service INFINITI M35 2006 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 419 of 5621

![INFINITI M35 2006 Factory Workshop Manual AT-340

ASSEMBLY

Revision: 2006 January2006 M35/M45

ASSEMBLYPFP:00000

Assembly (1)NCS001RA

1. As shown in the figure, use a drift [22 mm (0.87 in) dia. commer-

cial service tool] to drive manual shaft INFINITI M35 2006 Factory Workshop Manual AT-340

ASSEMBLY

Revision: 2006 January2006 M35/M45

ASSEMBLYPFP:00000

Assembly (1)NCS001RA

1. As shown in the figure, use a drift [22 mm (0.87 in) dia. commer-

cial service tool] to drive manual shaft](/img/42/57023/w960_57023-418.png)

AT-340

ASSEMBLY

Revision: 2006 January2006 M35/M45

ASSEMBLYPFP:00000

Assembly (1)NCS001RA

1. As shown in the figure, use a drift [22 mm (0.87 in) dia. commer-

cial service tool] to drive manual shaft oil seals into the transmis-

sion case until it is flush.

CAUTION:

Apply ATF to manual shaft oil seals.

Do not reuse manual shaft oil seals.

2. Install detent spring and spacer in transmission case. Tighten

detent spring and spacer bolts to the specified torque. Refer to

AT-278, "

Components" .

3. Install manual shaft to transmission case.

4. Install parking rod to manual plate.

SCIA5259E

SCIA5248E

SCIA5716E

SCIA5220E

Page 444 of 5621

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-365

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsNCS001RD

*1: Refer to MA-12, "Fluids and Lubricants" .

Vehicle Speed at Which Gear Shifting OccursNCS001RE

2WD MODELS

At half throttle, the accelerator opening is 4/8 of the full opening.

At half throttle, the accelerator opening is 4/8 of the full opening.

AWD MODELS

At half throttle, the accelerator opening is 4/8 of the full opening. Applied modelVQ35DE engine VK45DE engine

2WD AWD 2WD

Automatic transmission model RE5R05A

Transmission model code number 97X06, 98X1A 97X07, 98X0E 95X12, 95X7A

Stall torque ratio 1.72: 1 1.85: 1

Transmission gear ratio1st 3.842 3.827

2nd 2.353 2.368

3rd 1.529 1.520

4th 1.000 1.000

5th 0.839 0.834

Reverse 2.765 2.613

Recommended fluid Genuine NISSAN Matic J ATF*1

Fluid capacity 10.3 liter (10-7/8 US qt, 9-1/8 Imp qt)

CAUTION:

Use only Genuine NISSAN Matic J ATF. Do not mix with other fluid.

Using ATF other than Genuine NISSAN Matic J ATF will deteriorate in driveability and A/T durability, and may damage the

A/T, which is not covered by the warranty.

Engine model VQ35DE

Throttle positionVehicle speed km/h (MPH)

D

1 D2D2 D3D3 D4D4 D5D5 D4D4 D3D3 D2D2 D1

Full throttle 50 - 58

(31 - 36)85 - 93

(53 - 58)127 - 135

(79 - 84)196 - 204

(122 - 127)192 - 200

(119 - 124)114- 122

(71 - 76)70 - 78

(43 - 48)26 - 34

(16 - 21)

Half throttle 40 - 48

(25 - 30)69 - 77

(43 - 48)107 - 115

(66 - 71)139 - 147

(86 - 91)111 - 11 9

(69 - 74)67 - 75

(42 - 47)34 - 42

(21 - 26)19 - 27

(12 - 17)

Engine model VK45DE

Throttle positionVehicle speed km/h (MPH)

D

1 D2D2 D3D3 D4D4 D5D5 D4D4 D3D3 D2D2 D1

Full throttle 54 - 62

(34 - 39)89 - 97

(55 - 60)139 - 147

(86 - 91)207 - 215

(129 - 134)203 - 211

(126 - 131)122 - 130

(76 - 81)73 - 81

(45 - 50)28 - 36

(17 - 22)

Half throttle 46 - 54

(29 - 34)81 - 89

(50 - 55)126 - 134

(78 - 83)155 - 163

(96 - 101)128 - 136

(80 - 85)70 - 78

(43 - 48)28 - 36

(17 - 22)7 - 15

(4 - 9)

Engine model VQ35DE

Throttle positionVehicle speed km/h (MPH)

D

1 D2D2 D3D3 D4D4 D5D5 D4D4 D3D3 D2D2 D1

Full throttle 48 - 56

(30 - 35)81 - 89

(50 - 55)121 - 129

(75 - 80)188 - 196

(117 - 122)184 - 192

(114 - 119)109 - 117

(68 - 73)66 - 74

(41 - 46)25 - 33

(16 - 21)

Half throttle 38 - 46

(24 - 29)66 - 74

(41 - 46)102 - 110

(63 - 68)133 - 141

(83 - 88)106 - 114

(66 - 71)64 - 72

(40 - 45)32 - 40

(20 - 25)18 - 26

(11 - 16)

Page 445 of 5621

AT-366

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

Vehicle Speed at Which Lock-Up Occurs/ReleasesNCS001RF

2WD MODELS

At closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal: OFF)

At half throttle, the accelerator opening is 4/8 of the full opening.

At closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal: OFF)

At half throttle, the accelerator opening is 4/8 of the full opening.

AW D M OD E LS

At closed throttle, the accelerator opening is less than 1/8 condition. (Closed throttle position signal: OFF)

At half throttle, the accelerator opening is 4/8 of the full opening.

Stall SpeedNCS001RG

Line PressureNCS001RH

A/T Fluid Temperature SensorNCS001RI

Engine model VQ35DE

Throttle positionVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

Closed throttle 53 - 61 (33 - 38) 50 - 58 (31 - 36)

Half throttle 196 - 204 (122 - 127) 138 - 146 (86 - 91)

Engine model VK45DE

Throttle positionVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

Closed throttle 67 - 75 (42 - 47) 50 - 58 (31 - 36)

Half throttle 181 - 189 (112 - 117) 160 - 168 (99 - 104)

Engine model VQ35DE

Throttle positionVehicle speed km/h (MPH)

Lock-up ON Lock-up OFF

Closed throttle 51 - 59 (32 - 37) 48 - 56 (30 - 35)

Half throttle 188 - 196 (117 - 122) 132 - 140 (82 - 87)

Engine model Stall speed

VQ35DE 2,650 - 2,950 rpm

VK45DE 2,260 - 2,560 rpm

Engine speedLine pressure [kPa (kg/cm

2 , psi)]

“R” position “D”, “M” positions

At idle speed 425 - 465 (4.3 - 4.7, 62 - 67) 379 - 428 (3.9 - 4.4, 55 - 62)

At stall speed 1,605 - 1,950 (16.4 - 19.9, 233 - 283) 1,310 - 1,500 (13.4 - 15.3, 190 - 218)

Name Condition CONSULT-II “DATA MONITOR” (Approx.) Resistance (Approx.)

ATF TEMP SE 10

C (32F) 3.3 V 15 k

20C (68F) 2.7 V 6.5 k

80C (176F) 0.9 V 0.9 k

ATF TEMP SE 20

C (32F) 3.3 V 10 k

20C (68F) 2.5 V 4 k

80C (176F) 0.7 V 0.5 k

Page 446 of 5621

SERVICE DATA AND SPECIFICATIONS (SDS)

AT-367

D

E

F

G

H

I

J

K

L

MA

B

AT

Revision: 2006 January2006 M35/M45

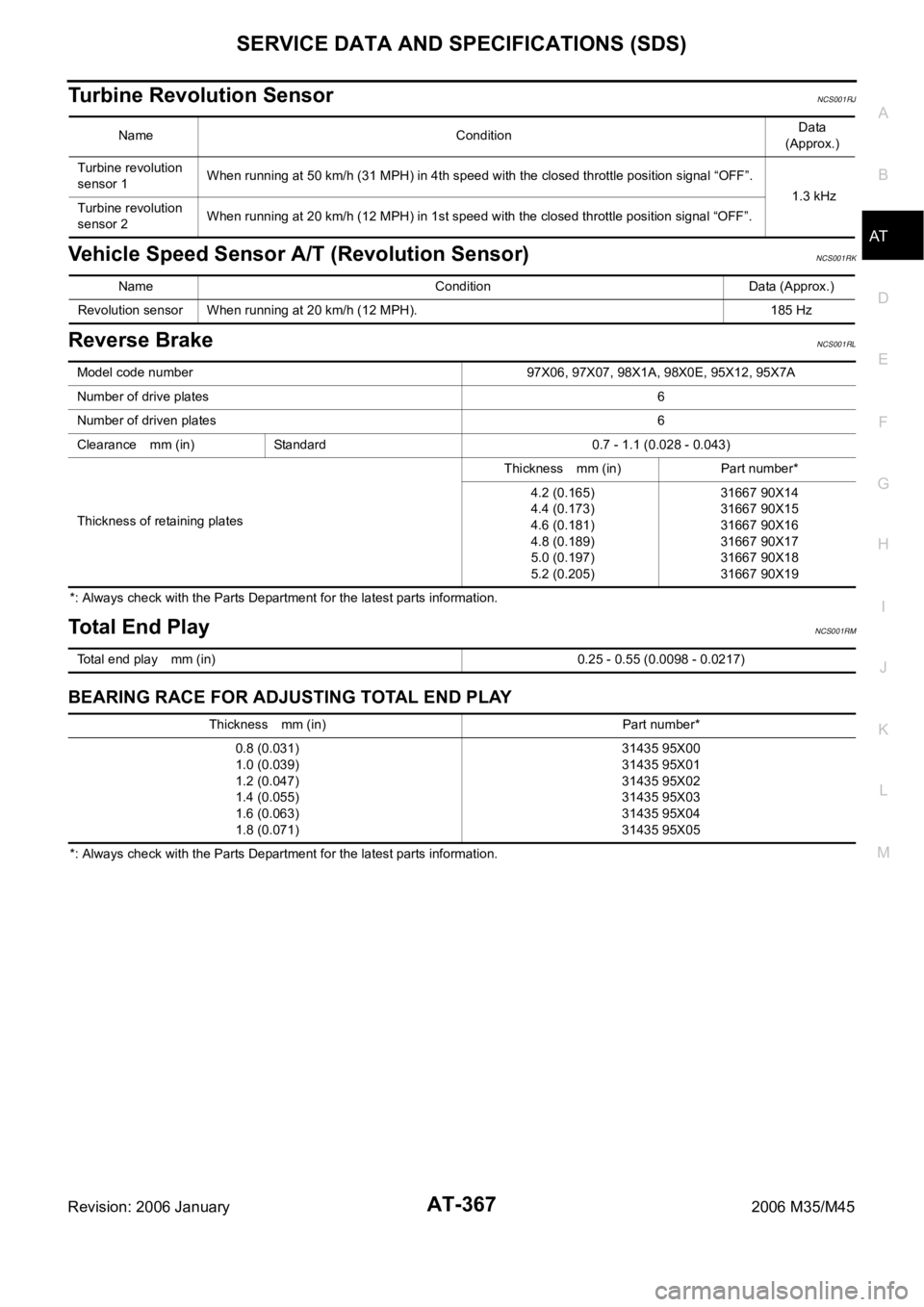

Turbine Revolution SensorNCS001RJ

Vehicle Speed Sensor A/T (Revolution Sensor)NCS001RK

Reverse BrakeNCS001RL

*: Always check with the Parts Department for the latest parts information.

Total End PlayNCS001RM

BEARING RACE FOR ADJUSTING TOTAL END PLAY

*: Always check with the Parts Department for the latest parts information. Name ConditionData

(Approx.)

Turbine revolution

sensor 1When running at 50 km/h (31 MPH) in 4th speed with the closed throttle position signal “OFF”.

1.3 kHz

Turbine revolution

sensor 2When running at 20 km/h (12 MPH) in 1st speed with the closed throttle position signal “OFF”.

Name Condition Data (Approx.)

Revolution sensor When running at 20 km/h (12 MPH). 185 Hz

Model code number 97X06, 97X07, 98X1A, 98X0E, 95X12, 95X7A

Number of drive plates6

Number of driven plates6

Clearance mm (in) Standard 0.7 - 1.1 (0.028 - 0.043)

Thickness of retaining platesThickness mm (in) Part number*

4.2 (0.165)

4.4 (0.173)

4.6 (0.181)

4.8 (0.189)

5.0 (0.197)

5.2 (0.205) 31667 90X14

31667 90X15

31667 90X16

31667 90X17

31667 90X18

31667 90X19

Total end play mm (in) 0.25 - 0.55 (0.0098 - 0.0217)

Thickness mm (in) Part number*

0.8 (0.031)

1.0 (0.039)

1.2 (0.047)

1.4 (0.055)

1.6 (0.063)

1.8 (0.071)31435 95X00

31435 95X01

31435 95X02

31435 95X03

31435 95X04

31435 95X05

Page 447 of 5621

AT-368

SERVICE DATA AND SPECIFICATIONS (SDS)

Revision: 2006 January2006 M35/M45

Page 448 of 5621

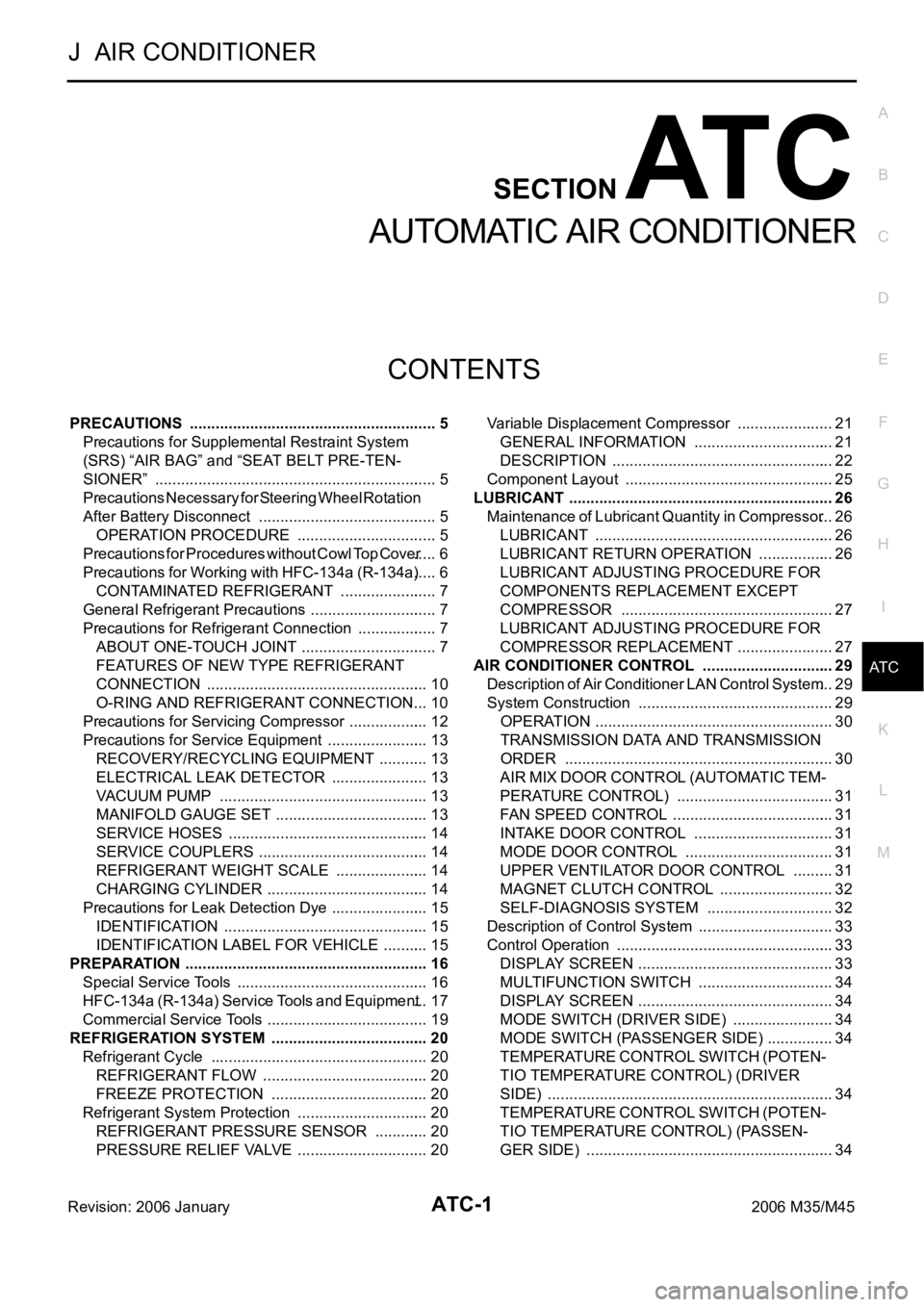

ATC-1

AUTOMATIC AIR CONDITIONER

J AIR CONDITIONER

CONTENTS

C

D

E

F

G

H

I

K

L

M

SECTION AT C

A

B

AT C

Revision: 2006 January2006 M35/M45

AUTOMATIC AIR CONDITIONER

PRECAUTIONS .......................................................... 5

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 5

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 5

OPERATION PROCEDURE ................................. 5

Precautions for Procedures without Cowl Top Cover ..... 6

Precautions for Working with HFC-134a (R-134a) ..... 6

CONTAMINATED REFRIGERANT ....................... 7

General Refrigerant Precautions .............................. 7

Precautions for Refrigerant Connection ................... 7

ABOUT ONE-TOUCH JOINT ................................ 7

FEATURES OF NEW TYPE REFRIGERANT

CONNECTION .................................................... 10

O-RING AND REFRIGERANT CONNECTION ... 10

Precautions for Servicing Compressor ................... 12

Precautions for Service Equipment ........................ 13

RECOVERY/RECYCLING EQUIPMENT ............ 13

ELECTRICAL LEAK DETECTOR ....................... 13

VACUUM PUMP ................................................. 13

MANIFOLD GAUGE SET .................................... 13

SERVICE HOSES ............................................... 14

SERVICE COUPLERS ........................................ 14

REFRIGERANT WEIGHT SCALE ...................... 14

CHARGING CYLINDER ...................................... 14

Precautions for Leak Detection Dye ....................... 15

IDENTIFICATION ................................................ 15

IDENTIFICATION LABEL FOR VEHICLE ........... 15

PREPARATION ......................................................... 16

Special Service Tools ............................................. 16

HFC-134a (R-134a) Service Tools and Equipment ... 17

Commercial Service Tools ...................................... 19

REFRIGERATION SYSTEM ..................................... 20

Refrigerant Cycle ................................................... 20

REFRIGERANT FLOW ....................................... 20

FREEZE PROTECTION ..................................... 20

Refrigerant System Protection ............................... 20

REFRIGERANT PRESSURE SENSOR ............. 20

PRESSURE RELIEF VALVE ............................... 20Variable Displacement Compressor ....................... 21

GENERAL INFORMATION ................................. 21

DESCRIPTION .................................................... 22

Component Layout ................................................. 25

LUBRICANT .............................................................. 26

Maintenance of Lubricant Quantity in Compressor ... 26

LUBRICANT ........................................................ 26

LUBRICANT RETURN OPERATION .................. 26

LUBRICANT ADJUSTING PROCEDURE FOR

COMPONENTS REPLACEMENT EXCEPT

COMPRESSOR .................................................. 27

LUBRICANT ADJUSTING PROCEDURE FOR

COMPRESSOR REPLACEMENT ....................... 27

AIR CONDITIONER CONTROL ............................... 29

Description of Air Conditioner LAN Control System ... 29

System Construction .............................................. 29

OPERATION ........................................................ 30

TRANSMISSION DATA AND TRANSMISSION

ORDER ............................................................... 30

AIR MIX DOOR CONTROL (AUTOMATIC TEM-

PERATURE CONTROL) ..................................... 31

FAN SPEED CONTROL ...................................... 31

INTAKE DOOR CONTROL ................................. 31

MODE DOOR CONTROL ................................... 31

UPPER VENTILATOR DOOR CONTROL .......... 31

MAGNET CLUTCH CONTROL ........................... 32

SELF-DIAGNOSIS SYSTEM .............................. 32

Description of Control System ................................ 33

Control Operation ................................................... 33

DISPLAY SCREEN .............................................. 33

MULTIFUNCTION SWITCH ................................ 34

DISPLAY SCREEN .............................................. 34

MODE SWITCH (DRIVER SIDE) ........................ 34

MODE SWITCH (PASSENGER SIDE) ................ 34

TEMPERATURE CONTROL SWITCH (POTEN-

TIO TEMPERATURE CONTROL) (DRIVER

SIDE) ................................................................... 34

TEMPERATURE CONTROL SWITCH (POTEN-

TIO TEMPERATURE CONTROL) (PASSEN-

GER SIDE) .......................................................... 34

Page 450 of 5621

ATC-3

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45 INSPECTION FLOW ......................................... . 111

Memory Function .................................................. 112

INSPECTION FLOW .......................................... 112

Ambient Sensor Circuit ......................................... 113

COMPONENT DESCRIPTION .......................... 113

AMBIENT TEMPERATURE INPUT PROCESS .. 113

DIAGNOSIS PROCEDURE FOR AMBIENT

SENSOR ............................................................ 113

COMPONENT INSPECTION ............................. 115

In-Vehicle Sensor Circuit ....................................... 116

COMPONENT DESCRIPTION .......................... 116

DIAGNOSIS PROCEDURE FOR IN-VEHICLE

SENSOR ............................................................ 117

COMPONENT INSPECTION ............................. 118

Sunload Sensor Circuit ......................................... 119

COMPONENT DESCRIPTION .......................... 119

SUNLOAD INPUT PROCESS ........................... 119

DIAGNOSIS PROCEDURE FOR SUNLOAD

SENSOR ............................................................ 119

COMPONENT INSPECTION ............................121

Intake Sensor Circuit ............................................122

COMPONENT DESCRIPTION .........................122

DIAGNOSIS PROCEDURE FOR INTAKE SEN-

SOR ..................................................................122

COMPONENT INSPECTION ............................123

CONTROLLER .......................................................124

Removal and Installation of Multifunction Switch . 124

REMOVAL ........................................................

.124

INSTALLATION .................................................124

AUTO AMP .............................................................125

Removal and Installation of Unified Meter and A/C

Auto Amp. ............................................................125

REMOVAL ........................................................

.125

INSTALLATION .................................................125

AMBIENT SENSOR ................................................126

Removal and Installation ......................................126

REMOVAL ........................................................

.126

INSTALLATION .................................................126

IN-VEHICLE SENSOR ............................................127

Removal and Installation ......................................127

REMOVAL ........................................................

.127

INSTALLATION .................................................127

SUNLOAD SENSOR ..............................................128

Removal and Installation ......................................128

REMOVAL ........................................................

.128

INSTALLATION .................................................128

INTAKE SENSOR .................................................. .129

Removal and Installation ......................................129

REMOVAL ........................................................

.129

INSTALLATION .................................................129

BLOWER UNIT .......................................................130

Removal and Installation ......................................130

REMOVAL ........................................................

.130

INSTALLATION .................................................130

Disassembly and Assembly .................................131

BLOWER MOTOR ..................................................132

Removal and Installation ......................................132

REMOVAL ........................................................

.132

INSTALLATION .................................................132INTAKE DOOR MOTOR .........................................133

Removal and Installation ......................................133

REMOVAL ........................................................

.133

INSTALLATION .................................................133

IN-CABIN MICROFILTER .......................................134

Removal and Installation ......................................134

FUNCTION .......................................................

.134

REPLACEMENT TIMING ..................................134

REPLACEMENT PROCEDURES .....................134

HEATER & COOLING UNIT ASSEMBLY ...............135

Removal and Installation ......................................135

REMOVAL ........................................................

.135

INSTALLATION .................................................136

Disassembly and Assembly ..................................138

MODE DOOR MOTOR ............................................140

Removal and Installation ......................................140

REMOVAL ........................................................

.140

INSTALLATION .................................................140

AIR MIX DOOR MOTOR .........................................141

Removal and Installation ......................................141

REMOVAL ........................................................

.141

INSTALLATION .................................................141

UPPER VENTILATOR DOOR MOTOR ..................142

Removal and Installation ......................................142

REMOVAL ........................................................

.142

INSTALLATION .................................................142

HEATER CORE .......................................................143

Removal and Installation ......................................143

REMOVAL ........................................................

.143

INSTALLATION .................................................143

DUCTS AND GRILLES ...........................................144

Removal and Installation ......................................144

COMPONENT LAYOUT ....................................144

REMOVAL ........................................................

.146

INSTALLATION .................................................150

REFRIGERANT LINES ...........................................151

HFC-134a (R-134a) Service Procedure ...............151

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................151

Components ....................................................

.....153

VQ35DE ............................................................153

VK45DE .............................................................154

Removal and Installation of Compressor ..............155

REMOVAL ........................................................

.155

INSTALLATION .................................................157

Check Disc to Pulley Clearance ...........................157

Removal and Installation of Low-Pressure Flexible

Hose and Pipe ......................................................158

REMOVAL ........................................................

.158

INSTALLATION .................................................158

Removal and Installation of High-Pressure Flexible

Hose .....................................................................159

REMOVAL ........................................................

.159

INSTALLATION .................................................160

Removal and Installation of High-Pressure Pipe 1

(Engine Compartment) .........................................160

REMOVAL ........................................................

.160

INSTALLATION .................................................161

Removal and Installation of Low-Pressure Pipe 1

Page 451 of 5621

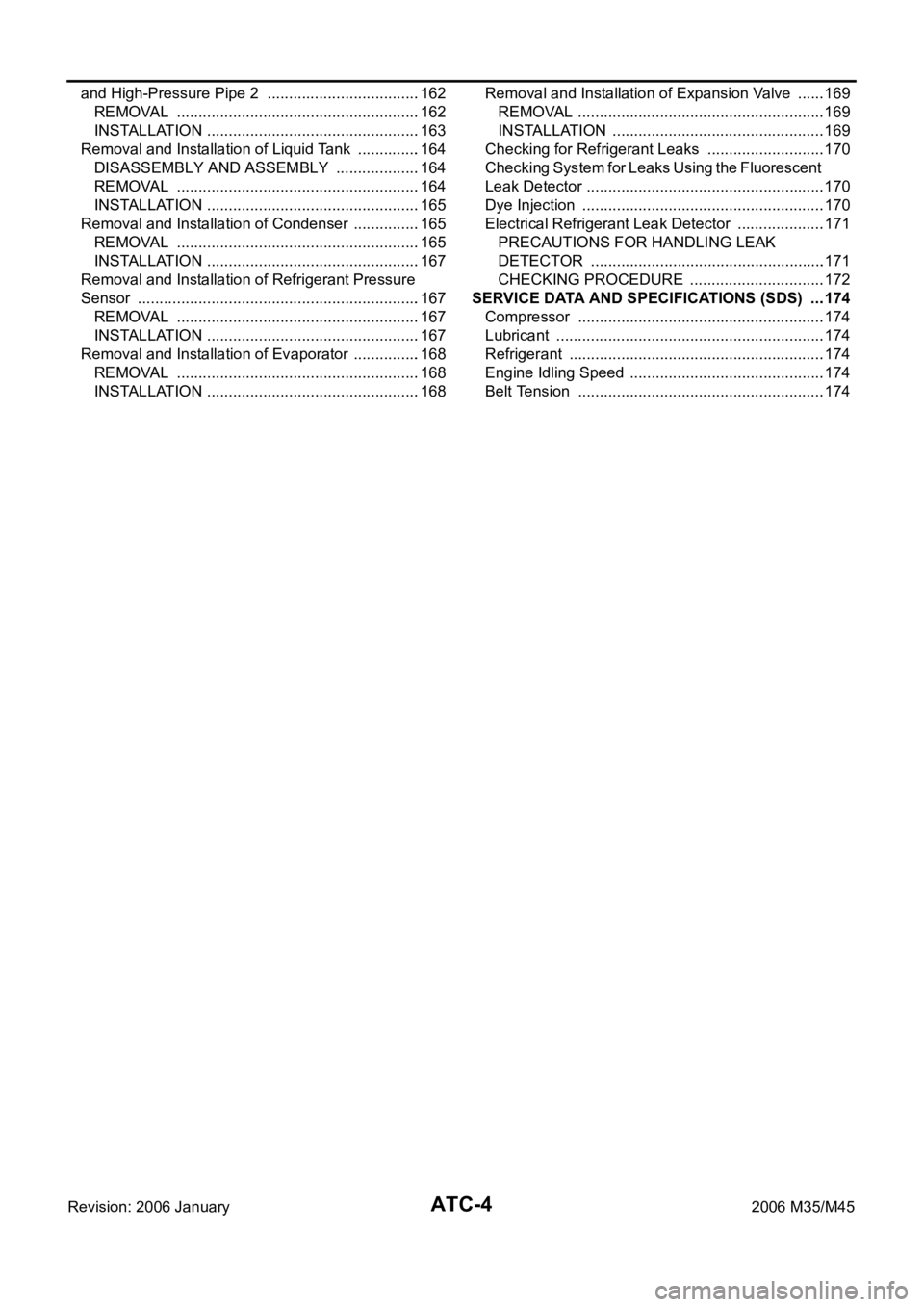

ATC-4Revision: 2006 January2006 M35/M45 and High-Pressure Pipe 2 ....................................162

REMOVAL ........................................................

.162

INSTALLATION ..................................................163

Removal and Installation of Liquid Tank ...............164

DISASSEMBLY AND ASSEMBLY ....................164

REMOVAL ........................................................

.164

INSTALLATION ..................................................165

Removal and Installation of Condenser ................165

REMOVAL ........................................................

.165

INSTALLATION ..................................................167

Removal and Installation of Refrigerant Pressure

Sensor ..................................................................167

REMOVAL ........................................................

.167

INSTALLATION ..................................................167

Removal and Installation of Evaporator ................168

REMOVAL ........................................................

.168

INSTALLATION ..................................................168Removal and Installation of Expansion Valve .......169

REMOVAL ..........................................................169

INSTALLATION ..................................................169

Checking for Refrigerant Leaks ............................170

Checking System for Leaks Using the Fluorescent

Leak Detector ........................................................170

Dye Injection .........................................................170

Electrical Refrigerant Leak Detector .....................171

PRECAUTIONS FOR HANDLING LEAK

DETECTOR .......................................................171

CHECKING PROCEDURE ................................172

SERVICE DATA AND SPECIFICATIONS (SDS) ....174

Compressor ..........................................................174

Lubricant ...............................................................174

Refrigerant ............................................................174

Engine Idling Speed ..............................................174

Belt Tension ..........................................................174

Page 452 of 5621

PRECAUTIONS

ATC-5

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

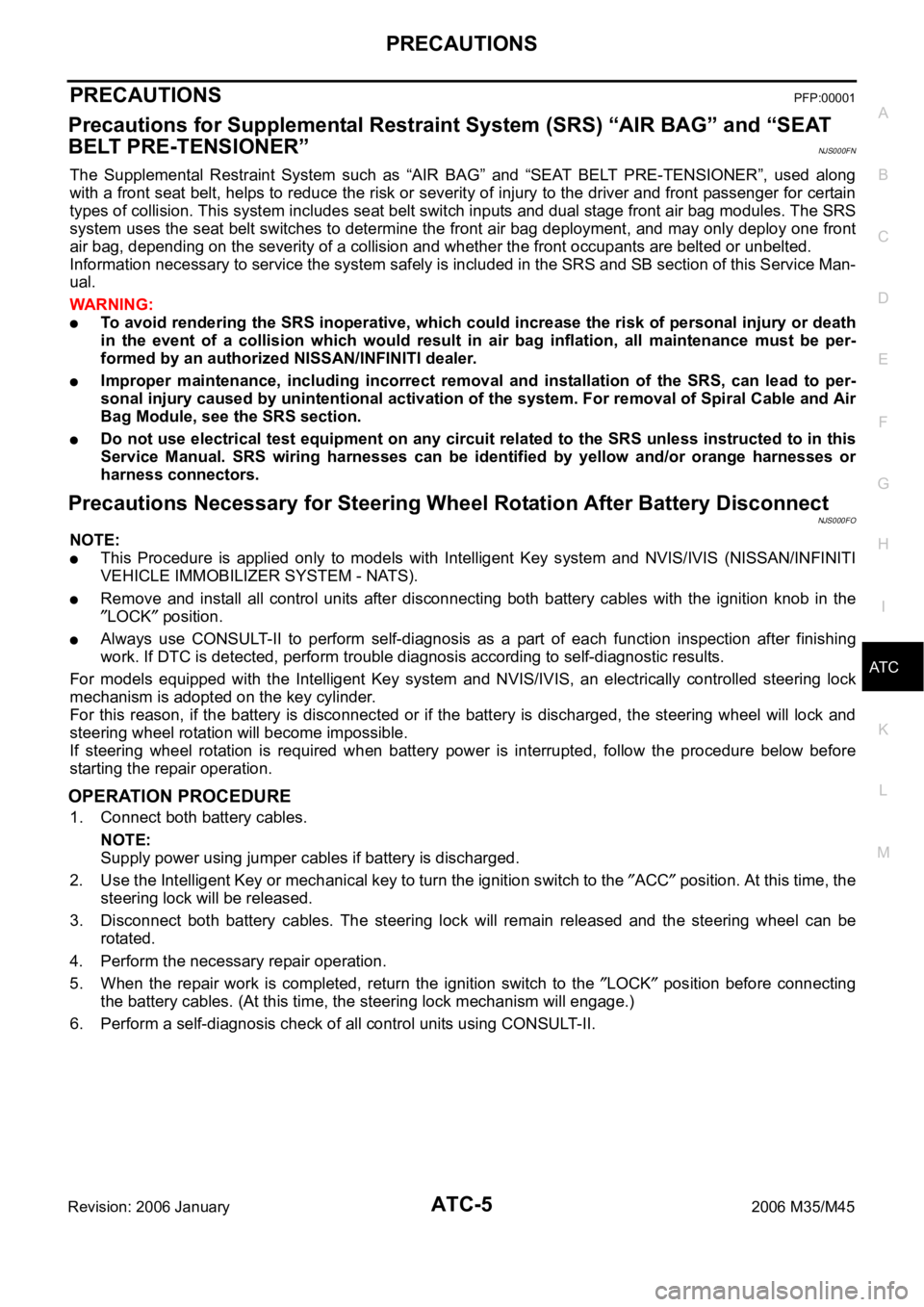

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

NJS000FN

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WAR NING :

To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectNJS000FO

NOTE:

This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the

ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the

LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Page 454 of 5621

PRECAUTIONS

ATC-7

C

D

E

F

G

H

I

K

L

MA

B

AT C

Revision: 2006 January2006 M35/M45

CONTAMINATED REFRIGERANT

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, take appropriate steps

shown below:

Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant

into the atmosphere.

Explain that recovery of the contaminated refrigerant could damage service equipment and refrigerant

supply.

Suggest the customer return the vehicle to the location of previous service where the contamination may

have occurred.

In case of repairing, recover the refrigerant using only dedicated equipment and containers. Never

recover contaminated refrigerant into the existing service equipment. If the facility does not have

dedicated recovery equipment, contact a local refrigerant product retailer for available service. This refrig-

erant must be disposed of in accordance with all federal and local regulations. In addition, replacement of

all refrigerant system components on the vehicle is recommended.

If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact Nissan Cus-

tomer Affairs for further assistance.

General Refrigerant PrecautionsNJS000FR

WAR NING :

Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Remove HFC-134a (R-134a) from the A/C system, using certified service equipment meet-

ing requirements of SAE J-2210 [HFC-134a (R-134a) recycling equipment], or J-2209 [HFC-134a (R-

134a) recovery equipment]. If accidental system discharge occurs, ventilate work area before

resuming service. Additional health and safety information may be obtained from refrigerant and

lubricant manufacturers.

Never release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

Never store or heat refrigerant containers above 52C (126F).

Never heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

Never intentionally drop, puncture, or incinerate refrigerant containers.

Keep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

Refrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent

suffocation.

Never pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condition-

ing systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury

or property damage. Additional health and safety information may be obtained from refrigerant

manufacturers.

Precautions for Refrigerant ConnectionNJS000FS

A new type refrigerant connection has been introduced to all refrigerant lines except the following location.

Expansion valve to evaporator

Refrigerant pressure sensor to liquid tank

ABOUT ONE-TOUCH JOINT

Description

One-touch joints are pipe joints which do not require tools during piping connection.

Unlike conventional connection methods using union nuts and flanges, controlling tightening torque at

connection point is not necessary.

When removing a pipe joint, use a disconnector.