mirror INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 4696 of 5621

INTERIOR ROOM LAMP

LT-269

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

through front door lock assembly (driver side) (key cylinder switch) terminals 5 and 4

through grounds M16 and M70.

When a signal, or combination of door open signals is received by BCM, ground is supplied

to foot lamp driver side and passenger side terminals 2

to personal lamp LH and RH terminals 1

to map lamp terminal 2 and 5

through BCM terminal 48,

to step lamp (driver side, passenger side, rear LH and RH) terminals 2

to kicking plate illumination (driver side and passenger side) terminals 2

through BCM terminal 47.

With power and ground supplied, the interior lamps illuminate.

SWITCH OPERATION

When any front door switch is ON (door is opened), ground is supplied

to step lamp (driver side, passenger side, rear LH and RH) terminals 2

to kicking plate illumination (driver side and passenger side) terminals 2

through BCM terminal 47.

And power is supplied

through BCM terminal 41

to step lamp (driver side, passenger side, rear LH and RH) terminals 1

to kicking plate illumination (driver side and passenger side) terminals 1.

When any door switch is ON (door is opened) and personal lamp and map lamp is DOOR position, ground is

supplied

to personal lamp LH and RH terminal 1

to map lamp terminals 2 and 5

through BCM terminal 48.

And power is supplied

through BCM terminal 41

to personal lamp LH and RH terminals 3

to map lamp terminal 3.

When map lamp switch is ON, ground is supplied

to map lamp terminal 1

through grounds M16 and M70.

And power is supplied

through BCM terminal 41

to map lamp terminal 3.

When personal lamp LH and RH switch is ON, ground is supplied

to personal lamp LH and RH terminals 2

through grounds M16 and M70.

And power is supplied

through BCM terminal 41

to personal lamp LH and RH terminals 3.

When trunk lid lock assembly (trunk room lamp switch) is ON, ground is supplied

to trunk room lamp (upper and lower) terminals 2

through trunk lid lock assembly (trunk room lamp switch) terminals 1 and 2

through grounds B5, B40 and B131.

And power is supplied

through BCM terminal 41

to trunk room lamp (upper and lower) terminals 1.

When vanity mirror lamp LH and RH switch is ON, ground is supplied

Page 4697 of 5621

LT-270

INTERIOR ROOM LAMP

Revision: 2006 January2006 M35/M45

to vanity mirror lamp LH and RH terminals 2

through grounds M16 and M70.

And power is supplied

through BCM terminal 41

to vanity mirror lamp (LH and RH) terminals 1.

ROOM LAMP TIMER OPERATION

BCM controls applicable lamps to illuminate for 15 seconds (can be set maximum 30 seconds) by timer oper-

ation under following conditions. BCM also controls applicable lamps to brighten for 1 second (can be set max-

imum 5 seconds) when turned ON, or to dim for 3 seconds (can be set maximum 5 seconds) when turned

OFF. (Timer operating time and dimming/brightening time can be changed with CONSULT-II. Refer to LT- 2 8 5 ,

"WORK SUPPORT (INT LAMP)" .) This control operates as follows.

Applicable lamps

Room lamp system: map lamp, foot lamp (driver side and passenger side) and personal lamp (rear LH

and rear RH).

BCM controls room lamp timer operation under following condition.

Condition 1: Door lock state changes.*

BCM judges as the door lock is unlocked under either case below.

–The Intelligent Key unit sends door lock/unlock trunk open request signal (driver side unlock or passenger

side unlock) to BCM through CAN communication line by unlock operation of intelligent key, outside key

antenna and front door request switch (driver side) or outside key antenna and front door request switch

(passenger side).

–Key cylinder switch state (unlock) signal is sent to BCM through power window serial link when front door

lock assembly (driver side) (key cylinder switch) is unlocked (ON) by power window main switch unlock

operation.

And fulfills all the conditions below.

–The engine switch (push switch) is OFF.

–All the doors are closed.

*: This setting can be changed by CONSULT-II. Refer to LT-285, "

WORK SUPPORT (INT LAMP)" .

Condition 2: Any door switch state changes.*

The BCM terminal value of operated door switch is changed when any door is opened and then closed.

From that BCM judges as the door is opened and then closed.

And fulfills all the conditions below.

–The engine switch (push switch) is OFF.

–All the doors are closed.

*: This setting can be changed by CONSULT-II. Refer to LT-285, "

WORK SUPPORT (INT LAMP)" .

Condition 3: Engine switch (push switch) state changes.*

The Intelligent Key unit judges as the engine switch (push switch) is OFF and sends push-button ignition

switch (push switch) signal to PDU (power distribution unit) when push-button ignition switch (push

switch) turned OFF. Then PDU (power distribution unit) turns OFF, IGN power supply and ACC power

supply.

And fulfills the conditions below.

–All the doors are closed.

*:This setting can be changed by CONSULT-II. Refer to LT- 2 8 5 , "

WORK SUPPORT (INT LAMP)" .

NOTE:

When timer operation signal is input during former timer operation, BCM goes for latter timer operation.

Page 4698 of 5621

INTERIOR ROOM LAMP

LT-271

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

ROOM LAMP TIMER OPERATING TIME

CONDITIONS FOR CANCELING TIMER

Timer operation is cancelled in any of the following conditions.

Driver door is locked.

Any door is opened.

Turn ignition switch is ACC or ON.

ROOM LAMP TIMER INAPPLICABLE LAMPS OPERATION

Step lamp system: step lamp (driver side, passenger side, rear LH and rear RH) and kicking plate illumi-

nation (driver side and passenger side).

Step lamp system lamps are ON/OFF linked with any door (driver side, passenger side, rear LH and rear

RH) opened and then closed.

Vanity mirror lamp LH and RH.

Operated side vanity mirror lamp is ON/OFF linked with vanity mirror opened and then closed.

Trunk room lamp (lower) and trunk room lamp (upper).

Trunk room lamps (lower and upper) are ON/OFF linked with trunk opened and then closed.

INTERIOR ROOM LAMP BATTERY SAVER FUNCTION

Applicable lamps

Room lamp system: map lamp, foot lamp (driver side and passenger side) and personal lamp (rear LH

and rear RH).

Step lamp system: step lamp (driver side, passenger side, rear LH and rear RH) and kicking plate illumi-

nation (driver side and passenger side).

Vanity mirror lamp LH and RH.

Trunk room lamp (lower) and trunk room lamp (upper).

If the any applicable lamp is left illuminated, BCM turns OFF the battery saver output power supply 30 or 60

minutes to prevent run down of the battery. (Factory setting time is 30 minutes. And timer setting can be

changed by CONSULT-II. Refer to LT-287, "

WORK SUPPORT (BATTERY SAVER)" .)

When the push-button ignition switch (push switch) is turned from ON to OFF, the timer is activated.

If any of the following door switch signal condition is changed with the push-button ignition switch (push

switch) in OFF position, the timer is activated when the change is occurred.

Door switch signals (driver side, passenger side, rear LH and RH), front door lock assembly (driver side) (key

cylinder switch) signal and Intelligent Key unlock signal.

SKIB4934E

Page 4720 of 5621

INTERIOR ROOM LAMP

LT-293

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

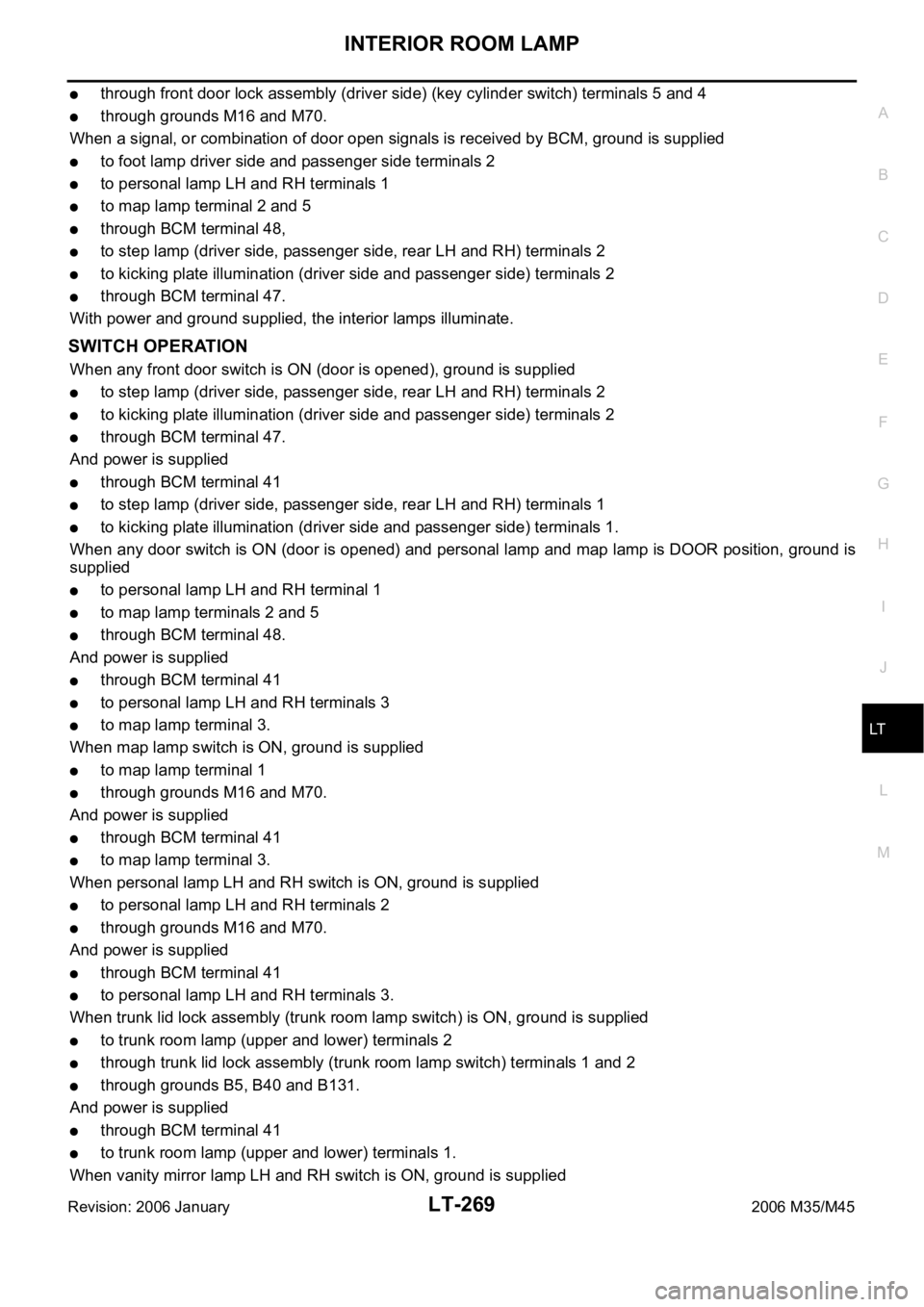

Foot Lamp (Passenger Side)NKS003TC

BULB REPLACEMENT

1. Insert a screwdriver or similar tool and remove lens (1).

2. Remove bulb (2).

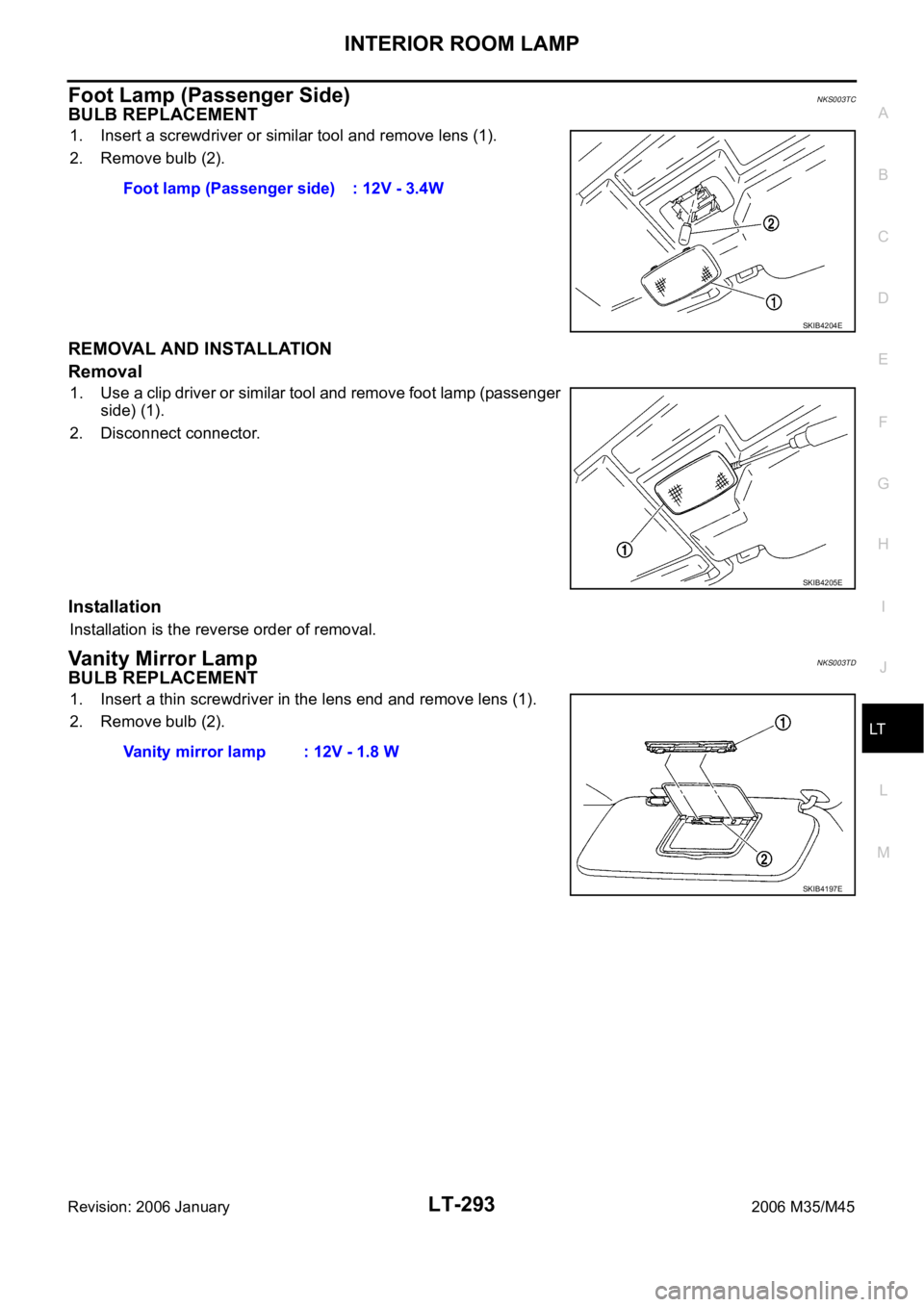

REMOVAL AND INSTALLATION

Removal

1. Use a clip driver or similar tool and remove foot lamp (passenger

side) (1).

2. Disconnect connector.

Installation

Installation is the reverse order of removal.

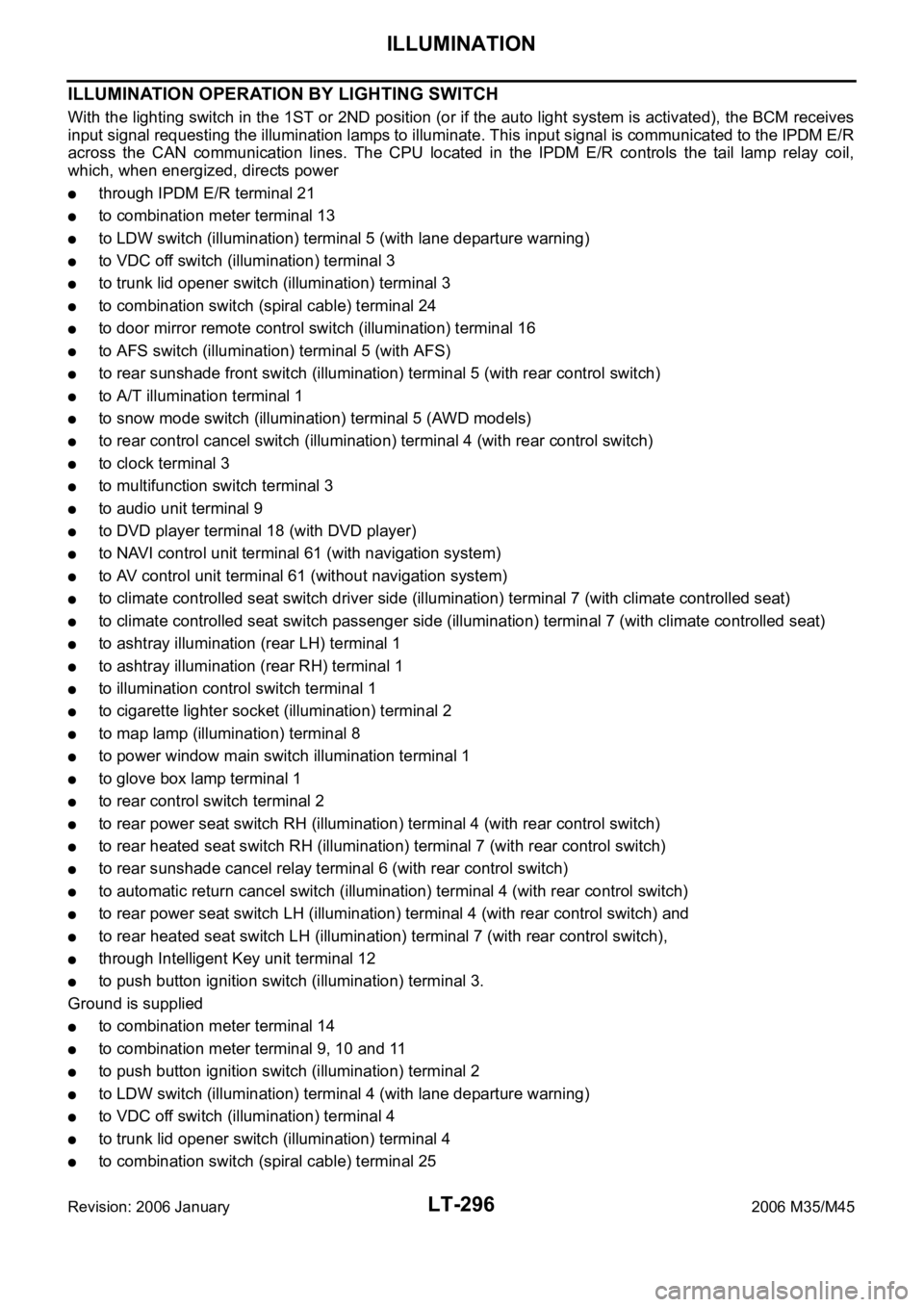

Vanity Mirror LampNKS003TD

BULB REPLACEMENT

1. Insert a thin screwdriver in the lens end and remove lens (1).

2. Remove bulb (2).Foot lamp (Passenger side) : 12V - 3.4W

SKIB4204E

SKIB4205E

Vanity mirror lamp : 12V - 1.8 W

SKIB4197E

Page 4723 of 5621

LT-296

ILLUMINATION

Revision: 2006 January2006 M35/M45

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND position (or if the auto light system is activated), the BCM receives

input signal requesting the illumination lamps to illuminate. This input signal is communicated to the IPDM E/R

across the CAN communication lines. The CPU located in the IPDM E/R controls the tail lamp relay coil,

which, when energized, directs power

through IPDM E/R terminal 21

to combination meter terminal 13

to LDW switch (illumination) terminal 5 (with lane departure warning)

to VDC off switch (illumination) terminal 3

to trunk lid opener switch (illumination) terminal 3

to combination switch (spiral cable) terminal 24

to door mirror remote control switch (illumination) terminal 16

to AFS switch (illumination) terminal 5 (with AFS)

to rear sunshade front switch (illumination) terminal 5 (with rear control switch)

to A/T illumination terminal 1

to snow mode switch (illumination) terminal 5 (AWD models)

to rear control cancel switch (illumination) terminal 4 (with rear control switch)

to clock terminal 3

to multifunction switch terminal 3

to audio unit terminal 9

to DVD player terminal 18 (with DVD player)

to NAVI control unit terminal 61 (with navigation system)

to AV control unit terminal 61 (without navigation system)

to climate controlled seat switch driver side (illumination) terminal 7 (with climate controlled seat)

to climate controlled seat switch passenger side (illumination) terminal 7 (with climate controlled seat)

to ashtray illumination (rear LH) terminal 1

to ashtray illumination (rear RH) terminal 1

to illumination control switch terminal 1

to cigarette lighter socket (illumination) terminal 2

to map lamp (illumination) terminal 8

to power window main switch illumination terminal 1

to glove box lamp terminal 1

to rear control switch terminal 2

to rear power seat switch RH (illumination) terminal 4 (with rear control switch)

to rear heated seat switch RH (illumination) terminal 7 (with rear control switch)

to rear sunshade cancel relay terminal 6 (with rear control switch)

to automatic return cancel switch (illumination) terminal 4 (with rear control switch)

to rear power seat switch LH (illumination) terminal 4 (with rear control switch) and

to rear heated seat switch LH (illumination) terminal 7 (with rear control switch),

through Intelligent Key unit terminal 12

to push button ignition switch (illumination) terminal 3.

Ground is supplied

to combination meter terminal 14

to combination meter terminal 9, 10 and 11

to push button ignition switch (illumination) terminal 2

to LDW switch (illumination) terminal 4 (with lane departure warning)

to VDC off switch (illumination) terminal 4

to trunk lid opener switch (illumination) terminal 4

to combination switch (spiral cable) terminal 25

Page 4724 of 5621

ILLUMINATION

LT-297

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

to door mirror remote control switch (illumination) terminal 15

to AFS switch (illumination) terminal 6 (with AFS)

to rear sunshade front switch (illumination) terminal 6 (with rear control switch)

to A/T illumination terminal 2

to snow mode switch (illumination) terminal 6 (ADW models)

to rear control cancel switch (illumination) terminal 5 (with rear control switch)

to clock terminal 4

to multifunction switch terminal 4

to audio unit terminal 8

to DVD player terminal 17 (With DVD player)

to climate controlled seat switch driver side (illumination) terminal 8 (with climate controlled seat) and

to climate controlled seat switch passenger side (illumination) terminal 8 (with climate controlled seat)

through illumination control switch terminal 2

to illumination control switch terminal 3

through grounds M16 and M70,

to cigarette lighter socket (illumination) terminal 1

to map lamp (illumination) terminal 4

to power window main switch illumination terminal 2 and

to glove box lamp terminal 2

through grounds M16 and M70,

to ashtray illumination (rear LH) terminal 2

to ashtray illumination (rear RH) terminal 2

to automatic return cancel switch (illumination) terminal 2 (With rear control switch)

to rear power seat switch LH (illumination) terminal 3 (With rear control switch)

to rear heated seat switch LH (illumination) terminal 8 (With rear control switch)

through grounds B5, B40 and B131,

through rear sunshade cancel relay terminal 7(With rear control switch)

to rear sunshade rear switch (illumination) terminal 7 (With rear control switch)

through grounds B5, B40, B131 and B559.

to rear control switch terminal 4

to rear power seat switch RH (illumination) terminal 3 (With rear control switch)

to rear heated seat switch RH (illumination) terminal 8 (With rear control switch)

through grounds B5, B40, B131 and B559.

With power and ground supplied, illumination lamps illuminate.

EXTERIOR LAMP BATTERY SAVER CONTROL

BCM activates the exterior lamp battery saver control function and turns off the exterior lamps to prevent bat-

tery from over discharge when the combination switch (lighting switch) is in 1ST or 2ND position and/or the

front fog lamp switch ON and the door lock operation is performed by keyless entry system.

CAN Communication System DescriptionNKS003TI

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitNKS003TJ

Refer to LAN-34, "CAN Communication Unit" .

Page 4742 of 5621

BULB SPECIFICATIONS

LT-315

C

D

E

F

G

H

I

J

L

MA

B

LT

Revision: 2006 January2006 M35/M45

BULB SPECIFICATIONSPFP:26297

HeadlampNKS003TQ

Exterior LampNKS003TR

Interior Lamp/IlluminationNKS003TS

NOTE:

This lamp is used as both front ashtray and front cigarette lighter. Item Wattage (W)

Low (Halogen type)55 (H1)

Low (Xenon type)35 (D2S)

High60 (HB3)

Item Wattage (W)

Front combination lampFront turn signal lamp 21

Parking lamp (Clearance lamp) 5

Front side marker lamp 5

Rear combination lampStop/Tail lamp LED

Rear turn signal lamp 21 (amber)

Rear side marker lamp LED

Back-up lamp18

Side turn signal lamp5

Front fog lamp55 (H11)

License plate lamp5

High-mounted stop lampLED

Item Wattage (W)

Map lamp8

Personal lamp8

Trunk room lampUpper

5

Lower

Front ashtray and front cigarette lighter illumination

NOTE1.4

Rear ashtray illumination1.4

Ste p lamp5

Vanity mirror lamp1.8

Center console indirect illuminationLED

Glove box lamp1.4

Foot lampDriver side

3.4

Passenger side

Kicking plateDriver side

LED

Passenger side

Power window indirect illuminationLED

Page 4921 of 5621

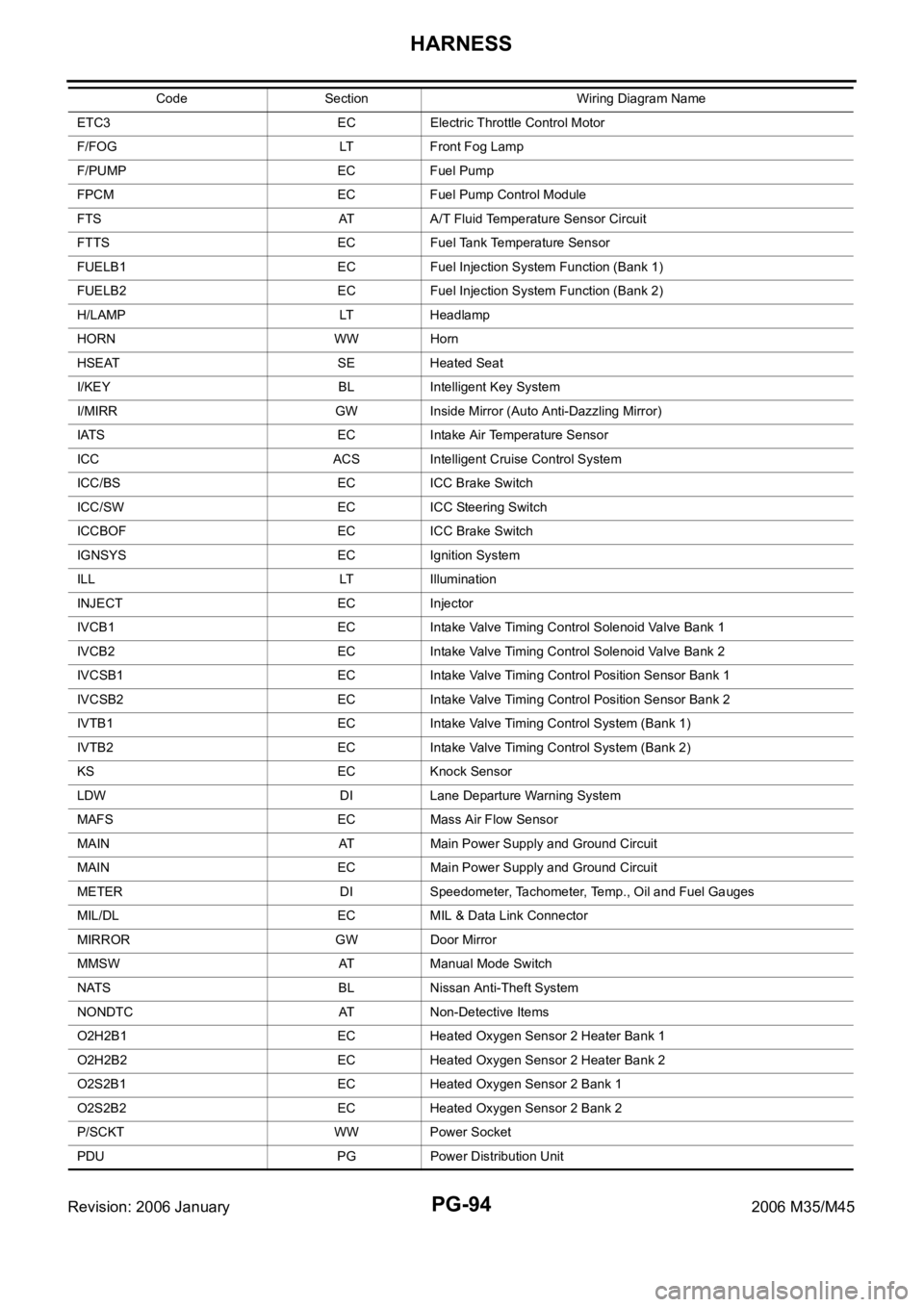

PG-94

HARNESS

Revision: 2006 January2006 M35/M45

ETC3 EC Electric Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FPCM EC Fuel Pump Control Module

FTS AT A/T Fluid Temperature Sensor Circuit

FTTS EC Fuel Tank Temperature Sensor

FUELB1 EC Fuel Injection System Function (Bank 1)

FUELB2 EC Fuel Injection System Function (Bank 2)

H/LAMP LT Headlamp

HORN WW Horn

HSEAT SE Heated Seat

I/KEY BL Intelligent Key System

I/MIRR GW Inside Mirror (Auto Anti-Dazzling Mirror)

IATS EC Intake Air Temperature Sensor

ICC ACS Intelligent Cruise Control System

ICC/BS EC ICC Brake Switch

ICC/SW EC ICC Steering Switch

ICCBOF EC ICC Brake Switch

IGNSYS EC Ignition System

ILL LT Illumination

INJECT EC Injector

IVCB1 EC Intake Valve Timing Control Solenoid Valve Bank 1

IVCB2 EC Intake Valve Timing Control Solenoid Valve Bank 2

IVCSB1 EC Intake Valve Timing Control Position Sensor Bank 1

IVCSB2 EC Intake Valve Timing Control Position Sensor Bank 2

IVTB1 EC Intake Valve Timing Control System (Bank 1)

IVTB2 EC Intake Valve Timing Control System (Bank 2)

KS EC Knock Sensor

LDW DI Lane Departure Warning System

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Circuit

MAIN EC Main Power Supply and Ground Circuit

METER DI Speedometer, Tachometer, Temp., Oil and Fuel Gauges

MIL/DL EC MIL & Data Link Connector

MIRROR GW Door Mirror

MMSW AT Manual Mode Switch

NATS BL Nissan Anti-Theft System

NONDTC AT Non-Detective Items

O2H2B1 EC Heated Oxygen Sensor 2 Heater Bank 1

O2H2B2 EC Heated Oxygen Sensor 2 Heater Bank 2

O2S2B1 EC Heated Oxygen Sensor 2 Bank 1

O2S2B2 EC Heated Oxygen Sensor 2 Bank 2

P/SCKT WW Power Socket

PDU PG Power Distribution Unit Code Section Wiring Diagram Name

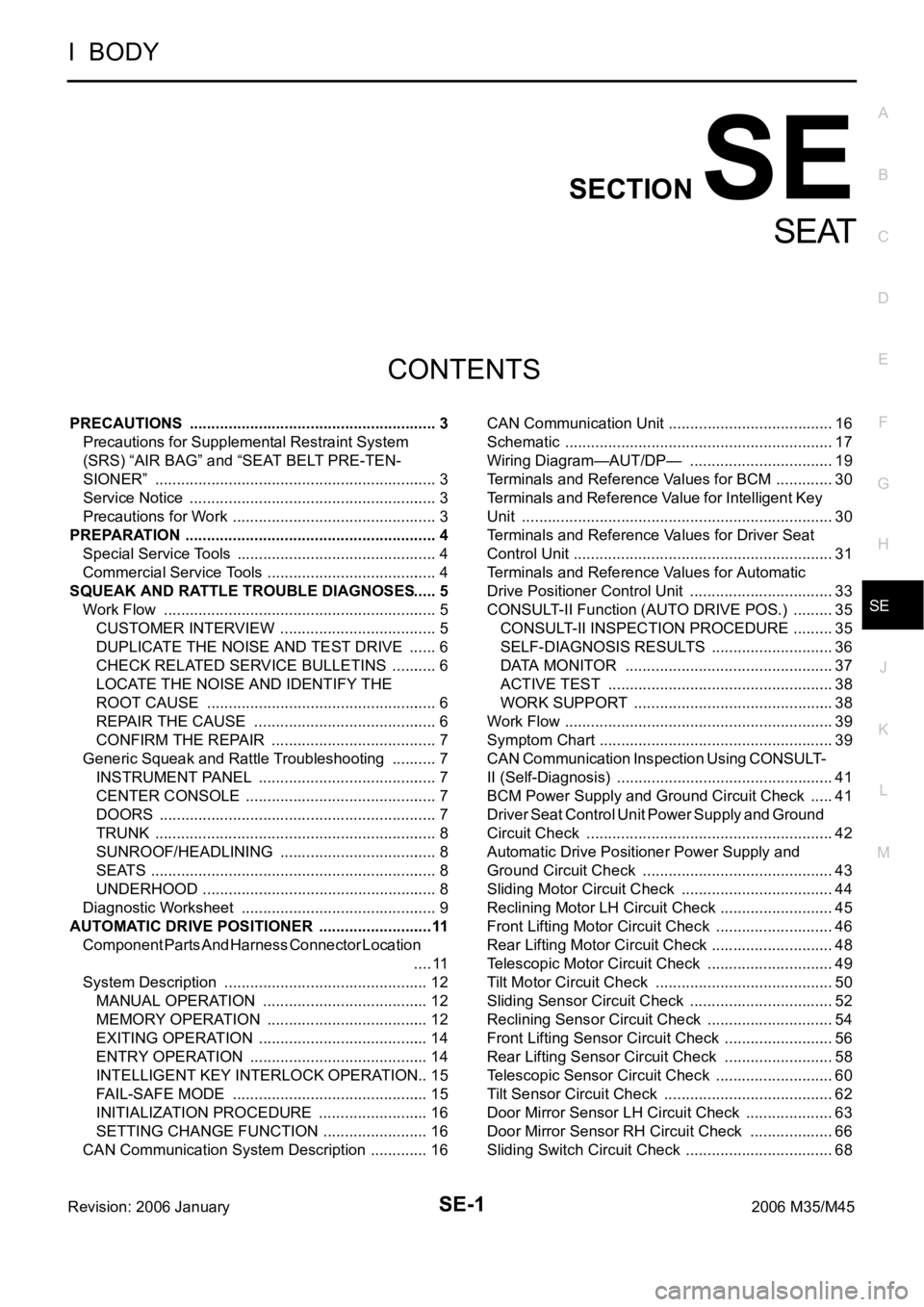

Page 5182 of 5621

SE-1

SEAT

I BODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTION SE

A

B

SE

Revision: 2006 January2006 M35/M45

SEAT

PRECAUTIONS .......................................................... 3

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 3

Service Notice .......................................................... 3

Precautions for Work ...........................................

..... 3

PREPARATION ........................................................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 4

SQUEAK AND RATTLE TROUBLE DIAGNOSES ..... 5

Work Flow ................................................................ 5

CUSTOMER INTERVIEW ..................................... 5

DUPLICATE THE NOISE AND TEST DRIVE ....... 6

CHECK RELATED SERVICE BULLETINS ........... 6

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 6

REPAIR THE CAUSE ........................................... 6

CONFIRM THE REPAIR ....................................... 7

Generic Squeak and Rattle Troubleshooting ........... 7

INSTRUMENT PANEL .......................................... 7

CENTER CONSOLE ............................................. 7

DOORS ................................................................. 7

TRUNK .................................................................. 8

SUNROOF/HEADLINING ..................................... 8

SEATS ................................................................... 8

UNDERHOOD ....................................................... 8

Diagnostic Worksheet .............................................. 9

AUTOMATIC DRIVE POSITIONER ...........................11

Component Parts And Harness Connector Location

.... 11

System Description ................................................ 12

MANUAL OPERATION ....................................... 12

MEMORY OPERATION ...................................... 12

EXITING OPERATION ........................................ 14

ENTRY OPERATION .......................................... 14

INTELLIGENT KEY INTERLOCK OPERATION ... 15

FAIL-SAFE MODE .............................................. 15

INITIALIZATION PROCEDURE .......................... 16

SETTING CHANGE FUNCTION ......................... 16

CAN Communication System Description .............. 16CAN Communication Unit ....................................... 16

Schematic ............................................................... 17

Wiring Diagram—AUT/DP— .................................. 19

Terminals and Reference Values for BCM .............. 30

Terminals and Reference Value for Intelligent Key

Unit ......................................................................... 30

Terminals and Reference Values for Driver Seat

Control Unit ............................................................. 31

Terminals and Reference Values for Automatic

Drive Positioner Control Unit .................................. 33

CONSULT-II Function (AUTO DRIVE POS.) .......... 35

CONSULT-II INSPECTION PROCEDURE .......... 35

SELF-DIAGNOSIS RESULTS ............................. 36

DATA MONITOR ................................................. 37

ACTIVE TEST ..................................................... 38

WORK SUPPORT ............................................... 38

Work Flow ............................................................... 39

Symptom Chart ....................................................... 39

CAN Communication Inspection Using CONSULT-

II (Self-Diagnosis) ................................................... 41

BCM Power Supply and Ground Circuit Check ...... 41

Driver Seat Control Unit Power Supply and Ground

Circuit Check .......................................................... 42

Automatic Drive Positioner Power Supply and

Ground Circuit Check ............................................. 43

Sliding Motor Circuit Check .................................... 44

Reclining Motor LH Circuit Check ........................... 45

Front Lifting Motor Circuit Check ............................ 46

Rear Lifting Motor Circuit Check ............................. 48

Telescopic Motor Circuit Check .............................. 49

Tilt Motor Circuit Check .......................................

... 50

Sliding Sensor Circuit Check .................................. 52

Reclining Sensor Circuit Check .............................. 54

Front Lifting Sensor Circuit Check .......................... 56

Rear Lifting Sensor Circuit Check .......................... 58

Telescopic Sensor Circuit Check ............................ 60

Tilt Sensor Circuit Check ........................................ 62

Door Mirror Sensor LH Circuit Check ..................... 63

Door Mirror Sensor RH Circuit Check .................... 66

Sliding Switch Circuit Check ................................... 68

Page 5183 of 5621

SE-2Revision: 2006 January2006 M35/M45 Reclining Switch Circuit Check ............................... 70

Lifting Switch (Front) Circuit Check ........................ 72

Lifting Switch (Rear) Circuit Check ......................... 74

Power Seat Switch Ground Circuit Check .............. 75

Telescopic Switch Circuit Check ............................. 76

Tilt Switch Circuit Check ......................................

... 78

Seat Memory and Set Switch Circuit Check ........... 80

Seat Memory Indicator Lamp Circuit Check ........... 81

Door Mirror Sensor Power Supply and Ground Cir-

cuit Check ............................................................... 83

A/T Device (Detention Switch) Circuit Check ......... 85

Front Door Switch (Driver Side) Circuit Check ....... 86

UART Communication Line Circuit Check .............. 87

Lumber Support Circuit Check ............................... 89

POWER SEAT(PASSENGER SIDE) ......................... 91

Component Parts and Harness Connector Location ... 91

Wiring Diagram—SEAT—/Passenger Side ............ 92

Terminals and Reference Values for BCM .............. 94

POWER SEAT(REAR) .............................................. 95

Component Parts and Harness Connector Location ... 95

System Description ................................................. 95

REAR POWER SEAT LH AND RH OPERATION ... 95

REAR SEAT RETREAT FUNCTION ................... 96

Schematic ............................................................... 97

Wiring Diagram—R/SEAT— ................................... 98

Terminals and Reference Values for Rear Seat Con-

trol Unit .................................................................102

Work Flow .............................................................103

Trouble Diagnoses Symptom Chart ......................103

Rear Power Seat Power Supply Circuit Inspection .103

Rear Seat Control Unit Power Supply and Ground

Circuit Inspection ..................................................104

Rear Seat Sliding Motor Circuit Inspection ...........105

Rear Power Seat Switch Circuit Inspection ..........106

Automatic Return Cancel Switch Circuit Inspection .108

Automatic Return Cancel Switch Inspection .........109

Rear Door Switch Circuit Inspection .....................110

Rear Seat Sliding Sensor Circuit Inspection ..........111

CLIMATE CONTROLLED SEAT .............................113

Component Parts and Harness Connector Location .113

System Description ...............................................113

Schematic .............................................................117

Wiring Diagram—C/SEAT— .................................118

Terminal and Reference Value for Climate Con-

trolled Seat Control Unit ......................................

.123

Work Flow .............................................................124

Preliminary Check ................................................124

Trouble Diagnoses Symptom Chart .....................

.125

Climate Controlled Seat Control Unit Power Supply

Circuit Check ........................................................126

Climate Controlled Seat Control Unit Power Supply

and Ground Circuit Inspection ..............................127

Climate Controlled Seat Switch Power Supply Cir-cuit Inspection .......................................................130

Climate Controlled Seat Switch Circuit Inspection .131

Climate Controlled Seat Switch Indicator Circuit

Inspection ..............................................................133

Seat Cushion Thermal Electric Device Circuit

Inspection ..............................................................135

Seatback Thermal Electric Device Circuit Inspec-

tion ........................................................................136

Seat Cushion Thermal Electric Device Sensor Cir-

cuit Inspection .......................................................137

Seatback Thermal Electric Device Sensor Circuit

Inspection ..............................................................139

Climate Controlled Seat Blower Motor Circuit

Inspection ..............................................................140

Climate Controlled Seat Control Unit Inspection ...142

HEATED SEAT ........................................................143

Component Parts and Harness Connector Location .143

System Description ...............................................143

Schematic .............................................................145

Wiring Diagram —HSEAT— .................................146

Terminals and Reference Values for Rear Seat Con-

trol Unit ..................................................................151

Work Flow .............................................................151

Trouble Diagnoses Symptom Chart ......................151

Rear Heated Seat Power Supply and Ground Circuit

Inspection ..............................................................152

Rear Seat Control Unit Power Supply and Ground

Circuit Inspection ..................................................153

Rear Heated Seat Switch Circuit Inspection .........155

Rear Heated Seat Indicator Power Supply Circuit

Inspection ..............................................................157

Rear Heated Seat Indicator Circuit Inspection ......158

Rear Heated Seat Circuit Inspection .....................160

Rear Seatback Heater Circuit Inspection ..............161

FRONT SEAT ..........................................................163

Driver's Seat Components ....................................163

Passenger's Seat Components .............................165

Removal and Installation .......................................167

REMOVAL ..........................................................167

INSTALLATION ..................................................167

Disassembly and Assembly ..................................168

SEATBACK ........................................................168

SEAT CUSHION ................................................169

CLIMATE CONTROLLED SEAT ........................171

REAR SEAT .............................................................172

Bench Seat Components ......................................172

Power Seat (Split Type) Components ...................174Removal and Installation .......................................176

BENCH SEAT ....................................................176

POWER SEAT ...................................................176

Disassembly and Assembly ..................................177

BENCH SEAT ....................................................177

POWER SEAT ...................................................179