Ras INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5124 of 5621

PRE-CRASH SEAT BELT

SB-25

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

5. CHECK BRAKE PEDAL STROKE SENSOR

Check continuity between brake pedal stroke sensor while perform-

ing brake operation.

OK or NG

OK >> Check harness connection.

If it is OK, replace pre-crash seat belt control unit.

If it is NG, repair or replace malfunction part.

NG >> Replace brake pedal stroke sensor.

Pre-Crash Seat Belt Motor LH Circuit Check [B2452]NHS0008E

1. CHECK LH SEAT BELT MOTOR CIRCUIT

With CONSULT-II

Select “SELF-DIAG RESULTS” of CONSULT-II, and then make sure

that “SB MOTOR LH CIRC” is displayed.

Without CONSULT-II

When CONSULT-II is not used, omit this inspection, and then GO TO 2.

Displayed B2452?

Ye s > > G O T O 2 .

No >> Pre-crash seat belt motor LH circuit is OK.

Brake pedal stroke

sensor connectorTerminal ConditionResistance

(K)

(Approx.)

E125 21

Brake released

depressed1.0 0.2

30.2

1.0

PHIA1137E

CONSULT-II display CONSULT-II display code

NO DTC –

SB MOTOR LH CIRC B2452

PHIA0768E

Page 5125 of 5621

SB-26

PRE-CRASH SEAT BELT

Revision: 2006 January2006 M35/M45

2. CHECK LH SEAT BELT MOTOR HARNESS

1. Turn the ignition switch OFF.

2. Disconnect pre-crash seat belt control unit connector and pre-crash seat belt motor LH connector.

3. Check continuity between pre-crash seat belt control unit har-

ness connector and pre-crash seat belt motor LH harness con-

nector.

4. Check continuity between pre-crash seat belt control unit har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3. CHECK SEAT BELT MOTOR

Check continuity between pre-crash seat belt motor LH.

OK or NG

OK >> Replace pre-crash seat belt control unit.

NG >> Replace pre-crash seat belt motor LH.

AB

Continuity Pre-crash seat

belt control unit

connectorTe r m i n a lPre-crash seat

belt motor LH

connectorTerminal

B1424

B321

Ye s

62

A

GroundContinuity

Pre-crash seat belt

control unit connectorTerminal

B1424

No

6

PHIA1138E

Pre-crash seat belt

motor LH connectorTerminal Continuity

B32 1 2 Yes

PHIA1139E

Page 5126 of 5621

![INFINITI M35 2006 Factory Service Manual PRE-CRASH SEAT BELT

SB-27

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Pre-Crash Seat Belt Motor RH Circuit Check [B2451]NHS0008F

1. CHECK RH SEAT BELT MOTOR CIRCUIT

With CONSULT-II

S INFINITI M35 2006 Factory Service Manual PRE-CRASH SEAT BELT

SB-27

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Pre-Crash Seat Belt Motor RH Circuit Check [B2451]NHS0008F

1. CHECK RH SEAT BELT MOTOR CIRCUIT

With CONSULT-II

S](/img/42/57023/w960_57023-5125.png)

PRE-CRASH SEAT BELT

SB-27

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Pre-Crash Seat Belt Motor RH Circuit Check [B2451]NHS0008F

1. CHECK RH SEAT BELT MOTOR CIRCUIT

With CONSULT-II

Select SELF-DIAG RESULTS” of CONSULT-II, and then make sure

that “SB MOTOR RH CIRC” is displayed.

Without CONSULT-II

When CONSULT-II is not used, omit this inspection, and then GO TO 2.

Displayed B2451?

Ye s > > G O T O 2 .

No >> Pre-crash seat belt motor RH circuit is OK.

2. CHECK RH SEAT BELT MOTOR HARNESS

1. Turn the ignition switch OFF.

2. Disconnect pre-crash seat belt control unit connector and pre-crash seat belt motor RH connector.

3. Check continuity between pre-crash seat belt control unit har-

ness connector and pre-crash seat belt motor RH harness con-

nector.

4. Check continuity between pre-crash seat belt control unit har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

CONSULT-II display CONSULT-II display code

NO DTC –

SB MOTOR RH CIRC B2451

PHIA0767E

AB

Continuity Pre-crash seat

belt control unit

connectorTerminalPre-crash seat

belt motor RH

connectorTerminal

B1421

B82

Ye s

3 1

A

GroundContinuity

Pre-crash seat belt

control unit connectorTerminal

B1421

No

3

PHIA1140E

Page 5127 of 5621

SB-28

PRE-CRASH SEAT BELT

Revision: 2006 January2006 M35/M45

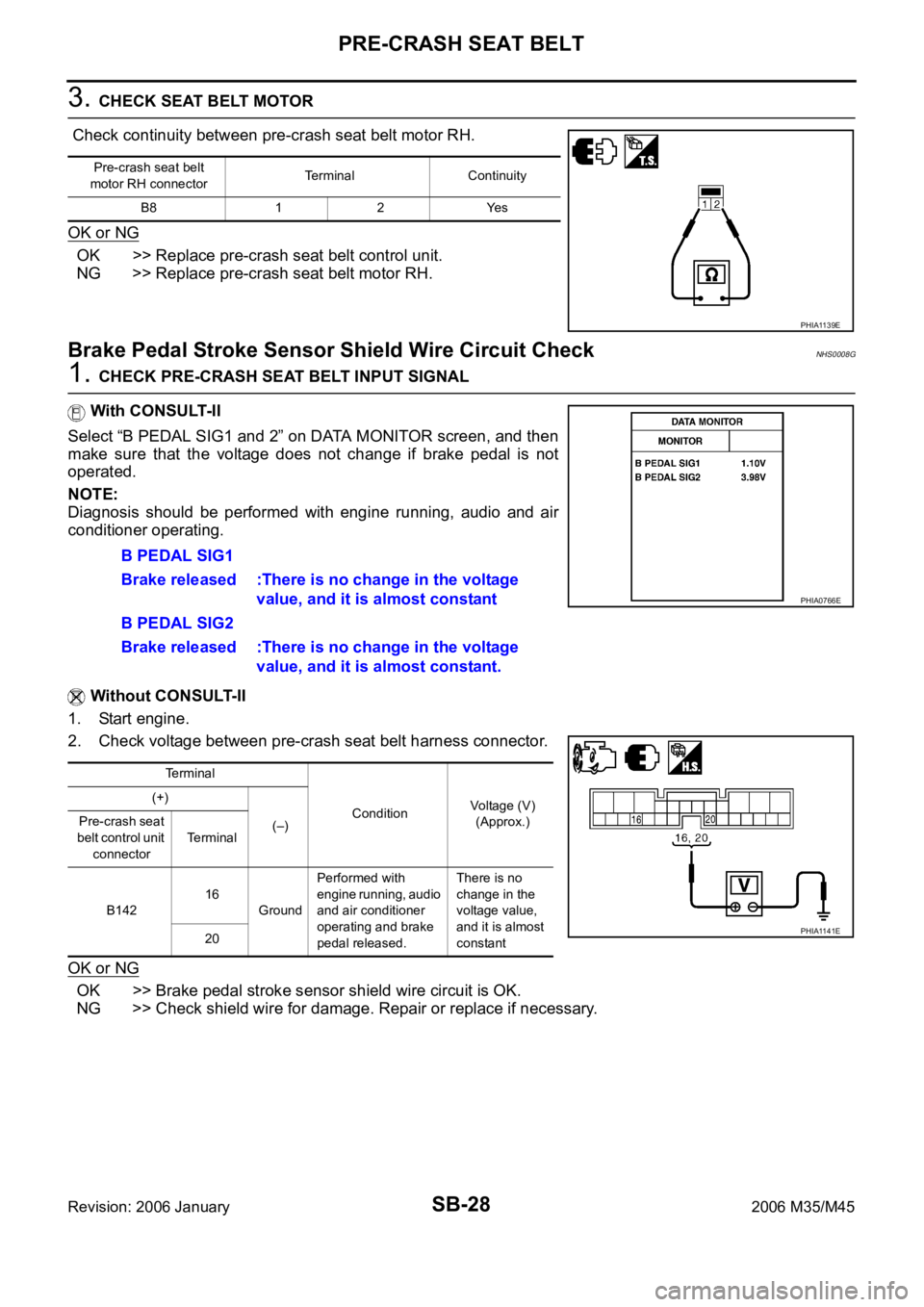

3. CHECK SEAT BELT MOTOR

Check continuity between pre-crash seat belt motor RH.

OK or NG

OK >> Replace pre-crash seat belt control unit.

NG >> Replace pre-crash seat belt motor RH.

Brake Pedal Stroke Sensor Shield Wire Circuit CheckNHS0008G

1. CHECK PRE-CRASH SEAT BELT INPUT SIGNAL

With CONSULT-II

Select “B PEDAL SIG1 and 2” on DATA MONITOR screen, and then

make sure that the voltage does not change if brake pedal is not

operated.

NOTE:

Diagnosis should be performed with engine running, audio and air

conditioner operating.

Without CONSULT-II

1. Start engine.

2. Check voltage between pre-crash seat belt harness connector.

OK or NG

OK >> Brake pedal stroke sensor shield wire circuit is OK.

NG >> Check shield wire for damage. Repair or replace if necessary.

Pre-crash seat belt

motor RH connectorTerminal Continuity

B8 1 2 Yes

PHIA1139E

B PEDAL SIG1

Brake released :There is no change in the voltage

value, and it is almost constant

B PEDAL SIG2

Brake released :There is no change in the voltage

value, and it is almost constant.

Terminal

ConditionVoltage (V)

(Approx.) (+)

(–) Pre-crash seat

belt control unit

connectorTerminal

B14216

GroundPerformed with

engine running, audio

and air conditioner

operating and brake

pedal released.There is no

change in the

voltage value,

and it is almost

constant 20

PHIA0766E

PHIA1141E

Page 5128 of 5621

PRE-CRASH SEAT BELT

SB-29

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

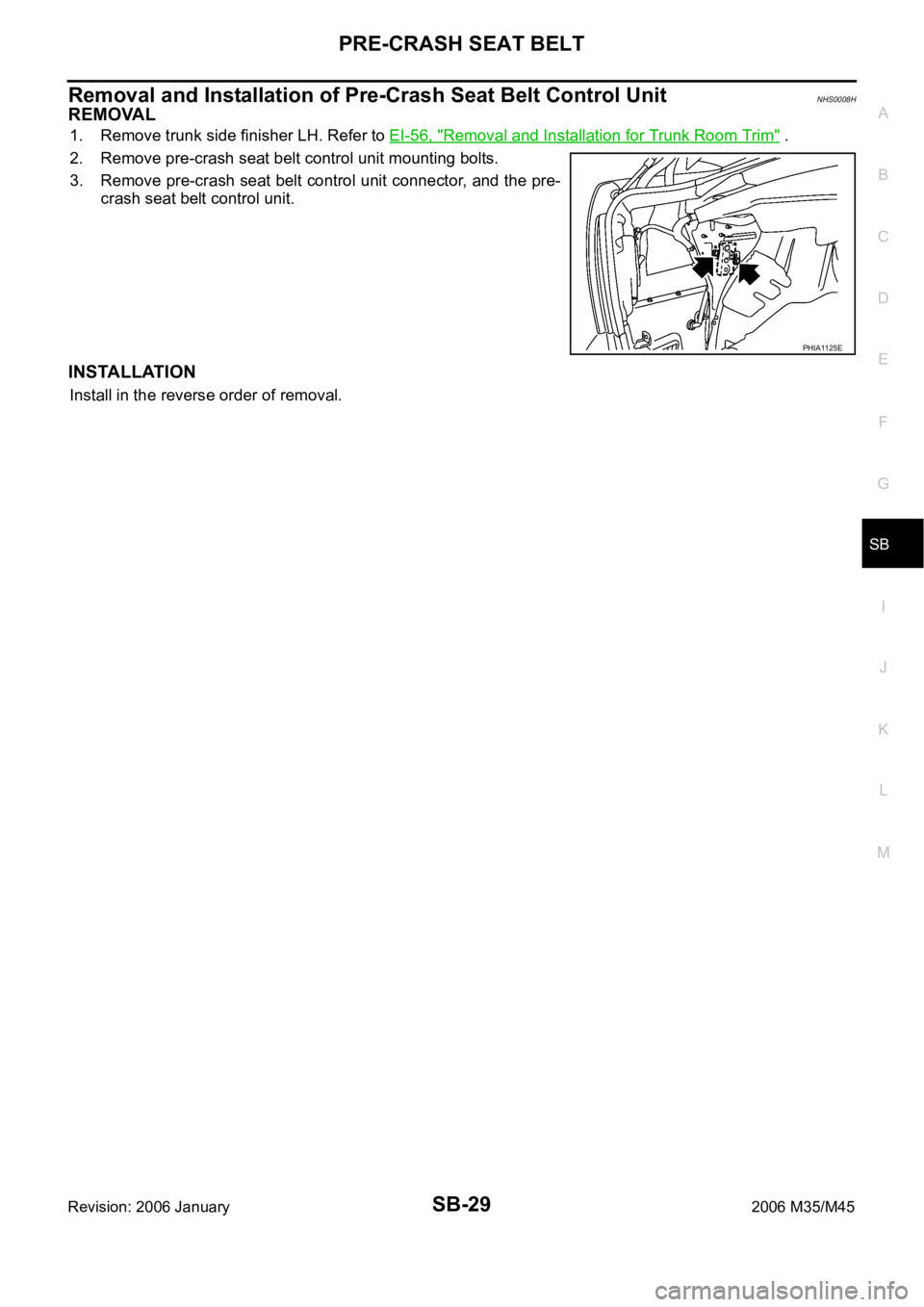

Removal and Installation of Pre-Crash Seat Belt Control UnitNHS0008H

REMOVAL

1. Remove trunk side finisher LH. Refer to EI-56, "Removal and Installation for Trunk Room Trim" .

2. Remove pre-crash seat belt control unit mounting bolts.

3. Remove pre-crash seat belt control unit connector, and the pre-

crash seat belt control unit.

INSTALLATION

Install in the reverse order of removal.

PHIA1125E

Page 5129 of 5621

SB-30

SEAT BELTS

Revision: 2006 January2006 M35/M45

SEAT BELTSPFP:86884

System DescriptionNHS0008I

SEAT BELT WARNING CHIME

With ignition switch turned ON and seat belt unfastened (seat belt switch ON), warning chime will sound

for approximately 6 seconds.

If warning chime does not sound, refer to DI-74, "Seat Belt Buckle Switch Signal Inspection" .

SEAT BELT WARNING LAMP

Fasten driver's seat belt.

The seat belt warning lamp should go out.

If the seat belt warning lamp does not go out, refer to DI-43, "Wiring Diagram — WARN —" .

Removal and Installation of Front Seat Belt NHS0008J

CAUTION:

Before servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least 3

minutes.

REMOVAL OF SEAT BELT RETRACTOR

1. Remove the outer anchor.

Remove the belt tension sensor cover and cover protector (passenger side only).

Disconnect the belt tension sensor connector (passenger side only).

Remove the fixing bolt of the outer anchor.

1. Outer anchor 2. Shoulder anchor 3. Pre-tensioner seat belt retractor

4. Belt tension sensor cover (passen-

ger side only)5. Cover protector (passenger side

only)6. Belt tension sensor connector (pas-

senger side only)

7. Anchor bolt 8. Anchor nut 9. Seat belt pre-tensioner connector

10. Pre-crash seat belt connector 11. Bolt 12. Seat belt adjuster

PHIA1106E

Page 5133 of 5621

SB-34

SEAT BELTS

Revision: 2006 January2006 M35/M45

NOTE:

Apply the tape so that there is no looseness or wrinkling.

6. Remove the clip fixing the seat belt and check that the webbing returns smoothly.

6. Repeat steps above as necessary to check the other seat belts.

SEAT BELT RETRACTOR ON-VEHICLE CHECK

Emergency Locking Retractors (ELR) and Automatic Locking Retractors (ALR)

NOTE:

All seat belt retractors are of the Emergency Locking Retractors (ELR) type. In an emergency (sudden stop)

the retractor will lock and prevent the webbing from extending any further. All 3-point type seat belt retractors

except the driver's seat belt also have an Automatic Locking Retractors (ALR) mode. The ALR mode (also

called child restraint mode) is used when installing child seats. The ALR mode is activated when the seat belt

is fully extended. When the webbing is then retracted partially, the ALR mode automatically locks the seat belt

in a specific position so the webbing cannot be extended any further. To cancel the ALR mode, allow the seat

belt to fully wind back into the retractor.

Check the seat belt retractors using the following test(s) to determine if a retractor assembly is operating prop-

erly.

ELR Function Stationary Check

Grasp the shoulder webbing and pull forward quickly. The retractor should lock and prevent the belt from

extending further.

ALR Function Stationary Check

1. Pull out entire length of seat belt from retractor until a click is heard.

2. Retract the webbing partially. A clicking noise should be heard as the webbing retracts indicating that the

retractor is in the Automatic Locking Retractors (ALR) mode.

3. Grasp the seat belt and try to pull out the retractor. The webbing must lock and not extend any further. If

NG, replace the retractor assembly.

4. Allow the entire length of the webbing to retract to cancel the automatic locking mode.

ELR Function Moving Check

WAR NING :

Perform the following test in a safe, open area clear of other vehicles and obstructions (for example, a

large, empty parking lot). Road surface must be paved and dry. DO NOT perform the following test on

wet or gravel roads or on public streets and highways. This could result in an accident and serious

personal injury. The driver and passenger must be prepared to brace themselves in the event the

retractor does not lock.

1. Fasten driver's seat belt. Buckle a passenger into the seat for the belt that is to be tested.

2. Proceed to the designated safe area.

3. Drive the vehicle at approximately 16 km/h (10 MPH). Notify any passengers of a pending sudden stop

and the driver and passenger must be prepared to brace themselves in the event the retractor does not

lock, apply brakes firmly and make a very hard stop.

During stop, seat belts should lock and not be extended. If the seat belt retractor assembly does not lock, per-

form the retractor off-vehicle check.

Page 5165 of 5621

SC-28

CHARGING SYSTEM

Revision: 2006 January2006 M35/M45

Trouble Diagnoses with Battery/Starting/Charging System Tester (Charging)NKS003NP

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter and alternator test segments must be done

as a set from start to finish.

Before starting, perform the preliminary inspection. Refer to SC-32, "

PRELIMINARY INSPECTION" .

1. Stop the operation of the power generation voltage variable control in either of the following procedures.

After selecting “ENGINE” of “SELECT SYSTEM” using CONSULT-II, set the DUTY value of “ALTERNA-

TOR DUTY” to 0% by selecting “ALTERNATOR DUTY” of “ACTIVE TEST”. Continue “ACTIVE TEST”

until the end of inspection. (When the DUTY value is 0 or 100%, the normal power generation is per-

formed according to the characteristic of the IC regulator of the alternator.)

Turn the ignition switch OFF, and disconnect the battery current sensor connector. [However, DTC

(P1550 - P1554) of the engine might remain. After finishing the inspection, connect the battery current

sensor connector and erase the self-diagnostic results history of the engine using CONSULT-II.]

2. Turn off all loads on the vehicle electrical system.

3. Perform battery and starting system test with Battery/Starting/

Charging system tester.

4. Press “ENTER” to begin the charging system test.

5. Start engine.

6. Press “ENTER” until “LOADS OFF REV ENGINE 5 SEC” is dis-

played.

7. Raise and hold the engine speed at 1,500 to 2,000 rpm for about

5 seconds, then return the engine to idle.

Once the increase in engine rpm is detected, press “ENTER” to

continue.

NOTE:

If after 30 seconds an increase in engine idle speed is not

detected, “RPM NOT DETECTED” will display.

Some engines may have a higher idle initially after starting,

particularly when the engine is cold. The tester may detect

this without any other action being taken. If this occurs, con-

tinue on with the testing process. The final results will not be affected.

8. The tester now checks the engine at idle and performs the

DIODE/RIPPLE check.

9. When complete, the tester will prompt you to turn on the follow-

ing electrical loads.

Heater fan set to highest speed. Do not run the A/C or wind-

shield defroster.

Headlamp high beam

Rear window defogger

NOTE:

Do not run the windshield wipers or any other cyclical loads.

SEL417X

SEL418X

SEL419X

Page 5194 of 5621

AUTOMATIC DRIVE POSITIONER

SE-13

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

*: Door mirror operation starts with the start of seat sliding operation.

Storing Memory Procedure

1. Turn ignition switch to ON.

2. Shift A/T selector lever to P position.

3. Adjust position of driver seat, steering and mirror position.

4. Press set switch.

Indicator LED for which driver seat positions are already retained in memory is illuminated for 5 sec-

onds.

Indicator LED for which driver seat positions are not retained in memory is illuminated for 0.5 second.

5. Press memory switch for which driver seat positions are to be entered in memory for more than 0.5 sec-

ond within 5 seconds after pressing the set switch (during the indicator LED is illuminated).

To enter driver seat positions in blank memory, indicator LED will be illuminated for 5 seconds.

To modify driver seat positions, indicator LED will be turned OFF for 0.5 second then illuminated for 5

seconds.

6.

If you need setting of INTELLIGENT KEY INTERLOCK OPERATION, continue this procedure.

If you don't need setting of INTELLIGENT KEY INTERLOCK OPERATION, the procedure is finished.

Conform the operations of each part with the MEMORY OPERATION.

7. Press intelligent key unlock button within 5 seconds after pressing memory switch.

(While memory switch LED is illuminated.)

8. Conform the operations of each part with MEMORY OPERATION and INTELLIGENT KEY INTERLOCK

OPERATION.

NOTE:

Driving position is erased from the memory when battery cable is disconnected.

Order of priority Operated portion

1* Seat sliding

2 Steering telescopic

3 Steering wheel tilt

4 Seat reclining

5 Seat lifter (front)

6 Seat lifter (rear)

Page 5217 of 5621

SE-36

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

6. Select diagnosis mode.

“DATA MONITOR”, “ACTIVE TEST”, “SELF-DIAG RESULTS“,

“ECU PART NUMBER”, “CAN DIAG SUPPORT MNTR” and

“WORK SUPPORT” are available.

SELF-DIAGNOSIS RESULTS

HOW TO READ SELF-DIAG RESULTS

NOTE:

CAN communication malfunction and detention switch malfunction are displayed on “TIME”. (1)

–If error is detected in the present, “CRNT” is displayed.

–If error is detected in the past (present error is not detected), “PAST” is displayed.

–If error has never been detected, nothing is displayed on “TIME”.

Any items other than CAN communication malfunction and detention switch malfunction are counted. (2)

–If error is detected, error detection frequency is displayed from “1” to “127” on “TIME”.

–If error has never been detected, nothing is displayed on “TIME”.

–Can clear the detected memory.

Normal: Clear memory in normal condition, history is erased and nothing is displayed on “TIME”.

Error: Clear memory in error condition, error is detected again and “1” is displayed on “TIME”.

DISPLAY ITEM LIST

BCIA0031E

CONSULT-II display Item Malfunction is detected when...Reference

page

CAN COMM CIRC

[U1000]CAN communication Malfunction is detected in CAN communication.SE-41

SEAT SLIDE

[B2112]Seat slide motorWhen any manual and automatic operations are not performed, if

any motor operations of seat slide is detected for 0.1 second or

more, status is judged “Output error”.SE-44

SE-52

SEAT RECLINING

[B2113]Seat reclining motorWhen any manual and automatic operations are not performed, if

any motor operations of seat reclining is detected for 0.1 second or

more, status is judged “Output error”.SE-45

SE-54

PIIB6449E