relay INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5309 of 5621

SE-128

CLIMATE CONTROLLED SEAT

Revision: 2006 January2006 M35/M45

3. CHECK CLIMATE CONTROLLED SEAT RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect climate controlled seat relay.

3. Check voltage between climate controlled seat relay connector

and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness between climate controlled seat relay and ground.

4. CHECK CLIMATE CONTROLLED SEAT RELAY

Check continuity climate controlled seat relay.

OK or NG

OK >> GO TO 5.

NG >> Replace climate controlled seat relay.

Terminal

Voltage (V)

(Approx.) (+)

(–)

Climate controlled

seat relay connectorTe r m i n a l

E165

Ground Battery voltage

7

PIIB6070E

Climate controlled

seat relay connectorTerminal Condition Continuity

E163512V direct current

supply between

terminals 1and 2Ye s

No current supply No

6712V direct current

supply between

terminals 1and 2Ye s

No current supply No

SEC202B

Page 5310 of 5621

CLIMATE CONTROLLED SEAT

SE-129

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

5. CHECK CLIMATE CONTROLLED SEAT CONTROL UNIT HARNESS CIRCUIT

1. Check continuity between climate controlled seat control unit

connector and climate controlled seat relay connector.

2. Check continuity between climate controlled seat control unit connector and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between climate controlled seat control unit and climate controlled seat

relay.

6. CHECK CLIMATE CONTROLLED SEAT CONTROL UNIT GROUND CIRCUIT

Check continuity between climate controlled seat control unit con-

nector and ground.

OK or NG

OK >> Climate controlled seat control unit power supply and ground circuit is OK.

NG >> Repair or replace harness between climate controlled seat control unit and ground.

AB

Continuity Climate controlled

seat control unit

connectorTerminalClimate controlled

seat relay

connectorTerminal

B284

(driver side)2

E166

Ye s 4

B294

(passenger side)2

3

4

A

GroundContinuity Climate controlled

seat control unit

connectorTe r m i n a l

B284 (driver side)

B294 (passenger side)2

No

4

PIIB6071E

Terminal Continuity

Climate controlled

seat control unit

connectorTerminal

Ground Yes

B284

(driver side)

B294

(passenger side)3

PIIB6072E

Page 5324 of 5621

HEATED SEAT

SE-143

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

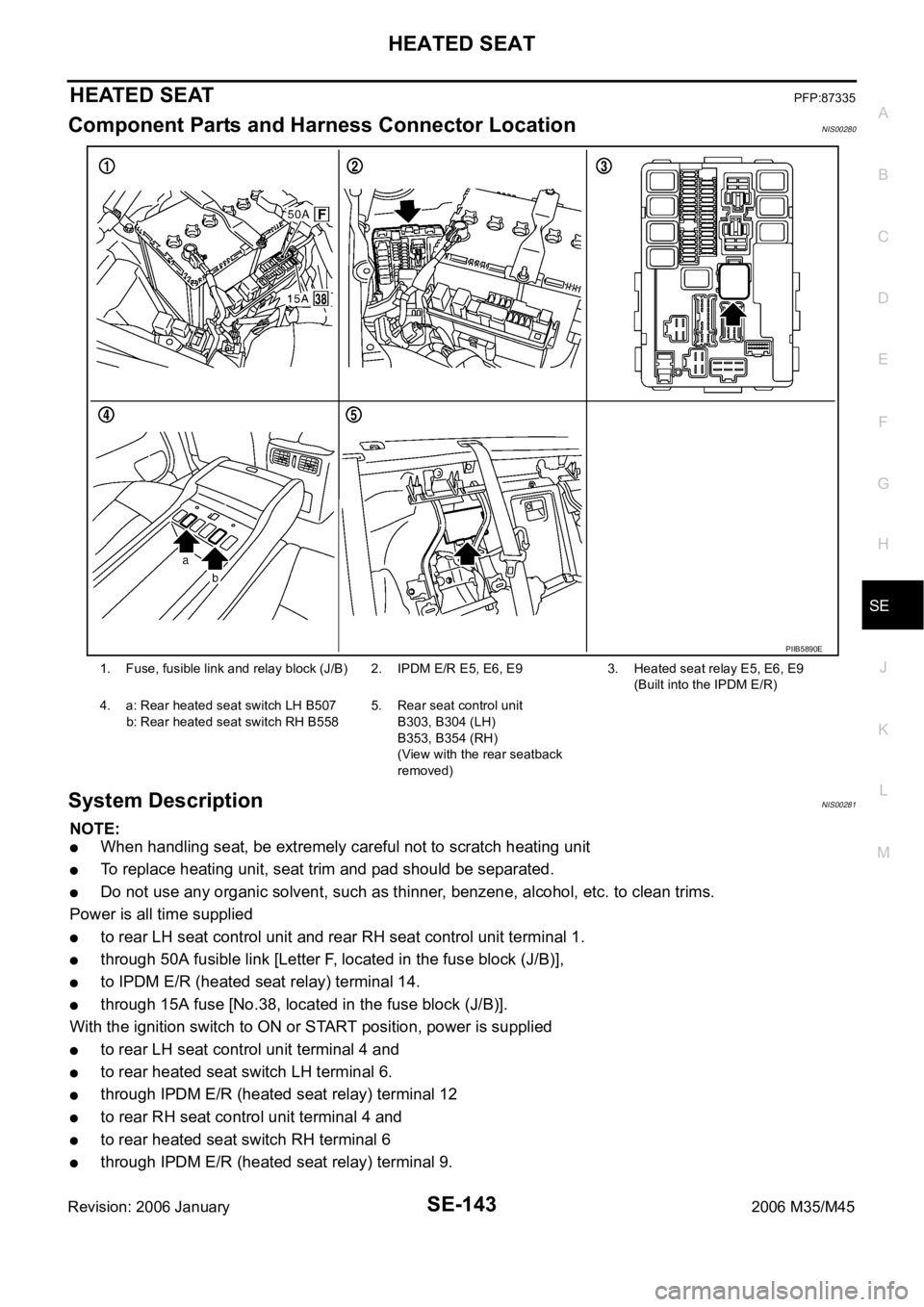

HEATED SEATPFP:87335

Component Parts and Harness Connector LocationNIS00280

System Description NIS00281

NOTE:

When handling seat, be extremely careful not to scratch heating unit

To replace heating unit, seat trim and pad should be separated.

Do not use any organic solvent, such as thinner, benzene, alcohol, etc. to clean trims.

Power is all time supplied

to rear LH seat control unit and rear RH seat control unit terminal 1.

through 50A fusible link [Letter F, located in the fuse block (J/B)],

to IPDM E/R (heated seat relay) terminal 14.

through 15A fuse [No.38, located in the fuse block (J/B)].

With the ignition switch to ON or START position, power is supplied

to rear LH seat control unit terminal 4 and

to rear heated seat switch LH terminal 6.

through IPDM E/R (heated seat relay) terminal 12

to rear RH seat control unit terminal 4 and

to rear heated seat switch RH terminal 6

through IPDM E/R (heated seat relay) terminal 9.

1. Fuse, fusible link and relay block (J/B) 2. IPDM E/R E5, E6, E93. Heated seat relay E5, E6, E9

(Built into the IPDM E/R)

4. a: Rear heated seat switch LH B507

b: Rear heated seat switch RH B5585. Rear seat control unit

B303, B304 (LH)

B353, B354 (RH)

(View with the rear seatback

removed)

PIIB5890E

Page 5333 of 5621

SE-152

HEATED SEAT

Revision: 2006 January2006 M35/M45

Rear Heated Seat Power Supply and Ground Circuit InspectionNIS00287

1. CHECK FUSIBLE LINK AND FUSE

Check 50A fusible link (letter F located in the fuse and fusible link box).

Check 15A fuse (No.38, located in fuse block).

Check circuit breaker.

NOTE:

Refer to SE-143, "

Component Parts and Harness Connector Location" .

OK or NG

OK >> GO TO 2.

NG >> If fuse or circuit breaker is blown, be sure to eliminate cause of malfunction before installing new

fuse or new circuit breaker, refer to PG-3, "

POWER SUPPLY ROUTING CIRCUIT" .

2. CHECK HEATED SEAT RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Check voltage between IPDM E/R (heated seat relay) connector

and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness between fuse block (J/B) and IPDM E/R (heated seat relay).

3. CHECK HEATED SEAT RELAY GROUND CIRCUIT

1. Disconnect IPDM E/R (heated seat relay) connector.

2. Check continuity between IPDM E/R (heated seat relay) con-

nector and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Repair or replace harness between IPDM E/R (heated

seat relay) and ground.

Terminal

Voltage (V)

(Approx.) (+)

(–) IPDM E/R

(heated seat relay)

connectorTerminal

E6 14 Ground Battery voltage

PIIB5995E

Te r m i n a l

Continuity IPDM E/R

(heated seat relay)

connectorTerminal

Ground

E9 54 Yes

PIIB5996E

Page 5335 of 5621

SE-154

HEATED SEAT

Revision: 2006 January2006 M35/M45

3. CHECK REAR SEAT CONTROL UNIT HARNESS

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R (heated seat relay) and rear seat control unit connector.

3. Check continuity between IPDM E/R (heated seat relay) con-

nector and rear seat control unit connector.

4. Check continuity between rear seat control unit connector and

ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness between rear seat control unit and IPDM E/R (heated seat relay).

4. CHECK REAR SEAT CONTROL UNIT GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear seat control unit connector.

3. Check continuity between rear seat control unit connector and

ground.

OK or NG

OK >> Rear seat control unit power supply and ground circuit is OK.

NG >> Repair or replace harness between rear seat control unit and ground.

AB

Continuity

Rear seat control

unit connectorTe r m i n a lIPDM E/R

(heated seat relay)

connectorTerminal

B303 (LH)

4E6 12

Ye s

B353 (RH) E5 9

A

GroundContinuity

Rear seat control unit connector Terminal

B303 (LH)

B353 (RH)4No

PIIB5999E

Te r m i n a l

Continuity

Rear seat control

unit connectorTerminal

Ground B303 (LH)

B353 (RH)8

Ye s

B304 (LH)

B354 (RH)13

PIIB6000E

Page 5338 of 5621

HEATED SEAT

SE-157

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

Rear Heated Seat Indicator Power Supply Circuit InspectionNIS0028A

1. CHECK REAR HEATED SEAT INDICATOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect rear heated seat switch connector.

3. Check voltage between rear heated seat switch connector and

ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2. CHECK REAR HEATED SEAT INDICATOR HARNESS

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R (heated seat relay) connector.

3. Check continuity between IPDM E/R (heated seat relay) con-

nector and rear heated seat switch connector.

4. Check continuity between rear heated seat switch connector

and ground.

OK or NG

OK >> Check the condition of the harness and connector.

NG >> Replace or replace harness between IPDM E/R (heated seat relay) and rear heated seat switch.

Te r m i n a l

ConditionVoltage (V)

(Approx.) (+)

(–) Rear heated

seat switch

connectorTerminal

B507 (LH)

B558 (RH)6 GroundIgnition

switchON Battery voltage

OFF 0

PIIB6005E

AB

Continuity

Rear heated seat

switch connectorTerminalIPDM E/R

(heated seat relay)

connectorTerminal

B507 (LH)

6E6 12

Ye s

B558 (RH) E5 9

A

GroundContinuity

Rear heated seat

switch connectorTerminal

B507 (LH)

B558 (RH)6No

PIIB6006E

Page 5417 of 5621

STC-2Revision: 2006 January2006 M35/M45 Inspection 2: Motor Power Supply System ............. 35

Inspection 3: RAS Motor Output Malfunction ......... 37

Inspection 4: Vehicle Speed Signal ........................ 38

Inspection 5: Steering Angle Signal Malfunction .... 38

Inspection 6: Rear Main Signal and Rear Sub Signal

Malfunction ............................................................. 40

Inspection 7: VDC Malfunction ............................... 42

Inspection 8: Engine Speed Signal Malfunction ..... 43

Inspection 9: CAN Communication System Mal-

function ................................................................... 43Inspection 10: Stop Lamp Switch Harness ............. 44

Inspection 11: RAS Warning Lamp Harness ........... 44

Diagnosis Chart by Symptom 1 .............................. 46

Diagnosis Chart by Symptom 2 .............................. 46

Check RAS Static/Dynamic Characteristics ............ 48

Component Parts Inspection ................................... 49

RAS MOTOR RELAY ........................................... 49

RAS MOTOR ....................................................... 49

REAR WHEEL STEERING ANGLE SENSOR .... 49

Page 5434 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-19

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

Component Parts LocationNGS000EC

A. RAS warning lamp B. Steering angle sensor C. RAS control unit

D. RAS mo INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-19

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

Component Parts LocationNGS000EC

A. RAS warning lamp B. Steering angle sensor C. RAS control unit

D. RAS mo](/img/42/57023/w960_57023-5433.png)

TROUBLE DIAGNOSIS

STC-19

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

Component Parts LocationNGS000EC

A. RAS warning lamp B. Steering angle sensor C. RAS control unit

D. RAS motor relay E. RAS motor F. Rear wheel steering angle sensor

G. Noise suppressor

SGIA1053J

Page 5442 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-27

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

STANDARD BY CONSULT-II

CAUTION:

The output signal indicates the RAS control unit calculation data. The norm INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-27

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

STANDARD BY CONSULT-II

CAUTION:

The output signal indicates the RAS control unit calculation data. The norm](/img/42/57023/w960_57023-5441.png)

TROUBLE DIAGNOSIS

STC-27

[RAS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

STANDARD BY CONSULT-II

CAUTION:

The output signal indicates the RAS control unit calculation data. The normal values will be displayed

even in the event that the output circuit (harness) is open.

Monitor itemDATA MONITOR

Malfunction inspection

checklist

Condition Reference values

VHCL SPEED SE (km/h)Ignition switch ON or engine

running Almost in accordance with the speed-

ometer display. It is not a malfunction,

through it might not be corresponding

just after ignition switch is turned ON.STC-38, "

Inspection 4:

Vehicle Speed Signal"

STEERING ANG ()Turning steering wheel clock-

wise or counterclockwise.Displays the angle when the steering

wheel turns from the neutral positionSTC-38, "

Inspection 5:

Steering Angle Signal

Malfunction"

ENGINE SPEED (rpm) Engine runningAlmost in accordance with tachometer

displaySTC-43, "

Inspection 8:

Engine Speed Signal

Malfunction"

POWER STR SOL (A)Accelerate the vehicle from 0

to 100 km/h (0 to 62 MPH)0 km/h (0 MPH): Approx. 1.10 A

100 km/h (62 MPH): Approx. 0.54 ASTC-46, "Diagnosis

Chart by Symptom 2"

RR ST ANG-MAI (V)

Perform the ACTIVE TEST

and stroke the actuator (with

tires off the ground)Neutral: Approx. 2.4 V

Turn steering wheel to right for full

stroke: Approx. 4.4 V

Turn steering wheel to left for full

stroke: Approx. 0.4 VSTC-40, "Inspection 6:

Rear Main Signal and

Rear Sub Signal Mal-

function"RR ST ANG- SUB (V)

RR ST ANG-VOL (V)

Ignition switch ON or engine

runningApprox. 5 VSTC-40, "

Inspection 6:

Rear Main Signal and

Rear Sub Signal Mal-

function"

C/U VOLTAGE (V) Battery voltage (Approx. 12 V)STC-35, "

Inspection 1:

RAS Control Unit Mal-

function"

MOTOR VOLTAGE (V) Battery voltage (Approx. 12V)STC-35, "

Inspection 2:

Motor Power Supply

System"

MOTOR CURRENT (A)Perform the ACTIVE TEST

and stroke the actuator.It is normal when there is the current

output at strokeSTC-35, "

Inspection 2:

Motor Power Supply

System"

MTR CRNT OPE (A)Turning steering wheel clock-

wise or counterclockwise

while ignition switch is ON or

running the engineNeutral (Steering force is zero and

straight-ahead position): Approx. 0 A

The value is changed according to

steering left or right STC-37, "

Inspection 3:

RAS Motor Output

Malfunction"

STOP LAMP SWDepressing or releasing brake

pedalBrake pedal depressed: ONSTC-44, "

Inspection

10: Stop Lamp Switch

Harness"Brake pedal not depressed: OFF

RAS RELAY

Ignition switch ON or engine

runningIgnition switch ON: ONSTC-35, "

Inspection 2:

Motor Power Supply

System"

FAIL SAFE Not activatedSelf-diagnosis and

suspect system

inspection on DATA

MONITOR

WARNING LAMP (ON/OFF)RAS warning lamp ON: ON

RAS warning lamp OFF: OFFWarning lamp circuit

inspection

Page 5443 of 5621

![INFINITI M35 2006 Factory Service Manual STC-28

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

CONSULT-II Function (RAS)NGS000EG

FUNCTION

CONSULT-II can display each self-diagnostic item using the diagnostic test modes shown foll INFINITI M35 2006 Factory Service Manual STC-28

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

CONSULT-II Function (RAS)NGS000EG

FUNCTION

CONSULT-II can display each self-diagnostic item using the diagnostic test modes shown foll](/img/42/57023/w960_57023-5442.png)

STC-28

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

CONSULT-II Function (RAS)NGS000EG

FUNCTION

CONSULT-II can display each self-diagnostic item using the diagnostic test modes shown following.

CONSULT-II SETTING PROCEDURE

Refer to GI-39, "CONSULT-II Start Procedure" .

SELF-DIAG RESULT MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. Touch “PRINT” to print out the self-diagnostic results if necessary. Check RAS warning lamp if “NO FAIL-

URE” is displayed.

3. Perform the appropriate inspection from the display item list, and repair or replace the malfunctioning

component. Refer to STC-28, "

Display Item List" .

Display Item List

CAUTION:

When malfunctions are detected in several systems, including the “CAN COMM [U1000]” and

“CONTROL_UNIT (CAN) [U1010]”, inspect the CAN communication system.

Mode Function Reference

SELF-DIAG RESULTSReceives self-diagnosis results from RAS control unit and

indicates DTCs.STC-28, "

SELF-DIAG RESULT

MODE"

DATA MONITORReceives input/output signals from RAS control unit and

indicates and stores them to facilitate locating cause of

malfunctions.STC-30, "DATA MONITOR MODE"

CAN DIAG SUPPORT MNTRMonitors transmitting/receiving status of CAN communi-

cation.STC-31, "CAN Communication"

ACTIVE TESTSends command to RAS actuator to change output sig-

nals and check operation of output system.STC-30, "ACTIVE TEST MODE"

ECU PART NUMBER Displays RAS control unit part number.STC-30, "RAS CONTROL UNIT

PART NUMBER"

DTC code Diagnostic item Diagnostic item is detected when... Check items

C1923 STEERING_ANGLE_SEN [NO_CHANGE] (ꞏ a)While driving at 60 km/h (37 MPH)

or more, steering angle does not

change for a while.STC-38

C1924 STEERING_ANGLE_SEN [NO_NEUT_STATE] (ꞏ b)When driving some distance, no

neutral signal (ON signal) is input.STC-38

C1915 RR_ST_ANGLE_SENSOR [MAIN_SIGNAL] (ꞏ a)The main sensor input signal is

malfunctioning for some time

against the sensor power supply

value.STC-40

C1916 RR_ST_ANGLE_SENSOR [SUB_SIGNAL] (ꞏ b)When the main sensor input signal

is 2.4 - 2.6 V, the sub sensor input

signal is malfunctioning for some

time compared to the sensor power

supply value.STC-40

C1917, C1918 RR_ST_ANGLE_SENSOR [OFFSET_SIG1,2] (ꞏ c)An excessive difference has

occurred in the input values of main

sensor and sub sensor.STC-40

C1914 RR_ST_ANGLE_SENSOR [ABNORMAL_VOL] (ꞏ d)Higher or lower value compared to

the standard voltage.STC-40

C1921 MOTOR_OUTPUTNo engine speed is input for a cer-

tain time.STC-43

C1911 MOTOR_VOLTAGE [LOW_VOLTAGE] (ꞏ a)The motor power supply voltage is

lower than ignition power supply

voltage with RAS motor relay ON.STC-35