stall INFINITI M35 2006 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 90 of 5621

PREPARATION

AT-11

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Commercial Service ToolsNCS001JH

To o l n a m eDescription

Power toolLoosening bolts and nuts

Drift

a: 22 mm (0.87 in) dia.Installing manual shaft oil seals

Drift

a: 64 mm (2.52 in) dia.Installing rear oil seal (AWD models)

PBIC0190E

NT083

SCIA5338E

Page 91 of 5621

AT-12

A/T FLUID

Revision: 2006 January2006 M35/M45

A/T FLUIDPFP:KLE40

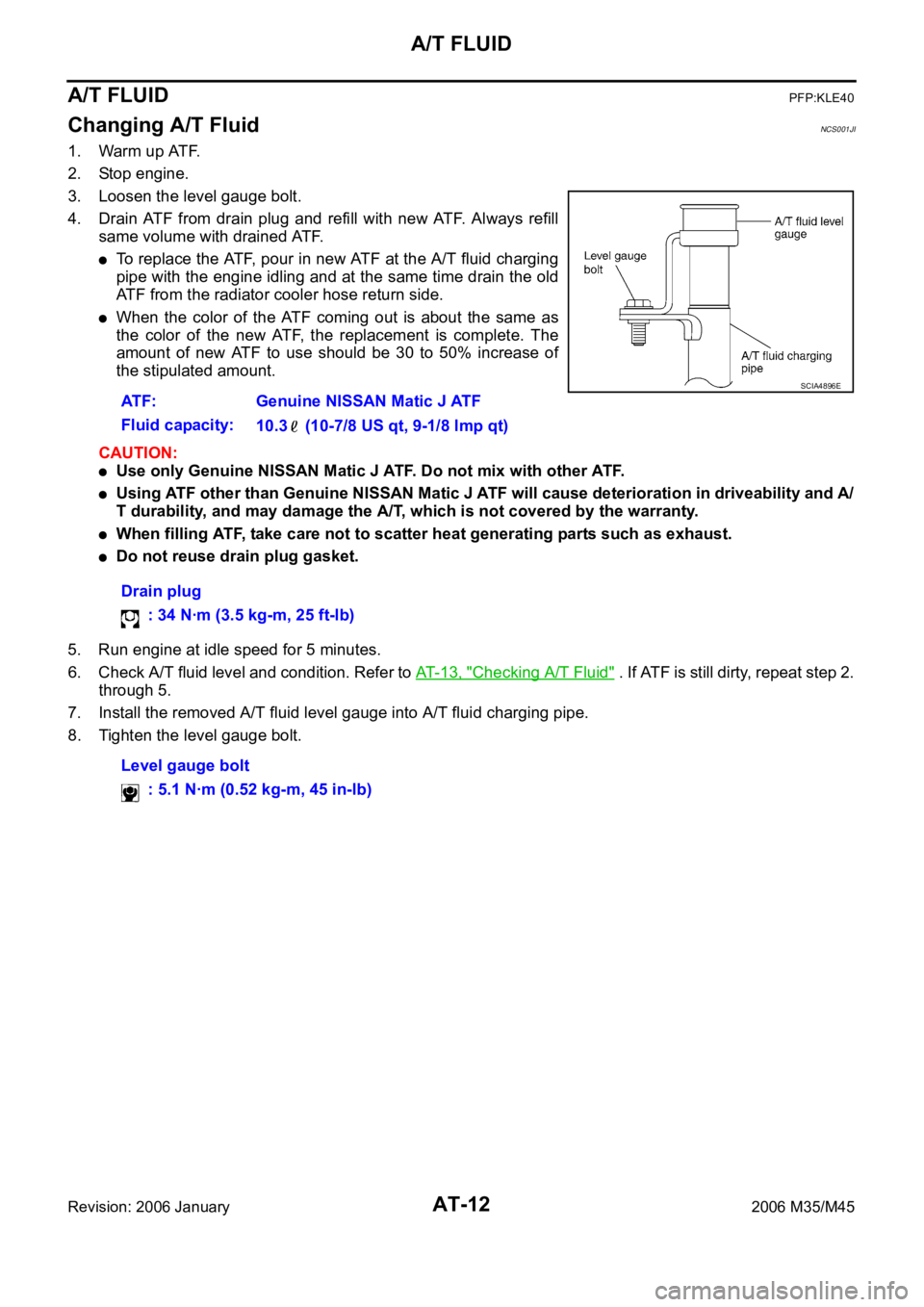

Changing A/T FluidNCS001JI

1. Warm up ATF.

2. Stop engine.

3. Loosen the level gauge bolt.

4. Drain ATF from drain plug and refill with new ATF. Always refill

same volume with drained ATF.

To replace the ATF, pour in new ATF at the A/T fluid charging

pipe with the engine idling and at the same time drain the old

ATF from the radiator cooler hose return side.

When the color of the ATF coming out is about the same as

the color of the new ATF, the replacement is complete. The

amount of new ATF to use should be 30 to 50% increase of

the stipulated amount.

CAUTION:

Use only Genuine NISSAN Matic J ATF. Do not mix with other ATF.

Using ATF other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and A/

T durability, and may damage the A/T, which is not covered by the warranty.

When filling ATF, take care not to scatter heat generating parts such as exhaust.

Do not reuse drain plug gasket.

5. Run engine at idle speed for 5 minutes.

6. Check A/T fluid level and condition. Refer to AT- 1 3 , "

Checking A/T Fluid" . If ATF is still dirty, repeat step 2.

through 5.

7. Install the removed A/T fluid level gauge into A/T fluid charging pipe.

8. Tighten the level gauge bolt.ATF: Genuine NISSAN Matic J ATF

Fluid capacity:

10.3 (10-7/8 US qt, 9-1/8 lmp qt)

Drain plug

: 34 Nꞏm (3.5 kg-m, 25 ft-lb)

Level gauge bolt

: 5.1 Nꞏm (0.52 kg-m, 45 in-lb)

SCIA4896E

Page 93 of 5621

AT-14

A/T FLUID

Revision: 2006 January2006 M35/M45

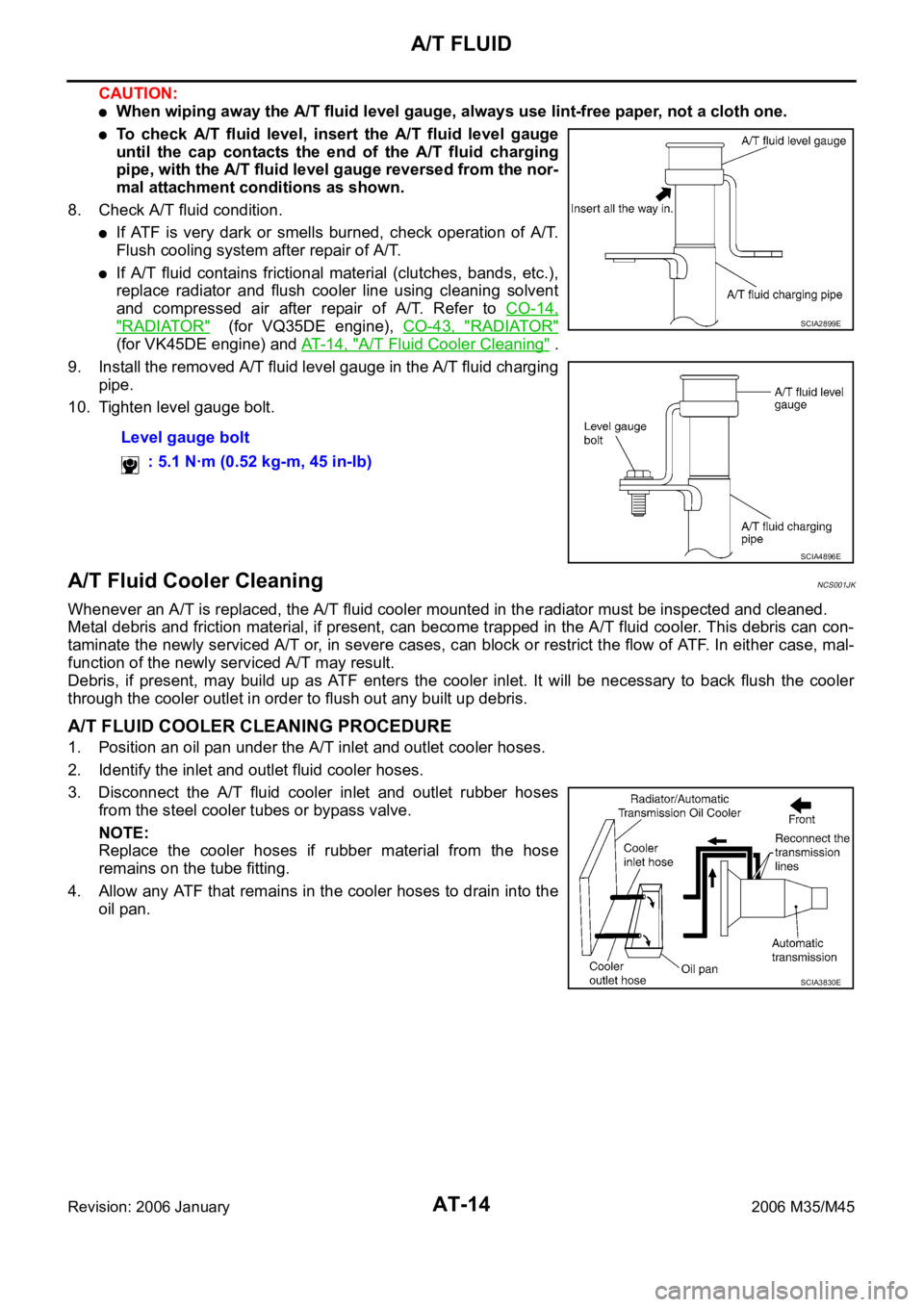

CAUTION:

When wiping away the A/T fluid level gauge, always use lint-free paper, not a cloth one.

To check A/T fluid level, insert the A/T fluid level gauge

until the cap contacts the end of the A/T fluid charging

pipe, with the A/T fluid level gauge reversed from the nor-

mal attachment conditions as shown.

8. Check A/T fluid condition.

If ATF is very dark or smells burned, check operation of A/T.

Flush cooling system after repair of A/T.

If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to CO-14,

"RADIATOR" (for VQ35DE engine), CO-43, "RADIATOR"

(for VK45DE engine) and AT- 1 4 , "A/T Fluid Cooler Cleaning" .

9. Install the removed A/T fluid level gauge in the A/T fluid charging

pipe.

10. Tighten level gauge bolt.

A/T Fluid Cooler CleaningNCS001JK

Whenever an A/T is replaced, the A/T fluid cooler mounted in the radiator must be inspected and cleaned.

Metal debris and friction material, if present, can become trapped in the A/T fluid cooler. This debris can con-

taminate the newly serviced A/T or, in severe cases, can block or restrict the flow of ATF. In either case, mal-

function of the newly serviced A/T may result.

Debris, if present, may build up as ATF enters the cooler inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

A/T FLUID COOLER CLEANING PROCEDURE

1. Position an oil pan under the A/T inlet and outlet cooler hoses.

2. Identify the inlet and outlet fluid cooler hoses.

3. Disconnect the A/T fluid cooler inlet and outlet rubber hoses

from the steel cooler tubes or bypass valve.

NOTE:

Replace the cooler hoses if rubber material from the hose

remains on the tube fitting.

4. Allow any ATF that remains in the cooler hoses to drain into the

oil pan.Level gauge bolt

: 5.1 Nꞏm (0.52 kg-m, 45 in-lb)

SCIA2899E

SCIA4896E

SCIA3830E

Page 123 of 5621

AT-44

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSISPFP:00004

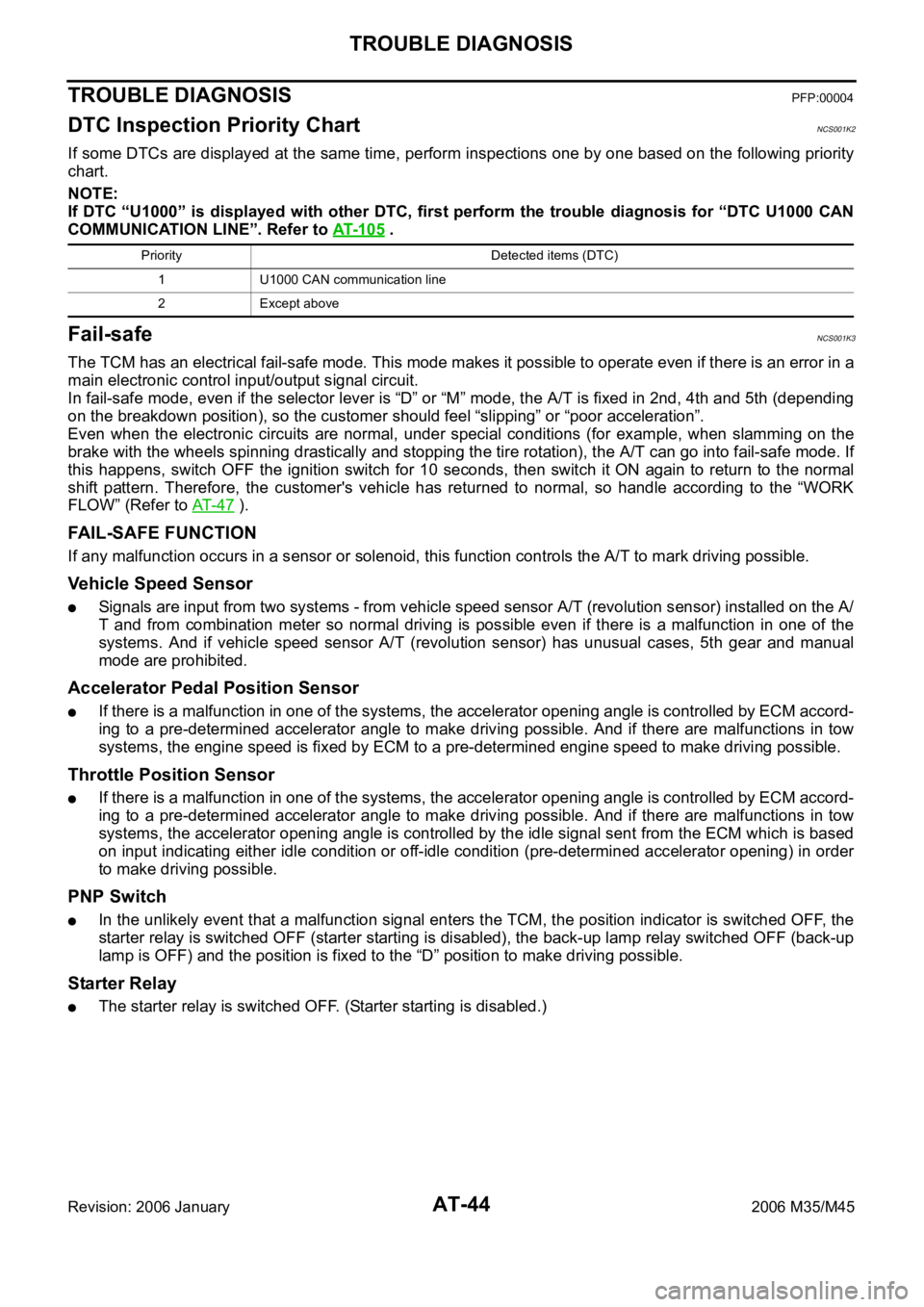

DTC Inspection Priority ChartNCS001K2

If some DTCs are displayed at the same time, perform inspections one by one based on the following priority

chart.

NOTE:

If DTC “U1000” is displayed with other DTC, first perform the trouble diagnosis for “DTC U1000 CAN

COMMUNICATION LINE”. Refer to AT- 1 0 5

.

Fail-safeNCS001K3

The TCM has an electrical fail-safe mode. This mode makes it possible to operate even if there is an error in a

main electronic control input/output signal circuit.

In fail-safe mode, even if the selector lever is “D” or “M” mode, the A/T is fixed in 2nd, 4th and 5th (depending

on the breakdown position), so the customer should feel “slipping” or “poor acceleration”.

Even when the electronic circuits are normal, under special conditions (for example, when slamming on the

brake with the wheels spinning drastically and stopping the tire rotation), the A/T can go into fail-safe mode. If

this happens, switch OFF the ignition switch for 10 seconds, then switch it ON again to return to the normal

shift pattern. Therefore, the customer's vehicle has returned to normal, so handle according to the “WORK

FLOW” (Refer to AT- 4 7

).

FAIL-SAFE FUNCTION

If any malfunction occurs in a sensor or solenoid, this function controls the A/T to mark driving possible.

Vehicle Speed Sensor

Signals are input from two systems - from vehicle speed sensor A/T (revolution sensor) installed on the A/

T and from combination meter so normal driving is possible even if there is a malfunction in one of the

systems. And if vehicle speed sensor A/T (revolution sensor) has unusual cases, 5th gear and manual

mode are prohibited.

Accelerator Pedal Position Sensor

If there is a malfunction in one of the systems, the accelerator opening angle is controlled by ECM accord-

ing to a pre-determined accelerator angle to make driving possible. And if there are malfunctions in tow

systems, the engine speed is fixed by ECM to a pre-determined engine speed to make driving possible.

Throttle Position Sensor

If there is a malfunction in one of the systems, the accelerator opening angle is controlled by ECM accord-

ing to a pre-determined accelerator angle to make driving possible. And if there are malfunctions in tow

systems, the accelerator opening angle is controlled by the idle signal sent from the ECM which is based

on input indicating either idle condition or off-idle condition (pre-determined accelerator opening) in order

to make driving possible.

PNP Switch

In the unlikely event that a malfunction signal enters the TCM, the position indicator is switched OFF, the

starter relay is switched OFF (starter starting is disabled), the back-up lamp relay switched OFF (back-up

lamp is OFF) and the position is fixed to the “D” position to make driving possible.

Starter Relay

The starter relay is switched OFF. (Starter starting is disabled.)

Priority Detected items (DTC)

1 U1000 CAN communication line

2 Except above

Page 127 of 5621

AT-48

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DIAGNOSTIC WORKSHEET

Information from Customer

KEY POINTS

WHAT..... Vehicle and A/T model

WHEN..... Date, Frequencies

WHERE..... Road conditions

HOW..... Operating conditions, Symptoms

Diagnostic Worksheet Chart

Customer name MR/MS Model and Year VIN

Trans. Model Engine Mileage

Malfunction Date Manuf. Date In Service Date

Frequency

Continuous Intermittent ( times a day)

Symptoms

Vehicle does not move. ( Any position Particular position)

No up-shift ( 1st 2nd 2nd 3rd 3rd 4th 4th 5th)

No down-shift ( 5th 4th 4th 3rd 3rd 2nd 2nd 1st)

Lock-up malfunction

Shift point too high or too low.

Shift shock or slip ( N D N R Lock-up Any drive position)

Noise or vibration

No kick down

No pattern select

Others

()

A/T CHECK indicator lamp

Continuously lit Not lit

Malfunction indicator lamp (MIL)

Continuously lit Not lit

1 Read the item on cautions concerning fail-safe and understand the customer's complaint.AT- 4 4

2

A/T fluid inspectionAT- 5 3

Leak (Repair leak location.)

State

Amount

3

Stall test and line pressure testAT- 5 3, AT-

55 Stall test

Torque converter one-way clutch

Front brake

High and low reverse clutch

Low coast brake

Forward brake

Reverse brake

Forward one-way clutch

1st one-way clutch

3rd one-way clutch

Engine

Line pressure low

Except for input clutch and direct

clutch, clutches and brakes OK

Line pressure inspection - Suspected part:

Page 132 of 5621

TROUBLE DIAGNOSIS

AT-53

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

Inspections before Trouble DiagnosisNCS001K7

A/T FLUID CHECK

A/T Fluid Leakage and A/T Fluid Level Check

Inspect for A/T fluid leakage and check the A/T fluid level. Refer to AT- 1 3 , "Checking A/T Fluid" .

A/T Fluid Condition Check

Inspect the A/T fluid condition.

STALL TEST

Stall Test Procedure

1. Inspect the amount of engine oil. Replenish the engine oil if necessary.

2. Drive for about 10 minutes to warm up the vehicle so that the A/

T fluid temperature is 50 to 80

C (122 to 176F). Inspect the

amount of ATF. Replenish if necessary.

3. Securely engage the parking brake so that the tires do not turn.

4. Engine start, apply foot brake, and place selector lever in “D”

position.

Fluid condition Conceivable Cause Required Operation

Varnished (viscous

varnish state)Clutch, brake

scorchedReplace the ATF and check the A/T

main unit and the vehicle for mal-

functions (wire harnesses, cooler

pipes, etc.)

Milky white or cloudy Water in the fluidReplace the ATF and check for

places where water is getting in.

Large amount of metal

powder mixed inUnusual wear of

sliding parts within

A/TReplace the ATF and check for

improper operation of the A/T.

SAT638A

SAT647B

SCIA7463E

SCIA6787E

Page 133 of 5621

AT-54

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

5. While holding down the foot brake, gradually press down the

accelerator pedal.

6. Quickly read off the stall speed, then quickly remove your foot

from the accelerator pedal.

CAUTION:

Do not hold down the accelerator pedal for more than 5 sec-

onds during this test.

7. Move the selector lever to the “N” position.

8. Cool down the ATF.

CAUTION:

Run the engine at idle for at least 1 minute.

9. Repeat steps 5 through 8 with selector lever in “R” position.

Judgement of Stall Test

O: Stall speed within standard value position

H: Stall speed higher than standard value

L: Stall speed lower than standard value

Stall test standard value positionStall speed

VQ35DE models: 2,650 - 2,950 rpm

VK45DE models: 2,260 - 2,560 rpm

SAT514G

SCIA6788E

Selector lever position

Possible location of malfunction

“D”, “M” “R”

Stall speed HO

Forward brake

Forward one-way clutch

1st one-way clutch

3rd one-way clutch

OH

Reverse brake

LL

Engine and torque converter one-way clutch

HH

Line pressure low

Does not shift-up “D” or “M” position 1 2 Slipping in 2nd, 3rd or 4th gear Direct clutch slippage

Does not shift-up “D” or “M” position 2

3 Slipping in 3rd, 4th or 5th gear High and low reverse clutch slippage

Does not shift-up “D” or “M” position 3

4 Slipping in 4th or 5th gear Input clutch slippage

Does not shift-up “D” or “M” position 4

5 Slipping in 5th gear Front brake slippage

Page 134 of 5621

TROUBLE DIAGNOSIS

AT-55

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

LINE PRESSURE TEST

Line Pressure Test Port

Line Pressure Test Procedure

1. Inspect the amount of engine oil and replenish if necessary.

2. Drive the car for about 10 minutes to warm it up so that the ATF reaches in range of 50 to 80

C (122 to

176

F), then inspect the amount of ATF and replenish if necessary.

NOTE:

The A/T fluid temperature rises in range of 50 to 80

C (122 to 176F) during 10 minutes of driving.

3. Remove the front propeller shaft from vehicle (with AWD models). Refer to PR-5, "

Removal and Installa-

tion" .

4. After warming up remove the oil pressure detection plug and

install the oil pressure gauge [ST2505S001(J-34301-C)].

CAUTION:

When using the oil pressure gauge, be sure to use the O-

ring attached to the oil pressure detection plug.

5. Securely engage the parking brake so that the tires do not turn.

6. Start the engine, then measure the line pressure at both idle and

the stall speed.

CAUTION:

Keep the brake pedal pressed all the way down during

measurement.

When measuring the line pressure at the stall speed,

refer to AT- 5 3 , "

STALL TEST" .

7. After the measurements are complete, install the oil pressure

detection plug and tighten to the specified torque.

SCIA2187E

SCIA5309E

SCIA7463E

: 7.3 Nꞏm (0.74 kg-m, 65 in-lb)SAT493G

Page 135 of 5621

AT-56

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

CAUTION:

Do not reuse O-ring.

Apply ATF to O-ring.

Line Pressure

Judgement of Line Pressure Test

Engine speedLine pressure [kPa (kg/cm

2 , psi)]

“R” position “D”, “M” positions

At idle speed 425 - 465 (4.3 - 4.7, 62 - 67) 379 - 428 (3.9 - 4.4, 55 - 62)

At stall speed 1,605 - 1,950 (16.4 - 19.9, 233 - 283) 1,310 - 1,500 (13.4 - 15.3, 190 - 218)

Judgement Possible cause

Idle speedLow for all positions

(“P”, “R”, “N”, “D”, “M”)Possible causes include malfunctions in the pressure supply system and low oil pump out-

put.

For example

Oil pump wear

Pressure regulator valve or plug sticking or spring fatigue

Oil strainer oil pump pressure regulator valve passage oil leak

Engine idle speed too low

Only low for a specific

positionPossible causes include an oil pressure leak in a passage or device related to the position

after the pressure is distributed by the manual valve.

HighPossible causes include a sensor malfunction or malfunction in the line pressure adjustment

function.

For example

Accelerator pedal position signal malfunction

A/T fluid temperature sensor malfunction

Line pressure solenoid malfunction (sticking in OFF state, filter clog, cut line)

Pressure regulator valve or plug sticking

Stall speedOil pressure does not

rise higher than the oil

pressure for idle.Possible causes include a sensor malfunction or malfunction in the pressure adjustment

function.

For example

Accelerator pedal position signal malfunction

TCM breakdown

Line pressure solenoid malfunction (shorting, sticking in ON state)

Pressure regulator valve or plug sticking

Pilot valve sticking or pilot filter clogged

The pressure rises, but

does not enter the stan-

dard position.Possible causes include malfunctions in the pressure supply system and malfunction in the

pressure adjustment function.

For example

Accelerator pedal position signal malfunction

Line pressure solenoid malfunction (sticking, filter clog)

Pressure regulator valve or plug sticking

Pilot valve sticking or pilot filter clogged

Only low for a specific

positionPossible causes include an oil pressure leak in a passage or device related to the position

after the pressure is distributed by the manual valve.

Page 167 of 5621

AT-88

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

68

OthersEngine does not start

in “N” or “P” position.

Refer to AT-190, "Engine Cannot Be

Started in “P” or “N”

Position" .ON vehicle1. Push-button ignition switch and starterPG-3

, SC-

10

2. Control linkage adjustmentAT- 2 2 7

3. PNP switchAT- 11 3

69Engine starts in posi-

tions other than “N” or

“P”.ON vehicle1. Push-button ignition switch and starterPG-3

, SC-

10

2. Control linkage adjustmentAT- 2 2 7

3. PNP switchAT- 11 3

70 Engine stall.ON vehicle1. A/T fluid level and stateAT- 5 3

2. Engine speed signalAT- 1 2 4

3. Turbine revolution sensorAT- 11 7

4. Torque converter clutch solenoid valveAT- 1 2 6

5. CAN communication lineAT- 1 0 5

6. Control valve with TCMAT- 2 3 6

OFF vehicle 7. Torque converterAT- 2 9 8

71Engine stalls when

selector lever shifted

“N”

“D”or “R”.ON vehicle1. A/T fluid level and stateAT- 5 3

2. Engine speed signalAT- 1 2 4

3. Turbine revolution sensorAT- 11 7

4. Torque converter clutch solenoid valveAT- 1 2 6

5. CAN communication lineAT- 1 0 5

6. Control valve with TCMAT- 2 3 6

OFF vehicle 7. Torque converterAT- 2 9 8

72Engine speed does

not return to idle.

Refer to AT-212,

"Engine Speed Does

Not Return to Idle" .ON vehicle1. A/T fluid level and stateAT- 5 3

2. ATF pressure switch 5 and direct clutch solenoid valveAT- 1 7 6,

AT- 1 5 5

3. ATF pressure switch 1 and front brake solenoid valveAT- 1 7 2

,

AT- 1 5 1

4. Accelerator pedal position sensorAT- 1 3 2

5. Vehicle speed sensorꞏA/T and vehicle speed sensorꞏMTRAT- 11 9,

AT- 1 4 0

6. CAN communication lineAT- 1 0 5

7. Control valve with TCMAT- 2 3 6

OFF vehicle8. Front brake (brake band)AT- 2 9 89. Direct clutchAT- 3 3 7

No. Item Symptom Condition Diagnostic ItemReference

page