brake rotor INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4 of 5621

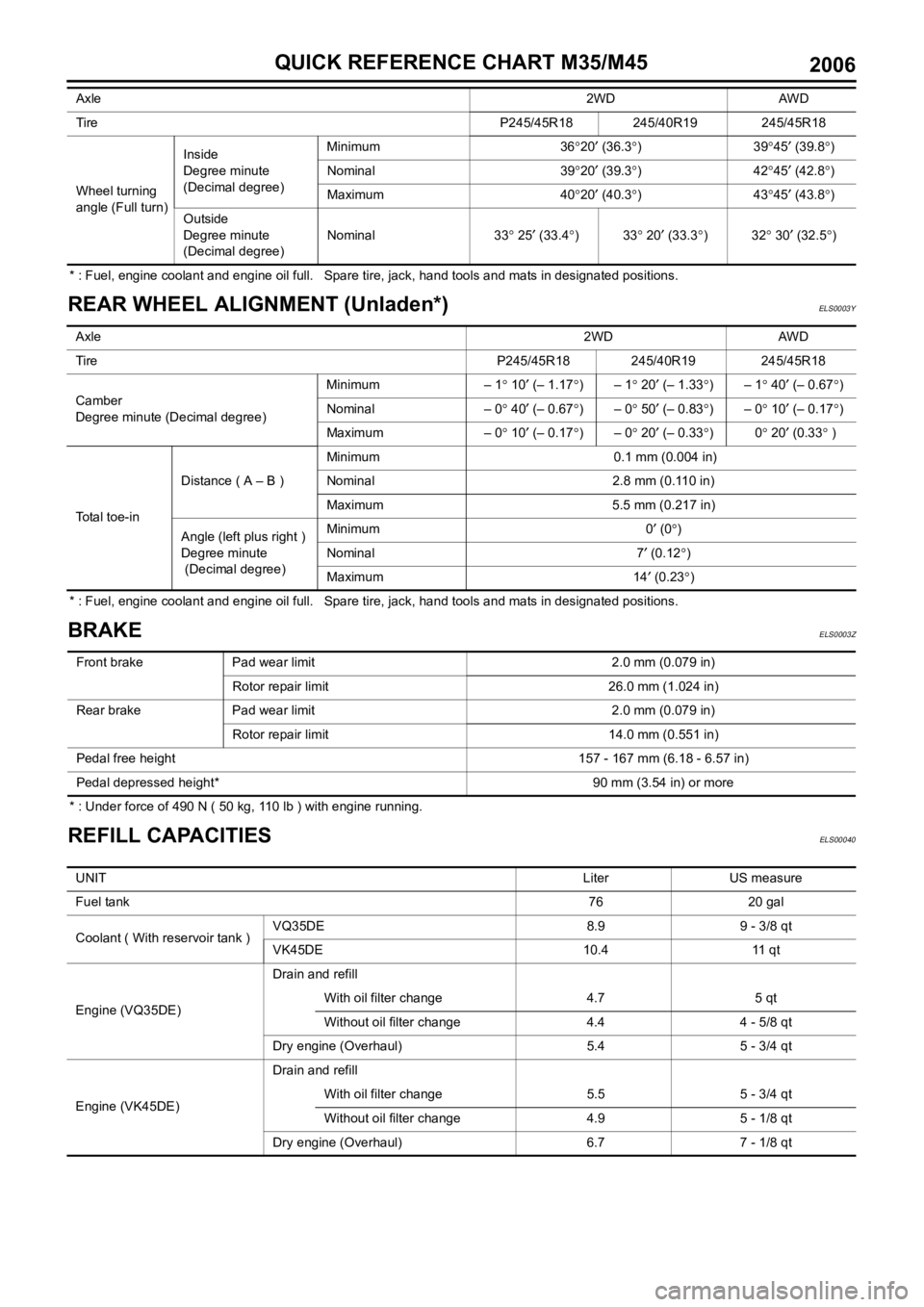

QUICK REFERENCE CHART M35/M45

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

REAR WHEEL ALIGNMENT (Unladen*)ELS0003Y

* : Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

BRAKEELS0003Z

* : Under force of 490 N ( 50 kg, 110 lb ) with engine running.

REFILL CAPACITIESELS00040

Wheel turning

angle (Full turn)Inside

Degree minute

(Decimal degree)Minimum 36

20 (36.3)3945 (39.8)

Nominal 39

20 (39.3)4245 (42.8)

Maximum 40

20 (40.3)4345 (43.8)

Outside

Degree minute

(Decimal degree)Nominal 33

25 (33.4)33 20 (33.3)32 30 (32.5) Axle2WD AWD

Tire P245/45R18 245/40R19 245/45R18

Axle2WD AWD

Tire P245/45R18 245/40R19 245/45R18

Camber

Degree minute (Decimal degree)Minimum – 1

10 (– 1.17)– 1 20 (– 1.33)– 1 40 (– 0.67)

Nominal – 0

40 (– 0.67)– 0 50 (– 0.83)– 0 10 (– 0.17)

Maximum – 0

10 (– 0.17)– 0 20 (– 0.33) 0 20 (0.33 )

Total toe-inDistance ( A – B )Minimum 0.1 mm (0.004 in)

Nominal 2.8 mm (0.110 in)

Maximum 5.5 mm (0.217 in)

Angle (left plus right )

Degree minute

(Decimal degree)Minimum 0

(0)

Nominal 7

(0.12)

Maximum 14

(0.23)

Front brake Pad wear limit 2.0 mm (0.079 in)

Rotor repair limit 26.0 mm (1.024 in)

Rear brake Pad wear limit 2.0 mm (0.079 in)

Rotor repair limit 14.0 mm (0.551 in)

Pedal free height 157 - 167 mm (6.18 - 6.57 in)

Pedal depressed height* 90 mm (3.54 in) or more

UNITLiter US measure

Fuel tank76 20 gal

Coolant ( With reservoir tank )VQ35DE 8.9 9 - 3/8 qt

VK45DE 10.4 11 qt

Engine (VQ35DE)Drain and refill

With oil filter change 4.7 5 qt

Without oil filter change 4.4 4 - 5/8 qt

Dry engine (Overhaul) 5.4 5 - 3/4 qt

Engine (VK45DE)Drain and refill

With oil filter change 5.5 5 - 3/4 qt

Without oil filter change 4.9 5 - 1/8 qt

Dry engine (Overhaul) 6.7 7 - 1/8 qt

2006

Page 1276 of 5621

BR-1

BRAKE SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTION BR

A

B

BR

Revision: 2006 January2006 M35/M45

BRAKE SYSTEM

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover ..... 3

Precautions for Brake System .................................. 3

PREPARATION ........................................................... 4

Commercial Service Tools ........................................ 4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

BRAKE PEDAL .......................................................... 6

Inspection and Adjustment ....................................... 6

ADJUSTMENT ...................................................... 7

Removal and Installation .......................................... 7

COMPONENTS .................................................... 7

REMOVAL ........................................................

..... 8

INSPECTION AFTER REMOVAL ......................... 8

INSTALLATION ..................................................... 9

BRAKE FLUID .......................................................... 10

On-Board Inspection .............................................. 10

CHECKING BRAKE FLUID LEVEL .................... 10

Checking Brake Line .............................................. 10

Drain and Refill ....................................................... 10

Bleeding Brake System ........................................... 11

BRAKE TUBE AND HOSE ....................................... 12

Hydraulic Circuit ..................................................... 12

Removal and Installation of Front Brake Tube and

Brake Hose ............................................................ 13

REMOVAL ........................................................

... 13

INSTALLATION ................................................... 13

Removal and Installation of Rear Brake Tube and

Brake Hose ............................................................ 13

REMOVAL ........................................................

... 13

INSTALLATION ................................................... 14

Inspection after Installation .................................... 14

BRAKE MASTER CYLINDER .................................. 15

On-Board Inspection .............................................. 15

LEAK INSPECTION ............................................ 15

Removal and Installation ........................................ 15REMOVAL ........................................................

... 15

INSTALLATION ................................................... 15

Disassembly and Assembly .................................... 16

COMPONENTS ................................................... 16

Disassembly and Assembly .................................... 16

DISASSEMBLY ................................................... 16

ASSEMBLY ......................................................... 17

BRAKE BOOSTER ................................................... 18

On-Board Inspection and Service ........................... 18

OPERATION CHECK .......................................... 18

AIR TIGHT CHECK ............................................. 18

Removal and Installation ........................................ 19

COMPONENTS ................................................... 19

REMOVAL ........................................................

... 19

INSTALLATION ................................................... 19

VACUUM LINES ....................................................... 21

Components ........................................................... 21

Removal and Installation ........................................ 22

Inspection ............................................................... 22

VISUAL INSPECTION ......................................... 22

CHECK VALVE INSPECTION ............................. 22

FRONT DISC BRAKE ............................................... 23

On-Board Inspection ............................................

... 23

PAD WEAR INSPECTION ................................... 23

Components ........................................................... 23

Removal and Installation of Brake Pad .................. 24

REMOVAL ........................................................

... 24

INSTALLATION ................................................... 24

Removal and Installation of Brake Caliper Assembly

... 25

REMOVAL ........................................................

... 25

INSTALLATION ................................................... 25

Disassembly and Assembly of Brake Caliper

Assembly ................................................................ 26

DISASSEMBLY ................................................... 26

INSPECTION AFTER DISASSEMBLY ................ 26

ASSEMBLY ......................................................... 27

DISC ROTOR INSPECTION ............................... 28

BRAKE BURNISHING PROCEDURE ................. 28

REAR DISC BRAKE ................................................. 29

Page 1277 of 5621

BR-2Revision: 2006 January2006 M35/M45 On-Board Inspection ............................................ ... 29

PAD WEAR INSPECTION ................................... 29

Components ........................................................... 29

Removal and Installation of Brake Pad ................... 30

REMOVAL ........................................................

... 30

INSTALLATION .................................................... 30

Removal and Installation of Brake Caliper Assembly

... 31

REMOVAL ........................................................

... 31

INSTALLATION .................................................... 31

Disassembly and Assembly of Brake Caliper Assembly ................................................................ 32

DISASSEMBLY .................................................... 32

INSPECTION AFTER DISASSEMBLY ................ 32

ASSEMBLY .......................................................... 33

DISC ROTOR INSPECTION ............................... 34

BRAKE BURNISHING PROCEDURE ................. 34

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 35

General Specifications ......................................... ... 35

Brake Pedal ............................................................ 35

Brake Booster ......................................................... 35

Check Valve ............................................................ 35

Front Disc Brake ..................................................... 35

Rear Disc Brake ...................................................... 36

Page 1278 of 5621

PRECAUTIONS

BR-3

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

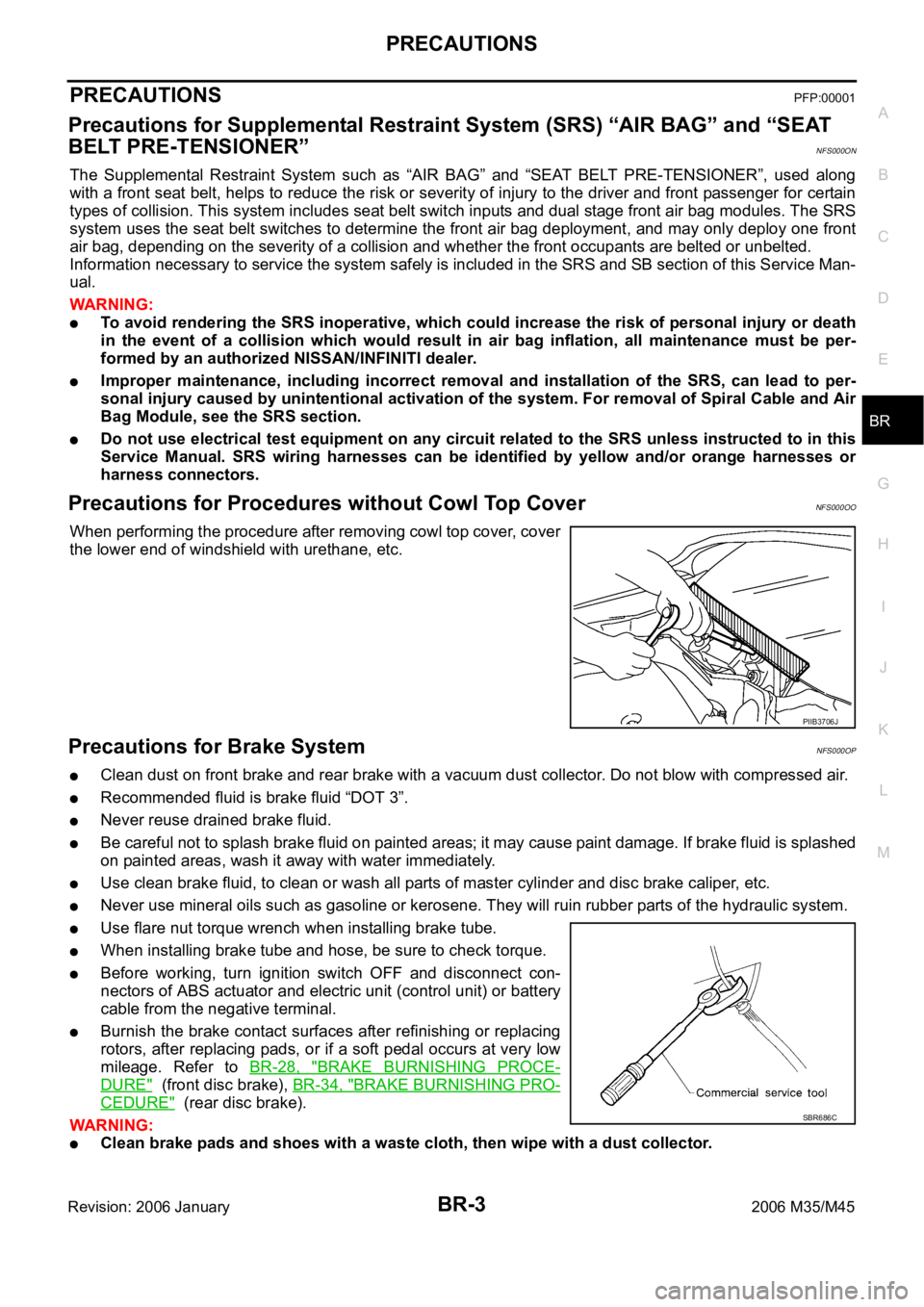

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NFS000ON

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Procedures without Cowl Top CoverNFS000OO

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions for Brake SystemNFS000OP

Clean dust on front brake and rear brake with a vacuum dust collector. Do not blow with compressed air.

Recommended fluid is brake fluid “DOT 3”.

Never reuse drained brake fluid.

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is splashed

on painted areas, wash it away with water immediately.

Use clean brake fluid, to clean or wash all parts of master cylinder and disc brake caliper, etc.

Never use mineral oils such as gasoline or kerosene. They will ruin rubber parts of the hydraulic system.

Use flare nut torque wrench when installing brake tube.

When installing brake tube and hose, be sure to check torque.

Before working, turn ignition switch OFF and disconnect con-

nectors of ABS actuator and electric unit (control unit) or battery

cable from the negative terminal.

Burnish the brake contact surfaces after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low

mileage. Refer to BR-28, "

BRAKE BURNISHING PROCE-

DURE" (front disc brake), BR-34, "BRAKE BURNISHING PRO-

CEDURE" (rear disc brake).

WAR NING :

Clean brake pads and shoes with a waste cloth, then wipe with a dust collector.

PIIB3706J

SBR686C

Page 1280 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

BR-5

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNFS000OR

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: Applicable Reference page

BR-23

, BR-29

BR-23

, BR-29

BR-23

, BR-29

—

—

BR-28

, BR-34

—

—

—

BR-28

, BR-34

—

NVH in PR section

NHV in RFD section

NVH in FAX, RAX and FSU, RSU section

NVH in WT section

NVH in WT section

NVH in RAX section

NVH in PS section

Possible cause and

SUSPECTED PARTS

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

Drum out of round

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

STEERING

Symptom BRAKENoiseShake

Shimmy, Judder

Page 1299 of 5621

BR-24

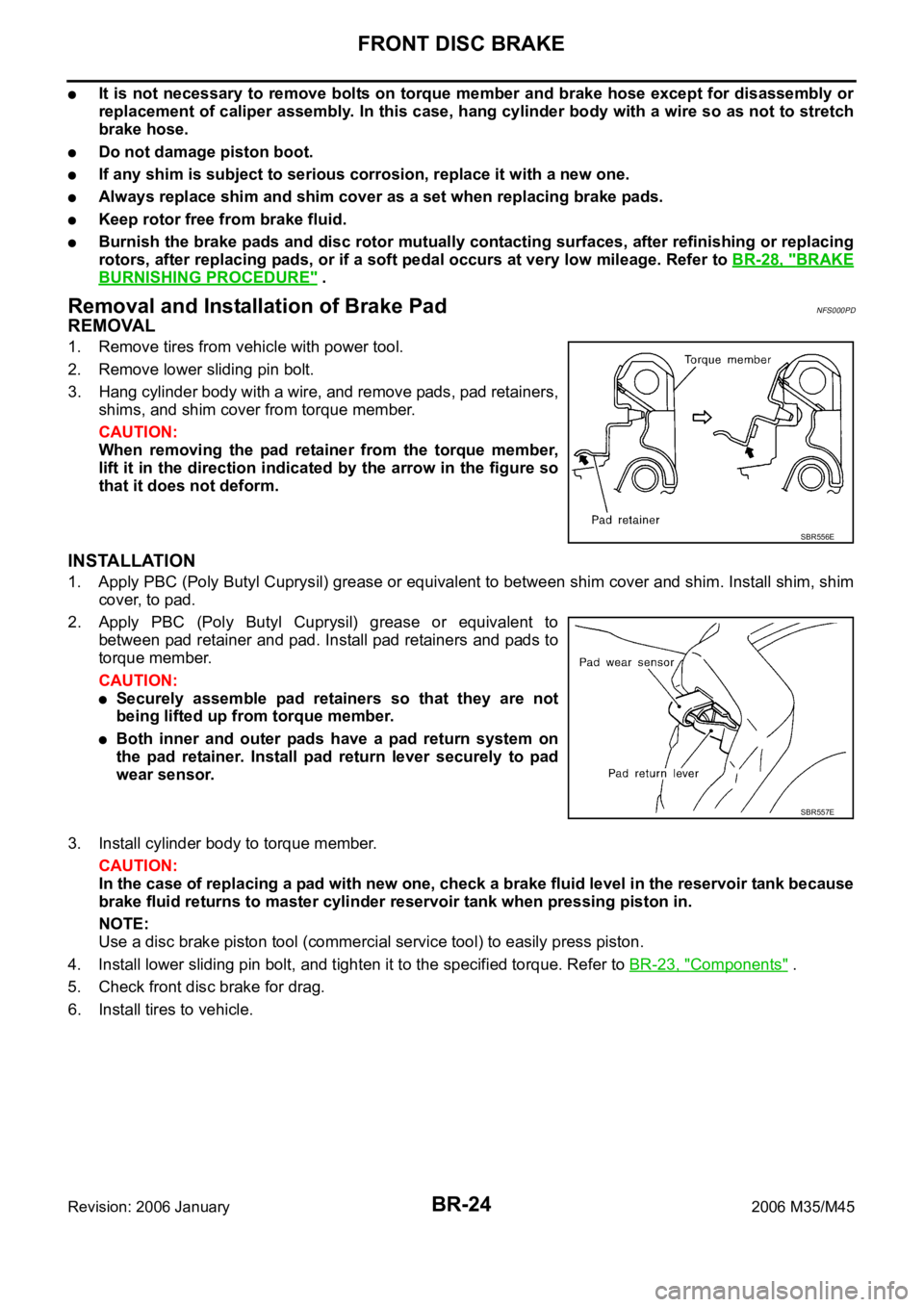

FRONT DISC BRAKE

Revision: 2006 January2006 M35/M45

It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

Do not damage piston boot.

If any shim is subject to serious corrosion, replace it with a new one.

Always replace shim and shim cover as a set when replacing brake pads.

Keep rotor free from brake fluid.

Burnish the brake pads and disc rotor mutually contacting surfaces, after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low mileage. Refer to BR-28, "

BRAKE

BURNISHING PROCEDURE" .

Removal and Installation of Brake PadNFS000PD

REMOVAL

1. Remove tires from vehicle with power tool.

2. Remove lower sliding pin bolt.

3. Hang cylinder body with a wire, and remove pads, pad retainers,

shims, and shim cover from torque member.

CAUTION:

When removing the pad retainer from the torque member,

lift it in the direction indicated by the arrow in the figure so

that it does not deform.

INSTALLATION

1. Apply PBC (Poly Butyl Cuprysil) grease or equivalent to between shim cover and shim. Install shim, shim

cover, to pad.

2. Apply PBC (Poly Butyl Cuprysil) grease or equivalent to

between pad retainer and pad. Install pad retainers and pads to

torque member.

CAUTION:

Securely assemble pad retainers so that they are not

being lifted up from torque member.

Both inner and outer pads have a pad return system on

the pad retainer. Install pad return lever securely to pad

wear sensor.

3. Install cylinder body to torque member.

CAUTION:

In the case of replacing a pad with new one, check a brake fluid level in the reservoir tank because

brake fluid returns to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool (commercial service tool) to easily press piston.

4. Install lower sliding pin bolt, and tighten it to the specified torque. Refer to BR-23, "

Components" .

5. Check front disc brake for drag.

6. Install tires to vehicle.

SBR556E

SBR557E

Page 1300 of 5621

FRONT DISC BRAKE

BR-25

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

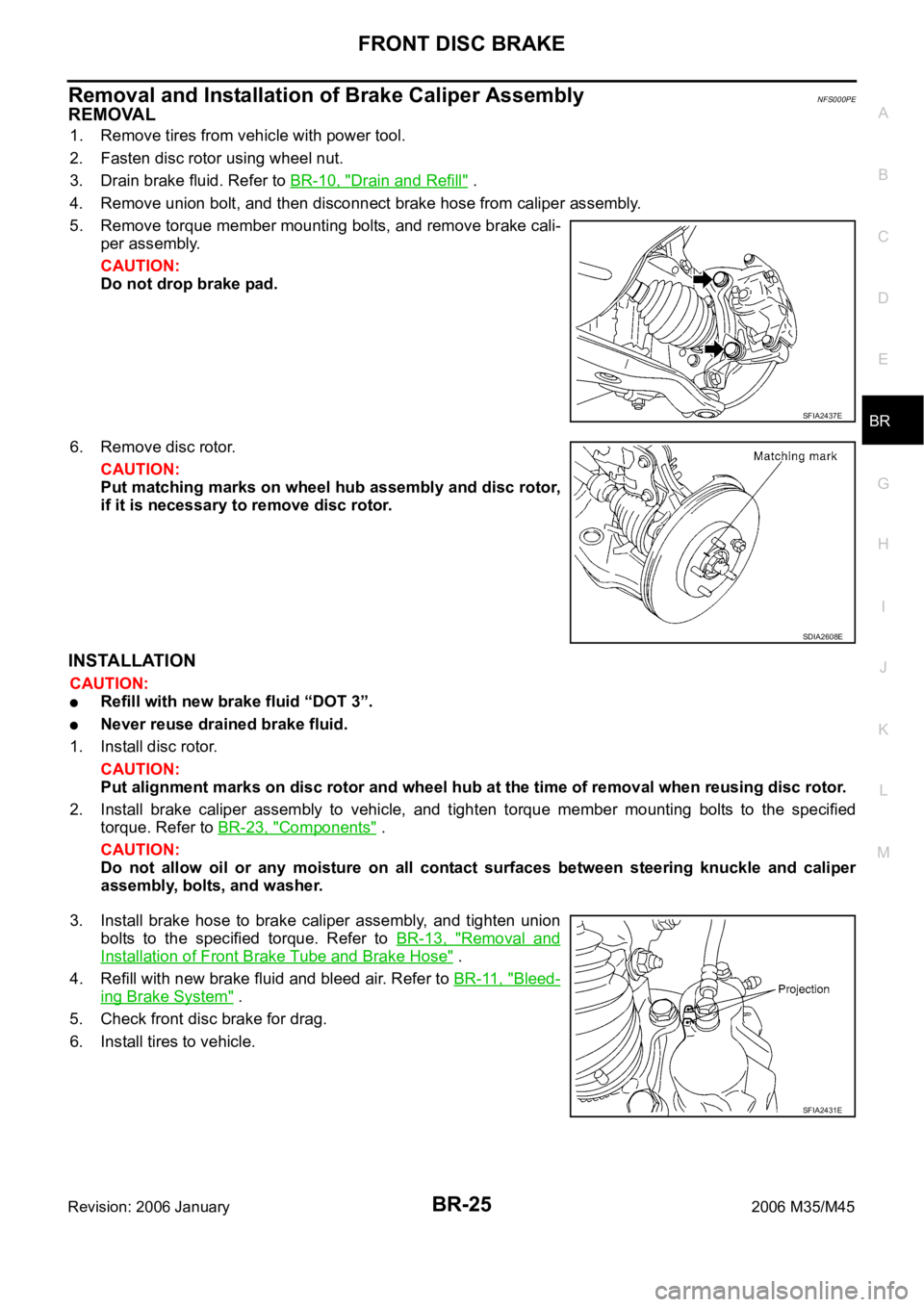

Removal and Installation of Brake Caliper AssemblyNFS000PE

REMOVAL

1. Remove tires from vehicle with power tool.

2. Fasten disc rotor using wheel nut.

3. Drain brake fluid. Refer to BR-10, "

Drain and Refill" .

4. Remove union bolt, and then disconnect brake hose from caliper assembly.

5. Remove torque member mounting bolts, and remove brake cali-

per assembly.

CAUTION:

Do not drop brake pad.

6. Remove disc rotor.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor,

if it is necessary to remove disc rotor.

INSTALLATION

CAUTION:

Refill with new brake fluid “DOT 3”.

Never reuse drained brake fluid.

1. Install disc rotor.

CAUTION:

Put alignment marks on disc rotor and wheel hub at the time of removal when reusing disc rotor.

2. Install brake caliper assembly to vehicle, and tighten torque member mounting bolts to the specified

torque. Refer to BR-23, "

Components" .

CAUTION:

Do not allow oil or any moisture on all contact surfaces between steering knuckle and caliper

assembly, bolts, and washer.

3. Install brake hose to brake caliper assembly, and tighten union

bolts to the specified torque. Refer to BR-13, "

Removal and

Installation of Front Brake Tube and Brake Hose" .

4. Refill with new brake fluid and bleed air. Refer to BR-11, "

Bleed-

ing Brake System" .

5. Check front disc brake for drag.

6. Install tires to vehicle.

SFIA2437E

SDIA2608E

SFIA2431E

Page 1303 of 5621

BR-28

FRONT DISC BRAKE

Revision: 2006 January2006 M35/M45

DISC ROTOR INSPECTION

Visual Inspection

Check surface of disc rotor for uneven wear, cracks, and serious damage. Replace if there are.

Runout Inspection

1. Fix disc rotor to wheel hub using wheel nuts (2 or more posi-

tions).

2. Inspect runout using a dial gauge. [Measured at 10 mm (0.39 in)

inside the disc edge.]

NOTE:

Before measuring, make sure that wheel bearing axial end play

is within the specification. Refer to FA X - 5 , "

WHEEL BEARING

INSPECTION" .

3. When runout exceeds limit value, displace mounting positions of

disc rotor by one hole. And then find a position of the minimum value for runout.

4. Replace or lathe disc rotor if runout is outside the specified value after performing the above operation.

(“MAD DL-8700”, “AMMCO 700 and 705” or equivalent.)

Thickness Inspection

Check thickness of the disc rotor using a micrometer. Replace disc

rotor if thickness is under the wear limit.

BRAKE BURNISHING PROCEDURE

Burnish contact surfaces between disc rotors and pads according to following procedure after refinishing or

replacing rotors, after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Be careful of vehicle speed because the brake does not operate easily until pad and disc rotor are

securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake for a few minutes to cool the brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted. Runout limit : 0.035 mm (0.0014 in)

(with it attached to the vehicle)

BRA0580D

Standard thickness : 28.0 mm (1.102 in)

Wear limit : 26.0 mm (1.024 in)

Thickness variation

(Measured at 8 positions): 0.015 mm (0.0006 in)

SBR020B

Page 1305 of 5621

BR-30

REAR DISC BRAKE

Revision: 2006 January2006 M35/M45

WAR NING :

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of air borne

particles or other materials.

CAUTION:

While removing cylinder body, do not depress brake pedal because piston will pop out.

It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of caliper assembly. In this case, hang cylinder body with a wire so as not to stretch

brake hose.

Do not damage piston boot.

If any shim is subject to serious corrosion, replace it with a new one.

Always replace shim and shim covers as a set when replacing brake pads.

Keep rotor free from brake fluid.

Burnish the brake pads and disc rotor mutually contacting surfaces after refinishing or replacing

rotors, after replacing pads, or if a soft pedal occurs at very low mileage. Refer to BR-34, "

BRAKE

BURNISHING PROCEDURE" .

Removal and Installation of Brake PadNFS000PI

REMOVAL

1. Remove tires from vehicle with power tool.

2. Remove lower sliding pin bolt.

3. Hang cylinder body with a wire, and remove pads, pad retainers, shims, and shim cover from torque mem-

ber.

CAUTION:

Deform pad retainer when removing pad retainer from torque member.

INSTALLATION

1. Apply PBC (Poly Butyl Cuprysil) grease or equivalent to between shim cover and shim. Install inner shim,

inner shim cover to inner pad, and outer shim, outer shim cover to outer pad.

2. Install pad retainers and pads to torque member.

3. Press in piston until pads can be installed, and then install cylin-

der body to torque member.

CAUTION:

In the case of replacing a pad with new one, check a brake

fluid level in the reservoir tank because brake fluid returns

to master cylinder reservoir tank when pressing piston in.

NOTE:

Use a disc brake piston tool (commercial service tool) to easily

press piston.

4. Install upper sliding pin bolt and tighten to the specified torque.

Refer to BR-29, "

Components" .

5. Check rear disc brake for drag.

6. Install tires to vehicle.

3: Apply polyglycol ether based lubricant.

: Apply brake fluid.

PFIA0273E

Page 1306 of 5621

REAR DISC BRAKE

BR-31

C

D

E

G

H

I

J

K

L

MA

B

BR

Revision: 2006 January2006 M35/M45

Removal and Installation of Brake Caliper AssemblyNFS000PJ

REMOVAL

1. Remove tires from vehicle with power tool.

2. Fasten disc rotor using wheel nut.

3. Drain brake fluid. Refer to BR-10, "

Drain and Refill" .

4. Remove union bolt and then disconnect brake hose from caliper

assembly.

5. Remove torque member mounting, bolts, and remove brake cal-

iper assembly.

CAUTION:

Do not drop brake pad.

6. Remove disc rotor.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor,

if it necessary to remove disc rotor.

INSTALLATION

CAUTION:

Refill with new brake fluid “DOT 3”.

Never reuse drained brake fluid.

1. Install disc rotor.

CAUTION:

Alignment marks of disc rotor and wheel hub put at the time of removal when reusing disc rotor.

2. Install brake caliper assembly vehicle, and tighten torque member mounting bolts to the specified torque.

CAUTION:

Before installing caliper assembly, wipe off oil and moisture on all mounting surfaces of rear axle

and caliper assembly and threads, bolts and washers.

3. Install L-shaped pin of brake hose and then tighten union bolt to

the specified torque. Refer to BR-13, "

Removal and Installation

of Rear Brake Tube and Brake Hose" .

4. Refill with new brake fluid and bleed air. Refer to BR-11, "

Bleed-

ing Brake System" .

5. Check rear disc brake for drag.

6. Install tires to vehicle.

SFIA2972E

SDIA2638E

SFIA2049E