pressure INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5553 of 5621

WT-28

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

Trouble Diagnosis ChartNES000K9

SELF-DIAGNOSIS

NOTICE:

186 kPa (1.86 kg/cm2 , 27 psi): Standard air pressure is for 230 kpa (2.3 kg/cm2 , 33 psi) vehicles. Item

Reference Self-diagnosis function CONSULT-II

DTC (warning lamp blinks) Diagnosis item Diagnosis item

11Front-left tire pressure drops to * kPa

(* kg/cm

2 , * psi) or less. (Notice)FLAT_TIRE_FL

— 12Front-right tire pressure drops to * kPa

(* kg/cm

2 , * psi) or less. (Notice)FLAT_TIRE_FR

13Rear-right tire pressure drops to * kPa

(* kg/cm

2 , * psi) or less. (Notice)FLAT_TIRE_RR

14Rear-left tire pressure drops to * kPa (*

kg/cm

2 , * psi) or less. (Notice)FLAT_TIRE_RL

21 Transmitter no data (front - left) [NO_DATA]_FL

WT-30

22 Transmitter no data (front - right) [NO_DATA]_FR

23 Transmitter no data (rear - right) [NO_DATA]_RR

24 Transmitter no data (rear - left) [NO_DATA]_RL

25 Receiver data error (front - left) [RECEIVER_ERR]_FL

WT-31

26 Receiver data error (front - right) [RECEIVER_ERR]_FR

27 Receiver data error (rear - right) [RECEIVER_ERR]_RR

28 Receiver data error (rear - left) [RECEIVER_ERR]_RL

35Transmitter pressure data error (front -

left)[PRESSDATA_ERR]_FL

WT-32

36Transmitter pressure data error (front -

right)[PRESSDATA_ERR]_FR

37Transmitter pressure data error (rear -

right)[PRESSDATA_ERR]_RR

38Transmitter pressure data error (rear -

left)[PRESSDATA_ERR]_RL

41Transmitter function code error (front -

left)[CODE_ERROR]_FL

WT-32

42Transmitter function code error (front -

right)[CODE_ERROR]_FR

43Transmitter function code error (rear -

right)[CODE_ERROR]_RR

44Transmitter function code error (rear -

left)[CODE_ERROR]_RL

45Transmitter battery voltage low (front -

left)[BATT_VOLT_LOW]_FL

WT-33

46Transmitter battery voltage low (front -

right)[BATT_VOLT_LOW]_FR

47Transmitter battery voltage low (rear -

right)[BATT_VOLT_LOW]_RR

48Transmitter battery voltage low (rear -

left)[BATT_VOLT_LOW]_RL

51 Receiver ID no registration RECEIVER_ID_NO_REGWT-33

52 Vehicle speed signal VHCL_SPED_SIG_ERRWT-34

— CAN COMM CIRCUITWT-34

Page 5555 of 5621

WT-30

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMSPFP:00000

Inspection 1: Transmitter no DataNES000KA

MALFUNCTION CODE NO. 21, 22, 23, 24

1. CHECK CONTROL UNIT

Drive for several minutes. Check all tire pressures with CONSULT-II “DATA MONITOR”.

Are all tire pressures displayed 0 kPa?

YES >> GO TO 2.

NO >> GO TO 3.

2. CHECK TIRE PRESSURE RECEIVER CONNECTOR

1. Disconnect tire pressure receiver harness connector E74 (FR-LH), E75 (FR-RH), B116 (RR-RH), B115

(RR-LH).

2. Check terminals for damage or loose connection.

3. Reconnect harness connector.

OK or NG

OK >> Replace low tire pressure warning control unit. Refer to WT-40, "Low Tire Pressure Warning Con-

trol Unit" , then GO TO 3.

NG >> Repair or replace tire pressure receiver harness connector.

3. ID REGISTRATION

Perform ID registration of all transmitters.

Are there any tires that ID can not be registered to?

YES >> Replace transmitter of the tire, then GO TO 5.

NO >> GO TO 4.

4. VEHICLE DRIVING

Drive at a speed of 40 km/h (25 MPH) or more for several minutes without stopping.

Check all tire pressures with CONSULT-II “DATA MONITOR” within 15 minutes after vehicle speed becomes

17 km/h (11 MPH).

Does

“DATA MONITOR ” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> GO TO 5.

5. ID REGISTRATION AND VEHICLE DRIVING

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for

10 minutes. Then check all tire pressures with CONSULT-II “DATA MONITOR” within 5 minutes.

Does

“DATA MONITOR” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> GO TO the inspection applicable to DTC.

Page 5556 of 5621

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

WT-31

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

Inspection 2: Receiver Data ErrorNES000KB

MALFUNCTION CODE NO. 25, 26, 27, 28

1. CHECK LOW TIRE PRESSURE WARNING CONTROL UNIT AND RECEIVER CONNECTOR

1. Turn ignition switch OFF, disconnect low tire pressure warning control unit harness connector and receiver

harness connector, and check terminal for deformation, disconnection, looseness, and so on. If there is a

malfunction, repair or replace the terminal.

2. Reconnect connector securely, and perform self-diagnosis.

Does

“SELF-DIAG RESULTS” display as normal without any warning lamp?

YES >> Connector terminal connection is loose, damaged, open, or shorted.

NO >> GO TO 2.

2. CHECK TIRE PRESSURE RECEIVER POWER SUPPLY AND GROUND CIRCUIT

1. Turn ignition switch OFF, and disconnect tire pressure receiver harness connector E74, E75, B115, B116.

2. Check continuity between tire pressure receiver harness con-

nector E74, E75, B115, B116 and ground.

3. Turn ignition switch ON, and then check voltage between tire

pressure receiver harness connector E74, E75, B115, B116 and

ground.

OK or NG

OK >> GO TO 3.

NG >> GO TO 4.

3. CHANGE THE TIRE PRESSURE RECEIVER POSITION (EXAMPLE OF FRONT LH SIDE)

1. Replace right from left for front and rear receivers.

2. Perform self-diagnosis.

Is the initial indication of self-diagnosis displayed?

YES >> GO TO 4

NO >> Replace tire pressure receiver front RH when indicating RH tire pressure receiver malfunction. Terminal 4 – Ground : Continuity exist.

SGIA1249E

1 – Ground : Battery voltage (Approx.12 V)

SGIA1250E

Page 5557 of 5621

WT-32

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

4. CHECK RECEIVER HARNESS (EXAMPLE OF FRONT LH SIDE)

1. Turn ignition switch OFF, disconnect low tire pressure warning

control unit harness connector M19 and receiver harness con-

nector E74.

2. Check continuity between low tire pressure warning control unit

harness connector M19 and receiver harness connector E74.

OK or NG

OK >> Replace low tire pressure warning control unit.

NO >> Harness between Low tire warning control unit and

Receiver until open or shorted. Repair or replace harness.

Inspection 3: Transmitter Pressure Data ErrorNES000KC

MALFUNCTION CODE NO. 35, 36, 37, 38

1. CHECK ALL TIRE PRESSURES

Check all tire pressures. Refer to WT-41, "

SERVICE DATA AND SPECIFICATIONS (SDS)" .

Are there any tires whose pressure is

“64 psi” or more?

YES >> Adjust tire pressure to specified value.

NO >> GO TO 2.

2. VEHICLE DRIVING

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more for several minutes without stopping.

Check all tire pressures with CONSULT-II “DATA MONITOR” within 15 minutes after vehicle speed

becomes 17 km/h (11 MPH).

>> Replace tire pressure transmitter with new one if “DATA MONITOR” display 64 psi or more. Then

GO TO 3.

3. ID REGISTRATION AND VEHICLE DRIVING

1. Perform ID registration of all tire pressure transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for

10 minutes. Then check all tire pressures with CONSULT-II “DATA MONITOR” within 5 minutes.

Does

“DATA MONITOR” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> GO TO the inspection applicable to DTC.

Inspection 4: Transmitter Function Code ErrorNES000KD

MALFUNCTION CODE NO. 41, 42, 43, 44

1. ID REGISTRATION (CORRECTION OF TRANSMITTER LOCATION)

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for

10 minutes.

>> GO TO 2. Terminal 27 – 2 : Continuity exist.

Terminal 11 – 3 : Continuity exist.

SEIA0666E

Page 5558 of 5621

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

WT-33

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

2. REPLACE TIRE PRESSURE TRANSMITTER

1. Check low tire pressure warning condition again, and replace malfunctioning tire pressure transmitter.

2. Perform ID registration of all transmitter.

Can ID registration of all tire pressure transmitters be completed?

YES >> GO TO 3.

NO >> GO TO the inspection 1. Refer to WT-30, "

Inspection 1: Transmitter no Data" .

3. VEHICLE DRIVING

Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for 10

minutes. Then check all tire pressures with CONSULT-II “DATA MONITOR” within 5 minutes.

Does

“DATA MONITOR” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> Replace malfunctioning transmitter, and perform “Step 3” again.

Inspection 5: Transmitter Battery Voltage LowNES000KE

MALFUNCTION CODE NO. 45, 46, 47, 48

1. ID REGISTRATION (CORRECTION OF TRANSMITTER LOCATION)

1. Perform ID registration of all transmitters.

2. Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for

10 minutes.

>> GO TO 2.

2. REPLACE TIRE PRESSURE TRANSMITTER

1. Check low tire pressure warning lamp condition again, and replace malfunctioning tire pressure transmit-

ter.

2. Perform ID registration of all tire pressure transmitter.

Can ID registration of all tire pressure transmitters be completed?

YES >> GO TO 3.

NO >> GO TO the inspection 1. Refer to WT-30, "

Inspection 1: Transmitter no Data" .

3. VEHICLE DRIVING

Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for 10

minutes. Then check all tire pressures with CONSULT-II “DATA MONITOR” within 5 minutes.

Does

“DATA MONITOR” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> Replace malfunctioning transmitter, and perform “Step 3” again.

Inspection 6: Receiver ID No RegistrationNES000KF

MALFUNCTION CODE NO. 51

1. ID REGISTRATION

1. Perform ID registration of all tire pressure transmitters. Refer to WT-19, "

ID Registration Procedure" .

2. Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for

10 minutes.

>> GO TO 2.

Page 5559 of 5621

WT-34

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

2. REPLACE TIRE PRESSURE TRANSMITTER

1. Check low tire pressure warning condition again, and replace malfunctioning tire pressure transmitter.

2. Perform ID registration of all transmitter.

Can ID registration of all tire pressure transmitters be completed?

YES >> GO TO 3.

NO >> GO TO the inspection 1. Refer to WT-30, "

Inspection 1: Transmitter no Data" .

3. VEHICLE DRIVING

Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for 10

minutes. Then check all tire pressures with CONSULT-II “DATA MONITOR” within 5 minutes.

Does

“DATA MONITOR” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> Replace malfunctioning transmitter, and perform “Step 3” again.

Inspection 7: Vehicle Speed SignalNES000KG

MALFUNCTION CODE NO. 52

1. CHECK SELF-DIAGNOSIS RESULTS

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)” “AIR PRESSURE MONITOR”.

–If “AIR PRESSURE MONITOR” is not displayed, print the “SELECT SYSTEM” screen. Then refer to LAN-

7, "Precautions When Using CONSULT-II" .

NOTE:

Just after starting engine, or turning ignition switch ON, it may not be displayed even if “START (NISSAN

BASED VHCL)” is touched. In this case, reconnect CONSULT-II and CONSULT-II CONVERTER.

5. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

6. Check display contents in self-diagnostic results.

Is

“CAN COMM CIRCUIT” displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. GO TO LAN-7, "Precautions When Using CONSULT-

II" .

NO >> No malfunction. Check combination meter refer to DI-18, "

Trouble Diagnosis" .

Inspection 8: CAN Communication System MalfunctionNES000KS

1. CHECK LOW TIRE PRESSURE WARNING CONTROL UNIT CONNECTOR

1. Turn ignition switch OFF, disconnect low tire pressure warning control unit harness connector, and check

terminal for deformation, disconnection, looseness, etc.

2. Reconnect harness connector securely, and perform CONSULT-II self-diagnosis.

Is above displayed on self-diagnosis display?

YES >> If “CAN COMM CIRCUIT [U1000]” is displayed, print out self-diagnosis. And then, go to LAN-7,

"Precautions When Using CONSULT-II" .

NO >> Connector terminal connection is loose, damaged, open, or shorted. Repair or replace the termi-

nal.

Self-diagnostic results

CAN COMM CIRCUIT [U1000]

Page 5560 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

WT-35

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

TROUBLE DIAGNOSIS FOR SYMPTOMSPFP:00007

Inspection 1: Warning Lamp Does Not Come On When Ignition Switch Is Turned

On

NES000KH

1. CHECK SELF-DIAGNOSIS RESULTS

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)” “AIR PRESSURE MONITOR” “SELF-DIAG RESULTS”.

–If AIR PRESSURE MONITOR is not displayed, print the “SELECT SYSTEM” screen. Then refer to LAN-7,

"Precautions When Using CONSULT-II" .

NOTE:

Just after starting engine, or turning ignition switch ON, it may not be displayed even if “START (NISSAN

BASED VHCL)” is touched. In this case, reconnect CONSULT-II and CONSULT-II CONVERTER.

5. Check display contents in self-diagnostic results.

Is

“CAN COMM CIRCUIT” displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. GO TO LAN-7, "Precautions When Using CONSULT-

II" .

NO >> GO TO 2.

2. CHECK COMBINATION METER

Check combination meter function.

OK or NG

OK >> GO TO 3.

NG >> Check combination meter. Refer to DI-18, "

Trouble Diagnosis" .

3. CHECK LOW TIRE PRESSURE WARNING LAMP

Disconnect low tire pressure warning control unit harness connector M19.

Does the warning lamp activate?

YES >> Replace low tire pressure warning control unit. Refer to WT-40, "Low Tire Pressure Warning Con-

trol Unit" .

NO >> Check combination meter and repair or replace.

Page 5561 of 5621

WT-36

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

Inspection 2: Warning Lamp Stays On When Ignition Switch Is Turned OnNES000KI

1. CHECK CONNECTOR

1. Disconnect low tire pressure harness connectors M19.

2. Check terminals for damage or loose connections.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2. CHECK POWER SUPPLY CIRCUIT (IGN)

1. Turn ignition switch ON.

2. Measure voltage between low tire pressure warning control unit harness connector M19 and ground.

OK or NG

OK >> GO TO 3.

NG >> Check low tire pressure warning control unit power sup-

ply circuit for open or short.

3. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between low tire pressure warning control unit

harness connector M19 and ground.

OK or NG

OK >> Replace low tire pressure warning control unit. Refer to

WT-40, "

Low Tire Pressure Warning Control Unit" .

NG >> Repair or replace low tire pressure warning control unit

ground circuit.

Terminal

Vo l ta g e

(+) (–)

2 Ground 12 V

SEIA0656E

Terminal

Continuity

(+) (–)

17 Ground Should exist.

SEIA0657E

Page 5562 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

WT-37

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

Inspection 3: Warning Lamp Blinks When Ignition Switch Is Turned OnNES000KJ

NOTE:

If warning lamp blinks below, the system is normal.

Blink Mode A

This mode shows transmitter status is in OFF-mode.

Perform transmitter wake up operation. Refer to WT-21, "

Trans-

mitter Wake Up Operation" .

1. CHECK CONNECTOR

1. Disconnect low tire pressure warning control unit harness connector M19.

2. Check terminals for damage or loose connections.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2. CHECK TIRE PRESSURE WARNING CHECK SWITCH CIRCUIT

Check continuity between low tire pressure warning control unit har-

ness connector M19 and ground.

OK or NG

OK >> Replace low tire pressure warning control unit. Refer to

WT-40, "

Low Tire Pressure Warning Control Unit" .

NG >> Repair or replace harness connector.

Inspection 4: Turn Signal Lamp Blinks When Ignition Switch Is Turned OnNES000KK

1. CHECK TIRE PRESSURE WARNING CHECK SWITCH CIRCUIT

Check continuity between low tire pressure warning control unit har-

ness connector M19 and ground.

OK or NG

OK >> Check turn signal lamp operation. Refer to LT- 2 11 , "Sys-

tem Description" .

NG >> Repair or replace harness connector.

SEIA0347E

Terminal

Continuity

(+) (–)

5 Ground No

SEIA0658E

Terminal

Continuity

(+) (–)

5Ground No

SEIA0658E

Page 5565 of 5621

WT-40

REMOVAL AND INSTALLATION

Revision: 2006 January2006 M35/M45

3. Place wheel on turntable of tire machine. Ensure that transmitter

is 270 degree from mounting head when second side of tire is

fitted.

NOTE:

Do not touch transmitter at mounting head.

4. Lubricate tire well and fit second side of tire as normal. Ensure

that tire does not rotate relative to rim.

5. Inflate tire and fit to appropriate wheel position.

Low Tire Pressure Warning Control UnitNES000KN

REMOVAL

1. Remove instrument driver lower panel. Refer to IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Remove fixing bolt (1), and then remove low tire pressure warn-

ing control unit (2) from vehicle.

INSTALLATION

Installation is the reverse order of removal.

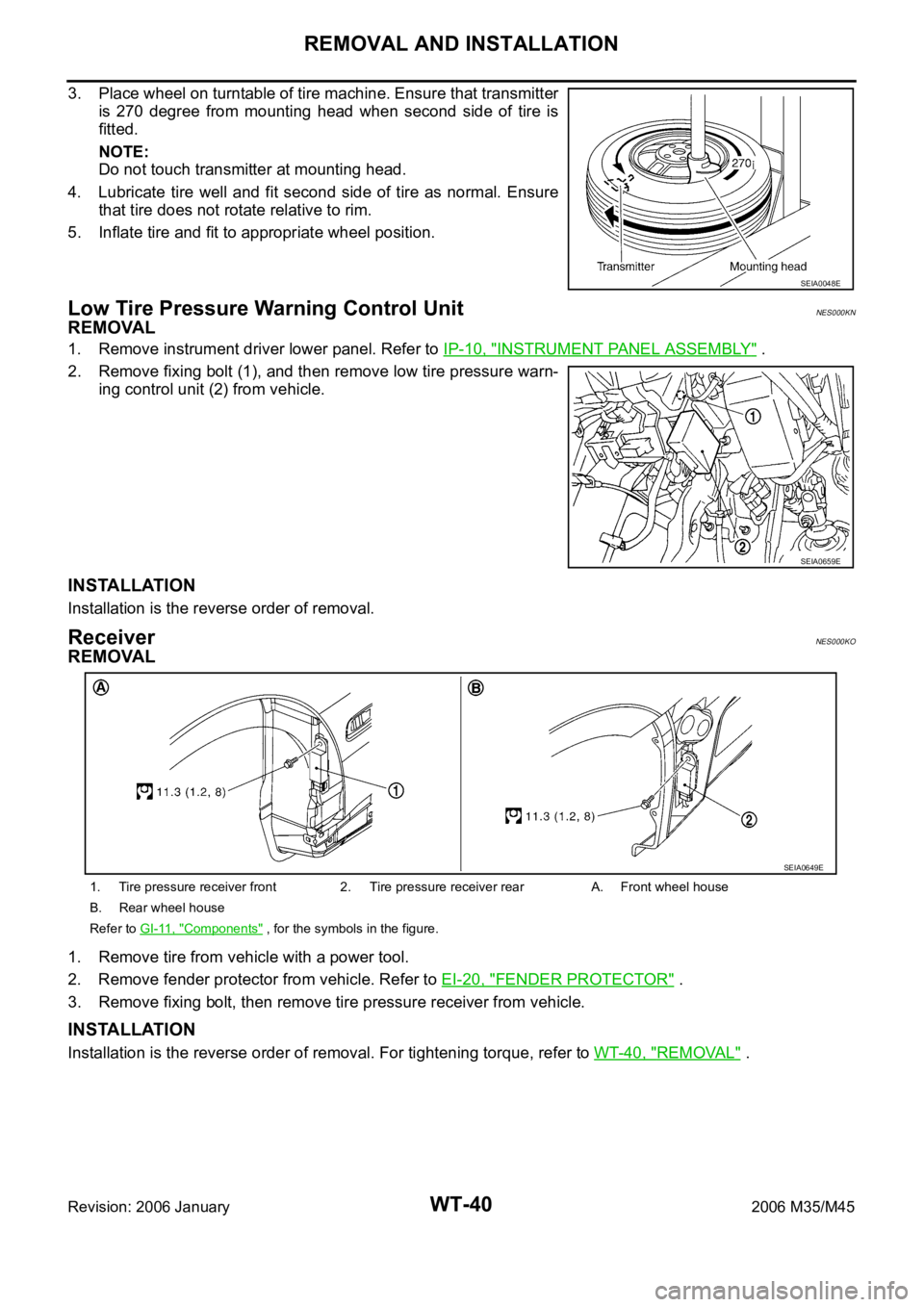

ReceiverNES000KO

REMOVAL

1. Remove tire from vehicle with a power tool.

2. Remove fender protector from vehicle. Refer to EI-20, "

FENDER PROTECTOR" .

3. Remove fixing bolt, then remove tire pressure receiver from vehicle.

INSTALLATION

Installation is the reverse order of removal. For tightening torque, refer to WT-40, "REMOVAL" .

SEIA0048E

SEIA0659E

1. Tire pressure receiver front 2. Tire pressure receiver rear A. Front wheel house

B. Rear wheel house

Refer to GI-11, "

Components" , for the symbols in the figure.

SEIA0649E