tow INFINITI M35 2006 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1458 of 5621

COMBINATION METERS

DI-25

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

Fuel Gauge Pointer Fluctuates, Indicator Wrong Value or VariesNKS003UB

1. CHECK FUEL GAUGE FLUCTUATION

Test drive vehicle to see if gauge fluctuates only during driving or at the instant of stopping.

Does the indication value vary only during driving or at the instant of stopping?

YES >> The pointer fluctuation may be caused by fuel level change in the fuel tank. Condition is normal.

NO >> Ask the customer about the situation when the symptom occurs in detail, and perform the trouble

diagnosis.

Fuel Gauge Does Not Move to FULL PositionNKS003UC

1. QUESTION 1

Does it take a long time for the pointer to move to FULL position?

YES >> GO TO 2.

NO >> GO TO 3.

2. QUESTION 2

Was the vehicle fueled with the ignition switch ON?

YES >> Be sure to fuel the vehicle with the ignition switch OFF. Otherwise, it will take a long time to move

to FULL position because of the characteristic of the fuel gauge.

NO >> GO TO 3.

3. QUESTION 3

Is the vehicle parked on an incline?

YES >> Check the fuel level indication with vehicle on a level surface.

NO >> GO TO 4.

4. QUESTION 4

During driving, does the fuel gauge pointer move gradually toward EMPTY position?

YES >> Check the fuel level sensor unit. Refer to DI-26, "CHECK FUEL LEVEL SENSOR UNIT" .

NO >> The float arm may interfere or bind with any of the components in the fuel tank.

Page 1538 of 5621

COMPASS

DI-105

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: 2006 January2006 M35/M45

COMPASSPFP:24835

System DescriptionNKS003W3

This unit displays earth magnetism and heading direction of vehicle.

DIRECTION DISPLAY

Push “COMP” switch (1) when ignition switch is in “ON” or “START”

position. The direction will be displayed.

Pushing “COMP” switch (1) a second time will turn off the display (2).

NOTE:

Do not install the ski rack, antenna, etc. which are attached to

the vehicle by means of a magnet. They affect the operation of

the compass.

The compass may not indicate the correct compass point in tun-

nels or while driving up or down a steep hill. (The compass

returns to the correct compass point when the vehicle moves to

an area where the geomagnetism is stabilized.)

When cleaning the mirror, use a paper towel or similar material

dampened with glass cleaner. Do not spray glass cleaner directly on the mirror as that may cause the liq-

uid cleaner to enter the mirror housing.

Zone Variation Change ProcedureNKS003W4

The difference between magnetic north and geographical north is known as variance. In some areas, this dif-

ference can sometimes be great enough to cause false compass reading.

Follow these instructions to set the variance for the particular loca-

tion if this happens:

1. Push “COMP” switch for more than 3 seconds. The current zone

number will appear in the display.

2. Find the current location and variance one number on the zone

variation chart.

3. Push “COMP” switch until the new zone number appears in the

display. After stopping pushing the switch in, the display will

show a compass direction within a few seconds.

Correction Functions of the Compass DisplayNKS003W5

AUTOMATIC CORRECTION

The compass display is equipped with automatic correction function. If the direction is not shown correctly,

perform manual correction procedure set out below.

MANUAL CORRECTION PROCEDURE

When the display reads “C” or “CAL”, calibrate the compass by driving the vehicle in 3 complete circles at less

than 8 km/h (5 MPH).

The compass can be calibrated by driving the vehicle on everyday route. The compass will be calibrated once

it has tracked 3 complete circles.

In places where the terrestrial magnetism is extremely disturbed, the initial correction procedure may start

automatically.

PKIB7654E

SEL168Y

Page 3018 of 5621

FRONT BUMPER

EI-13

C

D

E

F

G

H

J

K

L

MA

B

EI

Revision: 2006 January2006 M35/M45

Removal and Installation of Front Bumper GrilleNIS0024E

CAUTION:

Apply protection tape around outer circumference of front bumper grille (bumper fascia side).

REMOVAL

1. Disengage plastic pawls from vehicle inside using a plastic spatula.

2. While pulling the grille frontward, unlock the turn fastener around right end of the grille using a screw-

driver.

3. Insert a shop cloth to inside of front bumper grille as shown in

the figure, and then disengage lower plastic pawls by pulling

front bumper grille toward vehicle front.

4. Hold fog lamp opening of front bumper grille by hand as shown

in the figure, and then pull front bumper grille out toward vehicle

front by disengaging plastic pawls of both ends.

NOTE:

Plastic clips of both ends are engaged strongly. Strong power is

necessary to disengage them.

INSTALLATION

Install in reverse order of removal.

1. Bumper fascia assembly 2. Front bumper grille

PIIB4588E

PIIB4363J

PIIB4364J

Page 3020 of 5621

REAR BUMPER

EI-15

C

D

E

F

G

H

J

K

L

MA

B

EI

Revision: 2006 January2006 M35/M45

REMOVAL

1. Fully open trunk lid assembly.

2. Remove trunk floor carpet, trunk side box assembly, trunk rear plate, and trunk side finisher. Refer to EI-

56, "TRUNK ROOM TRIM & TRUNK LID FINISHER" .

3. Remove rear combination lamp (LH/RH). Refer to LT-266, "

Removal and Installation" .

4. Remove clips of rear combination lamp lower. (Figure to illustration B)

5. Remove clips of bumper fascia lower side.

6. Remove screws of bumper fascia left/right side. (Figure to illustration C)

7. Remove bumper fascia left/right bolt from trunk room inside. (Figure to illustration A)

8. Remove clip and bumper clamp from bumper fascia upper side, and then pull out bumper fascia toward

rear of vehicle. (Figure to illustration D)

9. Remove bumper fascia assembly.

CAUTION:

When removing bumper fascia, 2 workers are required so as to prevent it from dropping.

10. Remove bumper stay mounting clips, and remove bumper stay

(LH/RH).

11. Remove bumper energy absorber.

12. Remove bumper reinforcement mounting nuts and bumper reinforcement with power tool.

INSTALLATION

Install in the reverse order of removal.

NOTE:

After installing, perform fitting adjustment.

PIIB4119J

Page 3021 of 5621

EI-16

FRONT GRILLE

Revision: 2006 January2006 M35/M45

FRONT GRILLEPFP:62310

Removal and InstallationNIS0024G

CAUTION:

Apply protection tape around outer circumference of front grille (bumper fascia side).

REMOVAL

1. Fully open hood assembly.

2. Remove plastic clip from upper surface of the grille.

3. Remove plastic clip from front bumper upper side (convex part).

4. Pull front grille frontward. Disengage upper side plastic clip joint from back of front grille using pliers. (Fig-

ure to illustration A.)

5. Pull front grille out toward vehicle front. (Figure to illustration B.)

NOTE:

Plastic clips of front grille lower are engaged strongly. Strong power is necessary to disengage them. (When it

is not easy to disengage them, disengage the joint of lower side clip using a screwdriver while pulling the front

grille frontward.)

INSTALLATION

Install in the reverse order of removal.

1. Front grille

PIIB4647E

Page 3040 of 5621

DOOR FINISHER

EI-35

C

D

E

F

G

H

J

K

L

MA

B

EI

Revision: 2006 January2006 M35/M45

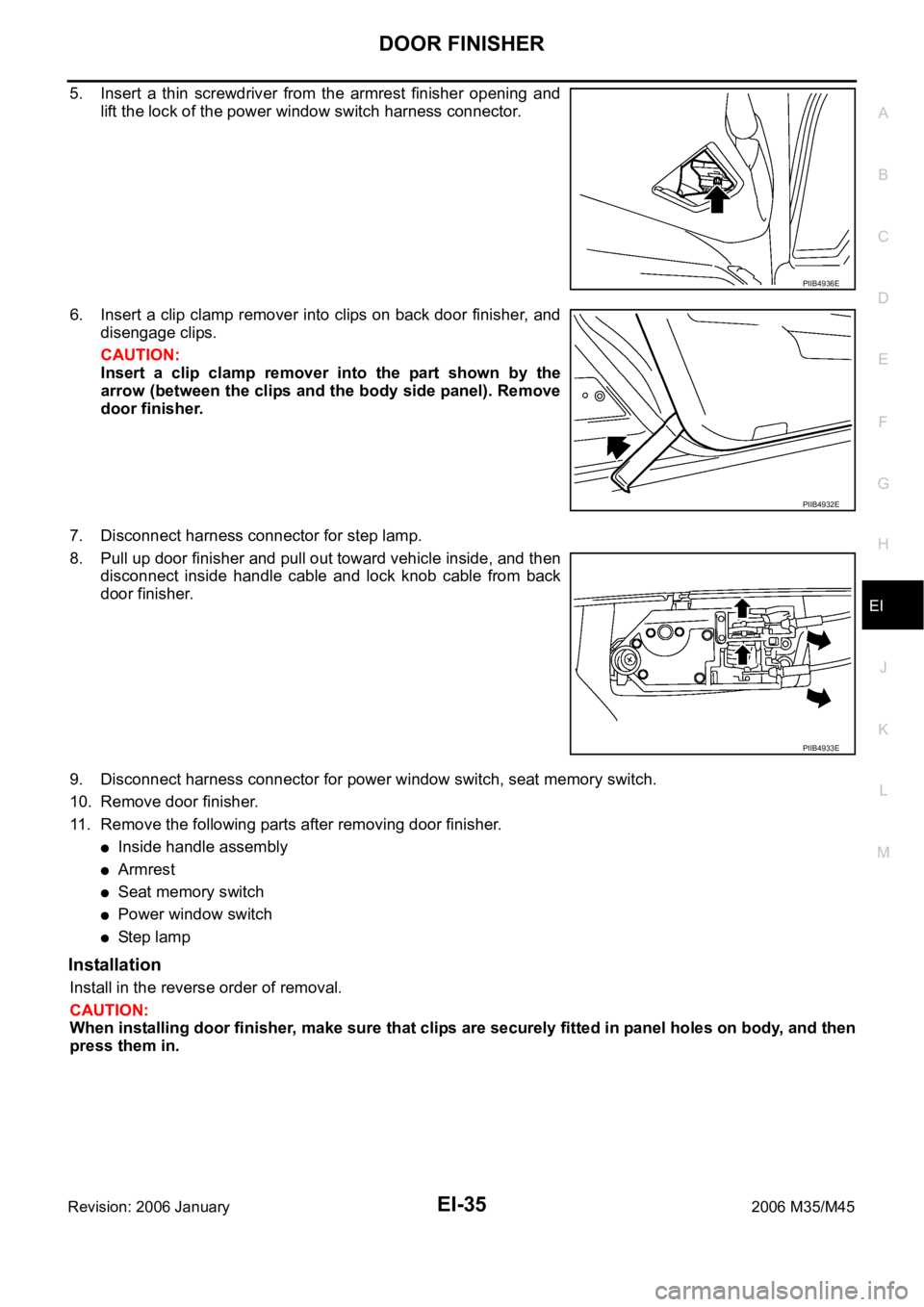

5. Insert a thin screwdriver from the armrest finisher opening and

lift the lock of the power window switch harness connector.

6. Insert a clip clamp remover into clips on back door finisher, and

disengage clips.

CAUTION:

Insert a clip clamp remover into the part shown by the

arrow (between the clips and the body side panel). Remove

door finisher.

7. Disconnect harness connector for step lamp.

8. Pull up door finisher and pull out toward vehicle inside, and then

disconnect inside handle cable and lock knob cable from back

door finisher.

9. Disconnect harness connector for power window switch, seat memory switch.

10. Remove door finisher.

11. Remove the following parts after removing door finisher.

Inside handle assembly

Armrest

Seat memory switch

Power window switch

St e p l am p

Installation

Install in the reverse order of removal.

CAUTION:

When installing door finisher, make sure that clips are securely fitted in panel holes on body, and then

press them in.

PIIB4936E

PIIB4932E

PIIB4933E

Page 3047 of 5621

EI-42

REAR PARCEL SHELF FINISHER

Revision: 2006 January2006 M35/M45

REAR PARCEL SHELF FINISHERPFP:79910

Removal and InstallationNIS0024W

REMOVAL

1. Remove rear seatback and rear seat cushion. Refer to SE-176, "Removal and Installation" .

2. Remove rear seat belt floor anchor bolt and rear seat belt shoulder anchor bolt. Refer to SB-32, "

Removal

and Installation of Rear Seat Belt" .

3. Disengage child anchor cover front pawls, and then pull out child anchor cover (LH/RH center) toward

front of vehicle. (Models with rear window sunshade)

4. Remove rear kicking plate inner, rear wheelhouse garnish, rear pillar finisher. Refer to EI-37, "

BODY SIDE

TRIM" .

1. Rear parcel shelf lid 2. High-mounted stop lamp 3. Child anchor cover

4. Rear parcel shelf finisher 5. Rear seat belt shoulder anchor cover 6. Rear window sunshade

PIIB4590E

Page 3059 of 5621

EI-54

HEADLINING

Revision: 2006 January2006 M35/M45

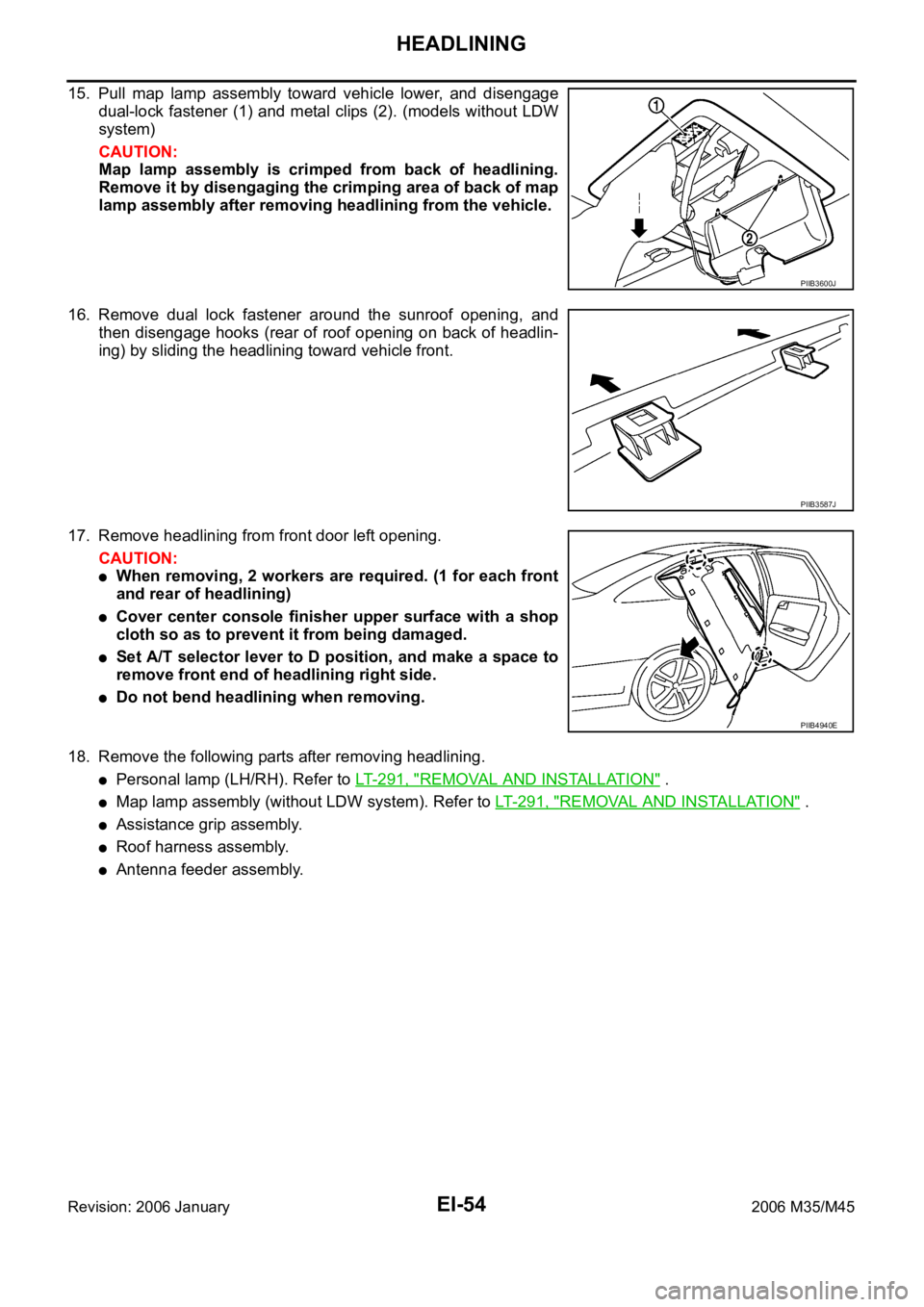

15. Pull map lamp assembly toward vehicle lower, and disengage

dual-lock fastener (1) and metal clips (2). (models without LDW

system)

CAUTION:

Map lamp assembly is crimped from back of headlining.

Remove it by disengaging the crimping area of back of map

lamp assembly after removing headlining from the vehicle.

16. Remove dual lock fastener around the sunroof opening, and

then disengage hooks (rear of roof opening on back of headlin-

ing) by sliding the headlining toward vehicle front.

17. Remove headlining from front door left opening.

CAUTION:

When removing, 2 workers are required. (1 for each front

and rear of headlining)

Cover center console finisher upper surface with a shop

cloth so as to prevent it from being damaged.

Set A/T selector lever to D position, and make a space to

remove front end of headlining right side.

Do not bend headlining when removing.

18. Remove the following parts after removing headlining.

Personal lamp (LH/RH). Refer to LT-291, "REMOVAL AND INSTALLATION" .

Map lamp assembly (without LDW system). Refer to LT- 2 9 1 , "REMOVAL AND INSTALLATION" .

Assistance grip assembly.

Roof harness assembly.

Antenna feeder assembly.

PIIB3600J

PIIB3587J

PIIB4940E

Page 3368 of 5621

FRONT DRIVE SHAFT

FAX-9

C

E

F

G

H

I

J

K

L

MA

B

FA X

Revision: 2006 January2006 M35/M45

14. Screw a drive shaft puller (suitable tool) into joint sub-assembly

screw part to a length of 30 mm (1.18 in) or more. Support drive

shaft with one hand and pull out joint sub-assembly with a slid-

ing hammer (suitable tool) from shaft.

CAUTION:

Align a sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle.

15. Remove the circular clip from shaft.

16. Remove boot from shaft.

17. Clean the old grease on joint sub-assembly with paper towels.

18. Apply the specified amount of grease (NISSAN genuine grease

or equivalent) inside joint sub-assembly serration hole until

grease begins to ooze from ball groove and serration hole. After

applying grease, use a shop cloth to wipe off old grease that has

oozed out.

19. Wrap serration on shaft with tape to protect the boot from dam-

age. Install new boot and boot bands to shaft.

20. Remove the tape wrapped around the serration on shaft.

21. Position circular clip on groove at the shaft edge. Align both

counter axles of the shaft edge and joint sub-assembly. Then,

assemble shaft with circular clip onto joint sub-assembly.

NOTE:

Drive joint inserter (suitable tool) is recommended when install-

ing circular clip.

SDIA0881J

SDIA2489E

SDIA2775E

SFA800

SDIA2490E

Page 3373 of 5621

FAX-14

FRONT DRIVE SHAFT

Revision: 2006 January2006 M35/M45

6. Remove snap ring. Remove spider assembly from the shaft.

7. Remove boot from the shaft.

8. Remove dust cover from housing. (RH side)

9. Clean old grease on housing with paper towels.

Wheel Side

1. Secure shaft in a vise.

CAUTION:

Protect shaft when securing in a vise using aluminum or, copper plates.

2. Remove boot bands, and then remove boot from joint sub-assembly.

3. Screw the drive shaft puller (suitable tool) 30 mm (1.18 in) or

more onto the thread on joint sub-assembly, and pull joint sub-

assembly out of shaft.

CAUTION:

Replace entire drive shaft assembly if joint sub-assembly

cannot be removed after five or more unsuccessful

attempts.

Align sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

4. Remove circular clip from shaft.

5. Remove boot from shaft.

6. Clean old grease on joint sub-assembly with paper towels while rotating ball cage.

INSPECTION AFTER DISASSEMBLY

Shaft

Check shaft for runout, cracks, or other damage. Replace if there are.

Joint Sub-Assembly (Wheel Side)

Check the following:

Joint sub-assembly for rough rotation and excessive axial looseness.

The inside of the joint sub-assembly for entry of foreign material.

Joint sub-assembly for compression scars, cracks, and fractures inside of joint sub-assembly.

Replace joint sub-assembly if there are any non-standard conditions of components.

Housing and Spider assembly (Front Final Drive side)

Replace housing and spider assembly if there is scratching or wear of housing roller contact surface or spider

roller contact surface.

NOTE:

Housing and spider assembly are used in a set.

SFA612

SDIA0606E