pressure INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4998 of 5621

SERVICE DATA AND SPECIFICATIONS (SDS)

PS-45

C

D

E

F

H

I

J

K

L

MA

B

PS

Revision: 2006 January2006 M35/M45

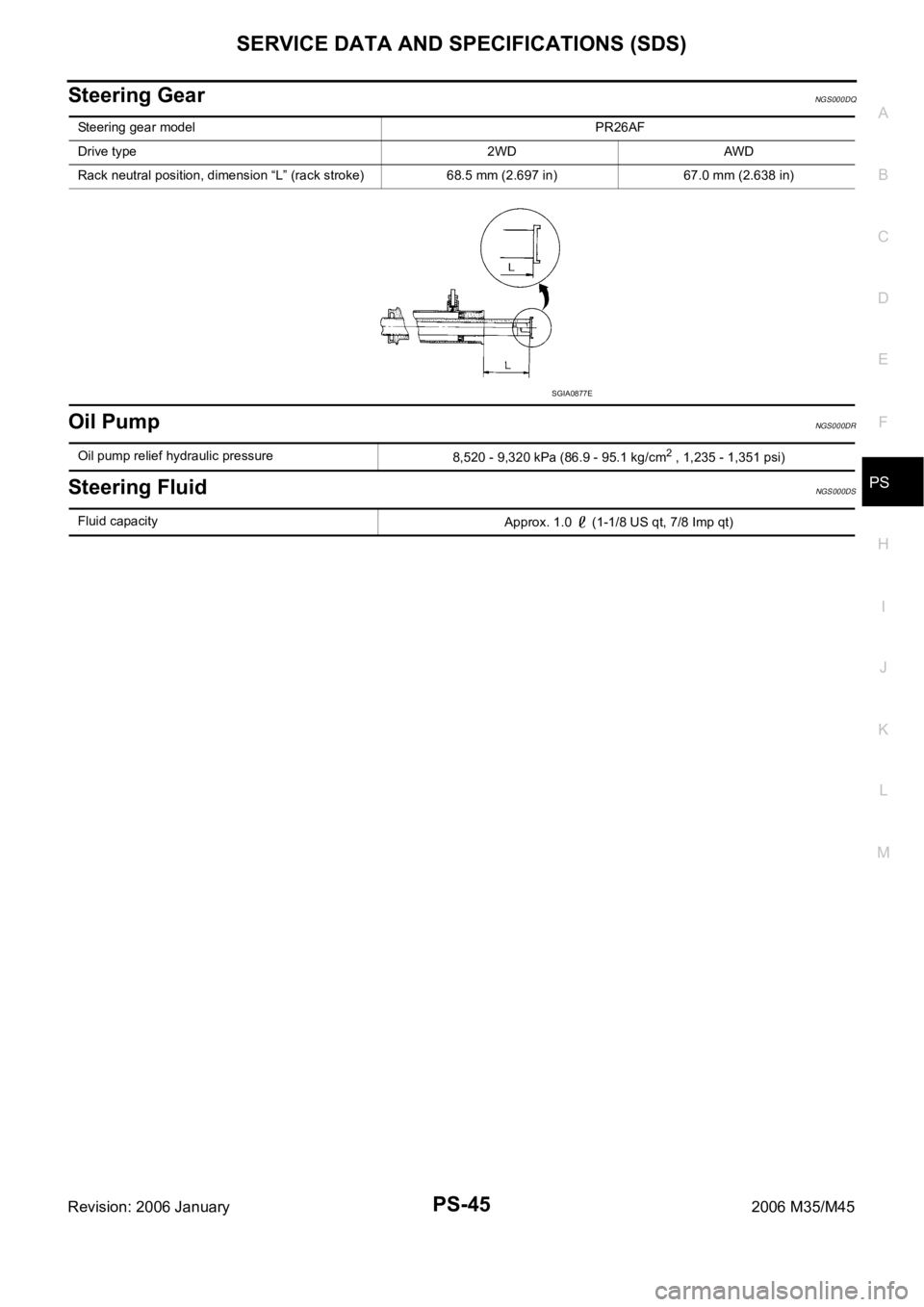

Steering GearNGS000DQ

Oil PumpNGS000DR

Steering FluidNGS000DS

Steering gear model PR26AF

Drive type 2WD AWD

Rack neutral position, dimension “L” (rack stroke) 68.5 mm (2.697 in) 67.0 mm (2.638 in)

SGIA0877E

Oil pump relief hydraulic pressure

8,520 - 9,320 kPa (86.9 - 95.1 kg/cm2 , 1,235 - 1,351 psi)

Fluid capacity

Approx. 1.0 (1-1/8 US qt, 7/8 Imp qt)

Page 5086 of 5621

REAR SUSPENSION ASSEMBLY

RSU-5

C

D

F

G

H

I

J

K

L

MA

B

RSU

Revision: 2006 January2006 M35/M45

REAR SUSPENSION ASSEMBLYPFP:55020

On-Vehicle Inspection and ServiceNES000J6

Make sure the mounting conditions (looseness, back lash) of each component and component conditions

(wear, damage) are normal.

SUSPENSION ARM BALL JOINT AXIAL END PLAY INSPECTION

Measure axial end play by placing and moving up/down with an iron pry bar or something similar between sus-

pension arm and axle.

CAUTION:

Be careful not to damage ball joint boot.

SHOCK ABSORBER INSPECTION

Check shock absorber for oil leakage, damage and replace if malfunction is detected.

Wheel Alignment InspectionNES000J7

DESCRIPTION

Measure wheel alignment under unladen conditions.

NOTE:

“Unladen conditions” means that fuel, engine coolant, and lubricant are full. Spare tire, jack, hand tools and

mats in designated positions.

PRELIMINARY INSPECTION

Check the following:

1. Tires for improper air pressure and wear.

2. Road wheels for runout. Refer to WT-6, "

ROAD WHEEL" .

3. Wheel bearing axial end play. Refer to RAX-5, "

WHEEL BEARING INSPECTION" .

4. Ball joint axial end play of suspension arm. Refer to RSU-5, "

SUSPENSION ARM BALL JOINT AXIAL

END PLAY INSPECTION" .

5. Shock absorber operation.

6. Each mounting point of axle and suspension for looseness and deformation.

7. Each of front lower link, rear lower link, radius rod, rear suspension member, suspension arm and shock

absorber for cracks, deformation, and other damage.

8. Vehicle height (posture).

GENERAL INFORMATION AND RECOMMENDATIONS

A four-wheel thrust alignment should be performed.

–This type of alignment is recommended for any NISSAN/INFINITI vehicle.

–The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel is

centered.

–The alignment rack itself should be capable of accepting any NISSAN/INFINITI vehicle.

–The rack should be checked to ensure that it is level.

Make sure the machine is properly calibrated.

–Your alignment equipment should be regularly calibrated in order to give correct information.

–Check with the manufacturer of your specific equipment for their recommended Service/Calibration

Schedule.Standard value

Axial end play : 0 mm (0 in)

Page 5152 of 5621

STARTING SYSTEM

SC-15

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

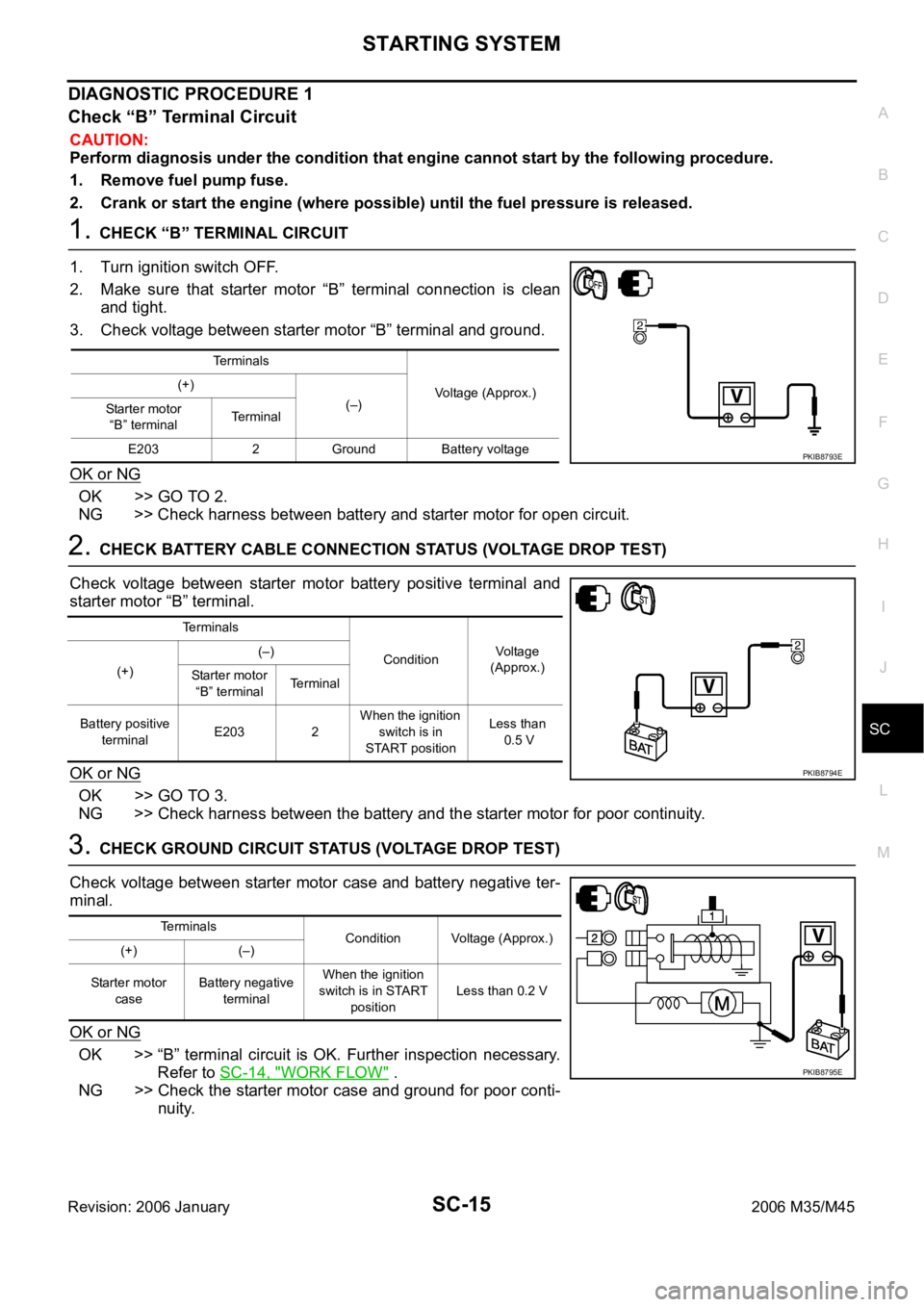

DIAGNOSTIC PROCEDURE 1

Check “B” Terminal Circuit

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1. CHECK “B” TERMINAL CIRCUIT

1. Turn ignition switch OFF.

2. Make sure that starter motor “B” terminal connection is clean

and tight.

3. Check voltage between starter motor “B” terminal and ground.

OK or NG

OK >> GO TO 2.

NG >> Check harness between battery and starter motor for open circuit.

2. CHECK BATTERY CABLE CONNECTION STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor battery positive terminal and

starter motor “B” terminal.

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter motor for poor continuity.

3. CHECK GROUND CIRCUIT STATUS (VOLTAGE DROP TEST)

Check voltage between starter motor case and battery negative ter-

minal.

OK or NG

OK >> “B” terminal circuit is OK. Further inspection necessary.

Refer to SC-14, "

WORK FLOW" .

NG >> Check the starter motor case and ground for poor conti-

nuity.

Terminals

Voltage (Approx.) (+)

(–)

Starter motor

“B” terminalTerminal

E203 2 Ground Battery voltage

PKIB8793E

Terminals

ConditionVoltage

(Approx.)

(+)(–)

Starter motor

“B” terminalTerminal

Battery positive

terminalE203 2 When the ignition

switch is in

START positionLess than

0.5 V

PKIB8794E

Terminals

Condition Voltage (Approx.)

(+) (–)

Starter motor

caseBattery negative

terminalWhen the ignition

switch is in START

positionLess than 0.2 V

PKIB8795E

Page 5153 of 5621

SC-16

STARTING SYSTEM

Revision: 2006 January2006 M35/M45

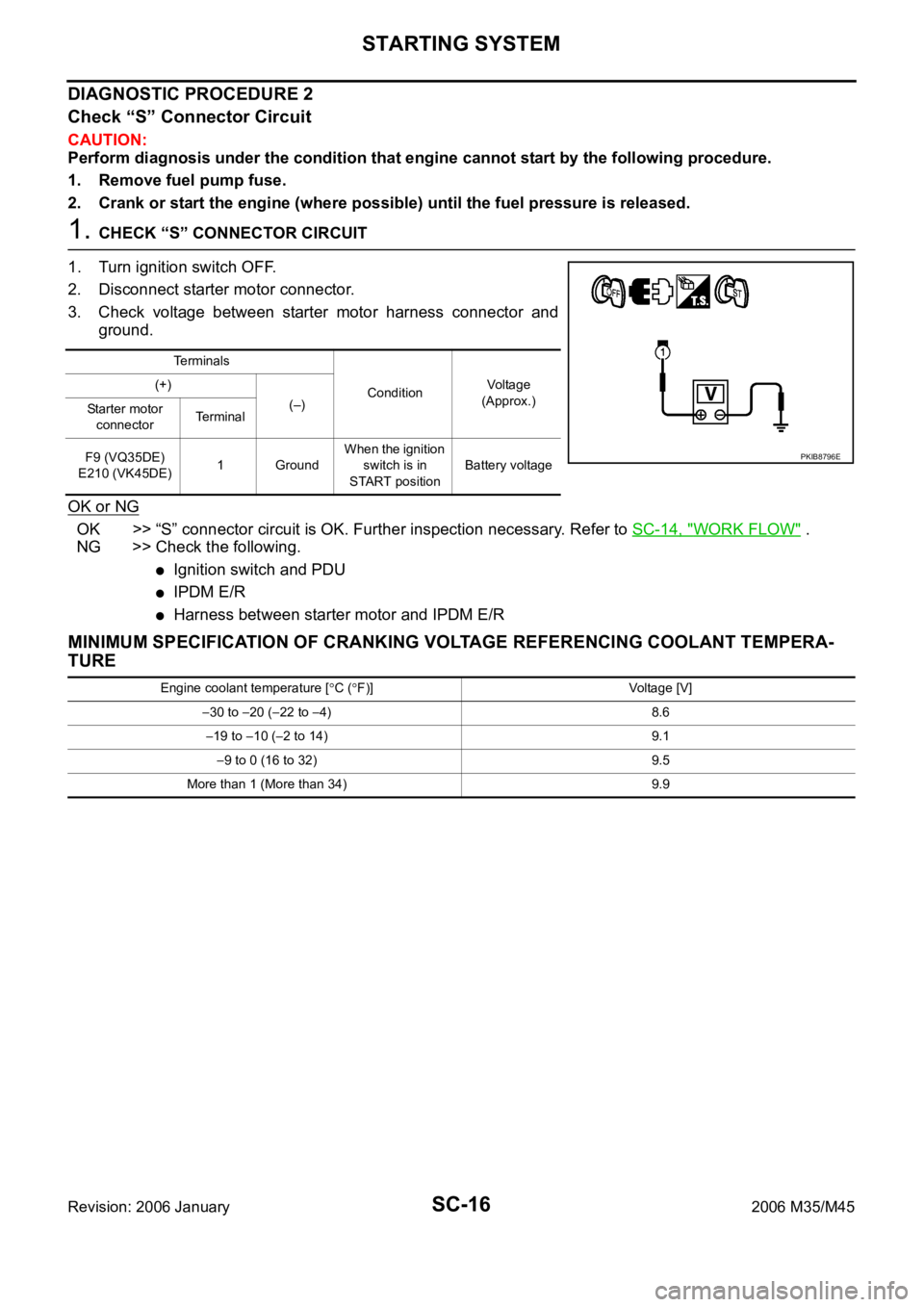

DIAGNOSTIC PROCEDURE 2

Check “S” Connector Circuit

CAUTION:

Perform diagnosis under the condition that engine cannot start by the following procedure.

1. Remove fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

1. CHECK “S” CONNECTOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect starter motor connector.

3. Check voltage between starter motor harness connector and

ground.

OK or NG

OK >> “S” connector circuit is OK. Further inspection necessary. Refer to SC-14, "WORK FLOW" .

NG >> Check the following.

Ignition switch and PDU

IPDM E/R

Harness between starter motor and IPDM E/R

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

Te r m i n a l s

ConditionVoltage

(Approx.) (+)

(–)

Starter motor

connectorTe r m i n a l

F9 (VQ35DE)

E210 (VK45DE)1 GroundWhen the ignition

switch is in

START positionBattery voltage

PKIB8796E

Engine coolant temperature [C (F)] Voltage [V]

30 to 20 (22 to 4) 8.6

19 to 10 (2 to 14) 9.1

9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Page 5174 of 5621

CHARGING SYSTEM

SC-37

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

Removal and Installation NKS003NR

VQ35DE ENGINE MODELS

Removal (2WD Models)

1. Disconnect the battery cable from the negative terminal.

2. Remove engine front undercover, using power tools.

3. Remove alternator and power steering oil pump belt. Refer to EM-15, "

DRIVE BELTS" .

4. Disconnect alternator connector (1).

5. Remove “B” terminal nut (2).

6. Remove the harness bracket bolts (A).

7. Remove oil pressure switch harness clip (A) from alternator stay.

8. Disconnect oil pressure switch connector (1).

9. Remove alternator mounting bolt (B) and alternator stay mount-

ing bolt (C) using power tools, then remove alternator stay (2).

10. Remove alternator mounting bolt (D), using power tools.

11. Remove alternator assembly downward from the vehicle.

1. “B” terminal nut 2. “B” terminal harness 3. Alternator connector

4. Alternator mounting bolt 5. Alternator stay mounting bolt 6. Alternator stay

7. Alternator : Nꞏm (kg-m, ft-lb) : Engine front

PKIB8815E

SKIB2605J

PKIB8817E

Page 5180 of 5621

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-43

C

D

E

F

G

H

I

J

L

MA

B

SC

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

BatteryNKS003NT

StarterNKS003NU

AlternatorNKS003NV

*: Adjustment range of power generation voltage variable control is 11.4 - 15.6 V. Ty p e110D26L

20 hour rate capacity [V - Ah] 12 - 75

Cold cranking current (For reference value) [A] 720

Applied modelVK45DE VQ35DE VQ35DE

2WD AWD

Ty p eM2T85771 S114-880 S114-881

MITSUBISHI

makeHITACHI make

Reduction gear type

System voltage [V] 12

No-loadTerminal voltage [V] 11

Current [A] Less than 145 Less than 90

Revolution [rpm] More than 3,300 More than 2,880

Minimum diameter of commutator [mm (in)] 31.4 (1.236) 28.0 (1.102)

Minimum length of brush [mm (in)] 11.0 (0.433) 10.5 (0.413)

Brush spring tension [N (kg, lb)]26.7 - 36.1

(2.72 - 3.68,

6.80 - 8.12)16.2 (1.65, 3.6)

Clearance between bearing metal and armature shaft [mm (in)] Less than 0.2 (0.008)

Clearance between pinion front edge and pinion stopper [mm (in)]0.5 - 2.0

(0.020 - 0.079)0.3 - 2.5 (0.012 - 0.098)

Applied model VK45DE VQ35DE

Ty p eA3TJ0591 A3TJ0691

MITSUBISHI make

Nominal rating [V - A] 12 -150

Ground polarityNegative

Minimum revolution under no-load (When 13.5 V is

applied)[rpm] Less than 1,300

Hot output current (When 13.5 V is applied) [A/rpm]More than 35/1,300

More than 105/2,500

More than 136/5,000

Regulated output voltage [V] 14.1 - 14.7 *

Minimum length of brush [mm (in)] More than 5.00 (0.197)

Brush spring pressure [N (g, oz)] 4.1 - 5.3 (418 - 540, 14.8 - 19.1)

Slip ring minimum outer diameter [mm (in)] More than 22.1 (0.870)

Rotor (Field coil) resistance [

] 1.6 - 2.0

Page 5368 of 5621

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS-7

C

D

E

F

G

I

J

K

L

MA

B

SRS

Revision: 2006 January2006 M35/M45

Occupant Classification System (OCS) NHS0008W

The occupant classification system identifies different size occupants, out of position occupants, and detects if

child seat is present in the front passenger seat. The occupant classification system receives inputs from the

occupant classification sensor (located inside the passenger seat cushion assembly) and belt tension sensor

(part of the passenger front seat belt assembly and located at the belt anchor location). Depending on classifi-

cation of passenger, the occupant classification system sends a signal to the diagnosis sensor unit. The diag-

nosis sensor unit uses this signal to determine full, partial, or non deployment of passenger front air bag in the

event of a collision. Depending on the signal received, the diagnosis sensor unit can disable the passenger

front air bag completely.

NOTE:

In case of customer concern, CONSULT-ll can be used to confirm the passenger air bag status (readiness).

Passenger Air Bag Status Condition NHS0008X

NOTE:

Passenger does not meet Ocuupant classification System specifications for passenger air bag activation.

Component Parts of Occupant Classification System NHS0008Y

Front Passenger Seat

(Condition)PASS AIR BAG OFF Indicator

(Status)Passenger Air Bag Status

(Readiness)CONSULT-ll Display

Seat occupied OFF Active (enabled) ON

seat occupiedNOTE ON Deactivated (disabled) OFF

Seat empty OFF Deactivated (disabled) OFF

PHIA1177E

1.Occupant classification system con-

trol unit2. Belt tension sensor 3. Seat pressure sensor

4. Bladder 5.Front passenger air bag OFF indica-

tor (Cutoff telltaile)

Page 5371 of 5621

SRS-10

TROUBLE DIAGNOSIS

Revision: 2006 January2006 M35/M45

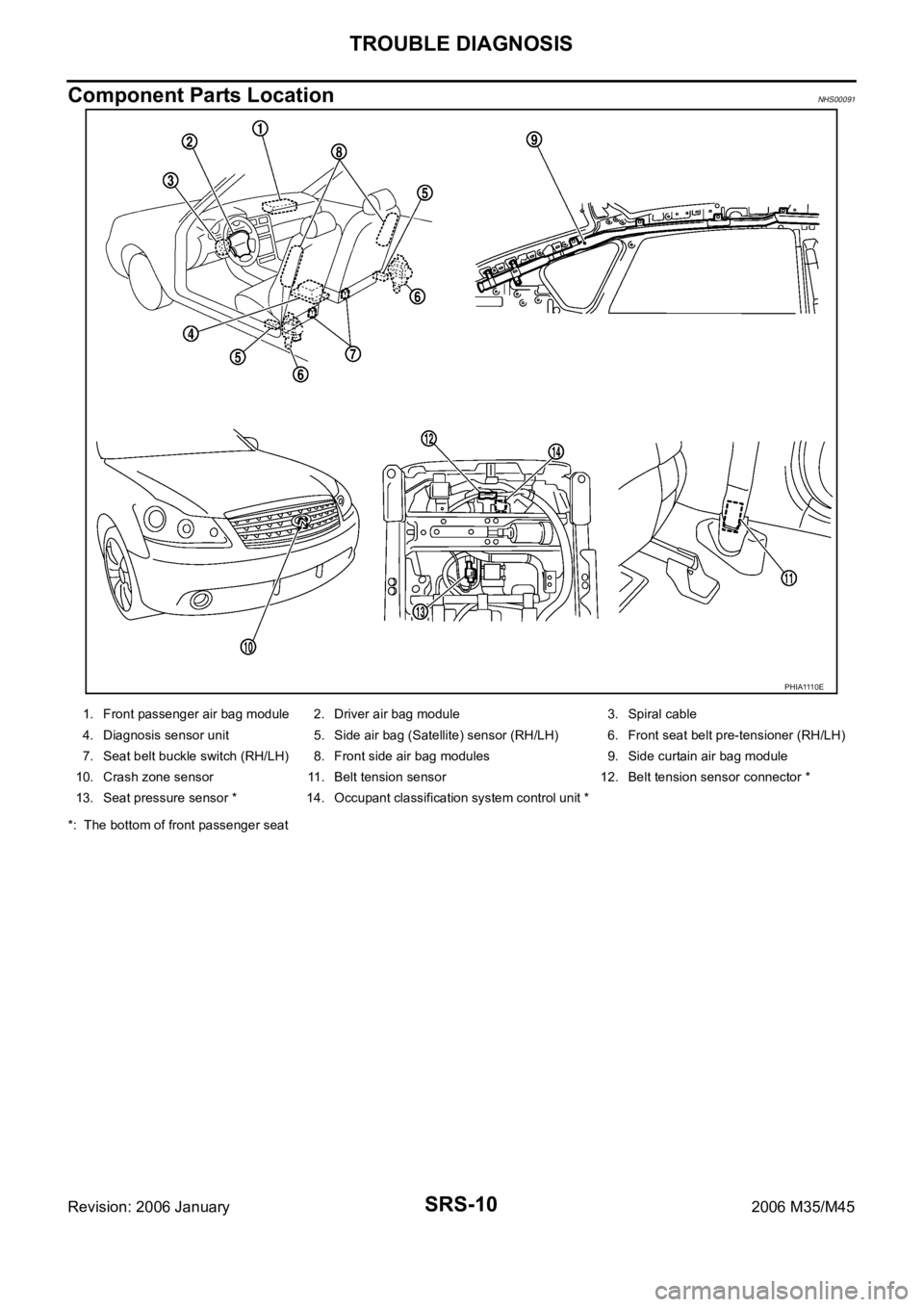

Component Parts LocationNHS00091

*: The bottom of front passenger seat

PHIA1110E

1. Front passenger air bag module 2. Driver air bag module 3. Spiral cable

4. Diagnosis sensor unit 5. Side air bag (Satellite) sensor (RH/LH) 6. Front seat belt pre-tensioner (RH/LH)

7. Seat belt buckle switch (RH/LH) 8. Front side air bag modules 9.Side curtain air bag module

10. Crash zone sensor 11. Belt tension sensor 12. Belt tension sensor connector *

13. Seat pressure sensor * 14. Occupant classification system control unit *

Page 5410 of 5621

OCCUPANT CLASSIFICATION SYSTEM CONTROL UNIT

SRS-49

C

D

E

F

G

I

J

K

L

MA

B

SRS

Revision: 2006 January2006 M35/M45

OCCUPANT CLASSIFICATION SYSTEM CONTROL UNITPFP:98852

Removal and InstallationNHS0009K

The occupant classification system control unit, seat pressure sensor, and bladder are an integral part of the

front passenger seat cushion and are replaced as an assembly. Refer to SE-165, "

Passenger's Seat Compo-

nents" .

Page 5424 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000E1

Check the following items with the vehicle stopped

Is air pr INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSIS

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000E1

Check the following items with the vehicle stopped

Is air pr](/img/42/57023/w960_57023-5423.png)

TROUBLE DIAGNOSIS

STC-9

[EPS]

C

D

E

F

H

I

J

K

L

MA

B

STC

Revision: 2006 January2006 M35/M45

For Fast and Accurate Trouble DiagnosisNGS000E1

Check the following items with the vehicle stopped

Is air pressure and size of tires proper?

Is the specified part used for the steering wheel?

Is control unit a genuine part?

Are there any fluid leakage from steering gear assembly, power steering oil pump, and hydraulic pipes,

etc? Refer to PS-8, "

POWER STEERING FLUID" .

Is the fluid level proper? Refer to PS-8, "POWER STEERING FLUID" .

Is the wheel alignment adjusted properly? Refer to FSU-19, "SERVICE DATA AND SPECIFICATIONS

(SDS)" (2WD), FSU-36, "SERVICE DATA AND SPECIFICATIONS (SDS)" (AWD).

Are there any damage or modification to suspension or body resulting in increased weight or altered

ground clearance?

Check each link installation condition of suspension and axle.

Check each connector connection condition.

Check the following items while driving the vehicle

Check conditions when the malfunction occurred (5W 1H).

Is the engine condition normal?

Basic InspectionNGS000E2

POWER SUPPLY CIRCUIT TERMINAL LOOSENESS AND BATTERY

Check battery terminals for looseness on both positive and negative ones and ground connection. Also make

sure that battery voltage does not drop.

Inspection: Power Steering Control Unit Power Supply Circuit and GroundNGS000E3

1. CHECK POWER STEERING CONTROL UNIT CONNECTOR

Turn ignition switch OFF, disconnect power steering control unit harness connector, and check terminal for

deformation, disconnection, looseness, etc.

OK or NG

OK >> GO TO 2.

NG >> Connector terminal connection is loose, damaged, open, or shorted. Repair or replace the termi-

nal.

2. CHECK POWER STEERING CONTROL UNIT GROUND CIRCUIT

Disconnect power steering control unit harness connector M8, and

then check continuity between power steering control unit harness

connector M8 and ground.

OK or NG

OK >> GO TO 3.

NG >> Ground circuit open or shorted. Repair or replace any

inoperative parts. Terminal 2 – Ground : Continuity exist.

SGIA1231E