wheel INFINITI M35 2006 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 903 of 5621

![INFINITI M35 2006 Factory Owners Manual AV-282

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

PlaceIn a parking lot When driving in a parking lot, or other loca-

tion where there are no roads on the INFINITI M35 2006 Factory Owners Manual AV-282

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

PlaceIn a parking lot When driving in a parking lot, or other loca-

tion where there are no roads on the](/img/42/57023/w960_57023-902.png)

AV-282

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

PlaceIn a parking lot When driving in a parking lot, or other loca-

tion where there are no roads on the map,

matching may place the vehicle mark on a

nearby road. When the vehicle returns to

the road, the vehicle mark may have devi-

ated from the correct location.

When driving in circle or turning the steer-

ing wheel repeatedly, direction errors accu-

mulate, and the vehicle mark may deviate

from the correct location.

If after traveling about 10 km (6

miles) the correct location has

not been restored, perform

location correction and, if nec-

essary, direction correction. Turntable

When the ignition switch is off, the naviga-

tion system cannot get the signal from the

gyroscope (angular speed sensor). There-

fore, the displayed direction may be wrong

and the correct road may not be easily

returned to after rotating the vehicle on a

turntable with the ignition off.

Slippery roads On snow, wet roads, gravel, or other roads

where tires may slip easily, accumulated

mileage errors may cause the vehicle mark

to deviate from the correct road.

Slopes When parking in sloped garages, when

traveling on banked roads, or in other

cases where the vehicle turns when tilted,

an error in the turning angle will occur, and

the vehicle mark may deviate from the

road.

Map dataRoad not displayed on the map screen

When driving on new roads or other roads

not displayed on the map screen, map

matching does not function correctly and

matches the location to a nearby road.

When the vehicle returns to a road which is

on the map, the vehicle mark may deviate

from the correct road.

Different road pattern

(Changed due to repair)

If the road pattern stored in the map data

and the actual road pattern are different,

map matching does not function correctly

and matches the location to a nearby road.

The vehicle mark may deviate from the

correct road.

Ve h ic leUse of tire chains

When tire chains are used, the mileage is

not correctly detected, and the vehicle

mark may deviate from the correct road.Drive the vehicle for a while. If

the distance is still deviated,

adjust it by using the distance

adjustment function. (If the tire

chain is removed, recover the

original value.) Cause (condition) Driving condition Remarks (correction, etc.)

SEL709V

SEL710V

SEL699V

ELK0201D

Page 904 of 5621

![INFINITI M35 2006 Factory Owners Manual TROUBLE DIAGNOSIS

AV-283

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

VEHICLE MARK SHOWS A POSITION WHICH IS COMPLETELY WRONG

In the following cases, INFINITI M35 2006 Factory Owners Manual TROUBLE DIAGNOSIS

AV-283

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

VEHICLE MARK SHOWS A POSITION WHICH IS COMPLETELY WRONG

In the following cases,](/img/42/57023/w960_57023-903.png)

TROUBLE DIAGNOSIS

AV-283

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

VEHICLE MARK SHOWS A POSITION WHICH IS COMPLETELY WRONG

In the following cases, the vehicle mark may appear on completely different position in the map depending on

the GPS satellite signal receiving conditions. In this case, perform location correction and direction correction.

When location correction has not been done

–If the receiving conditions of the GPS satellite signal is poor, if the vehicle mark becomes out of place, it

may move to a completely different location and not come back if location correction is not done. The

position will be corrected if the GPS signal can be received.

When the vehicle has traveled by ferry, or when the vehicle has been being towed

–Because calculation of the current location cannot be done when traveling with the ignition off, for exam-

ple when traveling by ferry or when being towed, the location before travel is displayed. If the precise loca-

tion can be detected with GPS, the location will be corrected.

VEHICLE MARK JUMPS

In the following cases, the vehicle mark may appear to jump as a result of automatic correction of the current

location.

When map matching has been done

–If the current location and the vehicle mark are different when map matching is done, the vehicle mark

may seem to jump. At this time, the location may be “corrected” to the wrong road or to a location which is

not on a road.

When GPS location correction has been done

–If the current location and the vehicle mark are different when the location is corrected using GPS mea-

surements, the vehicle mark may seem to jump. At this time, the location may be “corrected” to a location

which is not on a road.

Precautions

for drivingJust after the engine is started If the vehicle is driven off just after the

engine is started when the gyroscope

(angular speed sensor) correction is not

completed, the vehicle can lose its direc-

tion and may have deviated from the cor-

rect location.Wait for a short while before

driving after starting the engine.

Continuous driving without stopping When driving long distances without stop-

ping, direction errors may accumulate, and

the vehicle mark may deviate from the cor-

rect road.Stop and adjust the orientation.

Abusive driving Spinning the wheels or engaging in other

kinds of abusive driving may result in the

system being unable perform correct

detection, and may cause the vehicle mark

to deviate from the correct road.If after traveling about 10 km (6

miles) the correct location has

not been restored, perform

location correction and, if nec-

essary, direction correction.

How to

correct

locationPosition correction accuracy

If the accuracy of location settings is poor,

accuracy may be reduced when the correct

road cannot be found, particularly in places

where there are many roads.Enter in the road displayed on

the screen with an accuracy of

approx. 1 mm (0.04 in).

Caution: Whenever possible,

use detailed map for the cor-

rection.

Direction when location is corrected

If the accuracy of location settings during

correction is poor, accuracy may be

reduced afterwards.Perform direction correction. Cause (condition) Driving condition Remarks (correction, etc.)

SEL701V

SEL702V

Page 905 of 5621

![INFINITI M35 2006 Factory Owners Manual AV-284

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

VEHICLE MARK IS IN A RIVER OR SEA

The navigation system moves the vehicle mark with no distinction betwee INFINITI M35 2006 Factory Owners Manual AV-284

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

VEHICLE MARK IS IN A RIVER OR SEA

The navigation system moves the vehicle mark with no distinction betwee](/img/42/57023/w960_57023-904.png)

AV-284

[WITH MOBILE ENTERTAINMENT SYSTEM]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

VEHICLE MARK IS IN A RIVER OR SEA

The navigation system moves the vehicle mark with no distinction between land and rivers or sea. If the vehi-

cle mark is somehow out of place, it may appear that the vehicle is driving in a river or the sea.

VEHICLE MARK AUTOMATICALLY ROTATES

The system wrongly memorizes the rotating status as stopping when the ignition switch is turned ON with the

turntable rotating. That causes the vehicle mark to rotate when the vehicle is stopped.

WHEN DRIVING ON SAME ROAD, SOMETIMES VEHICLE MARK IS IN RIGHT PLACE AND

SOMETIMES IT IS WRONG PLACE

The conditions of the GPS antenna (GPS data) and gyroscope (angular speed sensor) change gradually.

Depending on the road traveled and the operation of the steering wheel, the location detection results will be

different. Therefore, even on a road on which the location has never been wrong, conditions may cause the

vehicle mark to deviate.

LOCATION CORRECTION BY MAP-MATCHING IS SLOW

The map matching function needs to refer to the data of the surrounding area. It is necessary to drive

some distance for the function to work.

Because map matching operates on this principle, when there are many roads running in similar direc-

tions in the surrounding area, no matching determination may be made. The location may not be cor-

rected until some special feature is found.

ALTHOUGH GPS RECEIVING DISPLAY IS GREEN, VEHICLE MARK DOES NOT RETURN TO

CORRECT LOCATION

The GPS accuracy has an error of approximately 10 m (30 ft). In some cases the vehicle mark may not be

on the correct street, even when GPS location-correction is done.

The navigation system compares the results of GPS location detection with the results from map-match-

ing location detection. The one which is determined to have higher accuracy is used.

GPS location correction may not be performed when the vehicle is stopped.

NAME OF CURRENT PLACE IS NOT DISPLAYED

The current place name may not be displayed if there are no place names displayed on the map screen.

CONTENTS OF DISPLAY DIFFER FOR BIRDVIEW® AND THE (FLAT) MAP SCREEN

Difference of the BIRDVIEW

® Screen From the Flat Map Screen Are As Follows

The current place name displays names which are primarily in the direction of vehicle travel.

The amount of time before the vehicle travel or turn angle is updated on the screen is longer than for the

(flat) map display.

The conditions for display of place names, roads, and other data are different for nearby areas and for

more distant areas.

Some thinning of the character data is done to prevent the display becoming to complex. In some cases

and in some locations, the display contents may differ.

The same place name, street name, etc. may be displayed multiple times.

Page 906 of 5621

![INFINITI M35 2006 Factory Owners Manual REMOVAL AND INSTALLATION

AV-285

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

REMOVAL AND INSTALLATIONPFP:00000

Removal and Installation/Precautions f INFINITI M35 2006 Factory Owners Manual REMOVAL AND INSTALLATION

AV-285

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

REMOVAL AND INSTALLATIONPFP:00000

Removal and Installation/Precautions f](/img/42/57023/w960_57023-905.png)

REMOVAL AND INSTALLATION

AV-285

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

REMOVAL AND INSTALLATIONPFP:00000

Removal and Installation/Precautions for ReplacementNKS004BG

REMOVAL OF BATTERY

When the battery is removed, the possible route line center position of rear view monitor may not be in the cor-

rect position. Perform the center position correction with the following procedure.

1. Fully turn the steering wheel to left/right.

2. Drive 100m (328.1 ft) or more at vehicle speed 30 km/h (18.6 MPH) or more.

Audio Unit NKS004BH

REMOVAL

1. Remove cluster lid C. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove screws (A) and remove audio unit (2) in conjunction

with unified meter and A/C amp (1).

3. Remove screws (A) and (B)

4. Remove meter and A/C amp (1), audio unit (2) and bracket (3).

CAUTION:

Be careful not to allow foreign material to enter from CD

slot.

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

Unified meter and A/C amp screws are different from other securing screws. Never confuse them

when installing.

Front Door SpeakerNKS004BI

REMOVAL

1. Remove front door finisher. Refer to EI-34, "DOOR FINISHER" .

2. Remove screws (A) and remove front door speaker (1).

INSTALLATION

Installation is the reverse order of removal.

SKIB4268E

SKIB4269E

SKIB4270E

Page 920 of 5621

![INFINITI M35 2006 Factory Owners Manual REMOVAL AND INSTALLATION

AV-299

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

Steering Angle SensorNKS004CA

REMOVAL

1. Remove combination switch. Refe INFINITI M35 2006 Factory Owners Manual REMOVAL AND INSTALLATION

AV-299

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

Steering Angle SensorNKS004CA

REMOVAL

1. Remove combination switch. Refe](/img/42/57023/w960_57023-919.png)

REMOVAL AND INSTALLATION

AV-299

[WITH MOBILE ENTERTAINMENT SYSTEM]

C

D

E

F

G

H

I

J

L

MA

B

AV

Revision: 2006 January2006 M35/M45

Steering Angle SensorNKS004CA

REMOVAL

1. Remove combination switch. Refer to SRS-40, "SPIRAL CABLE" .

2. Remove screws (A) and remove connector mount screw (B).

3. Remove steering angle sensor (1) from combination switch (2).

INSTALLATION

Installation is the reverse order of removal.

CAUTION:

Insert the projection area, and install steering wheel angle sensor while fitting adjusting the triangle

marks (Larger mark should be upward.).

SKIB4352E

Page 940 of 5621

BL-1

BODY, LOCK & SECURITY SYSTEM

I BODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION BL

A

B

BL

Revision: 2006 January2006 M35/M45

BODY, LOCK & SECURITY SYSTEM

PRECAUTIONS .......................................................... 6

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 6

Precautions for Procedures without Cowl Top Cover ..... 6

Precautions Necessary for Steering Wheel Rotation

after Battery Disconnect ........................................... 6

OPERATION PROCEDURE ................................. 6

Precautions for Work ...........................................

..... 7

PREPARATION ........................................................... 8

Special Service Tools ............................................... 8

Commercial Service Tools ........................................ 8

SQUEAK AND RATTLE TROUBLE DIAGNOSIS ...... 9

Work Flow ................................................................ 9

CUSTOMER INTERVIEW ..................................... 9

DUPLICATE THE NOISE AND TEST DRIVE ..... 10

CHECK RELATED SERVICE BULLETINS ......... 10

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE .................................................... 10

REPAIR THE CAUSE ......................................... 10

CONFIRM THE REPAIR ...................................... 11

Generic Squeak and Rattle Troubleshooting .......... 11

INSTRUMENT PANEL ......................................... 11

CENTER CONSOLE ............................................ 11

DOORS ................................................................ 11

TRUNK ................................................................ 12

SUNROOF/HEADLINING ................................... 12

SEATS ................................................................. 12

UNDERHOOD ..................................................... 12

Diagnostic Worksheet ............................................ 13

HOOD ....................................................................... 15

Fitting Adjustment .................................................. 15

Removal and Installation of Hood Assembly .......... 17

REMOVAL ........................................................

... 17

INSTALLETION ................................................... 18

Removal and Installation of Hood Lock Control ..... 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................... 19

Hood Lock Control Inspection ................................ 20RADIATOR CORE SUPPORT .................................. 21

Removal and Installation ........................................ 21

REMOVAL ........................................................

... 21

INSTALLATION ................................................... 22

FRONT FENDER ................................................... ... 23

Removal and Installation ........................................ 23

REMOVAL ........................................................

... 23

INSTALLATION ................................................... 23

POWER DOOR LOCK SYSTEM .............................. 24

Component Parts and Harness Connector Location ... 24

System Description ................................................. 25

DOOR LOCK ACTUATOR OPERATION ............. 26

FUEL LID OPERATION ....................................... 26

OUTLINE ............................................................. 26

CAN Communication System Description .............. 26

CAN Communication Unit ....................................... 26

Schematic ............................................................... 27

Wiring Diagram —D/LOCK— ................................. 28

Terminals and Reference Value of BCM ................. 31

Work Flow ............................................................... 31

CONSULT-II Function (BCM) ................................. 32

CONSULT-II INSPECTION PROCEDURE .......... 32

CONSULT-II APPLICATION ITEMS .................... 33

Trouble Diagnosis Chart by Symptom .................... 34

Power Supply and Ground Circuit Check of BCM ... 35

Check Door Lock and Unlock Switch ..................... 36

Check Door Lock Actuator/Driver Side ................... 38

Check Door Lock Actuator/Passenger Side ........... 39

Check Door Lock Actuator/Rear LH ....................... 40

Check Door Lock Actuator/Rear RH ....................... 40

Check Fuel Lid Opener Actuator ............................ 41

Door Key Cylinder Switch Check ............................ 42

INTELLIGENT KEY SYSTEM ................................... 44

Component Parts and Harness Connector Location ... 44

System Description ................................................. 48

DOOR LOCK/UNLOCK/TRUNK OPEN FUNC-

TION .................................................................... 48

REMOTE KEYLESS ENTRY FUNCTIONS ......... 52

ENGINE START FUNCTION ............................... 54

WARNING FUNCTION ........................................ 55

Page 945 of 5621

BL-6

PRECAUTIONS

Revision: 2006 January2006 M35/M45

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NIS001WA

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions for Procedures without Cowl Top CoverNIS001WB

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions Necessary for Steering Wheel Rotation after Battery DisconnectNIS001WC

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK

position, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Carry the Intelligent Key or insert it to the key slot and turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

PIIB3706J

Page 946 of 5621

PRECAUTIONS

BL-7

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-II.

Precautions for WorkNIS001WD

After removing and installing the opening/closing parts, be sure to carry out fitting adjustments to check

their operational.

Check the lubrication level, damage, and wear of each part. If necessary, grease or replace it.

Page 1227 of 5621

BL-288

BODY REPAIR

Revision: 2006 January2006 M35/M45

1. Hood

2. Front fender (RH&LH)

3. Side body assembly (RH&LH)

4. Outer front pillar reinforcement (RH&LH)

5. Center pillar reinforcement (RH&LH)

6. Outer roof side rail reinforcement (RH&LH)

7. Outer sill reinforcement (RH&LH)

8. Inner roof side rail (RH&LH)

9. Inner center pillar (RH&LH)

10. Front roof rail brace (RH&LH)

11. Outer sill (RH&LH)

12. Inner rear pillar assembly (RH&LH)

13. Inner rear pillar rear (RH&LH)

14. Inner rear pillar reinforcement (RH&LH)

15. Outer rear wheelhouse (RH&LH)

16. Outer rear wheelhouse extension (RH&LH)

17. Inner rear wheelhouse (RH&LH)

18. Side parcel shelf assembly (RH&LH)

19. Seat back support (RH&LH)

20. Parcel shelf assembly

21. Rear waist

22. Roof assembly

23. Front roof rail

24. Front roof bow

25. Rear roof bow

26. Rear roof rail

27. Rear fender assembly (RH&LH)

28. Rear fender extension (RH&LH)

29. Rear bumper side bracket

30. Fuel filler lid (RH)

31. Rear panel assembly

32. Upper rear bumper retainer

33. Lower rear bumper retainer

34. Front door assembly (RH&LH)

35. Outer front door panel (RH&LH)

36. Rear door assembly (RH&LH)

37. Outer rear door panel (RH&LH)

38. Trunk lid

39. Front bumper reinforcement

40. Rear bumper stay

41. Rear bumper reinforcement

Page 1229 of 5621

BL-290

BODY REPAIR

Revision: 2006 January2006 M35/M45

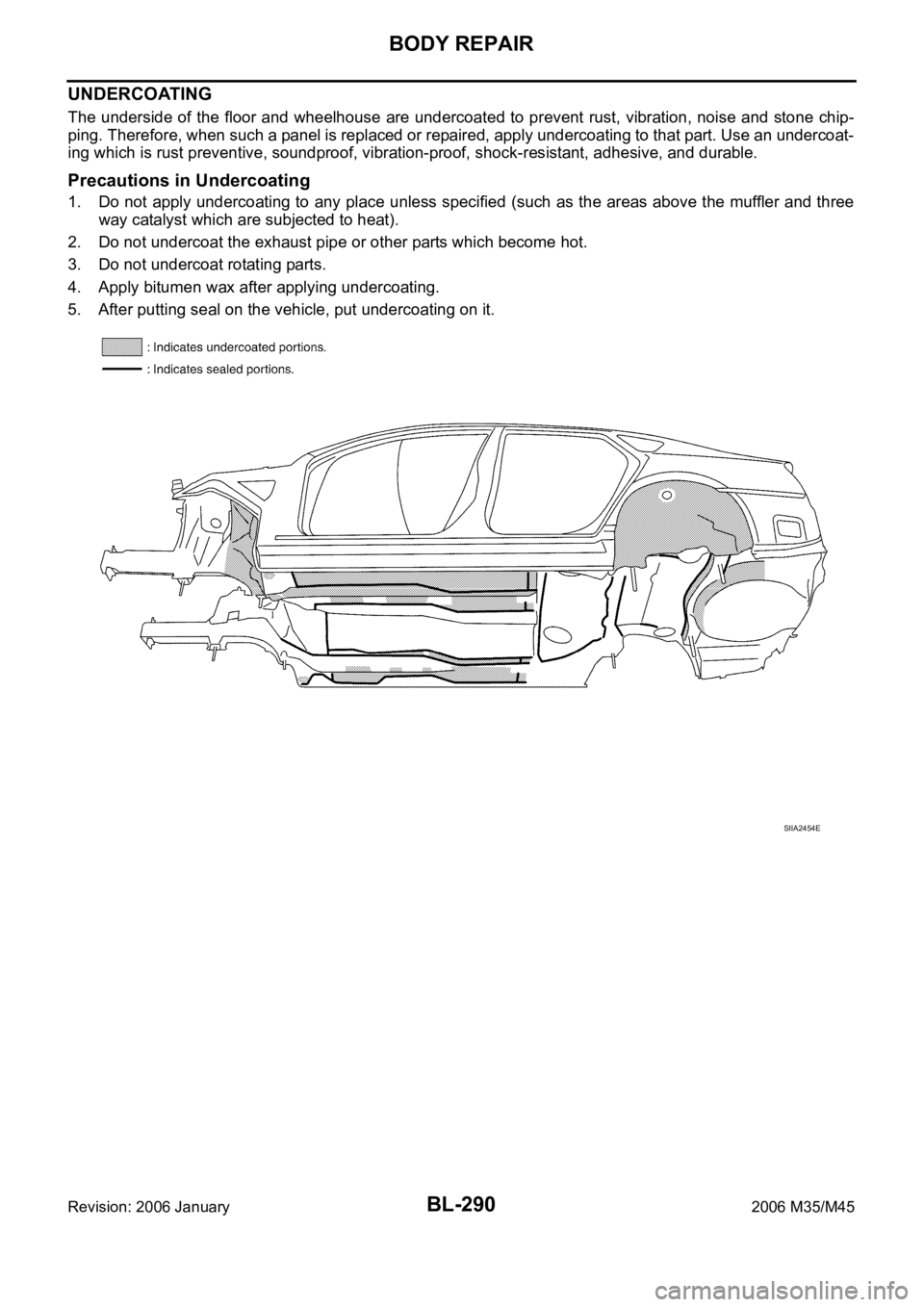

UNDERCOATING

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chip-

ping. Therefore, when such a panel is replaced or repaired, apply undercoating to that part. Use an undercoat-

ing which is rust preventive, soundproof, vibration-proof, shock-resistant, adhesive, and durable.

Precautions in Undercoating

1. Do not apply undercoating to any place unless specified (such as the areas above the muffler and three

way catalyst which are subjected to heat).

2. Do not undercoat the exhaust pipe or other parts which become hot.

3. Do not undercoat rotating parts.

4. Apply bitumen wax after applying undercoating.

5. After putting seal on the vehicle, put undercoating on it.

SIIA2454E