ECO mode INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 2948 of 5621

![INFINITI M35 2006 Factory Service Manual VARIABLE INDUCTION AIR CONTROL SYSTEM (VIAS)

EC-1405

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

8. CHECK VIAS CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT INFINITI M35 2006 Factory Service Manual VARIABLE INDUCTION AIR CONTROL SYSTEM (VIAS)

EC-1405

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

8. CHECK VIAS CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT](/img/42/57023/w960_57023-2947.png)

VARIABLE INDUCTION AIR CONTROL SYSTEM (VIAS)

EC-1405

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

8. CHECK VIAS CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 29 and VIAS control solenoid valve terminal 2.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 9.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

9. CHECK VIAS CONTROL SOLENOID VALVE

Refer to EC-1405, "

Component Inspection" .

OK or NG

OK >> GO TO 10.

NG >> Replace VIAS control solenoid valve.

10. CHECK INTERMITTENT INCIDENT

Refer to EC-878, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

>>INSPECTION END

Component InspectionNBS005PO

VIAS CONTROL SOLENOID VALVE

With CONSULT-II

1. Reconnect harness connectors disconnected.

2. Turn ignition switch ON.

3. Perform “VIAS SOL VALVE” in “ACTIVE TEST” mode.

4. Check air passage continuity and operation delay time under the

following conditions.

Operation takes less than 1 second.

Without CONSULT-II

Check air passage continuity and operation delay time under the fol-

lowing conditions.

Operation takes less than 1 second.Continuity should exist.

Condition

VIAS SOL VALVEAir passage continuity

between (A) and (B)Air passage continuity

between (A) and (C)

ON Yes No

OFF No Yes

PBIB0177E

ConditionAir passage continuity

between (A) and (B)Air passage continuity

between (A) and (C)

12V direct current supply

between terminals 1 and 2Ye s N o

No supply No Yes

SEF313Q

Page 2970 of 5621

![INFINITI M35 2006 Factory Service Manual FUEL PUMP

EC-1427

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

FUEL PUMPPFP:17042

DescriptionNBS005Q1

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signa INFINITI M35 2006 Factory Service Manual FUEL PUMP

EC-1427

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

FUEL PUMPPFP:17042

DescriptionNBS005Q1

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signa](/img/42/57023/w960_57023-2969.png)

FUEL PUMP

EC-1427

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

FUEL PUMPPFP:17042

DescriptionNBS005Q1

SYSTEM DESCRIPTION

*: ECM determines the start signal status by the signals of engine speed and battery voltage.

The ECM activates the fuel pump for several seconds after the ignition switch is turned ON to improve engine

startability. If the ECM receives a engine speed signal from the camshaft position sensor (PHASE), it knows

that the engine is rotating, and causes the pump to operate. If the engine speed signal is not received when

the ignition switch is ON, the engine stalls. The ECM stops pump operation and prevents battery discharging,

thereby improving safety. The ECM does not directly drive the fuel pump. It controls the ON/OFF fuel pump

relay, which in turn controls the fuel pump.

COMPONENT DESCRIPTION

A turbine type design fuel pump is used in the fuel tank.

Fuel level sensor unit and fuel pump (1)

Fuel pressure regulator (2)

Fuel tank temperature sensor (3)

CONSULT-II Reference Value in Data Monitor ModeNBS005Q2

Specification data are reference values.

Sensor Input signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed*

Fuel pump control Fuel pump relay

Battery Battery voltage*

Condition Fuel pump operation

Ignition switch is turned to ON. Operates for 1 second.

Engine running and crankingOperates.

When engine is stoppedStops in 1.5 seconds.

Except as shown aboveStops.

PBIB2707E

MONITOR ITEM CONDITION SPECIFICATION

FUEL PUMP RLY

For 1 seconds after turning ignition switch: ON

Engine running or crankingON

Except above OFF

Page 3068 of 5621

![INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced](/img/42/57023/w960_57023-3067.png)

PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectNBS005RR

NOTE:

This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the

ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the

LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precautions for Drain Engine Coolant and Engine OilNBS004MH

Drain engine coolant and engine oil when the engine is cooled.

Precautions for Disconnecting Fuel PipingNBS004MI

Before starting work, make sure no fire or spark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyNBS004MJ

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

PIIB3706J

Page 3097 of 5621

![INFINITI M35 2006 Factory Service Manual EM-34

[VQ35DE]

OIL PAN AND OIL STRAINER

Revision: 2006 January2006 M35/M45

b. Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000 ( — )] to the oil pan (lower) INFINITI M35 2006 Factory Service Manual EM-34

[VQ35DE]

OIL PAN AND OIL STRAINER

Revision: 2006 January2006 M35/M45

b. Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000 ( — )] to the oil pan (lower)](/img/42/57023/w960_57023-3096.png)

EM-34

[VQ35DE]

OIL PAN AND OIL STRAINER

Revision: 2006 January2006 M35/M45

b. Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000 ( — )] to the oil pan (lower) as shown in

the figure.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-48, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

CAUTION:

Attaching should be done within 5 minutes after coating.

c. Install oil pan (lower).

Tighten mounting bolts in numerical order as shown in the fig-

ure.

5. Install oil pan drain plug.

Refer to the figure of components of former page for installation direction of drain plug washer. Refer to

EM-29, "

Components (2WD Models)" .

6. Install in the reverse order of removal after this step.

NOTE:

At least 30 minutes after oil pan is installed, pour engine oil.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and adjust engine oil. Refer to LU-7, "ENGINE OIL" .

2. Start engine, and check there is no leak of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level again. Refer to LU-7, "

ENGINE OIL" .

PBIC2657E

PBIC0782E

Page 3104 of 5621

![INFINITI M35 2006 Factory Service Manual OIL PAN AND OIL STRAINER

EM-41

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

b. Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000 ( — INFINITI M35 2006 Factory Service Manual OIL PAN AND OIL STRAINER

EM-41

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

b. Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000 ( —](/img/42/57023/w960_57023-3103.png)

OIL PAN AND OIL STRAINER

EM-41

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

b. Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000 ( — )] to the oil pan (lower) as shown in

the figure.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-48, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

CAUTION:

Attaching should be done within 5 minutes after coating.

c. Install oil pan (lower).

Tighten mounting bolts in numerical order as shown in the fig-

ure.

5. Install oil pan drain plug.

Refer to the figure of components of former page for installation direction of drain plug washer. Refer to

EM-35, "

Components (AWD Models)" .

6. Install in the reverse order of removal after this step.

NOTE:

At least 30 minutes after oil pan is installed, pour engine oil.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level and adjust engine oil. Refer to LU-7, "ENGINE OIL" .

2. Start engine, and check there is no leak of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level again. Refer to LU-7, "

ENGINE OIL" .

PBIC2657E

PBIC0782E

Page 3155 of 5621

![INFINITI M35 2006 Factory Service Manual EM-92

[VQ35DE]

CAMSHAFT

Revision: 2006 January2006 M35/M45

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

Perform this inspection only when DTC P0011 or INFINITI M35 2006 Factory Service Manual EM-92

[VQ35DE]

CAMSHAFT

Revision: 2006 January2006 M35/M45

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

Perform this inspection only when DTC P0011 or](/img/42/57023/w960_57023-3154.png)

EM-92

[VQ35DE]

CAMSHAFT

Revision: 2006 January2006 M35/M45

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

Perform this inspection only when DTC P0011 or P0021 are detected in self-diagnostic results of

CONSULT-II and it is directed according to inspection procedure of EC section. Refer to EC-137,

"SELF-DIAG RESULTS MODE" .

Check when engine ins cold so as to prevent burns from any splashing engine oil.

1. Check the engine oil level. Refer to LU-7, "

ENGINE OIL" .

2. Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a. Release fuel pressure. Refer to EC-98, "

FUEL PRESSURE RELEASE" .

b. Disconnect ignition coil and injector harness connectors.

3. Remove intake valve timing control solenoid valve. Refer to EM-84, "

CAMSHAFT" .

4. Crank the engine, and then make sure that engine oil comes out

from camshaft bracket (No. 1) oil hole. End crank after checking.

WA R N I N G :

Be careful not to touch rotating parts (drive belts, idler pul-

ley, and crankshaft pulley, etc.).

CAUTION:

Engine oil may squirt from intake valve timing control sole-

noid valve installation hole during cranking. Use a shop

cloth to prevent the engine components and the vehicle. Do

not allow engine oil to get on rubber components such as

drive belt or engine mount insulators. Immediately wipe off

any splashed engine oil.

Clean oil groove between oil strainer and intake valve timing control solenoid valve if engine oil does not

come out from camshaft bracket (No. 1) oil hole. Refer to LU-5, "

LUBRICATION SYSTEM" .

5. Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT),

and then check each oil groove for clogging.

Clean oil groove if necessary. Refer to LU-5, "LUBRICATION SYSTEM" .

6. After inspection, install removed parts.

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak.

Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-12, "

RECOMMENDED FLUIDS AND LUBRICANTS" .

Use procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

Run engine to check for unusual noise and vibration.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal/installation, slack in the guide may

generate a pounding noise during and just after engine start. However, this is normal. Noise will stop after

hydraulic pressure rises.

Warm up engine thoroughly to make sure there is no leakage of fuel, or any oil/fluids including engine oil

and engine coolant.

Bleed air from lines and hoses of applicable lines, such as in cooling system.

After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

PBIC2869E

Page 3187 of 5621

![INFINITI M35 2006 Factory Service Manual EM-124

[VQ35DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

Disassembly and AssemblyNBS004O1

DISASSEMBLY

NOTE:

Explained here is how to disassemble with engine stand supporting transmission su INFINITI M35 2006 Factory Service Manual EM-124

[VQ35DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

Disassembly and AssemblyNBS004O1

DISASSEMBLY

NOTE:

Explained here is how to disassemble with engine stand supporting transmission su](/img/42/57023/w960_57023-3186.png)

EM-124

[VQ35DE]

CYLINDER BLOCK

Revision: 2006 January2006 M35/M45

Disassembly and AssemblyNBS004O1

DISASSEMBLY

NOTE:

Explained here is how to disassemble with engine stand supporting transmission surface. When using differ-

ent type of engine stand, note with difference in steps and etc.

1. Remove the engine assembly from the vehicle. Refer to EM-29, "

Removal and Installation (2WD Models)"

or EM-36, "Removal and Installation (AWD Models)" .

2. Remove the parts that may restrict installation of engine to widely use engine stand.

NOTE:

The procedure is described assuming that you use a widely use engine stand holding the surface, to

which transmission is installed.

Remove drive plate with power tool. Fix crankshaft with a ring gear stopper [SST: KV1011770

(J44716)], and remove mounting bolts.

Loosen mounting bolts in diagonal order.

1. Cylinder block 2. Reinforcement plate 3. Drive plate

4. Rear oil seal retainer 5. Cover 6. Gasket

7. Knock sensor 8. Oil jet 9. Thrust bearing

10. Pilot converter 11. Main bearing 12. Crankshaft

13. Crankshaft key 14. Main bearing cap 15. Main bearing cap bolt

16. Main bearing beam 17. Baffle plate (2WD models) 18. Top ring

19. Second ring 20. Oil ring 21. Piston

22. Piston pin 23. Snap ring 24. Connecting rod

25. Connecting rod bearing 26. Connecting rod bearing cap 27. Connecting rod bolt

1. Cylinder block 2. Gasket 3. Water connector

4. Gasket 5. Cylinder block heater 6. Connector protector cap

PBIC2614E

Page 3196 of 5621

![INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-133

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

13. Install connecting rod bearing cap.

Match the stamped cylinder number marks on connecting rod

with those INFINITI M35 2006 Factory Service Manual CYLINDER BLOCK

EM-133

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

13. Install connecting rod bearing cap.

Match the stamped cylinder number marks on connecting rod

with those](/img/42/57023/w960_57023-3195.png)

CYLINDER BLOCK

EM-133

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

13. Install connecting rod bearing cap.

Match the stamped cylinder number marks on connecting rod

with those on connecting rod bearing cap to install.

Be sure that front mark on connecting rod bearing cap is fac-

ing front of the engine.

14. Tighten connecting rod bolt as follows:

a. Inspect the outer diameter of connecting rod bolt. Refer to EM-149, "

CONNECTING ROD BOLT OUTER

DIAMETER" .

b. Apply engine oil to the threads and seats of connecting rod bolts.

c. Tighten connecting rod bolts.

d. Then tighten all connecting rod bolts 90 degrees clockwise

(Angle tightening).

CAUTION:

Always use the angle wrench [SST: KV10112100 (BT8653-

A)]. Avoid tightening based on visual check alone.

After tightening connecting rod bolts, make sure that crank-

shaft rotates smoothly.

Check the connecting rod side clearance. Refer to EM-140,

"CONNECTING ROD SIDE CLEARANCE" .

15. Install baffle plate to main bearing beam (2WD models).

16. Install new rear oil seal retainer to cylinder block.

Apply new engine oil to both oil seal lip and dust seal lip.

Apply a continuous bead of liquid gasket with the tube presser

[SST: WS39930000 ( — )] to rear oil seal retainer as

shown in the figure.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-48, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

CAUTION:

Replace with a new parts.

Attaching should be done within 5 minutes after coating.

Make sure the garter spring is in position and seal lips

not inverted.

NOTE:

Regard both rear oil seal and retainer as an assembly.

PBIC0809E

: 19.6 Nꞏm (2.0 kg-m, 14 ft-lb)

SEM953E

PBIC2661E

Page 3226 of 5621

![INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-163

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VK45DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004O5

When performing the proc INFINITI M35 2006 Factory Service Manual PRECAUTIONS

EM-163

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VK45DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004O5

When performing the proc](/img/42/57023/w960_57023-3225.png)

PRECAUTIONS

EM-163

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VK45DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004O5

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectNBS005RS

NOTE:

This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the

ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the

LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precautions for Drain Engine Coolant and Engine OilNBS004O7

Drain engine coolant and engine oil when engine is cooled.

Precautions for Disconnecting Fuel PipingNBS004O8

Before starting work, make sure no fire or spark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyNBS004O9

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

PIIB3706J

Page 3464 of 5621

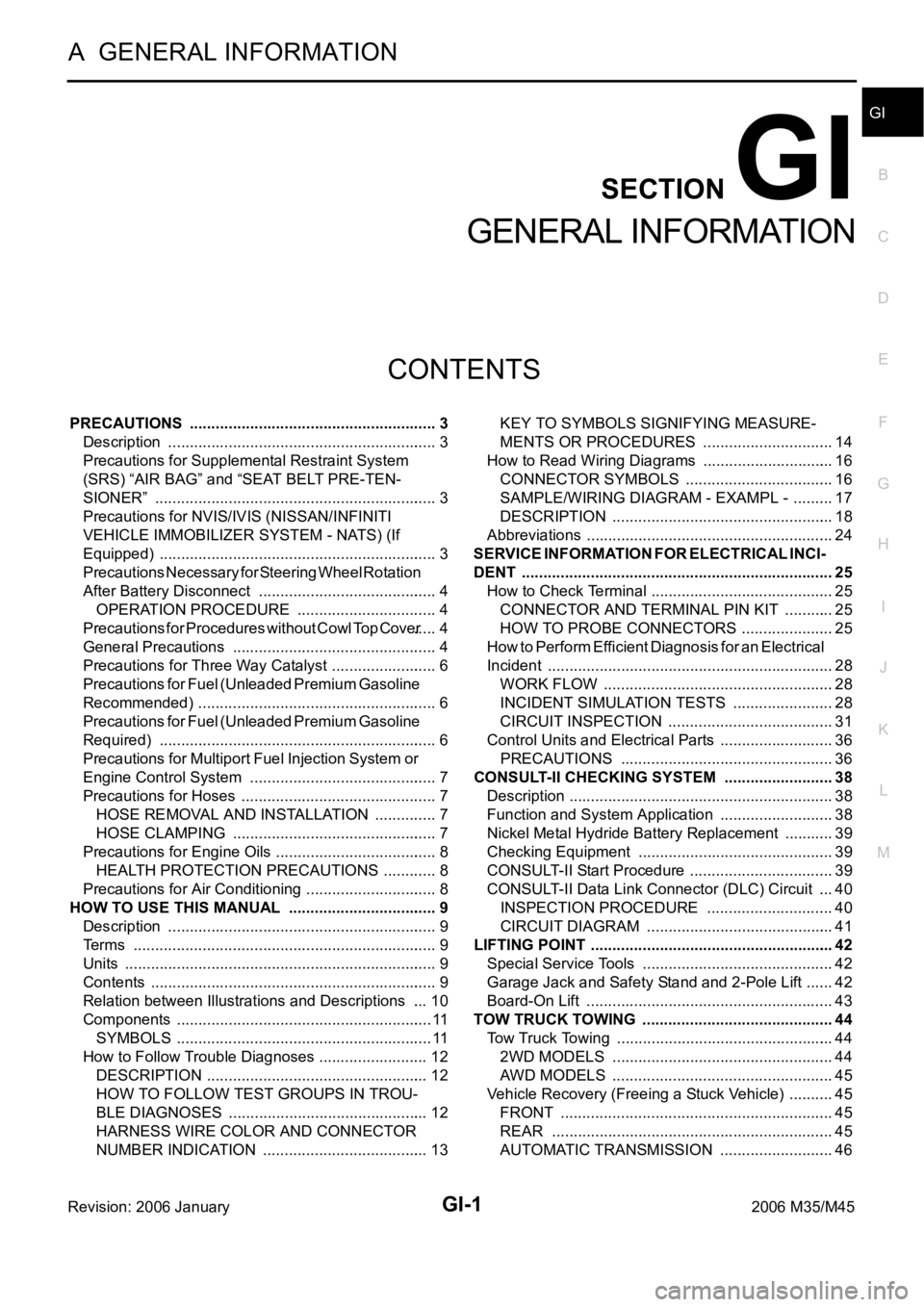

GI-1

GENERAL INFORMATION

A GENERAL INFORMATION

CONTENTS

C

D

E

F

G

H

I

J

K

L

MB

GI

SECTION GI

Revision: 2006 January2006 M35/M45

GENERAL INFORMATION

PRECAUTIONS .......................................................... 3

Description ............................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Precautions for NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS) (If

Equipped) ................................................................. 3

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 4

OPERATION PROCEDURE ................................. 4

Precautions for Procedures without Cowl Top Cover ..... 4

General Precautions ................................................ 4

Precautions for Three Way Catalyst ......................... 6

Precautions for Fuel (Unleaded Premium Gasoline

Recommended) ...................................................

..... 6

Precautions for Fuel (Unleaded Premium Gasoline

Required) ................................................................. 6

Precautions for Multiport Fuel Injection System or

Engine Control System ............................................ 7

Precautions for Hoses .............................................. 7

HOSE REMOVAL AND INSTALLATION ............... 7

HOSE CLAMPING ................................................ 7

Precautions for Engine Oils ...................................... 8

HEALTH PROTECTION PRECAUTIONS ............. 8

Precautions for Air Conditioning ............................... 8

HOW TO USE THIS MANUAL ................................... 9

Description ............................................................... 9

Terms ....................................................................... 9

Units ......................................................................... 9

Contents ................................................................... 9

Relation between Illustrations and Descriptions .... 10

Components ............................................................ 11

SYMBOLS ........................................................

.... 11

How to Follow Trouble Diagnoses .......................... 12

DESCRIPTION .................................................... 12

HOW TO FOLLOW TEST GROUPS IN TROU-

BLE DIAGNOSES ............................................... 12

HARNESS WIRE COLOR AND CONNECTOR

NUMBER INDICATION ....................................... 13KEY TO SYMBOLS SIGNIFYING MEASURE-

MENTS OR PROCEDURES ............................... 14

How to Read Wiring Diagrams ............................... 16

CONNECTOR SYMBOLS ................................... 16

SAMPLE/WIRING DIAGRAM - EXAMPL - .......... 17

DESCRIPTION .................................................... 18

Abbreviations .......................................................... 24

SERVICE INFORMATION FOR ELECTRICAL INCI-

DENT ......................................................................... 25

How to Check Terminal ........................................... 25

CONNECTOR AND TERMINAL PIN KIT ............ 25

HOW TO PROBE CONNECTORS ...................... 25

How to Perform Efficient Diagnosis for an Electrical

Incident ................................................................... 28

WORK FLOW ...................................................... 28

INCIDENT SIMULATION TESTS ........................ 28

CIRCUIT INSPECTION ....................................

... 31

Control Units and Electrical Parts ........................... 36

PRECAUTIONS .................................................. 36

CONSULT-II CHECKING SYSTEM .......................... 38

Description .............................................................. 38

Function and System Application ........................... 38

Nickel Metal Hydride Battery Replacement ............ 39

Checking Equipment .............................................. 39

CONSULT-II Start Procedure .................................. 39

CONSULT-II Data Link Connector (DLC) Circuit .... 40

INSPECTION PROCEDURE .............................. 40

CIRCUIT DIAGRAM ............................................ 41

LIFTING POINT ......................................................... 42

Special Service Tools ............................................. 42

Garage Jack and Safety Stand and 2-Pole Lift ....... 42

Board-On Lift .......................................................... 43

TOW TRUCK TOWING ............................................. 44

Tow Truck Towing ................................................... 44

2WD MODELS .................................................... 44

AWD MODELS .................................................... 45

Vehicle Recovery (Freeing a Stuck Vehicle) ........... 45

FRONT ................................................................ 45

REAR .................................................................. 45

AUTOMATIC TRANSMISSION ........................... 46