differential INFINITI M35 2006 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4778 of 5621

MA-1

MAINTENANCE

L MAINTENANCE

CONTENTS

C

D

E

F

G

H

I

J

K

M

SECTION MA

A

B

MA

Revision: 2006 January2006 M35/M45

MAINTENANCE

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

GENERAL MAINTENANCE ....................................... 4

Explanation of General Maintenance ....................... 4

PERIODIC MAINTENANCE ....................................... 7

Introduction of Periodic Maintenance ....................... 7

Schedule 1 ............................................................... 8

EMISSION CONTROL SYSTEM MAINTE-

NANCE .................................................................. 8

CHASSIS AND BODY MAINTENANCE ............... 9

Schedule 2 ............................................................. 10

EMISSION CONTROL SYSTEM MAINTE-

NANCE ................................................................ 10

CHASSIS AND BODY MAINTENANCE .............. 11

RECOMMENDED FLUIDS AND LUBRICANTS ...... 12

Fluids and Lubricants ............................................. 12

SAE Viscosity Number ........................................... 13

GASOLINE ENGINE OIL .................................... 13

Anti-Freeze Coolant Mixture Ratio ......................... 13

ENGINE MAINTENANCE (VQ35DE ENGINE) ......... 14

Checking Drive Belts .............................................. 14

Drive Belts Tension Adjustment ............................. 14

ALTERNATOR AND POWER STEERING OIL

PUMP BELT ........................................................ 15

A/C COMPRESSOR BELT ................................. 15

Changing Engine Coolant ...................................... 15

DRAINING ENGINE COOLANT ......................... 15

REFILLING ENGINE COOLANT ........................ 16

FLUSHING COOLING SYSTEM ......................... 17

Checking Fuel Lines ............................................ ... 18

Changing Air Cleaner Filter .................................... 18

VISCOUS PAPER TYPE ..................................... 18

Changing Engine Oil .............................................. 18

Changing Oil Filter ................................................. 19

REMOVAL ........................................................

... 19

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ............... 20

Changing Spark Plugs (Platinum-Tipped Type) ..... 20

REMOVAL ........................................................

... 20INSPECTION AFTER REMOVAL ....................... 21

INSTALLATION ................................................... 21

Checking EVAP Vapor Lines .................................. 21

ENGINE MAINTENANCE (VK45DE ENGINE) ......... 22

Checking Drive Belts .............................................. 22

Tension Adjustment .............................................

... 22

Changing Engine Coolant ....................................... 22

DRAINING ENGINE COOLANT .......................... 22

REFILLING ENGINE COOLANT ......................... 23

FLUSHING COOLING SYSTEM ......................... 24

Checking Fuel Lines ............................................ ... 25

Changing Air Cleaner Filter .................................... 25

VISCOUS PAPER TYPE ..................................... 25

Changing Engine Oil ............................................

... 25

Changing Oil Filter .................................................. 26

REMOVAL ........................................................

... 26

INSTALLATION ................................................... 26

INSPECTION AFTER INSTALLATION ................ 27

Changing Spark Plugs (Platinum-Tipped Type) ...... 27

REMOVAL ........................................................

... 27

INSPECTION AFTER REMOVAL ....................... 27

INSTALLATION ................................................... 28

Checking EVAP Vapor Lines .................................. 28

CHASSIS AND BODY MAINTENANCE ................... 29

Checking Exhaust System ...................................... 29

Checking A/T Fluid ................................................. 29

Changing A/T Fluid ................................................. 31

Checking Transfer Fluid ......................................... 31

Changing Transfer Fluid ......................................... 32

Checking Propeller Shaft ........................................ 32

Checking Differential Gear Oil ................................ 32

Changing Differential Gear Oil ................................ 33

Balancing Wheels (Bonding Weight Type) ............. 33

REMOVAL ........................................................

... 33

WHEEL BALANCE ADJUSTMENT ..................... 33

Tire Rotation ........................................................... 35

Checking Brake Fluid Level and Leaks .................. 35

Checking Brake Lines and Cables ......................... 35

Changing Brake Fluid ............................................. 35

Checking Disc Brake .............................................. 36

Page 4786 of 5621

PERIODIC MAINTENANCE

MA-9

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months. Replace the drive belts if found

damaged or if the auto belt tensioner reading (only for VK45DE engine) reaches the maximum limit.

(2) If operating mainly in dusty conditions, more frequent maintenance may be required.

(3) Maintenance-free item. For service procedures, refer to FL section.

(4) After 60,000 miles (96,000 km) or 48 months, replace every 30,000 miles (48,000 km) or 24 months.

(5) If valve noise increases, inspect valve clearance.

* Maintenance items and intervals with “*” are recommended by INFINITI for reliable vehicle operation. The owner need not perform

such maintenance in order to maintain the emission warranty or manufacturer recall liability. Other maintenance items and intervals are

required.

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. Spark plugs (PLATINUM-

TIPPED type)Replace every 105,000 miles (169,000 km).MA-20

,

MA-27

Intake & exhaust valve clear-

ance*NOTE (5)EM-93, "Valve Clear-

ance", EM-

222, "Va l v e

Clearance"

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title Perform at number of miles,

kilometers or months, which-

ever comes first.Miles x 1,000

(km x 1,000)

Months33.75

(54)

2737.5

(60)

3041.25

(66)

3345

(72)

3648.75

(78)

3952.5

(84)

4256.25

(90)

4560

(96)

48

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title Perform at number of miles,

kilometers or months,

whichever comes first.Miles x 1,000

(km x 1,000)

Months3.75

(6)

37.50

(12)

611 . 2 5

(18)

915

(24)

1218.75

(30)

1522.5

(36)

1826.25

(42)

2130

(48)

24

Brake lines & cables I IMA-35

Brake pads & rotors I I I IMA-36

Automatic transmission &

transfer fluid & differential

gear oilNOTE (1) I IMA-29,

MA-31

,

MA-32

Steering gear, linkage &

transfer gear, axle & sus-

pension partsIIIIMA-36,

MA-37

Tire rotation NOTE (2)MA-4,

MA-35

Drive shaft boots and pro-

peller shaft (AWD models) IIIIMA-38,

MA-32

Exhaust system I I I IMA-29

In-cabin microfilter R RAT C - 1 3 4

Climate controlled seat filterRSE-171

MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference

Section -

Page or -

Content Title Perform at number of miles,

kilometers or months,

whichever comes first.Miles x 1,000

(km x 1,000)

Months33.75

(54)

2737.5

(60)

3041.25

(66)

3345

(72)

3648.75

(78)

3952.5

(84)

4256.25

(90)

4560

(96)

48

Brake lines & cables I IMA-35

Brake pads & rotors I I I IMA-36

Automatic transmission &

transfer fluid & differential

gear oilNOTE (1) I IMA-29,

MA-31

,

MA-32

Steering gear, linkage &

transfer gear, axle & sus-

pension partsI IIIMA-36,

MA-37

Page 4788 of 5621

PERIODIC MAINTENANCE

MA-11

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

CHASSIS AND BODY MAINTENANCE

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary.

NOTE:

(1) Refer to “Tire rotation” under the “GENERAL MAINTENANCE” heading earlier in this section. MAINTENANCE OPERATIONMAINTENANCE INTERVAL

Reference Sec-

tion - Page or -

Content Title Perform at number of miles, kilo-

meters or months, whichever

comes first.Miles x 1,000

(km x 1,000)

Months7.5

(12)

615

(24)

1222.5

(36)

1830

(48)

2437.5

(60)

3045

(72)

3652.5

(84)

4260

(96)

48

Brake lines & cables I I I IMA-35

Brake pads & rotors I I I IMA-36

Automatic transmission & trans-

fer fluid & differential gear oilIIIIMA-29,

MA-31

,

MA-32

Steering gear, linkage & transfer

gear, axle & suspension partsIIMA-36,

MA-37

Tire rotation NOTE (1)MA-4,

MA-35

Drive shaft boots and propeller

shaft (AWD models) IIIIMA-38,

MA-32

Exhaust system I IMA-29

In-cabin microfilter R R R RATC-134

Climate controlled seat filter R RSE-171

Page 4789 of 5621

MA-12

RECOMMENDED FLUIDS AND LUBRICANTS

Revision: 2006 January2006 M35/M45

RECOMMENDED FLUIDS AND LUBRICANTSPFP:00000

Fluids and Lubricants NLS0007E

*1: For further details, see “SAE Viscosity Number”.

*2: Using automatic transmission fluid other than Genuine NISSAN Matic J ATF will cause deterioration in driveability and

automatic transmission durability, and may damage the automatic transmission, which is not covered by the INFINITI new

vehicle limited warranty.

*3: For hot climates, viscosity SAE 90 is suitable for ambient temperatures above 0

C (32F).

*4: DEXRONTM III/ MERCONTM or equivalent may also be used. Outside the continental United States and Alaska contact an INFINITI

dealer for more information regarding suitable fluids, including recommended brand(s) of DEXRON TM III/ MERCONTM automatic trans-

mission fluid.

*5: For Canada, NISSAN Automatic Transmission Fluid (ATF), DEXRON

TM III/ MERCONTM , or equivalent ATF may also be used.

*6: Available in mainland U.S.A. through your INFINITI dealer.Capacity (Approximate)

Recommended Fluids/Lubricants

US measureImp mea-

sureLiter

Engine oil

Drain and

refillWith oil fil-

ter changeVK45DE 5-3/4 qt 4-7/8 qt 5.5

For VK45DE engine

Genuine NISSAN engine oil

API Certification Mark*1

API grade SJ or SL, Energy Conserving*1

ILSAC grade GF-II & GF-III*1

For VQ35DE engine

Genuine NISSAN engine oil

API Certification Mark*1

API grade SG/SH, Energy Conserving I & II

or API grade SJ or SL, Energy Conserving *1

ILSAC grade GF-I, GF-II & GF-III *1 VQ35DE 5 qt 4 - 1/8 qt 4.7

Without oil

filter

changeVK45DE 5-1/8 qt 4-1/4 qt 4.9

VQ35DE 4-5/8 qt 3-7/8 qt 4.4

Dry engine (Overhaul)VK45DE 7-1/8 qt 5-7/8 qt 6.7

VQ35DE 5-3/4 qt 4-3/4 qt 5.4

Cooling

systemWith res-

ervoir tankVK45DE 11 qt 9-1/8 qt 10.4

Genuine NISSAN Long Life Antifreeze/ Coolant

or equivalent VQ35DE 9-3/8 qt 7-7/8 qt 8.9

Reservoir

tankVK45DE 5/8 qt 1/2 qt 0.6

VQ35DE 5/8 qt 1/2 qt 0.6

Automatic transmission fluid 10-7/8 qt 9-1/8 qt 10.3 Genuine NISSAN Matic J ATF *2

Differential gear oilFront 1-3/8 pt 1-1/8 pt 0.65

API GL-5, Viscosity SAE 80W-90 *3

Rear 3 pt 2-1/2 pt 1.40

Transfer fluid 2-5/8 pt 2-1/4 pt 1.25Genuine NISSAN Matic D ATF (Continental U.S.

and Alaska) or Canada NISSAN Automatic

Transmission Fluid*4

Power steering fluid (PSF) 1-1/8 qt 7/8 qt 1.0 Genuine NISSAN PSF or equivalent*5

Brake fluid — — —Genuine NISSAN Super Heavy Duty Brake

Fluid*6 or equivalent

DOT 3 (US FMVSS No. 116)

Multi-purpose grease — — — NLGI No. 2 (Lithium soap base)

Windshield washer fluid — — —Genuine NISSAN Windshield Washer Concen-

trate Cleaner & Antifreeze or equivalent

Fuel recommendationVK45DE — — —Refer to GI-6, "

Precautions for Fuel (Unleaded

Premium Gasoline Required)" .

VQ35DE — — —Refer to GI-6, "

Precautions for Fuel (Unleaded

Premium Gasoline Recommended)" .

Page 4809 of 5621

MA-32

CHASSIS AND BODY MAINTENANCE

Revision: 2006 January2006 M35/M45

Changing Transfer FluidNLS00083

CAUTION:

When draining fluid, protect exhaust tube flange with cover.

1. Drain fluid from drain plug and refill with new gear fluid.

(For details, refer to TF-9, "

Replacement" .)

2. Check fluid level.

CAUTION:

Carefully fill the fluid. (Fill up for Approx. 3 minutes.)

Checking Propeller ShaftNLS00084

Check propeller shaft for damage, looseness or grease leakage.

Checking Differential Gear OilNLS00085

Check for oil leakage.

(For details, refer to FFD-8, "

Checking Differential Gear Oil" and

RFD-9, "

Checking Differential Gear Oil" .) Fluid grade:

Genuine NISSAN Matic D ATF (Continental U.S.

and Alaska) or Canada NISSAN Automatic Trans-

mission Fluid

Refer to MA-12, "

RECOMMENDED FLUIDS AND

LUBRICANTS" .

Fluid capacity:

: Approx. 1.25 (2-5/8 US pt, 2-1/4 lmp pt)

Drain plug:

: 29.4 Nꞏm (3.0 kg-m, 22 ft-lb)

Filler plug:

: 35 Nꞏm (3.6 kg-m, 26 ft-lb)SDIA2087E

Tightening torque:

Refer to PR-6, "

REAR PROPELLER SHAFT"

SMA118A

SMA012C

Page 4810 of 5621

CHASSIS AND BODY MAINTENANCE

MA-33

C

D

E

F

G

H

I

J

K

MA

B

MA

Revision: 2006 January2006 M35/M45

Changing Differential Gear OilNLS00086

1. Drain oil from drain plug and refill with new gear oil.

(For details, refer to FFD-8, "

Changing Differential Gear Oil" and RFD-9, "Changing Differential Gear Oil"

.)

2. Check oil level.

Balancing Wheels (Bonding Weight Type)NLS00087

REMOVAL

1. Remove inner and outer balance weights from the road wheel.

CAUTION:

Be careful not to scratch the road wheel during removal.

2. Using releasing agent, remove double-faced adhesive tape from the road wheel.

CAUTION:

Be careful not to scratch the road wheel during removal.

After removing double-faced adhesive tape, wipe clean traces of releasing agent from the road

wheel.

WHEEL BALANCE ADJUSTMENT

If a tire balance machine has adhesion balance weight mode settings and drive-in weight mode setting,

select and adjust a drive-in weight mode suitable for road wheels.

1. Set road wheel on wheel balancer using the center hole as a guide. Start the tire balance machine.

2. When inner and outer unbalance values are shown on the wheel balancer indicator, multiply outer unbal-

ance value by 5/3 to determine balance weight that should be used. Select the outer balance weight with

a value closest to the calculated value above and install it to the designated outer position of, or at the

designated angle in relation to the road wheel.

CAUTION:

Do not install the inner balance weight before installing the outer balance weight. Oil grade and Viscosity:

Refer to MA-12, "

RECOMMENDED FLUIDS

AND LUBRICANTS" .

Capacity:

Front final drive (F160A)

0.65 (1 - 3/8 US pt, 1 - 1/8 lmp pt)

Rear final drive (R200)

1.4 (3 US pt, 2 - 1/2 lmp pt)

Filler plug:

Front final drive

: 34.5 N-m (3.5 kg-m, 25 ft-lb)

Rear final drive

: 34.5 N-m (3.5 kg-m, 25 ft-lb)

Drain plug:

Front final drive

: 34.5 N-m (3.5 kg-m, 25 ft-lb)

Rear final drive

: 34.5 N-m (3.5 kg-m, 25 ft-lb)

SDIA1151E

Page 4942 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PR-3

C

E

F

G

H

I

J

K

L

MA

B

PR

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNDS000E9

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: Applicable Reference pageFront

PR-4—

—

—

—

PR-4PR-5

NVH in FFD and RFD section

NVH in FAX, RAX, FSU and RSU section

NVH in WT section

NVH in WT section

NVH in RAX section

NVH in BR section

NVH in PS section

RearPR-6PR-10—

PR-7—

PR-6PR-9

Possible cause and SUSPECTED PARTS

Uneven rotating torque

Center bearing improper installation

Excessive center bearing axial end play

Center bearing mounting (insulator) cracks, damage or deterioration

Excessive joint angle

Rotation imbalance

Excessive runout

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomNoiseShake

Vibration

Page 4960 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PS-7

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Trouble Shooting ChartNGS000D4

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: ApplicableReference page

PS-8PS-8PS-23PS-23PS-23PS-8PS-10PS-10

EM-15

,EM-174PS-10—

PS-22PS-16PS-13PS-20

NVH in PR section

NVH in RFD section

NVH in FAX, RAX, FSU, RSU section

NVH in WT section

NVH in WT section

NVH in FAX section

NVH in BR section

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Outer socket ball joint swinging force

Outer socket ball joint rotating torque

Outer socket ball joint end play

Steering fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness of tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE and SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Symptom SteeringNoise

Shake

Vibration

Shimmy

Judder

Page 5003 of 5621

RAX-4

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNDS000FP

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: ApplicableReference page

—

RAX-10—

RAX-8—

NVH in PR section.

NVH in RFD section.

NVH in RAX and RSU sections.

Refer to REAR AXLE in this chart.

NVH in WT section.

NVH in WT section.

Refer to DRIVE SHAFT in this chart.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Excessive joint angle

Joint sliding resistance

Imbalance

Improper installation, looseness

Parts interference

PROPELLER SHAFT

DIFFERENTIAL

REAR AXLE AND REAR SUSPENSION

REAR AXLE

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomDRIVE

SHAFTNoise

Shake

REAR

AXLENoise

Shake

Vibration

Shimmy

Judder

Poor quality ride or handling

Page 5044 of 5621

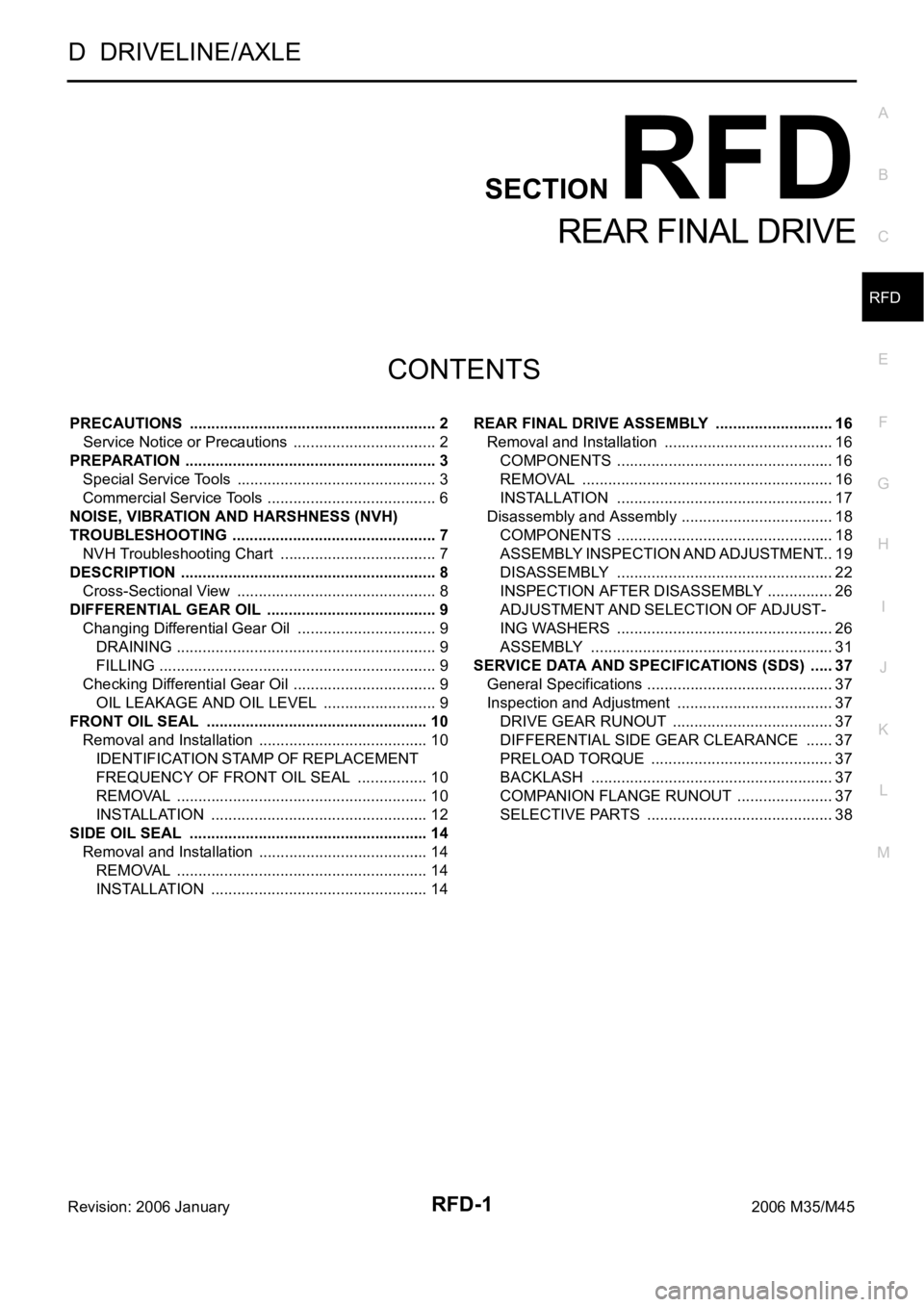

RFD-1

REAR FINAL DRIVE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION RFD

A

B

RFD

Revision: 2006 January2006 M35/M45

REAR FINAL DRIVE

PRECAUTIONS .......................................................... 2

Service Notice or Precautions .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 7

NVH Troubleshooting Chart ..................................... 7

DESCRIPTION ............................................................ 8

Cross-Sectional View ............................................... 8

DIFFERENTIAL GEAR OIL ........................................ 9

Changing Differential Gear Oil ................................. 9

DRAINING ............................................................. 9

FILLING ................................................................. 9

Checking Differential Gear Oil .................................. 9

OIL LEAKAGE AND OIL LEVEL ........................... 9

FRONT OIL SEAL .................................................

... 10

Removal and Installation ........................................ 10

IDENTIFICATION STAMP OF REPLACEMENT

FREQUENCY OF FRONT OIL SEAL ................. 10

REMOVAL ........................................................

... 10

INSTALLATION ................................................... 12

SIDE OIL SEAL ........................................................ 14

Removal and Installation ........................................ 14

REMOVAL ........................................................

... 14

INSTALLATION ................................................... 14REAR FINAL DRIVE ASSEMBLY ............................ 16

Removal and Installation ........................................ 16

COMPONENTS ................................................... 16

REMOVAL ........................................................

... 16

INSTALLATION ................................................... 17

Disassembly and Assembly .................................... 18

COMPONENTS ................................................... 18

ASSEMBLY INSPECTION AND ADJUSTMENT ... 19

DISASSEMBLY ................................................... 22

INSPECTION AFTER DISASSEMBLY ................ 26

ADJUSTMENT AND SELECTION OF ADJUST-

ING WASHERS ................................................... 26

ASSEMBLY ......................................................... 31

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 37

General Specifications ......................................... ... 37

Inspection and Adjustment ..................................... 37

DRIVE GEAR RUNOUT ...................................... 37

DIFFERENTIAL SIDE GEAR CLEARANCE ....... 37

PRELOAD TORQUE ........................................... 37

BACKLASH ......................................................... 37

COMPANION FLANGE RUNOUT ....................... 37

SELECTIVE PARTS ............................................ 38