spark INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 3297 of 5621

![INFINITI M35 2006 Factory Repair Manual EM-234

[VK45DE]

CYLINDER HEAD

Revision: 2006 January2006 M35/M45

If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal INFINITI M35 2006 Factory Repair Manual EM-234

[VK45DE]

CYLINDER HEAD

Revision: 2006 January2006 M35/M45

If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal](/img/42/57023/w960_57023-3296.png)

EM-234

[VK45DE]

CYLINDER HEAD

Revision: 2006 January2006 M35/M45

If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine

speed again with normal battery gravity.

If compression pressure is below minimum value, check valve clearances and parts associated with

combustion chamber (valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head

gasket). After the checking, measure compression pressure again.

If some cylinders have low compression pressure, pour small amount of engine oil into the spark plug

hole of the cylinder to re-check it for compression.

–If the added engine oil improves the compression, piston rings may be worn out or damaged. Check the

piston rings and replace if necessary.

–If the compression pressure remains at low level despite the addition of engine oil, valves may be mal-

functioning. Check valves for damage. Replace valve or valve seat accordingly.

If two adjacent cylinders have respectively low compression pressure and their compression remains

low even after the addition of engine oil, cylinder head gaskets are leaking. In such a case, replace cyl-

inder head gaskets.

8. After inspection is completed, install removed parts in the reverse order of removal.

9. Start engine, and make sure that engine runs smoothly.

10. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-811, "

TROUBLE DIAGNOSIS" .

ComponentsNBS004PG

Removal and InstallationNBS004PH

REMOVAL

1. Remove engine assembly from vehicle. Refer to EM-244, "ENGINE ASSEMBLY" .

2. Remove exhaust manifold. Refer to EM-183, "

EXHAUST MANIFOLD AND THREE WAY CATALYST" .

3. Remove camshaft. Refer to EM-215, "

CAMSHAFT" .

1. Engine coolant temperature sensor 2. Washer 3. Cylinder head gasket (left bank)

4. Harness bracket 5. Cylinder head (right bank) 6. Cylinder head bolt

7. Cylinder head gasket (right bank) 8. Cylinder head bolt 9. Cylinder head (left bank)

PBIC2756E

Page 3300 of 5621

![INFINITI M35 2006 Factory Repair Manual CYLINDER HEAD

EM-237

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Disassembly and AssemblyNBS004PI

COMPONENTS

DISASSEMBLY

1. Remove spark plug with spark plug wrench (commerci INFINITI M35 2006 Factory Repair Manual CYLINDER HEAD

EM-237

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Disassembly and AssemblyNBS004PI

COMPONENTS

DISASSEMBLY

1. Remove spark plug with spark plug wrench (commerci](/img/42/57023/w960_57023-3299.png)

CYLINDER HEAD

EM-237

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Disassembly and AssemblyNBS004PI

COMPONENTS

DISASSEMBLY

1. Remove spark plug with spark plug wrench (commercial service tool).

2. Remove adjusting shim and valve lifter.

Identify installation positions, and store them without mixing them up.

3. Remove valve collet.

Compress valve spring with valve spring compressor, attach-

ment and adapter (SST). Remove valve collet with magnetic

hand.

CAUTION:

When working, take care not to damage valve lifter holes.

4. Remove valve spring retainer and valve spring (with valve spring seat).

CAUTION:

Do not remove valve spring seat from valve spring.

5. Push valve stem to combustion chamber side, and remove valve.

1. Spark plug 2. Adjusting shim 3. Valve lifter

4. Valve collet 5. Valve spring retainer 6. Valve spring (with valve spring seat)

7. Valve oil seal 8. Valve guide 9. Valve seat

10. Valve (INT) 11. Valve (EXH) 12. Cylinder head (left bank)

13. Spark plug tube 14. Cylinder head (right bank)

PBIC2757E

PBIC2360E

Page 3301 of 5621

![INFINITI M35 2006 Factory Repair Manual EM-238

[VK45DE]

CYLINDER HEAD

Revision: 2006 January2006 M35/M45

Identify installation positions, and store them without mixing them up.

6. Remove valve oil seal with valve oil seal puller (SST).

7. I INFINITI M35 2006 Factory Repair Manual EM-238

[VK45DE]

CYLINDER HEAD

Revision: 2006 January2006 M35/M45

Identify installation positions, and store them without mixing them up.

6. Remove valve oil seal with valve oil seal puller (SST).

7. I](/img/42/57023/w960_57023-3300.png)

EM-238

[VK45DE]

CYLINDER HEAD

Revision: 2006 January2006 M35/M45

Identify installation positions, and store them without mixing them up.

6. Remove valve oil seal with valve oil seal puller (SST).

7. If valve seat must be replaced, refer to EM-242, "

VALVE SEAT REPLACEMENT" .

8. If valve guide must be replaced, refer to EM-240, "

VALVE GUIDE REPLACEMENT" .

9. Remove spark plug tube, as necessary.

Using pair of pliers, pull spark plug tube out of cylinder head.

CAUTION:

Take care not to damage cylinder head.

Once removed, spark plug tube will be deformed and cannot be reused. Do not remove it unless

absolutely necessary.

ASSEMBLY

1. When valve guide is removed, install it. Refer to EM-240, "VALVE GUIDE REPLACEMENT" .

2. When valve seat is removed, install it. Refer to EM-242, "

VALVE SEAT REPLACEMENT" .

3. Install new valve oil seal as follows:

a. Apply new engine oil on valve oil seal joint and seal lip.

b. Install with valve oil seal drift (SST) to match dimension in the

figure.

4. Install valve.

Install in the original position.

NOTE:

Larger diameter valves are for intake side.

5. Install valve spring (with valve spring seat).

Install smaller pitch (valve spring seat side) to cylinder head

side.

6. Install valve spring retainer.

PBIC0072E

PBIC0073E

PBIC0074E

Page 3302 of 5621

![INFINITI M35 2006 Factory Repair Manual CYLINDER HEAD

EM-239

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

7. Install valve collet.

Compress valve spring with valve spring compressor, attach-

ment and adapter INFINITI M35 2006 Factory Repair Manual CYLINDER HEAD

EM-239

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

7. Install valve collet.

Compress valve spring with valve spring compressor, attach-

ment and adapter](/img/42/57023/w960_57023-3301.png)

CYLINDER HEAD

EM-239

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

7. Install valve collet.

Compress valve spring with valve spring compressor, attach-

ment and adapter (SST). Install valve collet with magnetic

hand.

CAUTION:

When working, take care not to damage valve lifter holes.

Tap stem edge lightly with plastic hammer after installation to

check its installed condition.

8. Install valve lifter and adjusting shim.

Install it in the original position.

9. Install spark plug tube.

Press-fit spark plug tube as follows:

a. Remove old liquid gasket adhering to cylinder-head mounting hole.

b. Apply sealant to area within approximately 12 mm (0.47 in) from edge of spark plug tube press-fit side.

Use Genuine High Strength Locking Sealant or equivalent. Refer to GI-48, "

RECOMMENDED

CHEMICAL PRODUCTS AND SEALANTS" .

c. Using drift, press-fit spark plug tube so that its height “H” is as

specified in the figure.

CAUTION:

When press-fitting, take care not to deform spark plug

tube.

After press-fitting, wipe off liquid gasket protruding onto

cylinder head upper face.

10. Install spark plug with spark plug wrench (commercial service tool).

Inspection after DisassemblyNBS004PJ

VALVE DIMENSIONS

Check the dimensions of each valve. For the dimensions, refer

to EM-280, "

Valve Dimensions" .

If the dimensions are out of the standard, replace valve and

check the valve seat contact. Refer to EM-242, "

VA LV E S E AT

CONTACT" .

PBIC2360E

Standard press-fit height “H” :

: 38.4 - 39.4 mm (1.512 - 1.551 in)

PBIC2638E

SEM188A

Page 3340 of 5621

![INFINITI M35 2006 Factory Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

EM-277

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

SPARK PLUG

Unit: mm (in)

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

*: Total indicat INFINITI M35 2006 Factory Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

EM-277

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

SPARK PLUG

Unit: mm (in)

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

*: Total indicat](/img/42/57023/w960_57023-3339.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-277

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

SPARK PLUG

Unit: mm (in)

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

*: Total indicator reading

Va l v e L i f t e r

Unit: mm (in)

Valve Clearance

Unit: mm (in)

*: Approximately 80

C (176F) MakeNGK

Standard typePLFR5A-11

Hot typePLFR4A-11

Cold typePLFR6A-11

Gap (Nominal)1.1 (0.043)

ItemsStandard Limit

Camshaft journal clearanceNo. 1 0.045 - 0.083 (0.0018 - 0.0033) —

No. 2, 3, 4, 5 0.030 - 0.068 (0.0012 - 0.0027) —

Camshaft journal diameterNo. 1 25.938 - 25.955 (1.0212 - 1.0218) —

No. 2, 3, 4, 5 25.953 - 25.970 (1.0218 - 1.0224) —

Camshaft bracket inner diameter 26.000 - 26.021 (1.0236 - 1.0244)—

Camshaft end play 0.115 - 0.188 (0.0045 - 0.0074) —

Cam height “A”Intake 44.865 - 45.055 (1.7663 - 1.7738) 0.2 (0.008)

Exhaust 43.925 - 44.115 (1.7293 - 1.7368) 0.2 (0.008)

Camshaft runout [TIR*] 0.02 (0.001) 0.05 (0.002)

Camshaft sprocket runout [TIR*] — 0.15 (0.059)

SEM671

ItemsStandard

Valve lifter outer diameter 33.965 - 33.975 (1.3372 - 1.3776)

Valve lifter hole diameter 34.000 - 34.016 (1.3386 - 1.3392)

Valve lifter clearance 0.025 - 0.051 (0.0010 - 0.0020)

Items Cold Hot* (reference data)

Intake 0.26 - 0.34 (0.010 - 0.013) 0.304 -0.416 (0.012 - 0.016)

Exhaust 0.29 - 0.37 (0.011 - 0.015) 0.308 - 0.432 (0.012 - 0.017)

Page 3416 of 5621

FUEL SYSTEM

FL-3

C

D

E

F

G

H

I

J

K

L

MA

FL

Revision: 2006 January2006 M35/M45

FUEL SYSTEMPFP:17503

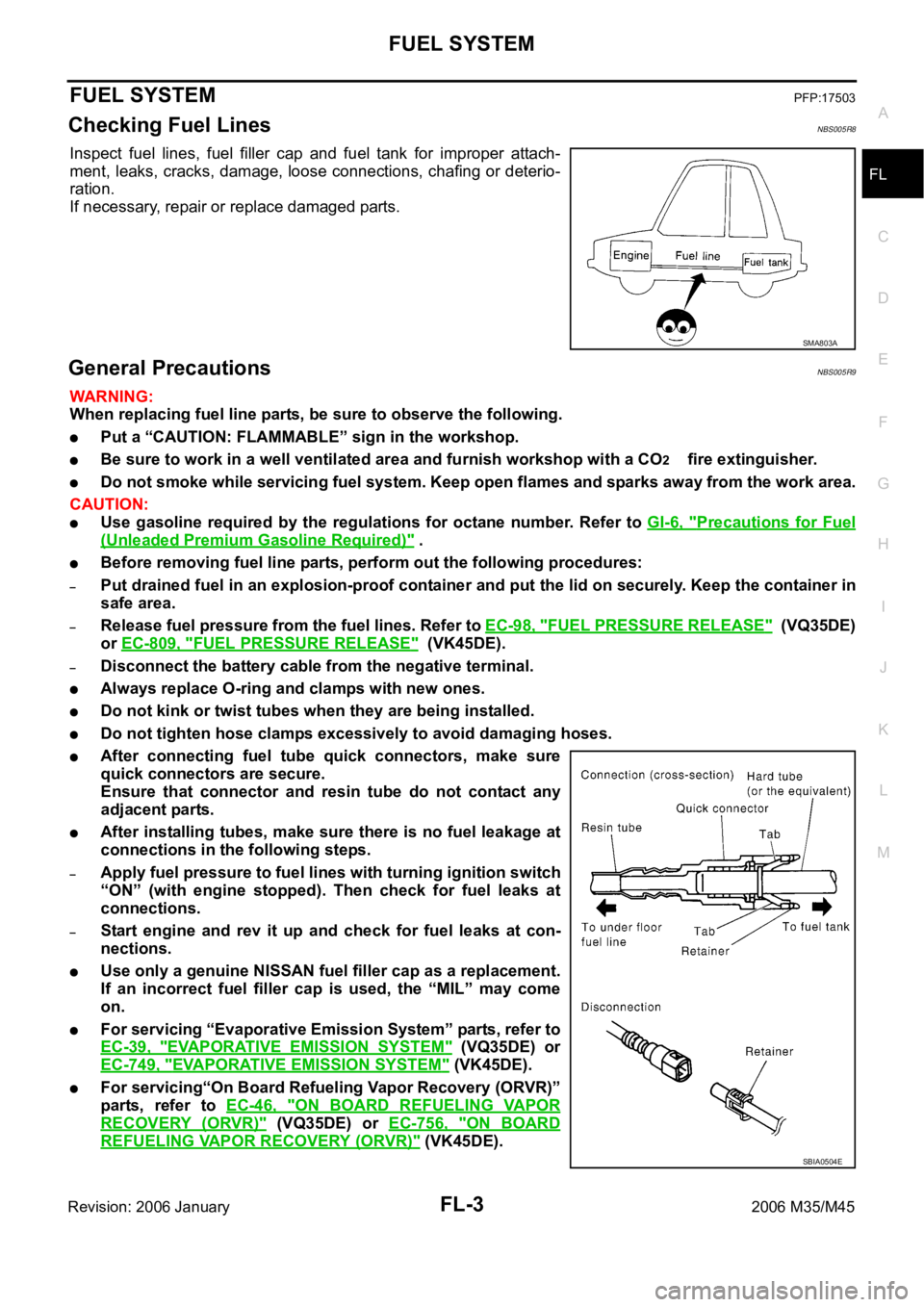

Checking Fuel LinesNBS005R8

Inspect fuel lines, fuel filler cap and fuel tank for improper attach-

ment, leaks, cracks, damage, loose connections, chafing or deterio-

ration.

If necessary, repair or replace damaged parts.

General PrecautionsNBS005R9

WAR NING :

When replacing fuel line parts, be sure to observe the following.

Put a “CAUTION: FLAMMABLE” sign in the workshop.

Be sure to work in a well ventilated area and furnish workshop with a CO2 fire extinguisher.

Do not smoke while servicing fuel system. Keep open flames and sparks away from the work area.

CAUTION:

Use gasoline required by the regulations for octane number. Refer to GI-6, "Precautions for Fuel

(Unleaded Premium Gasoline Required)" .

Before removing fuel line parts, perform out the following procedures:

–Put drained fuel in an explosion-proof container and put the lid on securely. Keep the container in

safe area.

–Release fuel pressure from the fuel lines. Refer to EC-98, "FUEL PRESSURE RELEASE" (VQ35DE)

or EC-809, "

FUEL PRESSURE RELEASE" (VK45DE).

–Disconnect the battery cable from the negative terminal.

Always replace O-ring and clamps with new ones.

Do not kink or twist tubes when they are being installed.

Do not tighten hose clamps excessively to avoid damaging hoses.

After connecting fuel tube quick connectors, make sure

quick connectors are secure.

Ensure that connector and resin tube do not contact any

adjacent parts.

After installing tubes, make sure there is no fuel leakage at

connections in the following steps.

–Apply fuel pressure to fuel lines with turning ignition switch

“ON” (with engine stopped). Then check for fuel leaks at

connections.

–Start engine and rev it up and check for fuel leaks at con-

nections.

Use only a genuine NISSAN fuel filler cap as a replacement.

If an incorrect fuel filler cap is used, the “MIL” may come

on.

For servicing “Evaporative Emission System” parts, refer to

EC-39, "

EVAPORATIVE EMISSION SYSTEM" (VQ35DE) or

EC-749, "

EVAPORATIVE EMISSION SYSTEM" (VK45DE).

For servicing“On Board Refueling Vapor Recovery (ORVR)”

parts, refer to EC-46, "

ON BOARD REFUELING VAPOR

RECOVERY (ORVR)" (VQ35DE) or EC-756, "ON BOARD

REFUELING VAPOR RECOVERY (ORVR)" (VK45DE).

SMA803A

SBIA0504E

Page 3469 of 5621

GI-6

PRECAUTIONS

Revision: 2006 January2006 M35/M45

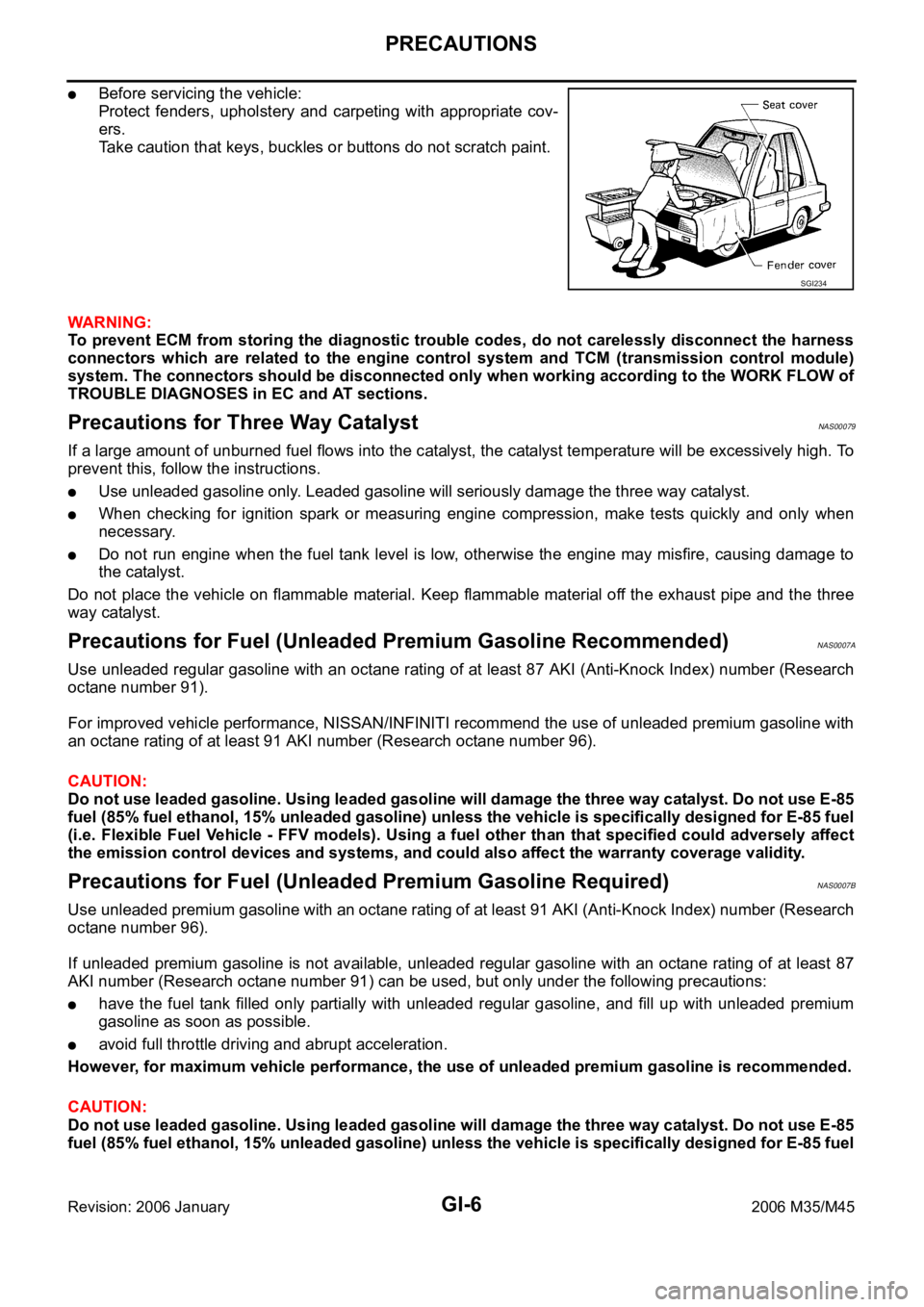

Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

WAR NING :

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for Three Way CatalystNAS00079

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

Use unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

When checking for ignition spark or measuring engine compression, make tests quickly and only when

necessary.

Do not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to

the catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precautions for Fuel (Unleaded Premium Gasoline Recommended)NAS0007A

Use unleaded regular gasoline with an octane rating of at least 87 AKI (Anti-Knock Index) number (Research

octane number 91).

For improved vehicle performance, NISSAN/INFINITI recommend the use of unleaded premium gasoline with

an octane rating of at least 91 AKI number (Research octane number 96).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unleaded gasoline) unless the vehicle is specifically designed for E-85 fuel

(i.e. Flexible Fuel Vehicle - FFV models). Using a fuel other than that specified could adversely affect

the emission control devices and systems, and could also affect the warranty coverage validity.

Precautions for Fuel (Unleaded Premium Gasoline Required)NAS0007B

Use unleaded premium gasoline with an octane rating of at least 91 AKI (Anti-Knock Index) number (Research

octane number 96).

If unleaded premium gasoline is not available, unleaded regular gasoline with an octane rating of at least 87

AKI number (Research octane number 91) can be used, but only under the following precautions:

have the fuel tank filled only partially with unleaded regular gasoline, and fill up with unleaded premium

gasoline as soon as possible.

avoid full throttle driving and abrupt acceleration.

However, for maximum vehicle performance, the use of unleaded premium gasoline is recommended.

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will damage the three way catalyst. Do not use E-85

fuel (85% fuel ethanol, 15% unleaded gasoline) unless the vehicle is specifically designed for E-85 fuel

SGI234

Page 3648 of 5621

IDX-7

A

C

D

E

F

G

H

I

J

K

L B

IDX

ALPHABETICAL INDEX

LT-266

Rear disc brake ................................................. BR-29

Rear door ............................................ BL-190, GW-67

Rear parcel shelf finisher ..................................... EI-42

Rear seat ......................................................... SE-172

Rear seat belt .................................................... SB-32

Rear suspension ............................................... RSU-5

Rear window ..................................................... GW-61

Rear window defogger ...................................... GW-73

Refrigerant connection precaution ..................... ATC-7

Refrigerant discharging evacuating charging ATC-151

Refrigerant general precaution .......................... ATC-7

Refrigerant lines ............................................ ATC-151

Refrigerant pressure sensor ........... EC-692, EC-1434,

ATC-98

, ATC-167

Refrigeration cycle ........................................... ATC-20

Removal and installation (A/T) ........... AT-271, AT-275

Removal and installation (Transfer) .................... TF-44

Reverse interlock door mirror ........................... GW-96

Revolution sensor (A/T) ...................... AT-119, AT-261

Rocker cover(VK45DE) ................................... EM-199

Rocker cover(VQ35DE) ..................................... EM-51

Room lamp - See Interior lamp ......................... LT-267

ROOM/L - Wiring diagram ................................ LT-274

RP/SEN - Wiring diagram ................ EC-693, EC-1435

S

SAE J1979 - Service $01 - 09 ............. EC-54

, EC-764

SEAT - Wiring diagram ...................................... SE-98

Seat belt inspection ........................................... SB-33

Seat belt, front ................................................... SB-30

Seat belt, rear .................................................... SB-32

Seat, rear ......................................................... SE-172

Self-diagnosis (Transfer) .................................... TF-22

SEN/PW - Wiring diagram ............... EC-500, EC-1219

SHIFT - Wiring diagram ................................... AT-230

Shift lock system .............................................. AT-229

Shock absorber (rear) ..................................... RSU-10

Side air bag (satellite) sensor .......................... SRS-46

Side curtain air bag .......................................... SRS-43

Side trim .............................................................. EI-37

SMJ (super multiple junction) .......................... PG-106

Spark plug replacement ..................................... MA-27

Spark plug replacement(VQ35DE) .................... MA-20

Spark plug(VK45DE) ....................................... EM-191

Spark plug(VQ35DE) ......................................... EM-43

Specification value ............................. EC-155, EC-868

Speedometer ........................................................ DI-5

Spiral cable ...................................................... SRS-40

SROOF - Wiring diagram .................................. RF-13

SRS - See Supplemental Restraint System ...... SRS-5

SRS - Wiring diagram ...................................... SRS-12

SRS Trouble diagnoses ..................................... SRS-8

Stabilizer bar (rear) ......................................... RSU-17

Stall test (A/T) .................................................... AT-53

Standardized relay ........................................... PG-109

START - Wiring diagram ................................... SC-11

Starter ................................................................ SC-10

Starting system .................................................. SC-10

Steering gear and linkage inspection ................ MA-36

Steering linkage ................................................. PS-18

Steering wheel and column ................... PS-10, PS-13

Steering wheel turning force .............................. PS-10

Stop lamp .......................................................... LT-243

Stop lamp switch .............................. EC-598, EC-1329

STSIG - Wiring diagram ................................... AT-109

Sun roof, electric ................................................ RF-10

Sunload sensor ............................. ATC-119, ATC-128

Sunroof .................................................. RF-25, RF-28

Sunshade ............................................................ EI-44

Supplemental Restraint System ....................... SRS-5

Supplemental restraint system - Wiring diagram ..........

SRS-12

Suspension ....................................................... MA-37

Symbols and abbreviations ...................... GI-11, GI-24

System readiness test (SRT) code ...... EC-60, EC-770

T

Tachometer ........................................................... DI-5

Tail lamp ........................................................... LT-249

TCM circuit diagram ........................................... AT-52

TCM inspection table ......................................... AT-89

Thermostat(VK45DE) ....................................... CO-55

Thermostat(VQ35DE) ....................................... CO-29

Three way catalyst function (Bank 1) EC-392, EC-1113

Three way catalyst function (Bank 2) EC-392, EC-1113

Three way catalyst precautions ............................ GI-6

Three way catalyst(VK45DE) .......................... EM-183

Throttle control motor ....................... EC-619, EC-1351

Throttle control motor relay .............. EC-607, EC-1338

Throttle position sensor (TPS) .......... EC-231, EC-354,

EC-533

, EC-535, EC-640, EC-954, EC-1077, EC-1259,

EC-1261

, EC-1372

Throttle valve closed position learning . EC-95, EC-806

Tie-rod ............................................................... PS-18

Timing chain(VK45DE) ................................... EM-203

Timing chain(VQ35DE) ..................................... EM-64

Tire rotation ....................................................... MA-35

TLID - Wiring diagram ...................................... BL-211

Top tether strap child restraint ........................... SB-37

Torque converter installation ............. AT-274, AT-277

Torque convertor clutch solenoid valve AT-126, AT-128

TPS1 - Wiring diagram .................... EC-356, EC-1079

TPS2 - Wiring diagram ...................... EC-233, EC-956

TPS3 - Wiring diagram .................... EC-642, EC-1374

Transfer control unit inspection table ................. TF-20

TRNSCV - Wiring diagram ............................... BL-281

Trouble diagnoses .............................................. GI-12

Trunk lid ........................................................... BL-203

Trunk lid opener - See Trunk lid ...................... BL-209

TURN - Wiring diagram .................................... LT-215

Turn signal lamp ............................................... LT-211

Two trip detection logic ........................ EC-54, EC-764

Tyre pressure monitoring system - trouble diagnoses ..

WT-13

Page 4778 of 5621

MA-1

MAINTENANCE

L MAINTENANCE

CONTENTS

C

D

E

F

G

H

I

J

K

M

SECTION MA

A

B

MA

Revision: 2006 January2006 M35/M45

MAINTENANCE

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 3

GENERAL MAINTENANCE ....................................... 4

Explanation of General Maintenance ....................... 4

PERIODIC MAINTENANCE ....................................... 7

Introduction of Periodic Maintenance ....................... 7

Schedule 1 ............................................................... 8

EMISSION CONTROL SYSTEM MAINTE-

NANCE .................................................................. 8

CHASSIS AND BODY MAINTENANCE ............... 9

Schedule 2 ............................................................. 10

EMISSION CONTROL SYSTEM MAINTE-

NANCE ................................................................ 10

CHASSIS AND BODY MAINTENANCE .............. 11

RECOMMENDED FLUIDS AND LUBRICANTS ...... 12

Fluids and Lubricants ............................................. 12

SAE Viscosity Number ........................................... 13

GASOLINE ENGINE OIL .................................... 13

Anti-Freeze Coolant Mixture Ratio ......................... 13

ENGINE MAINTENANCE (VQ35DE ENGINE) ......... 14

Checking Drive Belts .............................................. 14

Drive Belts Tension Adjustment ............................. 14

ALTERNATOR AND POWER STEERING OIL

PUMP BELT ........................................................ 15

A/C COMPRESSOR BELT ................................. 15

Changing Engine Coolant ...................................... 15

DRAINING ENGINE COOLANT ......................... 15

REFILLING ENGINE COOLANT ........................ 16

FLUSHING COOLING SYSTEM ......................... 17

Checking Fuel Lines ............................................ ... 18

Changing Air Cleaner Filter .................................... 18

VISCOUS PAPER TYPE ..................................... 18

Changing Engine Oil .............................................. 18

Changing Oil Filter ................................................. 19

REMOVAL ........................................................

... 19

INSTALLATION ................................................... 19

INSPECTION AFTER INSTALLATION ............... 20

Changing Spark Plugs (Platinum-Tipped Type) ..... 20

REMOVAL ........................................................

... 20INSPECTION AFTER REMOVAL ....................... 21

INSTALLATION ................................................... 21

Checking EVAP Vapor Lines .................................. 21

ENGINE MAINTENANCE (VK45DE ENGINE) ......... 22

Checking Drive Belts .............................................. 22

Tension Adjustment .............................................

... 22

Changing Engine Coolant ....................................... 22

DRAINING ENGINE COOLANT .......................... 22

REFILLING ENGINE COOLANT ......................... 23

FLUSHING COOLING SYSTEM ......................... 24

Checking Fuel Lines ............................................ ... 25

Changing Air Cleaner Filter .................................... 25

VISCOUS PAPER TYPE ..................................... 25

Changing Engine Oil ............................................

... 25

Changing Oil Filter .................................................. 26

REMOVAL ........................................................

... 26

INSTALLATION ................................................... 26

INSPECTION AFTER INSTALLATION ................ 27

Changing Spark Plugs (Platinum-Tipped Type) ...... 27

REMOVAL ........................................................

... 27

INSPECTION AFTER REMOVAL ....................... 27

INSTALLATION ................................................... 28

Checking EVAP Vapor Lines .................................. 28

CHASSIS AND BODY MAINTENANCE ................... 29

Checking Exhaust System ...................................... 29

Checking A/T Fluid ................................................. 29

Changing A/T Fluid ................................................. 31

Checking Transfer Fluid ......................................... 31

Changing Transfer Fluid ......................................... 32

Checking Propeller Shaft ........................................ 32

Checking Differential Gear Oil ................................ 32

Changing Differential Gear Oil ................................ 33

Balancing Wheels (Bonding Weight Type) ............. 33

REMOVAL ........................................................

... 33

WHEEL BALANCE ADJUSTMENT ..................... 33

Tire Rotation ........................................................... 35

Checking Brake Fluid Level and Leaks .................. 35

Checking Brake Lines and Cables ......................... 35

Changing Brake Fluid ............................................. 35

Checking Disc Brake .............................................. 36

Page 4779 of 5621

MA-2Revision: 2006 January2006 M35/M45 ROTOR ................................................................ 36

CALIPER ............................................................. 36

PAD ..................................................................... 36

Checking Steering Gear and Linkage ..................... 36

STEERING GEAR ............................................... 36

STEERING LINKAGE .......................................... 36

Checking Power Steering Fluid and Lines .............. 37

Axle and Suspension Parts ..................................... 37

Drive Shaft .............................................................. 38

Lubricating Locks, Hinges and Hood Latch ............ 38

Checking Seat Belt, Buckles, Retractors, Anchors

and Adjusters .......................................................... 39

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 40

Standard and Limit .................................................. 40

BELT DEFLECTION AND TENSION (VQ35DE) ... 40

BELT DEFLECTION AND TENSION (VK45DE) ... 40

ENGINE COOLANT CAPACITY (APPROXI-MATE) (VQ35DE) ................................................ 40

ENGINE COOLANT CAPACITY (APPROXI-

MATE) (VK45DE) ................................................. 40

RADIATOR ........................................................... 40

ENGINE OIL CAPACITY (APPROXIMATE)

(VQ35DE) ............................................................ 40

ENGINE OIL CAPACITY (APPROXIMATE)

(VK45DE) ............................................................. 41

SPARK PLUG (PLATINUM-TIPPED TYPE)

(VQ35DE) ............................................................ 41

SPARK PLUG (PLATINUM-TIPPED TYPE)

(VK45DE) ............................................................. 41

WHEEL BALANCE .............................................. 41