pressure INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5447 of 5621

![INFINITI M35 2006 Factory Service Manual STC-32

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000EN

Check the following items with the vehicle stopped

Is air pressure and size of tires p INFINITI M35 2006 Factory Service Manual STC-32

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000EN

Check the following items with the vehicle stopped

Is air pressure and size of tires p](/img/42/57023/w960_57023-5446.png)

STC-32

[RAS]

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000EN

Check the following items with the vehicle stopped

Is air pressure and size of tires proper?

Is the specified part used for the steering wheel?

Is control unit a genuine part?

Are there any fluid leakage from steering gear assembly, power steering oil pump, and hydraulic pipes,

etc? Refer to PS-8, "

POWER STEERING FLUID" .

Is the fluid level proper? Refer to PS-8, "POWER STEERING FLUID" .

Is the wheel alignment is adjusted properly? Refer to FSU-19, "SERVICE DATA AND SPECIFICATIONS

(SDS)" (2WD), FSU-36, "SERVICE DATA AND SPECIFICATIONS (SDS)" (AWD).

Are there any damage or modification to suspension or body resulting in increased weight or altered

ground clearance?

Check each link installation condition of suspension and axle.

Is the battery voltage proper?

Check each connector connection condition.

Check the following items while driving the vehicle

Conditions when the error occurred (5W 1H).

Is the engine is normal?

Basic InspectionNGS000EO

BASIC INSPECTION 1: POWER SUPPLY CIRCUIT TERMINAL LOOSENESS AND BATTERY

Check battery terminals for looseness on both positive and negative ones and ground connection. Also make

sure that battery voltage does not drop.

BASIC INSPECTION 2: RAS WARNING LAMP INSPECTION

1. Make sure RAS warning lamp turns on when ignition switch is turned ON.

If it does not turn on, refer to STC-33, "Trouble Diagnosis Chart" .

2. Make sure that RAS warning lamp turns off when the engine is started after ignition switch is turned ON. If

it does not turn off, perform self-diagnosis. Refer to STC-28, "

SELF-DIAG RESULT MODE" .

3. Always erase DTC memory after completing self-diagnosis. Refer to STC-29, "

How to Erase Self-Diag-

nostic Results" .

BASIC INSPECTION 3: RAS CONTROL UNIT POWER SUPPLY CIRCUIT AND GROUND CIR-

CUIT INSPECTION

1. CHECK RAS CONTROL UNIT CONNECTOR

Turn ignition switch OFF, disconnect RAS control unit harness connector, and check terminal for deformation,

disconnection, looseness, etc.

OK or NG

OK >> GO TO 2.

NG >> Poor connection of connector terminal. Repair or replace the terminal.

2. CHECK RAS CONTROL UNIT GROUND CIRCUIT

1. Disconnect RAS control unit harness connector B127, and then

check continuity between RAS control unit harness connector

B127 and ground.

OK or NG

OK >> GO TO 3.

NG >> Ground circuit open or shorted. Repair or replace any

inoperative parts. Terminal 34 – Ground : Continuity

SGIA1244E

Page 5476 of 5621

AWD SYSTEM

TF-11

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

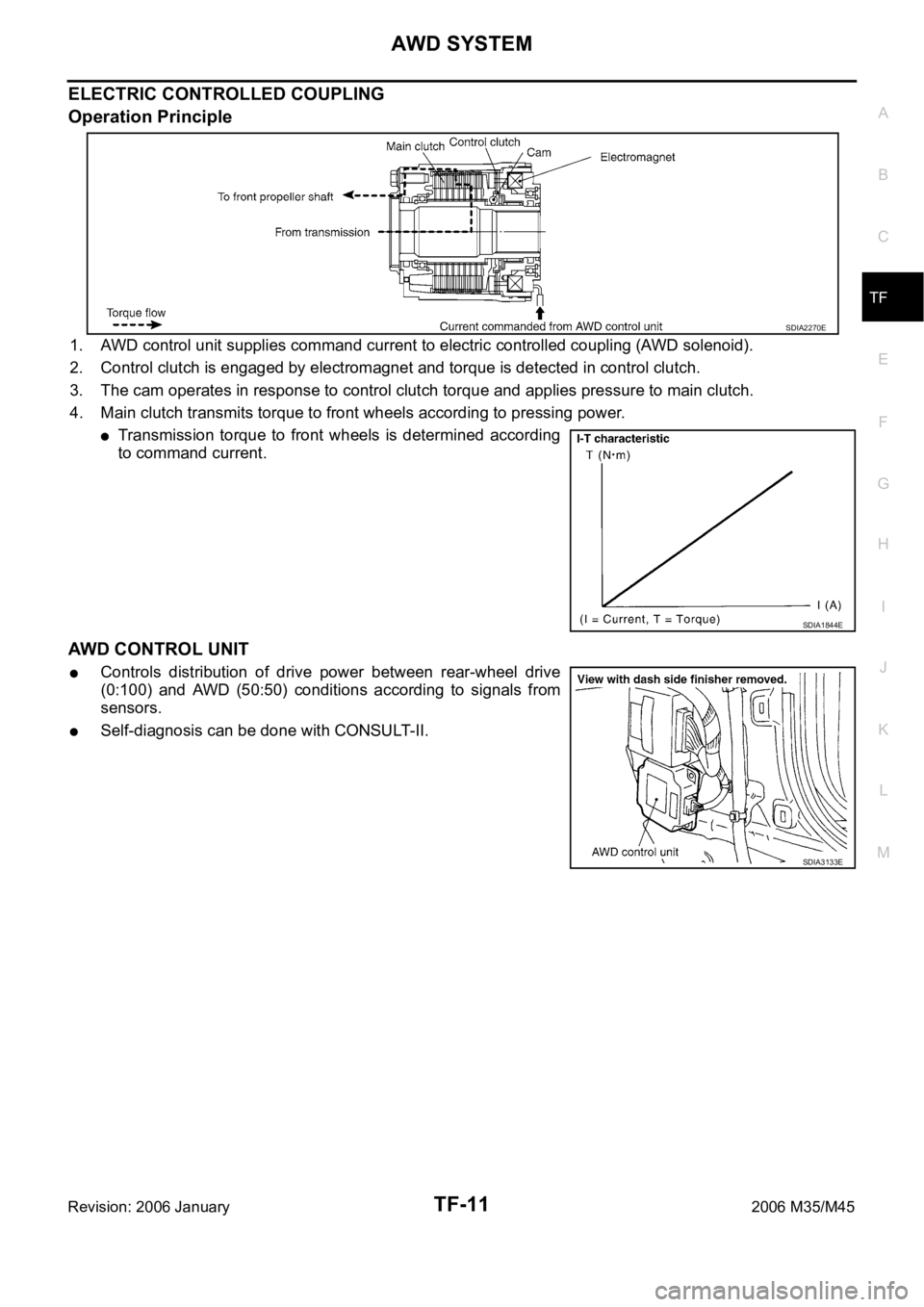

ELECTRIC CONTROLLED COUPLING

Operation Principle

1. AWD control unit supplies command current to electric controlled coupling (AWD solenoid).

2. Control clutch is engaged by electromagnet and torque is detected in control clutch.

3. The cam operates in response to control clutch torque and applies pressure to main clutch.

4. Main clutch transmits torque to front wheels according to pressing power.

Transmission torque to front wheels is determined according

to command current.

AWD CONTROL UNIT

Controls distribution of drive power between rear-wheel drive

(0:100) and AWD (50:50) conditions according to signals from

sensors.

Self-diagnosis can be done with CONSULT-II.

SDIA2270E

SDIA1844E

SDIA3133E

Page 5485 of 5621

TF-20

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

Trouble Diagnosis Chart for SymptomsNDS000DK

If AWD warning lamp turns ON, perform self-diagnosis. Refer to TF-22, "SELF-DIAG RESULT MODE" .

NOTE:

Light tight-corner braking symptom may occur depending on driving conditions. This is not malfunction.

AWD Control Unit Input/Output Signal Reference ValuesNDS000DL

AWD CONTROL UNIT INSPECTION TABLE

Specifications with CONSULT-II

Symptom Condition Check item Reference page

AWD warning lamp does not turn ON when

the ignition switch is turned to ON.

(AWD warning lamp check)Ignition switch: ONCAN communication line

TF-33

Unified meter and A/C amp.

Unified meter control unit

AWD warning lamp does not turn OFF sev-

eral seconds after engine started.Engine runningCAN communication line

TF-33

Power supply and ground for AWD con-

trol unit

Unified meter and A/C amp.

Unified meter control unit

AWD solenoid

AWD actuator relay (integrated in AWD

control unit)

Wheel sensor

Heavy tight-corner braking symptom occurs

when the vehicle is driven and the steering

wheel is turned fully to either side after the

engine is started. (See NOTE.)

While driving

Steering wheel is

turned fully to either

sidesCAN communication line

TF-35Accelerator pedal position signal

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (clutch sticking etc.)

Vehicle does not enter AWD mode even

though AWD warning lamp turned to OFF.While drivingCAN communication line

TF-36

AWD solenoid

Mechanical malfunction of electric con-

trolled coupling (Mechanical engage-

ment of clutch is not possible.)

While driving, AWD warning lamp flashes

rapidly. (When flashing in approx. 1 minute

and then turning OFF.)

Rapid flashing: 2 times/secondWhile drivingProtection function is activated due to

heavy load to electric controlled cou-

pling. (AWD system is not malfunction-

ing. Also, optional distribution of torque

sometimes becomes rigid before lamp

flashes rapidly, but it is not malfunction.)TF-37

While driving, AWD warning lamp flashes

slowly. (When continuing to flash until turn-

ing ignition switch OFF)

Slow flashing: 1 time/2 secondsWhile driving

Vehicle speed: 20 km/h

(12 MPH) or moreTire size is different between front and

rear of vehicle.TF-37

Monitor item [Unit] Content Condition Display value

FR RH SENSOR [km/h] or [mph]Wheel speed (Front wheel

right)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

FR LH SENSOR [km/h] or [mph]Wheel speed (Front wheel

left)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

Page 5486 of 5621

TROUBLE DIAGNOSIS

TF-21

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

*1 : The values are changed by throttle opening and engine speed.

*2 : Mode switch is not equipped, but displayed.

CONSULT-II Function (ALL MODE AWD/4WD)NDS000DM

FUNCTION

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

RR RH SENSOR [km/h] or [mph]Wheel speed (Rear wheel

right)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

RR LH SENSOR [km/h] or [mph]Wheel speed (Rear wheel

left)Vehicle stopped 0.00 km/h (0.00 mph)

Vehicle running

CAUTION:

Check air pressure of tire under

standard condition.Approximately equal to

the indication on speed-

ometer (Inside of

10%)

BATTERY VOLT [V]Power supply voltage for

AWD control unitIgnition switch: ON Battery voltage

THRTL POS SEN [%] Throttle opening conditionWhen depressing accelerator pedal

(Value rises gradually in response to

throttle position.)0 - 100%

ETS SOLENOID [A]Monitored value of current at

AWD solenoidEngine running

At idle speedApprox. 0.000A

Engine running

When depressing accelerator

pedalApprox. 0.000 - 0.500A*1

STOP LAMP SW [ON/OFF]Condition of brake pedal

operationBrake pedal: Depressed ON

Brake pedal: Released OFF

ENG SPEED SIG [RUN/STOP] Condition of engine runningEngine stopped

(Engine speed: Less than 400 rpm)STOP

Engine running

(Engine speed: 400 rpm or more)RUN

ETS ACTUATOR [ON/OFF]Operating condition of AWD

actuator relay (integrated in

AWD control unit)Engine stopped (Ignition

switch: ON)OFF

Engine running ON

4WD WARN LAMP [ON/OFF] AWD warning lamp conditionAWD warning lamp: ON ON

AWD warning lamp: OFF OFF

4WD MODE SW*

2 [AUTO]Input condition from mode

switchAlways AUTO

4WD MODE MON [AUTO] Control status of AWD Engine running AUTO

DIS-TIRE MONI [mm]Improper size tire installed

conditionVehicle running with normal size tire

installed0-4 mm

Vehicle running with improper size

tire installed (Front/rear tire size dif-

ference, wear condition)4-8 mm, 8- mm

P BRAKE SW [ON/OFF] Condition of parking brakeParking brake operated ON

Parking brake not operated OFF Monitor item [Unit] Content Condition Display value

Diagnostic test mode FunctionReference

page

Self-diagnostic results

Self-diagnostic results can be read and erased quickly.TF-22

Data monitorInput/Output data in the AWD control unit can be read.TF-24

Page 5502 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-37

C

E

F

G

H

I

J

K

L

MA

B

TF

Revision: 2006 January2006 M35/M45

3. CHECK AWD SOLENOID

Check AWD solenoid. Refer to TF-30, "

COMPONENT INSPECTION" .

OK or NG

OK >> GO TO 4.

NG >> Replace electric controlled coupling for malfunction of AWD solenoid. Refer to TF-45, "

Disassem-

bly and Assembly" .

4. CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e s" .

OK or NG

OK >> GO TO 5.

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

5. SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> Replace electric controlled coupling for mechanical malfunction (mechanical engagement of

clutch is not possible.). Refer to TF-45, "

Disassembly and Assembly" .

While Driving, AWD Warning Lamp Flashes Rapidly (When Flashing in Approx.

1 Minute and Then Turning OFF)

NDS000DY

NOTE:

Rapid flashing: 2 times/second

This symptom protects drivetrain parts when a heavy load is applied to the electric controlled coupling and

multiple disc clutch temperature increases. Also, optional distribution of torque sometimes becomes rigid

before lamp flashes rapidly. Both cases are not malfunction.

When this symptom occurs, stop vehicle and allow it to idle for some times. Flashing will stop and system will

be restored.

While Driving, AWD Warning Lamp Flashes Slowly (When Continuing to Flash

until Turning Ignition Switch OFF)

NDS000DZ

NOTE:

Slow flashing: 1 time/2 seconds

DIAGNOSTIC PROCEDURE

1. CHECK TIRE

Check the following.

Tire pressure

Wear condition

Longitudinal tire size (There is no difference between longitudinal tires.)

OK or NG

OK >> GO TO 2.

NG >> Drive at vehicle speed of 20 km/h (12 MPH) or more for 5 seconds or more after repairing or

replacing damaged parts. (Initialize improper size tire information.)

Page 5526 of 5621

WT-1

ROAD WHEELS & TIRES

E SUSPENSION

CONTENTS

C

D

F

G

H

I

J

K

L

M

SECTION WT

A

B

WT

Revision: 2006 January2006 M35/M45

ROAD WHEELS & TIRES

PRECAUTIONS .......................................................... 3

Precautions .............................................................. 3

PREPARATION ........................................................... 4

Special Service Tools [SST] ..................................... 4

Commercial Service Tools ........................................ 4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

ROAD WHEEL ............................................................ 6

Inspection ................................................................. 6

ALUMINUM WHEEL ............................................. 6

STEEL WHEEL ..................................................... 6

ROAD WHEEL TIRE ASSEMBLY .............................. 7

Balancing Wheels (Bonding Weight Type) ............... 7

REMOVAL ........................................................

..... 7

WHEEL BALANCE ADJUSTMENT ...................... 7

Rotation .................................................................... 8

LOW TIRE PRESSURE WARNING SYSTEM ............ 9

System Components ................................................ 9

System Description .................................................. 9

TRANSMITTER ..................................................... 9

RECEIVER .......................................................

... 10

LOW TIRE PRESSURE WARNING CONTROL

UNIT .................................................................... 10

LOW TIRE PRESSURE WARNING LAMP ......... 10

DISPLAY UNIT ..................................................... 11

CAN COMMUNICATION .......................................... 12

System Description ................................................ 12

TROUBLE DIAGNOSES .......................................... 13

How to Perform Trouble Diagnoses ....................... 13

BASIC CONCEPT ............................................... 13

Schematic .............................................................. 14

Wiring Diagram — T/WARN — .............................. 15

Control Unit Input/Output Signal Standard ............. 18

ID Registration Procedure ...................................... 19

ID REGISTRATION WITH ACTIVATION TOOL ... 19

ID REGISTRATION WITHOUT ACTIVATION

TOOL .................................................................. 20

Transmitter Wake Up Operation ............................. 21

WITH TRANSMITTER ACTIVATION TOOL ........ 21CONSULT-II Function (AIR PRESSURE MONI-

TOR) ....................................................................... 21

FUNCTION .......................................................

... 21

CONSULT-II SETTING PROCEDURE ................ 21

WORK SUPPORT MODE ................................... 22

SELF-DIAG RESULT MODE ............................... 22

DATA MONITOR MODE ...................................... 23

ACTIVE TEST MODE ......................................... 23

LOW TIRE PRESSURE WARNING CONTROL

UNIT PART NUMBER ......................................... 24

Diagnosis Procedure with Warning Lamp Function

(Without CONSULT-II) ............................................ 24

DESCRIPTION .................................................... 24

FUNCTION .......................................................

... 24

LOW TIRE PRESSURE WARNING LAMP DIAG-

NOSTIC CHART .................................................. 24

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 26

INTRODUCTION ................................................. 26

WORK FLOW ...................................................... 26

Preliminary Check .................................................. 27

Trouble Diagnosis Chart ......................................... 28

SELF-DIAGNOSIS .............................................. 28

DIAGNOSIS CHART BY SYMPTOM .................. 29

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC

ITEMS ........................................................................ 30

Inspection 1: Transmitter no Data ........................... 30

MALFUNCTION CODE NO. 21, 22, 23, 24 ......... 30

Inspection 2: Receiver Data Error .......................... 31

MALFUNCTION CODE NO. 25, 26, 27, 28 ......... 31

Inspection 3: Transmitter Pressure Data Error ....... 32

MALFUNCTION CODE NO. 35, 36, 37, 38 ......... 32

Inspection 4: Transmitter Function Code Error ....... 32

MALFUNCTION CODE NO. 41, 42, 43, 44 ......... 32

Inspection 5: Transmitter Battery Voltage Low ....... 33

MALFUNCTION CODE NO. 45, 46, 47, 48 ......... 33

Inspection 6: Receiver ID No Registration .............. 33

MALFUNCTION CODE NO. 51 ........................... 33

Inspection 7: Vehicle Speed Signal ........................ 34

Page 5527 of 5621

WT-2Revision: 2006 January2006 M35/M45 MALFUNCTION CODE NO. 52 ........................... 34

Inspection 8: CAN Communication System Mal-

function ................................................................... 34

TROUBLE DIAGNOSIS FOR SYMPTOMS .............. 35

Inspection 1: Warning Lamp Does Not Come On

When Ignition Switch Is Turned On ........................ 35

Inspection 2: Warning Lamp Stays On When Ignition

Switch Is Turned On ............................................ ... 36

Inspection 3: Warning Lamp Blinks When Ignition

Switch Is Turned On ............................................ ... 37

Inspection 4: Turn Signal Lamp Blinks When Ignition

Switch Is Turned On ............................................ ... 37

Inspection 5: ID Registration Can Not Be Completed ... 38REMOVAL AND INSTALLATION .............................. 39

Transmitter .............................................................. 39

REMOVAL ............................................................ 39

INSTALLATION .................................................... 39

Low Tire Pressure Warning Control Unit ................. 40

REMOVAL ............................................................ 40

INSTALLATION .................................................... 40

Receiver .................................................................. 40

REMOVAL ............................................................ 40

INSTALLATION .................................................... 40

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 41

Road Wheel ............................................................ 41

Tire .......................................................................... 41

Page 5530 of 5621

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

WT-5

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGPFP:00003

NVH Troubleshooting ChartNES000JN

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

: ApplicableReference page

FAX-5

, FSU-6WT-6WT-7WT-41WT-8—

—

WT-41

NVH in PR section.

NVH in RFD section.

NVH in FAX and FSU sections.

NVH in RAX and RSU sections.

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

NVH in FAX, RAX section.

NVH in BR section.

NVH in PS section.

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

SymptomTIRESNoise

Shake

Vibration

Shimmy

Judder

Poor quality ride or

handling

ROAD

WHEELNoiseShake

Shimmy, Judder

Poor quality ride or

handling

Page 5534 of 5621

LOW TIRE PRESSURE WARNING SYSTEM

WT-9

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

LOW TIRE PRESSURE WARNING SYSTEMPFP:40300

System ComponentsNES000JR

System DescriptionNES000JS

TRANSMITTER

A sensor-transmitter integrated with a valve is installed on a wheel,

and transmits a detected air pressure signal in the form of a radio

wave.

1. Tire pressure transmitter front LH 2. Tire pressure transmitter front RH 3. Tire pressure receiver front LH

4. Tire pressure receiver front RH 5. Low tire pressure warning control

unit6. Low tire pressure warning lamp

7. Display unit 8. Tire pressure transmitter rear LH 9. Tire pressure transmitter rear RH

10. Tire pressure receiver rear LH 11. Tire pressure receiver rear RH

SEIA0648E

SEIA0521E

Page 5535 of 5621

WT-10

LOW TIRE PRESSURE WARNING SYSTEM

Revision: 2006 January2006 M35/M45

RECEIVER

The receiver receives the air pressure signal transmitted by the transmitter in each wheel.

LOW TIRE PRESSURE WARNING CONTROL UNIT

The low tire pressure warning control unit (1) reads the air pressure

signal received by the receiver, and controls the low tire pressure

warning lamp and the buzzer operations. It also has a judgement

function to detect a system malfunction.

LOW TIRE PRESSURE WARNING LAMP

The combination meter receives tire pressure status from the low tire

pressure warning control unit using CAN communication. When a

low tire pressure condition is sensed by the low tire pressure control

unit, the combination meter low tire pressure warning lamp and

buzzer are activated.

Low Tire Pressure Warning Lamp Indication

*: Standard air pressure is for 230 kpa (2.3 kg/cm2 , 33 psi) vehicle. 1. Tire pressure receiver front 2. Tire pressure receiver rear A. Front wheel house

B. Rear wheel house

Refer to GI-11, "

Components" , for the symbols in the figure.

SEIA0649E

SEIA0650E

SEIA0434E

ConditionLow tire pressure warning

lampBuzzer

Less than 186 kPa

(1.86 kg/cm

2 , 27 psi) [Flat tire]*ON Sounds for 10 sec.

Low tire pressure warning system malfunction [Other diagnostic item]Warning lamp flashes 1 min,

then turns ONOFF