relay INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5445 of 5621

![INFINITI M35 2006 Factory Service Manual STC-30

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" INFINITI M35 2006 Factory Service Manual STC-30

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure"](/img/42/57023/w960_57023-5444.png)

STC-30

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS. Also, any malfunction

detected while in this mode will be displayed in real time.

Display Item List

ACTIVE TEST MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. When turning the steering wheel right or left, the rear wheel turns in the same direction. If the steering

wheel is not turned, the rear wheel turns left and right 5 times.

RAS CONTROL UNIT PART NUMBER

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. The part number described on RAS control unit sticker is displayed.

Item (Display or Unit) Remarks

VHCL SPEED SE (km/h) Vehicle speed received via CAN communication is displayed.

STEERING ANG (

) Steering angle received via CAN communication is displayed.

ENGINE SPEED (rpm) Engine speed received via CAN communication is displayed.

POWER STR SOL (A)Power steering solenoid controlling current that RAS control unit outputs is dis-

played.

RR ST ANG_MAI (V) Rear wheel steering angle main sensor output voltage is displayed.

RR ST ANG_SUB (V) Rear wheel angle sub sensor output voltage is displayed.

RR ST ANG_ VOL (V)Voltage supplied from RAS control unit to rear wheel steering angle sensor is

displayed.

C/U VOLTAGE (V) Voltage supplied to RAS control unit is displayed.

MOTOR VOLTAGE (V) Voltage supplied from RAS control unit to RAS motor is displayed.

MOTOR CURRENT (A) RAS motor relay controlling current that RAS control unit outputs is displayed.

MOTOR CRNT OPE (A) Current commanded value to RAS motor is displayed.

RR ANG OPE (

) Angle commanded value to rear wheel steering angle sensor is displayed.

STOP LAMP SW (ON/OFF) Condition of stop lamp switch ON/OFF is displayed.

HICAS RELAY (ON/OFF) RAS motor relay ON/OFF condition is displayed.

FAILSAFE (ON/OFF) Fail-safe ON/OFF condition is displayed.

WARNING LAMP (ON/OFF) RAS warning lamp operating condition is displayed.

STEERING ANG RR ST ANG_MAI RR ST ANG_SUB MOTOR CURRENT

0

(Neutral) 2.4 V 2.4 V No output (Approx. 0 A)

R 90

Approx. 4.4 V Approx. 4.4 V

Output (change)

L 90

Approx. 0.4 V Approx. 0.4 V

Page 5450 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-35

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

Inspection 1: RAS Control Unit MalfunctionNGS000EQ

1. CHECK SELF-DIAGNOSIS RESULTS

Check self-diagnosis res INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-35

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

Inspection 1: RAS Control Unit MalfunctionNGS000EQ

1. CHECK SELF-DIAGNOSIS RESULTS

Check self-diagnosis res](/img/42/57023/w960_57023-5449.png)

TROUBLE DIAGNOSIS

STC-35

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

Inspection 1: RAS Control Unit MalfunctionNGS000EQ

1. CHECK SELF-DIAGNOSIS RESULTS

Check self-diagnosis results.

With CONSULT-II

Without CONSULT-II

Is above displayed on self-diagnosis display?

YES >> Replace RAS control unit. Perform self-diagnosis again after replacing.

NO >> INSPECTION END

Inspection 2: Motor Power Supply SystemNGS000ER

1. CHECK RAS CONTROL UNIT CONNECTOR

1. Turn ignition switch OFF, disconnect RAS control unit harness connector and motor connector, and check

terminal for deformation, disconnection, looseness, etc.

2. Reconnect harness connector securely, and perform self-diagnosis.

With CONSULT-II

Without CONSULT-II

Is above displayed on self-diagnosis display?

YES >> GO TO 2.

NO >> Connector terminal connection is loose, damaged, open, or shorted. Repair or replace the termi-

nal.

2. CHECK RAS MOTOR RELAY BATTERY CIRCUIT

1. Turn ignition switch OFF, and disconnect RAS motor relay harness connector B126.

2. Check voltage between RAS motor relay harness connector

B126 and ground.

OK or NG

OK >> GO TO 3.

NG >> RAS motor relay power supply circuit open or shorted.

Repair or replace power supply circuit and fuse.

Self-diagnostic results

CONTROL_UNIT [ABNORMAL1 - 9]

DTC (warning lamp blinks)

11

Self-diagnosis results

MOTOR_VOLTAGE [LOW_VOLTAGE] (ꞏ a)

MOTOR_VOLTAGE [BAD_OBSTRCT] (ꞏ b)

DTC (warning lamp blinks)

12

Terminal 3 – Ground : Battery voltage (Approx. 12 V)

SGIA1246E

Page 5451 of 5621

![INFINITI M35 2006 Factory Service Manual STC-36

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

3. CHECK RAS MOTOR RELAY HARNESS

1. Disconnect RAS motor relay harness connector B126 and RAS control unit harness connector B127.

2. INFINITI M35 2006 Factory Service Manual STC-36

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

3. CHECK RAS MOTOR RELAY HARNESS

1. Disconnect RAS motor relay harness connector B126 and RAS control unit harness connector B127.

2.](/img/42/57023/w960_57023-5450.png)

STC-36

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

3. CHECK RAS MOTOR RELAY HARNESS

1. Disconnect RAS motor relay harness connector B126 and RAS control unit harness connector B127.

2. Check continuity between RAS motor relay harness connector

B126 and RAS control unit harness connector B127.

3. Check continuity between RAS motor relay harness connector

B126 and ground.

OK or NG

OK >> GO TO 4.

NG >> RAS motor relay harness open or shorted. Repair or replace applicable malfunctioning harness.

4. CHECK RAS MOTOR RELAY RESISTANCE

Check the resistance between RAS motor relay connector.

OK or NG

OK >> GO TO 5.

NG >> RAS motor relay malfunction (replacement)

5. CHECK RAS CONTROL UNIT OUTPUT SIGNAL

1. Connect RAS control unit harness connector B127 and RAS

motor relay harness connector B126.

2. Check voltage between RAS motor relay harness connector

B126 and ground.

OK or NG

OK >> Check RAS motor relay separately from other parts.

Refer to STC-49, "

RAS MOTOR RELAY" .

NG >> RAS control unit malfunction (replacement)Terminal 5 – 37 : Continuity exist.

Terminal 1 – 25 : Continuity exist.

2 – Ground : Continuity exist.

SGIA1265E

Terminal 1 – 2 : Approx. 74

SGIA1266E

1–Ground

Ignition switch ON : Battery voltage (Approx. 12 V)

Ignition switch OFF : Approx. 0V

SGIA1267E

Page 5464 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-49

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

Component Parts InspectionNGS000F4

RAS MOTOR RELAY

1. Check the resistance between RAS motor relay connecto INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-49

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

Component Parts InspectionNGS000F4

RAS MOTOR RELAY

1. Check the resistance between RAS motor relay connecto](/img/42/57023/w960_57023-5463.png)

TROUBLE DIAGNOSIS

STC-49

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

Component Parts InspectionNGS000F4

RAS MOTOR RELAY

1. Check the resistance between RAS motor relay connector.

2. When applying or not supplying approximately 12 V between

RAS motor relay connector, check continuity RAS motor relay

connector.

RAS MOTOR

1. Check the resistance RAS motor connector.

2. Remove RAS motor from RAS actuator, and then turn the motor

by 6 V battery.

CAUTION:

Do not apply 12 V (battery voltage) to the RAS motor termi-

nal because RAS motor might be damaged.

REAR WHEEL STEERING ANGLE SENSOR

1. Disconnect rear wheel steering angle sensor harness connector B104.

2. Check resistance of rear wheel steering angle sensor side con-

nectors.Terminal 1 – 2 : Approx. 74

SGIA1266E

Terminal 3 – 5 : When applying 12 V voltage: Continu-

ity exist.

: When not applying 12 V voltage: Con-

tinuity not exist.

SGIA1286E

Terminal 1 – 2 : Approx. 0.6

If it is normal, it turns.

SGIA1287E

Terminal 2 – 3

: Approx. 1 k

Terminal 4 – 3

Terminal 1 – 3 : Approx. 1.25 k

SGIA1288E

Page 5466 of 5621

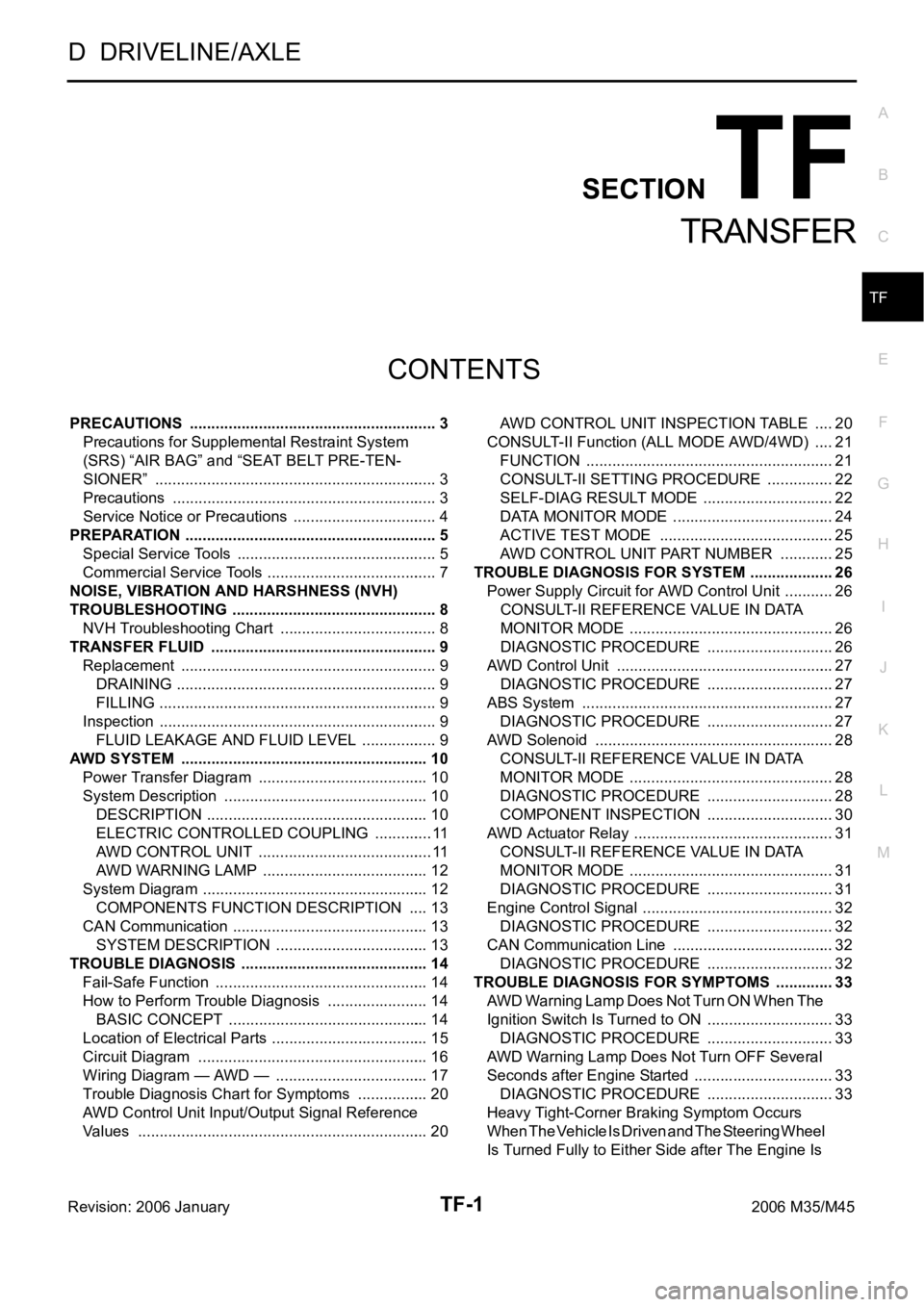

TF-1

TRANSFER

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION TF

A

B

TF

Revision: 2006 January2006 M35/M45

TRANSFER

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions .............................................................. 3

Service Notice or Precautions .................................. 4

PREPARATION ........................................................... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 7

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 8

NVH Troubleshooting Chart ..................................... 8

TRANSFER FLUID ..................................................... 9

Replacement ............................................................ 9

DRAINING ............................................................. 9

FILLING ................................................................. 9

Inspection ................................................................. 9

FLUID LEAKAGE AND FLUID LEVEL .................. 9

AWD SYSTEM .......................................................... 10

Power Transfer Diagram ........................................ 10

System Description ................................................ 10

DESCRIPTION .................................................... 10

ELECTRIC CONTROLLED COUPLING .............. 11

AWD CONTROL UNIT ......................................... 11

AWD WARNING LAMP ....................................... 12

System Diagram ..................................................... 12

COMPONENTS FUNCTION DESCRIPTION ..... 13

CAN Communication .............................................. 13

SYSTEM DESCRIPTION .................................... 13

TROUBLE DIAGNOSIS ............................................ 14

Fail-Safe Function .................................................. 14

How to Perform Trouble Diagnosis ........................ 14

BASIC CONCEPT ............................................... 14

Location of Electrical Parts ..................................... 15

Circuit Diagram ...................................................... 16

Wiring Diagram — AWD — .................................... 17

Trouble Diagnosis Chart for Symptoms ................. 20

AWD Control Unit Input/Output Signal Reference

Values .................................................................... 20AWD CONTROL UNIT INSPECTION TABLE ..... 20

CONSULT-II Function (ALL MODE AWD/4WD) ..... 21

FUNCTION .......................................................

... 21

CONSULT-II SETTING PROCEDURE ................ 22

SELF-DIAG RESULT MODE ............................... 22

DATA MONITOR MODE ...................................... 24

ACTIVE TEST MODE ......................................... 25

AWD CONTROL UNIT PART NUMBER ............. 25

TROUBLE DIAGNOSIS FOR SYSTEM .................... 26

Power Supply Circuit for AWD Control Unit ............ 26

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 26

DIAGNOSTIC PROCEDURE .............................. 26

AWD Control Unit ................................................... 27

DIAGNOSTIC PROCEDURE .............................. 27

ABS System ........................................................... 27

DIAGNOSTIC PROCEDURE .............................. 27

AWD Solenoid ........................................................ 28

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 28

DIAGNOSTIC PROCEDURE .............................. 28

COMPONENT INSPECTION .............................. 30

AWD Actuator Relay ............................................... 31

CONSULT-II REFERENCE VALUE IN DATA

MONITOR MODE ................................................ 31

DIAGNOSTIC PROCEDURE .............................. 31

Engine Control Signal ............................................. 32

DIAGNOSTIC PROCEDURE .............................. 32

CAN Communication Line ...................................... 32

DIAGNOSTIC PROCEDURE .............................. 32

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 33

AWD Warning Lamp Does Not Turn ON When The

Ignition Switch Is Turned to ON .............................. 33

DIAGNOSTIC PROCEDURE .............................. 33

AWD Warning Lamp Does Not Turn OFF Several

Seconds after Engine Started ................................. 33

DIAGNOSTIC PROCEDURE .............................. 33

Heavy Tight-Corner Braking Symptom Occurs

When The Vehicle Is Driven and The Steering Wheel

Is Turned Fully to Either Side after The Engine Is

Page 5485 of 5621

TF-20

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Trouble Diagnosis Chart for SymptomsNDS000DK

If AWD warning lamp turns ON, perform self-diagnosis. Refer to TF-22, "SELF-DIAG RESULT MODE" .

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunction.

AWD Control Unit Input/Output Signal Reference ValuesNDS000DL

AWD CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check item Reference page

AWD warning lamp does not turn ON when

the ignition switch is turned to ON.

(AWD warning lamp check)Ignition switch: ONCAN communication line

TF-33

Unified meter and A/C amp.

Unified meter control unit

AWD warning lamp does not turn OFF sev-

eral seconds after engine started.Engine runningCAN communication line

TF-33

Power supply and ground for AWD con-

trol unit

Unified meter and A/C amp.

Unified meter control unit

AWD solenoid

AWD actuator relay (integrated in AWD

control unit)

Wheel sensor

Heavy tight-corner braking symptom occurs

when the vehicle is driven and the steering

wheel is turned fully to either side after the

engine is started. (See NOTE.)

While driving

Steering wheel is

turned fully to either

sidesCAN communication line

TF-35Accelerator pedal position signal

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (clutch sticking etc.)

Vehicle does not enter AWD mode even

though AWD warning lamp turned to OFF.While drivingCAN communication line

TF-36

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (Mechanical engage-

ment of clutch is not possible.)

While driving, AWD warning lamp flashes

rapidly. (When flashing in approx. 1 minute

and then turning OFF.)

Rapid flashing: 2 times/secondWhile drivingProtection function is activated due to

heavy load to electric controlled cou-

pling. (AWD system is not malfunction-

ing. Also, optional distribution of torque

sometimes becomes rigid before lamp

flashes rapidly, but it is not malfunction.)TF-37

While driving, AWD warning lamp flashes

slowly. (When continuing to flash until turn-

ing ignition switch OFF)

Slow flashing: 1 time/2 secondsWhile driving

Vehicle speed: 20 km/h

(12 MPH) or moreTire size is different between front and

rear of vehicle.TF-37

Monitor item [Unit] Content Condition Display value

FR RH SENSOR [km/h] or [mph]Wheel speed (Front wheel

right)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

FR LH SENSOR [km/h] or [mph]Wheel speed (Front wheel

left)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

Page 5486 of 5621

TROUBLE DIAGNOSIS

TF-21

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

*1 : The values are changed by throttle opening and engine speed.

*2 : Mode switch is not equipped, but displayed.

CONSULT-II Function (ALL MODE AWD/4WD)NDS000DM

FUNCTION

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

RR RH SENSOR [km/h] or [mph]Wheel speed (Rear wheel

right)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

RR LH SENSOR [km/h] or [mph]Wheel speed (Rear wheel

left)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

BATTERY VOLT [V]Power supply voltage for

AWD control unitIgnition switch: ON Battery voltage

THRTL POS SEN [%] Throttle opening conditionWhen depressing accelerator pedal

(Value rises gradually in response to

throttle position.)0 - 100%

ETS SOLENOID [A]Monitored value of current at

AWD solenoidEngine running

At idle speedApprox. 0.000A

Engine running

When depressing accelerator

pedalApprox. 0.000 - 0.500A*1

STOP LAMP SW [ON/OFF]Condition of brake pedal

operationBrake pedal: Depressed ON

Brake pedal: Released OFF

ENG SPEED SIG [RUN/STOP] Condition of engine runningEngine stopped

(Engine speed: Less than 400 rpm)STOP

Engine running

(Engine speed: 400 rpm or more)RUN

ETS ACTUATOR [ON/OFF]Operating condition of AWD

actuator relay (integrated in

AWD control unit)Engine stopped (Ignition

switch: ON)OFF

Engine running ON

4WD WARN LAMP [ON/OFF] AWD warning lamp conditionAWD warning lamp: ON ON

AWD warning lamp: OFF OFF

4WD MODE SW*

2 [AUTO]Input condition from mode

switchAlways AUTO

4WD MODE MON [AUTO] Control status of AWD Engine running AUTO

DIS-TIRE MONI [mm]Improper size tire installed

conditionVehicle running with normal size tire

installed0-4 mm

Vehicle running with improper size

tire installed (Front/rear tire size dif-

ference, wear condition)4-8 mm, 8- mm

P BRAKE SW [ON/OFF] Condition of parking brakeParking brake operated ON

Parking brake not operated OFF Monitor item [Unit] Content Condition Display value

Diagnostic test mode FunctionReference

page

Self-diagnostic results

Self-diagnostic results can be read and erased quickly.TF-22

Data monitorInput/Output data in the AWD control unit can be read.TF-24

Page 5487 of 5621

TF-22

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

CONSULT-II SETTING PROCEDURE

Refer to GI-39, "CONSULT-II Start Procedure" .

SELF-DIAG RESULT MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. Start engine and drive at 30 km/h (19 MPH) or more for approx. 1 minute.

3. Stop vehicle. With engine at idle, touch “SELF-DIAG RESULTS”.

Display shows malfunction experienced since the last erasing

operation.

NOTE:

The details for “TIME” are as follow:

–“0”: Error currently detected with AWD control unit.

–Except for “0”: Error detected in the past and memorized

with AWD control unit.

Detects frequency of driving after DTC occurs (frequency

of turning ignition switch “ON/OFF”).

Display Item List

CAUTION:

If “CAN COMM CIRCUIT [U1000]” is displayed with other DTCs, first perform the trouble diagnosis for CAN communica-

tion line.

Make sure that ABS warning lamp turns OFF by driving for a minute at vehicle speed of 30 km/h (19 MPH) or more after

turning ignition switch “OFF” if AWD warning lamp turns ON with system malfunction of “ABS SYSTEM [C1203]”. AWD

warning lamp may not turn OFF if it is normal unless ignition switch turns OFF at once and engine restarts after that.

How to Erase Self-Diagnostic Results

1. Perform applicably inspection of malfunctioning item and then repair or replace.

2. Start engine and drive at 30 km/h (19 MPH) or more for approx. 1 minute.

3. Make sure that ABS warning lamp turns OFF.

CAN diagnostic support monitorThe results of transmit/receive diagnosis of CAN communication can be read.LAN-20

Active testDiagnostic Test Mode in which CONSULT-II drives some actuators apart from

the AWD control unit and also shifts some parameters in a specified range.TF-25

ECU part numberAWD control unit part number can be read.TF-25

Diagnostic test mode FunctionReference

page

SDIA2217E

Items (CONSULT-II screen

terms)Diagnostic item is detected when... Check item

CONTROLLER FAILURE

[C1201]Malfunction has occurred inside AWD control unit.TF-27, "

AWD Control Unit"

ABS SYSTEM

[C1203]Malfunction related to wheel sensor has been detected by ABS actu-

ator and electric unit (control unit).TF-27, "ABS System"

4WD SOLENOID

[C1204]Malfunction related to AWD solenoid has been detected.TF-28, "AWD Solenoid"

4WD ACTUATOR RLY

[C1205]Malfunction has been detected from AWD actuator relay integrated

with AWD control unit, or malfunction related to AWD solenoid has

been detected.TF-31, "AWD Actuator

Relay" or TF-28, "AWD

Solenoid"

ENGINE SIGNAL 1

[C1210]Malfunction has been detected from ECM.TF-32, "Engine Control Sig-

nal"

CAN COMM CIRCUIT

[U1000]Malfunction has been detected from CAN communication line.TF-32, "CAN Communica-

tion Line"

NO DTC IS DETECTED.

FURTHER TESTING MAY BE

REQUIRED.No NG item has been detected. —

Page 5489 of 5621

TF-24

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor mode is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS.

Also, any malfunction detected while in this mode will be displayed at real time.

Display Item List

: Standard –: Not applicable

Monitor item (Unit)SELECT MONITOR ITEM

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

FR RH SENSOR [km/h] or [mph]

Wheel speed calculated by front wheel

sensor RH signal is displayed.

FR LH SENSOR [km/h] or [mph]

Wheel speed calculated by front wheel

sensor LH signal is displayed.

RR RH SENSOR [km/h] or [mph]

Wheel speed calculated by rear wheel

sensor RH signal is displayed.

RR LH SENSOR [km/h] or [mph]

Wheel speed calculated by rear wheel

sensor LH signal is displayed.

BATTERY VOLT [V] – –

Power supply voltage for AWD control unit

THRTL POS SEN [%] – –

Throttle opening status is displayed.

ETS SOLENOID [A] – –

Monitored value of current at AWD sole-

noid

STOP LAMP SW [ON/OFF] – –

Stop lamp switch signal status via CAN

communication line is displayed.

ENG SPEED SIG [RUN/STOP] – –

Engine status is displayed.

ETS ACTUATOR [ON/OFF] – –

Operating condition of AWD actuator relay

(integrated in AWD control unit) is dis-

played.

4WD WARN LAMP [ON/OFF] – –

Control status of AWD warning lamp is dis-

played.

4WD MODE SW [AUTO] – –

Mode switch is not equipped, but dis-

played.

4WD MODE MON [AUTO] – –

Control status of AWD is displayed.

DIS-TIRE MONI [mm] – –

Improper size tire installed condition is dis-

played.

P BRAKE SW [ON/OFF] – –

Parking switch signal status via CAN com-

munication line is displayed.

Voltage [V] – –

The value measured by the voltage probe

is displayed.

Frequency [Hz] – –

The value measured by the pulse probe is

displayed. DUTY-HI (high) [%] – –DUTY-LOW (low) [%] – –

PLS WIDTH-HI [msec] – –

PLS WIDTH-LOW [msec] – –

Page 5496 of 5621

TROUBLE DIAGNOSIS FOR SYSTEM

TF-31

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

3. Check resistance between transfer assembly harness connector

F43 terminals 1 and 2.

4. If NG, replace electric controlled coupling. Refer to TF-45, "

Dis-

assembly and Assembly" .

AWD Ac tua t or R el a yNDS000DR

CONSULT-II REFERENCE VALUE IN DATA MONITOR MODE

Data are reference value.

DIAGNOSTIC PROCEDURE

Check the following if “4WD ACTUATOR RLY [C1205]” is displayed in self-diagnosis results of CONSULT-

II.

1. CHECK AWD SOLENOID SYSTEM

Perform self-diagnosis. Refer to TF-22, "

SELF-DIAG RESULT MODE" .

Is the

“4WD SOLENOID [C1204]” displayed?

YES >> Perform trouble diagnosis for AWD solenoid. Refer to TF-28, "AWD Solenoid" .

NO >> GO TO 2.

2. CHECK AWD ACTUATOR RELAY SIGNAL

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT- I I .

3. Start engine and read out ON/OFF signal of “ETS ACTUATOR”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3. CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e s" .

OK or NG

OK >> GO TO 4.

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts. 1 - 2 : Approx. 2.45

SDIA2162E

Monitor item Condition Display value

ETS ACTUATOR [ON/OFF]Engine stopped (Ignition switch: ON) OFF

Engine running ON

Monitor item Condition Display value

ETS ACTUATOREngine stopped (Ignition switch: ON) OFF

Engine running ON

SDIA1897E