display INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 1173 of 5621

BL-234

VEHICLE SECURITY (THEFT WARNING) SYSTEM

Revision: 2006 January2006 M35/M45

6. Touch “THEFT ALM”.

7. Select diagnosis mode.

“WORK SUPPORT”, “DATA MONITOR” and “ACTIVE TEST”

CONSULT-II APPLICATION ITEM

Work Support

Data Monitor

PIIA9936E

BCIA0031E

Test Item Description

SECURITY ALARM SET This mode is able to confirm and change security alarm ON-OFF setting.

THEFT ALM TRGThe switch which triggered vehicle security alarm is recorded. This mode is able to confirm and

erase the record of vehicle security alarm. The trigger data can be erased by touching “CLEAR”

on CONSULT-II screen.

Monitored Item Description

IGN ON SW Indicates [ON/OFF] condition of ignition switch.

ACC ON SW Indicates [ON/OFF] condition of ignition switch in ACC position.

KEY ON SW Indicates [ON/OFF] condition of key switch.

I-KEY DR UNLK Indicates [ON/OFF] condition of unlock signal from driver side door request switch.

I-KEY AS UNLK Indicates [ON/OFF] condition of unlock signal from passenger side door request switch.

I-KEY LOCK Indicates [ON/OFF] condition of lock signal from Intelligent Key.

I-KEY UNLOCK Indicates [ON/OFF] condition of unlock signal from Intelligent Key.

I-KEY TRNK/HAT Indicates [ON/OFF] condition of trunk opener signal from Intelligent Key.

TRUNK OPNR SW This is displayed even when it is not equipped.

TRUNK CYL SW This is displayed even when it is not equipped.

TRUNK OPN MNTR Indicates [ON/OFF] condition of trunk room lamp switch.

HOOD SW Indicates [ON/OFF] condition of hood switch.

DOOR SW-DR Indicates [ON/OFF] condition of front door switch LH.

DOOR SW-AS Indicates [ON/OFF] condition of front door switch RH.

DOOR SW-RR Indicates [ON/OFF] condition of rear door switch RH.

DOOR SW-RL Indicates [ON/OFF] condition of rear door switch LH.

BACK DOOR SW This is displayed even when it is not equipped.

KEY CYL LK-SW Indicates [ON/OFF] condition of lock signal from front door key cylinder switch.

KEY CYL UN-SW Indicates [ON/OFF] condition of unlock signal from front door key cylinder switch.

Page 1184 of 5621

VEHICLE SECURITY (THEFT WARNING) SYSTEM

BL-245

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

Diagnostic Procedure 2NIS00206

SECURITY INDICATOR LAMP CHECK

1. SECURITY INDICATOR LAMP ACTIVE TEST

With CONSULT-II

Check (“THEFT IND”) in “ACTIVE TEST” mode with CONSULT-II.

OK or NG

OK >> Security indicator lamp is OK.

NG >> GO TO 2.

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect security indicator lamp connector.

3. Check voltage between multi-function switch (security indicator

lamp) connector and ground.

OK or NG

OK >> Check the following.

Harness for open or short between BCM and multi-

function switch (security indicator lamp)

Security indicator lamp condition

NG >> Check the following.

15A fuse [No.37, located in fuse block (J/B)]

Harness for open or short between multi-function switch (security indicator lamp) and fuse Perform operation shown on display indicator lamp

should illuminate.

PIIA7005E

Terminals

Voltage (V)

(Approx.) (+)

(–)

Security indicator

lamp connectorTerminal

M69 1 Ground Battery voltage

PIIB6218E

Page 1209 of 5621

BL-270

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

Revision: 2006 January2006 M35/M45

CONSULT-II DIAGNOSTIC TEST MODE FUNCTION

NOTE:

When any initialization is performed, all ID previously registered will be erased and all NATS ignition keys

must be registered again.

The engine cannot be started with an unregistered key. In this case, the system will show “DIFFERENCE

OF KEY” or “LOCK MODE” as a self-diagnostic result on the CONSULT-II screen.

In rare case, “CHAIN OF ECM-IMMU” might be stored as a self-diagnostic result during key registration

procedure, even if the system is not malfunctioning.

HOW TO READ SELF-DIAGNOSTIC RESULTS

System Diagnosis mode DescriptionReference

page

NATS V5.0C/U INTIALIZATIONPerform registration again after repair, part replacement, and

additional key ID registration.

CAUTION:

“Control Unit Initialization” is activated only after per-

forming “Release steering lock”.Refer to the

Technical Bul-

letin.

SELF-DIAG RESULTS

Malfunctioning system stored in the ECM is displayed.

Printing the contents

Erasing the error recordBL-271

NATS BCM or S/ENTPIN READThe specified numbers of each control unit for acquisition of

password for control unit initialization are displayedRefer to the

Technical Bul-

letin.

STEERING LOCK

RELEASEIf the engine switch cannot be operated (the steering lock

cannot be released), release the steering lock forcibly and

make the engine switch operation possible.

CAUTION:

Always perform “Control Unit Initialization” and “Immo-

bilizer ID Registration” after performing “Release Steer-

ing Lock”.Refer to the

Technical Bul-

letin.

SELF-DIAG RESULTS

Malfunctioning system stored in the BCM is displayed.

Printing the contents

Erasing the error recordBL-271

NATS I-KEY SELF-DIAG RESULTS

Malfunctioning system stored in the Intelligent Key unit is

displayed.

Printing the contents

Erasing the error recordBL-272

PIIB6280E

Page 1212 of 5621

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

BL-273

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

3. CONFIRMATION BEFORE DIAGNOSIS

Before performing diagnostic procedure, grasp the operating systems with referring to the items below.

“System operation with carrying Intelligent Key”. Refer to BL-251, "OPERATION WHEN INTELLIGENT

KEY IS CARRIED" .

“System operation by using Key slot”. Refer to BL-251, "OPERATION WHEN INSERTING TO KEY SLOT"

.

>> GO TO 4.

4. CONFIRM SELF DIAGNOSIS 1

Start CONSULT-II with Push-button ignition switch in lock position and confirm SELF DIAG RESULT “Intelli-

gent Key”. Refer to BL-151, "

CONSULT-II Inspection Procedure" .

No malfunction>>GO TO 5.

Malfunction exist>>Repair the items displayed in “SELF DIAG RESULTS”. Refer to BL-152, "

SELF-DIAG-

NOSTIC RESULTS" .

5. CONFIRM SELF DIAGNOSIS 2

Start CONSULT-II with Push-button ignition switch in lock position and confirm SELF DIAG RESULTS “NATS

BCM or S/ENT” and “NATS I-KEY”. Refer toBL-268, "

CONSULT-II INSPECTION PROCEDURE" .

NOTE:

NATS program card is necessary to display “SELF DIAG RESULTS”.

No malfunction>>GO TO 6.

Malfunction exist>>Repair the items displayed in “SELF DIAG RESULTS”. Refer to BL-271, "

“NATS BCM OR

S/ENT” SELF-DIAGNOSTIC RESULTS ITEM CHART" and BL-272, "“NATS I-KEY” SELF-DIAG-

NOSTIC RESULTS ITEM CHART" .

6. CHECK INTELLIGENT KEY FUNCTION

Operate Push-button ignition switch with carrying Intelligent Key to check the power source position can be

turned with all of the Intelligent Keys.

CAUTION:

Operate Push-button ignition switch without depressing the brake pedal.

Can be operated with all of the Intelligent Keys>>GO TO 7.

Can not be operated with particular Intelligent Key>>Check the malfunctioning Intelligent Key. Refer to BL-

126, "INTELLIGENT KEY BATTERY INSPECTION" .

Can not be operated with any of the Intelligent Keys>>Perform Trouble diagnosis symptom chart 1. Refer to

BL-179, "

Trouble Diagnosis Symptom Chart 1" .

7. CHECK TURNING TIMING OF POWER SOURCE POSITION 1

Check the power source turning delay time after Push-button ignition switch is pushed. (Approx. 3 sec)

CAUTION:

Operate Push-button ignition switch without depressing the brake pedal.

No delay time exists>>GO TO 8.

Delay time exists>>Perform Trouble diagnosis symptom chart 2. Refer to BL-180, "

Trouble Diagnosis Symp-

tom Chart 2" .

Page 1214 of 5621

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

BL-275

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

Trouble Diagnoses Flow Chart for IVIS (NATS)NIS0020P

NOTE:

This procedure is used to resolve the engine start malfunction when the Intelligent Key inserted into the key

slot is used.

1. CHECK ENGINE FOR START

Check that the engine can be started when Push-button ignition switch is operated with Intelligent Key

inserted into the key slot.

NG >> GO TO 2.

OK >> System is normal.

2. CONFIRM SELF DIAGNOSIS

Confirm SELF DIAGNOSIS “NATS V5.0” using CONSULT-II.

NOTE:

NATS program card is necessary to display the “SELF DIAGNOSIS”.

No malfunction>>Re-check the engine for start according to “Work Flow”. Refer to BL-272, "

Work Flow" .

Malfunction related to IVIS (NATS) is displayed.>>GO TO 3.

Malfunctions related to “DON'T ERASE BEFORE CHECKING ENG DIAG” and IVIS (NATS) are displayed>>

GO TO 6.

3. TROUBLE DIAGNOSIS

Repair IVIS (NATS) according to “SELF DIAGNOSIS”.

>> GO TO 4.

4. ERASE SELF DIAGNOSIS

Erase the record of “SELF DIAGNOSIS” using CONSULT-II.

>> GO TO 5.

5. CHECK ENGINE FOR START

Check that the engine can be started when Push-button ignition switch is operated with Intelligent Key

inserted into the key slot.

NG >> GO TO 2.

OK >> Inspection END.

6. CONFIRM SELF DIAGNOSIS DISPLAY

IVIS (NATS) malfunction information and “DON'T ERASE BEFORE CHECKING ENG DIAG” are displayed on

the CONSULT-II screen.

NOTE:

This indication means that malfunctions have been detected in IVIS (NATS) and engine control system.

>> GO TO 7.

Page 1215 of 5621

BL-276

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

Revision: 2006 January2006 M35/M45

7. TROUBLE DIAGNOSIS

Repair IVIS (NATS) according to “SELF DIAGNOSIS”.

NOTE:

Do not erase “SELF DIAGNOSIS” using CONSULT-II.

>> GO TO 8.

8. CONFIRM SELF DIAGNOSIS

Confirm SELF DIAGNOSIS “ECM” using CONSULT-II.

>> GO TO 9.

9. CONFIRM SELF DIAGNOSIS DISPLAY

In case that malfunction of engine control system is displayed other than “NATS MALFUNCTION” in “SELF

DIAGNOSIS”, repair engine control system.

NOTE:

In case that only “NATS MALFUNCTION” is displayed, erase record of “SELF DIAGNOSIS”.

>> GO TO 10.

10. CHECK ENGINE FOR START

Check that the engine can be started when Push-button ignition switch is operated with Intelligent Key

inserted into the key slot.

NG >> GO TO 2.

OK >> GO TO 11.

11 . CONFIRM SELF DIAGNOSIS

Confirm SELF DIAGNOSIS “ECM” using CONSULT-II.

“NO DTC” is displayed.>>Inspection END.

Malfunction information is displayed.>>GO TO 2.

Page 1216 of 5621

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

BL-277

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

Symptom Chart for Security IndicatorNIS0020Q

Security indicator does not turn ON or flash.

CAUTION:

Follow Trouble Diagnosis Flowchart referring to “Diagnosis Procedure”. Determine malfunction-

ing condition before performing this diagnosis.

Make sure that vehicle is under the condition shown in “Conditions of vehicle” before starting

diagnosis.

Check systems shown in the “Action” column in this order.

CONDITIONS OF VEHICLE (OPERATING CONDITIONS)

Intelligent Key is not inserted into key slot.

Engine switch is not depressed.

Check Security Indicator HarnessNIS0020R

1. SECURITY INDICATOR LAMP ACTIVE TEST

With CONSULT-II

Check (“THEFT IND”) in “ACTIVE TEST” mode with CONSULT-II.

OK or NG

OK >> Security indicator lamp is OK.

NG >> GO TO 2.

Action Reference page

1. Check security indicator harnessBL-277

2. Replace BCMBCS-17

Perform operation shown on display indicator lamp

should illuminate.

PIIA7005E

Page 1217 of 5621

BL-278

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

Revision: 2006 January2006 M35/M45

2. CHECK HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect multifunction switch (security indicator) connector.

3. Check voltage between multifunction switch (security indicator)

connector and ground.

OK or NG

OK >> Check the following.

Harness for open or short between BCM and multifunction switch (security indicator)

Security indicator lamp condition

NG >> Check the following.

15A fuse [No.37, located in fuse block (J/B)]

Harness for open or short between multifunction switch (security indicator) and fuse

DTC P1612 CHAIN of ECM-IMMUNIS0020S

Self-diagnostic results:

“CHAIN OF ECM-IMMU” displayed on CONSULT-II screen

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-II, then perform the trouble diagno-

sis of malfunction system indicated “SELF-DIAG RESULTS” of “BCM”. Refer to BCS-15, "

CAN Com-

munication Inspection Using CONSULT-II (Self-Diagnosis)" .

1. CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “CHAIN OF ECM-IMMU”

displayed on CONSULT-II screen.

NOTE:

In rare case, “CHAIN OF ECM-IMMU” might be stored during key

registration procedure, even if the system is not malfunctioning.

Is CONSULT-II screen displayed as shown in figure?

Yes >> GO TO 2.

No >> GO TO BL-271, "

“NATS V5.0” SELF-DIAGNOSTIC

RESULTS ITEM CHART" .

Te r m i n a l s

Voltage (V)

(Approx.) (+)

(–) multifunction switch

(security indicator)

connectorTerminal

M69 1 Ground Battery voltage

PIIB6218E

PIIA1260E

Page 1219 of 5621

BL-280

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)

Revision: 2006 January2006 M35/M45

DTC P1611 ID DISCORD, IMM-ECMNIS0020T

Self-diagnostic results:

“ID DISCORD, IMM-ECM” displayed on CONSULT-II screen

1. CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “ID DISCORD, IMM-ECM” displayed on CONSULT-II screen.

NOTE:

“ID DISCORD IMM-ECM”:

Registered ID of BCM is in discord with that of ECM.

Is CONSULT-II screen displayed as shown in figure?

Yes >> GO TO 2.

No >> GO TO BL-271, "

“NATS V5.0” SELF-DIAGNOSTIC

RESULTS ITEM CHART" .

2. PERFORM INITIALIZATION WITH CONSULT-II

Perform initialization with CONSULT-II. Re-register all NATS ignition key IDs.

For initialization, refer to “CONSULT-II Operation Manual NATS-

IVIS/NVIS”.

NOTE:

If the initialization is not completed or malfunctions, CONSULT-II

shows message on the screen.

Can the system be initialized?

Ye s > >Start engine. (END)

(System initialization had not been completed.)

No >> ECM is malfunctioning.

Replace ECM.

Perform initialization with CONSULT-II

For initialization, refer to “CONSULT-II Operation Manual NATS-IVIS/NVIS”

Removal and Installation of Key SlotNIS0020U

REMOVAL

1. Remove instrument driver lower panel. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect key slot connector.

3. Remove key slot mounting screw, and then remove key slot.

INSTALLATION

Installation is in the reverse order of removal.

PIIA1262E

SEL297W

PIIB6284E

Page 1312 of 5621

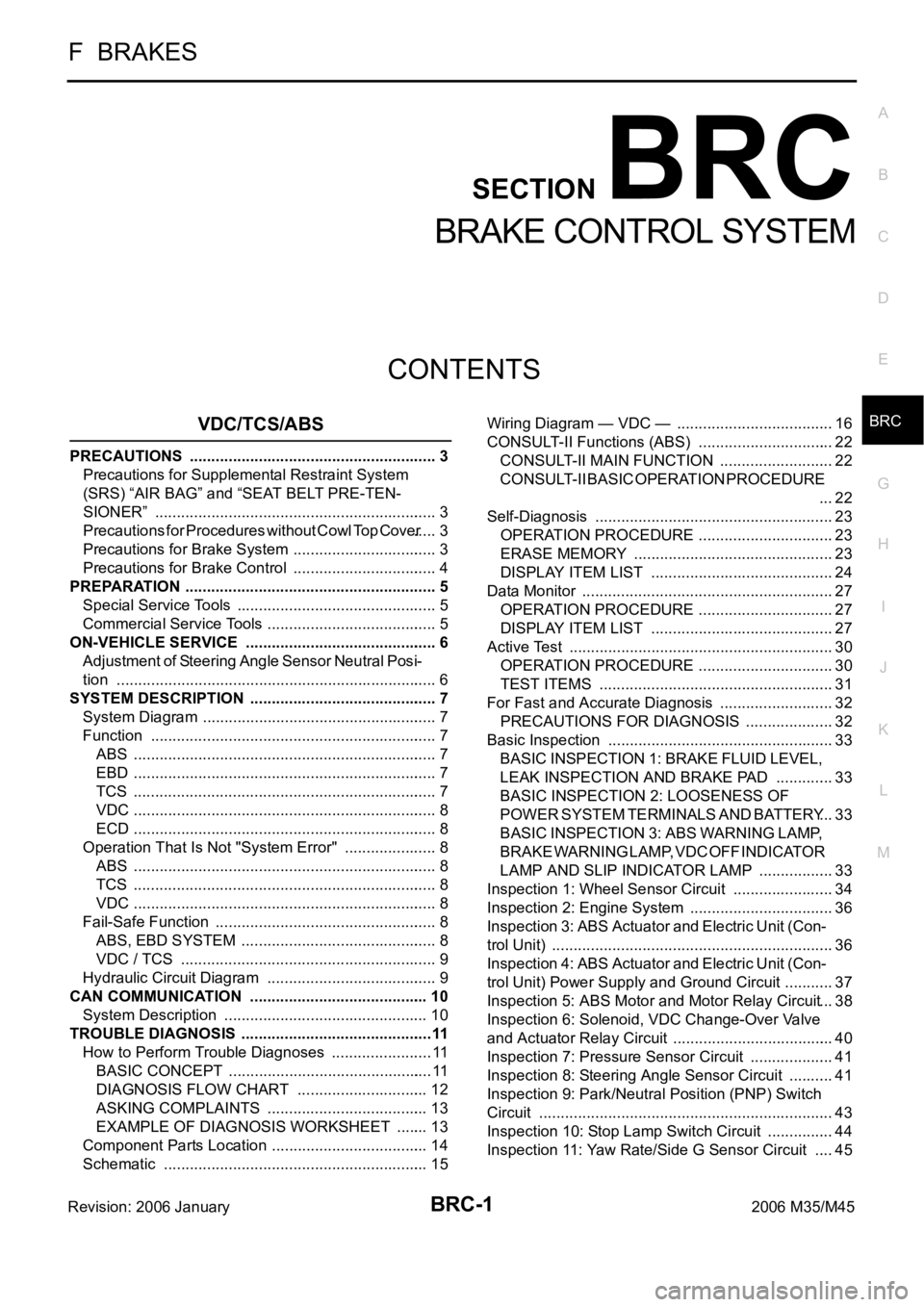

BRC-1

BRAKE CONTROL SYSTEM

F BRAKES

CONTENTS

C

D

E

G

H

I

J

K

L

M

SECTION BRC

A

B

BRC

Revision: 2006 January2006 M35/M45

BRAKE CONTROL SYSTEM

VDC/TCS/ABS

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for Procedures without Cowl Top Cover ..... 3

Precautions for Brake System .................................. 3

Precautions for Brake Control .................................. 4

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 5

ON-VEHICLE SERVICE ............................................. 6

Adjustment of Steering Angle Sensor Neutral Posi-

tion ........................................................................... 6

SYSTEM DESCRIPTION ............................................ 7

System Diagram ....................................................... 7

Function ................................................................... 7

ABS ....................................................................... 7

EBD ....................................................................... 7

TCS ....................................................................... 7

VDC ....................................................................... 8

ECD ....................................................................... 8

Operation That Is Not "System Error" ...................... 8

ABS ....................................................................... 8

TCS ....................................................................... 8

VDC ....................................................................... 8

Fail-Safe Function .................................................... 8

ABS, EBD SYSTEM .............................................. 8

VDC / TCS ............................................................ 9

Hydraulic Circuit Diagram ........................................ 9

CAN COMMUNICATION .......................................... 10

System Description ................................................ 10

TROUBLE DIAGNOSIS .............................................11

How to Perform Trouble Diagnoses ........................ 11

BASIC CONCEPT ................................................ 11

DIAGNOSIS FLOW CHART ............................... 12

ASKING COMPLAINTS ...................................... 13

EXAMPLE OF DIAGNOSIS WORKSHEET ........ 13

Component Parts Location ..................................... 14

Schematic .............................................................. 15Wiring Diagram — VDC — ..................................... 16

CONSULT-II Functions (ABS) ................................ 22

CONSULT-II MAIN FUNCTION ........................... 22

CONSULT-II BASIC OPERATION PROCEDURE

... 22

Self-Diagnosis .....................................................

... 23

OPERATION PROCEDURE ................................ 23

ERASE MEMORY ............................................... 23

DISPLAY ITEM LIST ........................................... 24

Data Monitor ........................................................... 27

OPERATION PROCEDURE ................................ 27

DISPLAY ITEM LIST ........................................... 27

Active Test .............................................................. 30

OPERATION PROCEDURE ................................ 30

TEST ITEMS ....................................................... 31

For Fast and Accurate Diagnosis ........................... 32

PRECAUTIONS FOR DIAGNOSIS ..................... 32

Basic Inspection ..................................................... 33

BASIC INSPECTION 1: BRAKE FLUID LEVEL,

LEAK INSPECTION AND BRAKE PAD .............. 33

BASIC INSPECTION 2: LOOSENESS OF

POWER SYSTEM TERMINALS AND BATTERY ... 33

BASIC INSPECTION 3: ABS WARNING LAMP,

BRAKE WARNING LAMP, VDC OFF INDICATOR

LAMP AND SLIP INDICATOR LAMP .................. 33

Inspection 1: Wheel Sensor Circuit ........................ 34

Inspection 2: Engine System .................................. 36

Inspection 3: ABS Actuator and Electric Unit (Con-

trol Unit) .................................................................. 36

Inspection 4: ABS Actuator and Electric Unit (Con-

trol Unit) Power Supply and Ground Circuit ............ 37

Inspection 5: ABS Motor and Motor Relay Circuit ... 38

Inspection 6: Solenoid, VDC Change-Over Valve

and Actuator Relay Circuit ...................................... 40

Inspection 7: Pressure Sensor Circuit .................... 41

Inspection 8: Steering Angle Sensor Circuit ........... 41

Inspection 9: Park/Neutral Position (PNP) Switch

Circuit ..................................................................... 43

Inspection 10: Stop Lamp Switch Circuit ................ 44

Inspection 11: Yaw Rate/Side G Sensor Circuit ..... 45