore, the control unit does not supply power to light up the

lamp.

INPUT-OUTPUT VOLTAGE CHART

The voltage value is based on the body ground.

*:If high resistance exists in the switch side circuit (caused by a single strand), terminal 2 does not detect approx. 0V. Control unit does

not detect the switch is ON even if the switch does not turn ON. Therefore, the control unit does not control ground to light up the lamp.

MGI034A

Pin

No.Item ConditionVoltage

value [V]In case of high resistance such as single strand [V] *

1 SwitchSwitch ON Battery voltage Lower than battery voltage Approx. 8 (Example)

Switch OFF Approx. 0 Approx. 0

2LampSwitch ON Battery voltage Approx. 0 (Inoperative lamp)

Switch OFF Approx. 0 Approx. 0

MGI035A

Pin

No.Item ConditionVoltage

value [V]In case of high resistance such as single strand [V] *

1 LampSwitch ON Approx. 0 Battery voltage (Inoperative lamp)

Switch OFF Battery voltage Battery voltage

2SwitchSwitch ON Approx. 0 Higher than 0 Approx. 4 (Example)

Switch OFF Approx. 5 Approx. 5

Page 3508 of 5621

TOW TRUCK TOWING

GI-45

C

D

E

F

G

H

I

J

K

L

MB

GI

Revision: 2006 January2006 M35/M45

AWD MODELS

INFINITI recommends that a dolly be used as illustrated when towing AWD models.

CAUTION:

Never tow AWD models with any of the wheels on the ground as this may cause serious and expen-

sive damage to the powertrain.

Vehicle Recovery (Freeing a Stuck Vehicle) NAS00082

FRONT

Securely install the vehicle recovery hook stored with jacking tools.

Make sure that the hook is properly secured in the stored place after

use.

WAR NING :

Stand clear of a stuck vehicle.

Do not spin your tires at high speed. This could cause them

to explode and result in serious injury. Parts of your vehicle

could also overheat and be damaged.

CAUTION:

Tow chains or cables must be attached only to the vehicle

recovery hooks or main structural members of the vehicle.

Otherwise, the vehicle body will be damaged.

Do not use the vehicle tie downs to free a vehicle stuck in sand, snow, mud, etc. Never tow the

vehicle using the vehicle tie downs or recovery hooks.

Always pull the cable straight out from the front of the vehicle. Never pull on the hook at an angle.

Pulling devices should be routed so they do not touch any part of the suspension, steering, brake

or cooling systems.

Pulling devices such as ropes or canvas straps are not recommended for use in vehicle towing or

recovery.

REAR

WAR NING :

Rear hook is not available.

PIIB6403E

PIIB3130E

Page 3512 of 5621

IDENTIFICATION INFORMATION

GI-49

C

D

E

F

G

H

I

J

K

L

MB

GI

Revision: 2006 January2006 M35/M45

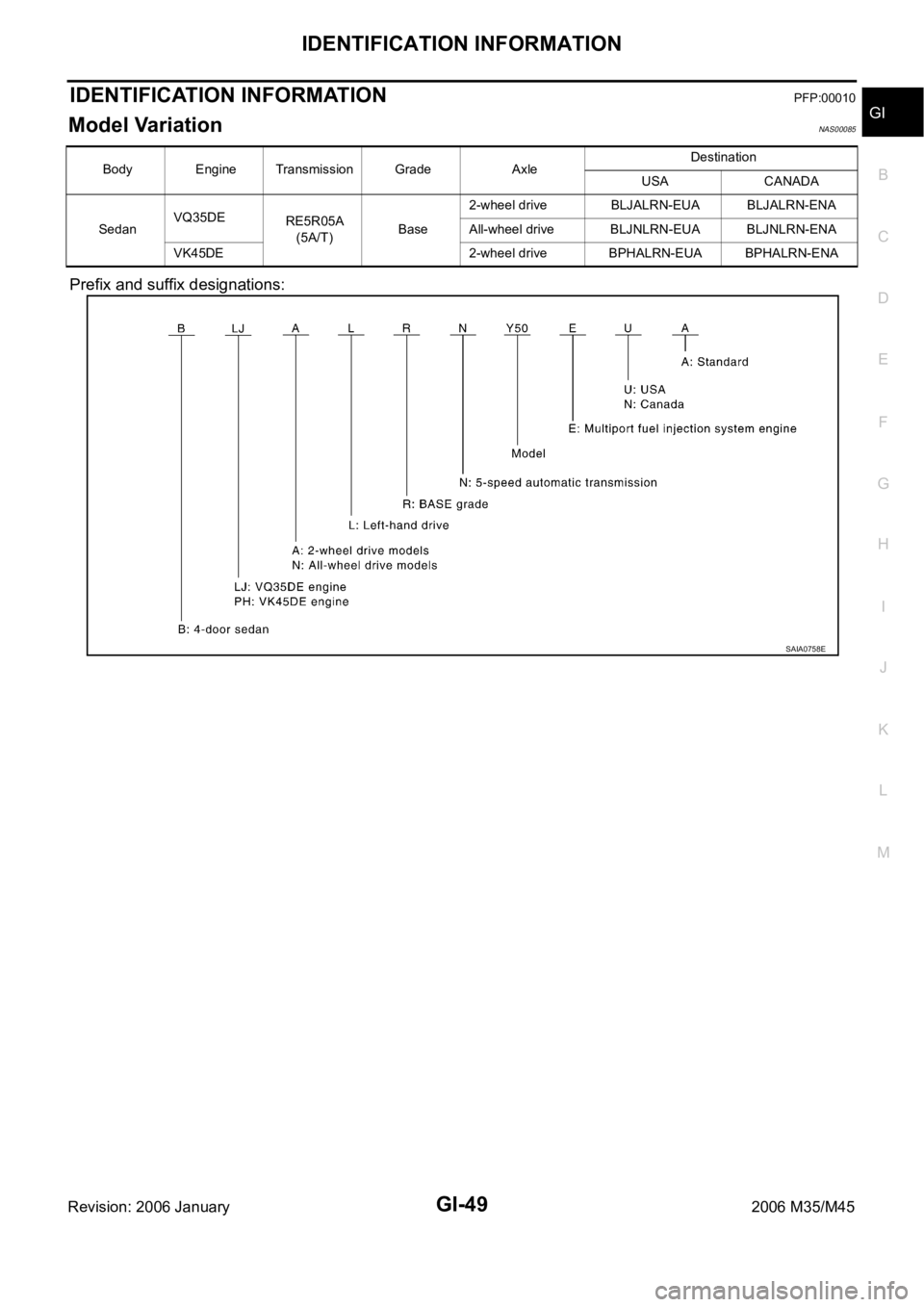

IDENTIFICATION INFORMATIONPFP:00010

Model Variation NAS00085

Prefix and suffix designations:

Body Engine Transmission Grade AxleDestination

USA CANADA

SedanVQ35DE

RE5R05A

(5A/T)Base2-wheel drive BLJALRN-EUA BLJALRN-ENA

All-wheel drive BLJNLRN-EUA BLJNLRN-ENA

VK45DE 2-wheel drive BPHALRN-EUA BPHALRN-ENA

SAIA0758E