steering wheel INFINITI M35 2006 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 2753 of 5621

![INFINITI M35 2006 Factory Repair Manual EC-1210

[VK45DE]

DTC P0550 PSP SENSOR

Revision: 2006 January2006 M35/M45

6. CHECK PSP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 12 and PSP sensor INFINITI M35 2006 Factory Repair Manual EC-1210

[VK45DE]

DTC P0550 PSP SENSOR

Revision: 2006 January2006 M35/M45

6. CHECK PSP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 12 and PSP sensor](/img/42/57023/w960_57023-2752.png)

EC-1210

[VK45DE]

DTC P0550 PSP SENSOR

Revision: 2006 January2006 M35/M45

6. CHECK PSP SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between ECM terminal 12 and PSP sensor terminal 2.

2. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 8.

NG >> GO TO 7.

7. DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E206, E72

Harness connectors E11, F2

Harness for open or short between power steering pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

8. CHECK PSP SENSOR

Refer to EC-1210, "

Component Inspection" .

OK or NG

OK >> GO TO 9.

NG >> Replace PSP sensor.

9. CHECK INTERMITTENT INCIDENT

Refer to EC-878, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

>>INSPECTION END

Component InspectionNBS005JN

POWER STEERING PRESSURE SENSOR

1. Reconnect all harness connectors disconnected.

2. Start engine and let it idle.

3. Check voltage between ECM terminal 12 and ground under the

following conditions.

Removal and InstallationNBS005JO

POWER STEERING PRESSURE SENSOR

Refer to PS-38, "HYDRAULIC LINE" . Continuity should exist.

Condition Voltage

Steering wheel is being turned. 0.5 - 4.5V

Steering wheel is not being turned. 0.4 - 0.8V

MBIB0126E

Page 2844 of 5621

![INFINITI M35 2006 Factory Repair Manual DTC P1568 ICC FUNCTION

EC-1301

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P1568 ICC FUNCTIONPFP:18995

On Board Diagnosis LogicNBS005ML

This self-diagnosis has the one tr INFINITI M35 2006 Factory Repair Manual DTC P1568 ICC FUNCTION

EC-1301

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P1568 ICC FUNCTIONPFP:18995

On Board Diagnosis LogicNBS005ML

This self-diagnosis has the one tr](/img/42/57023/w960_57023-2843.png)

DTC P1568 ICC FUNCTION

EC-1301

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

DTC P1568 ICC FUNCTIONPFP:18995

On Board Diagnosis LogicNBS005ML

This self-diagnosis has the one trip detection logic.

The MIL will not light up for this diagnosis.

NOTE:

If DTC P1568 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC

U1000, U1001. Refer to EC-886, "

DTC U1000, U1001 CAN COMMUNICATION LINE" .

If DTC P1568 is displayed with DTC U1010, first perform the trouble diagnosis for DTC U1010.

Refer to EC-889, "

DTC U1010 CAN COMMUNICATION" .

If DTC P1568 is displayed with DTC P0605, first perform the trouble diagnosis for DTC P0605.

Refer to EC-1215, "

DTC P0605 ECM"

DTC Confirmation ProcedureNBS005MM

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Step 4 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a road test

is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-II

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-II.

3. Press MAIN switch on ICC steering switch.

4. Drive the vehicle at more than 40 km/h (25 MPH).

5. Press SET/COAST switch.

6. If DTC is detected, go to EC-1301, "

Diagnostic Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-II” above.

Diagnostic ProcedureNBS005MN

1. REPLACE ICC UNIT

1. Replace ICC unit.

2. Perform ACS-10, "

ACTION TEST" .

3. Check DTC of ICC unit. Refer to ACS-39, "

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS" .

>>INSPECTION END

DTC No.Trouble Diagnosis

NameDTC Detecting Condition Possible Cause

P1568

1568ICC functionECM detects a difference between signals

from ICC unit is out of specified range.

Harness or connectors

(The CAN communication line is open or

shorted.)

ICC unit

ECM

SEF058Y

Page 3004 of 5621

![INFINITI M35 2006 Factory Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

EC-1461

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Fuel PressureNBS005QT

Idle Speed and INFINITI M35 2006 Factory Repair Manual SERVICE DATA AND SPECIFICATIONS (SDS)

EC-1461

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Fuel PressureNBS005QT

Idle Speed and](/img/42/57023/w960_57023-3003.png)

SERVICE DATA AND SPECIFICATIONS (SDS)

EC-1461

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EC

Revision: 2006 January2006 M35/M45

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Fuel PressureNBS005QT

Idle Speed and Ignition TimingNBS005QU

*: Under the following conditions:

Air conditioner switch: OFF

Electric load: OFF (Lights, heater fan & rear window defogger)

Steering wheel: Kept in straight-ahead position

Calculated Load ValueNBS005QV

Mass Air Flow SensorNBS005QW

*: Engine is warmed up to normal operating temperature and running under no load.

Intake Air Temperature SensorNBS005QX

Engine Coolant Temperature SensorNBS005QY

Fuel Tank Temperature SensorNBS005QZ

Crankshaft Position Sensor (POS)NBS005R0

Refer to EC-1105, "Component Inspection" .

Camshaft Position Sensor (PHASE)NBS005R1

Refer to EC-1112, "Component Inspection" .

A/F Sensor 1 HeaterNBS005R2

Fuel pressure at idling kPa (kg/cm2 , psi)Approximately 350 (3.57, 51)

Target idle speed No load* (in P or N position) 65050 rpm

Air conditioner: ON In P or N position 650 rpm or more

Ignition timing In P or N position 12

5 BTDC

Condition Calculated load value% (Using CONSULT-II or GST)

At idle14 - 33

At 2,500 rpm12 - 25

Supply voltageBattery voltage (11 - 14V)

Output voltage at idle0.9 - 1.2V*

Mass air flow (Using CONSULT-II or GST)2.0 - 6.0 gꞏm/sec at idle*

7.0 - 20.0 gꞏm/sec at 2,500 rpm*

Temperature C (F) Resistance k

25 (77)1.800 - 2.200

Temperature C (F) Resistance k

20 (68)2.1 - 2.9

50 (122)0.68 - 1.00

90 (194)0.236 - 0.260

Temperature C (F) Resistance k

20 (68)2.3 - 2.7

50 (122)0.79 - 0.90

Resistance [at 25C (77F)] 2.3 - 4.3

Page 3064 of 5621

EM-1

ENGINE MECHANICAL

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION EM

A

EM

Revision: 2006 January2006 M35/M45

ENGINE MECHANICAL

VQ35DE

PRECAUTIONS .......................................................... 5

Precautions for Procedures without Cowl Top Cover ..... 5

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect .......................................... 5

OPERATION PROCEDURE ................................. 5

Precautions for Drain Engine Coolant and Engine

Oil ............................................................................. 5

Precautions for Disconnecting Fuel Piping .............. 5

Precautions for Removal and Disassembly ............. 5

Precautions for Inspection, Repair and Replace-

ment ......................................................................... 6

Precautions for Assembly and Installation ............... 6

Precautions for Angle Tightening ............................. 6

Precautions for Liquid Gasket .................................. 6

REMOVAL OF LIQUID GASKET SEALING .......... 6

LIQUID GASKET APPLICATION PROCEDURE ..... 7

PREPARATION ........................................................... 8

Special Service Tools ............................................... 8

Commercial Service Tools ...................................... 10

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .............................................. 12

NVH Troubleshooting — Engine Noise .................. 12

Use the Chart Below to Help You Find the Cause

of the Symptom. ..................................................... 13

ENGINE ROOM COVER .......................................... 14

Components ........................................................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................

... 14

INSTALLATION ................................................... 14

DRIVE BELTS ........................................................... 15

Checking Drive Belts .............................................. 15

Tension Adjustment ................................................ 15

ALTERNATOR AND POWER STEERING OIL

PUMP BELT ........................................................ 16

A/C COMPRESSOR BELT ................................. 16

Removal and Installation ........................................ 16

REMOVAL ........................................................

... 16

INSTALLATION ................................................... 16AIR CLEANER AND AIR DUCT ............................... 17

Components ........................................................... 17

Removal and Installation ........................................ 17

REMOVAL ........................................................

... 17

INSTALLATION ................................................... 17

Changing Air Cleaner Filter .................................... 18

REMOVAL ........................................................

... 18

INSTALLATION ................................................... 18

INTAKE MANIFOLD COLLECTOR .......................... 19

Components ........................................................... 19

Removal and Installation ........................................ 19

REMOVAL ........................................................

... 19

INSPECTION AFTER REMOVAL ....................... 21

INSTALLATION ................................................... 22

INTAKE MANIFOLD ................................................. 24

Components ........................................................... 24

Removal and Installation ........................................ 24

REMOVAL ........................................................

... 24

INSPECTION AFTER REMOVAL ....................... 25

INSTALLATION ................................................... 25

EXHAUST MANIFOLD ............................................. 26

Components ........................................................... 26

Removal and Installation ........................................ 26

REMOVAL ........................................................

... 26

INSPECTION AFTER REMOVAL ....................... 27

INSTALLATION ................................................... 27

OIL PAN AND OIL STRAINER ................................. 29

Components (2WD Models) ................................... 29

Removal and Installation (2WD Models) ................ 29

REMOVAL ........................................................

... 29

INSPECTION AFTER REMOVAL ....................... 31

INSTALLATION ................................................... 31

INSPECTION AFTER INSTALLATION ................ 34

Components (AWD Models) ................................... 35

Removal and Installation (AWD Models) ................ 36

REMOVAL ........................................................

... 36

INSPECTION AFTER REMOVAL ....................... 38

INSTALLATION ................................................... 38

INSPECTION AFTER INSTALLATION ................ 41

Page 3066 of 5621

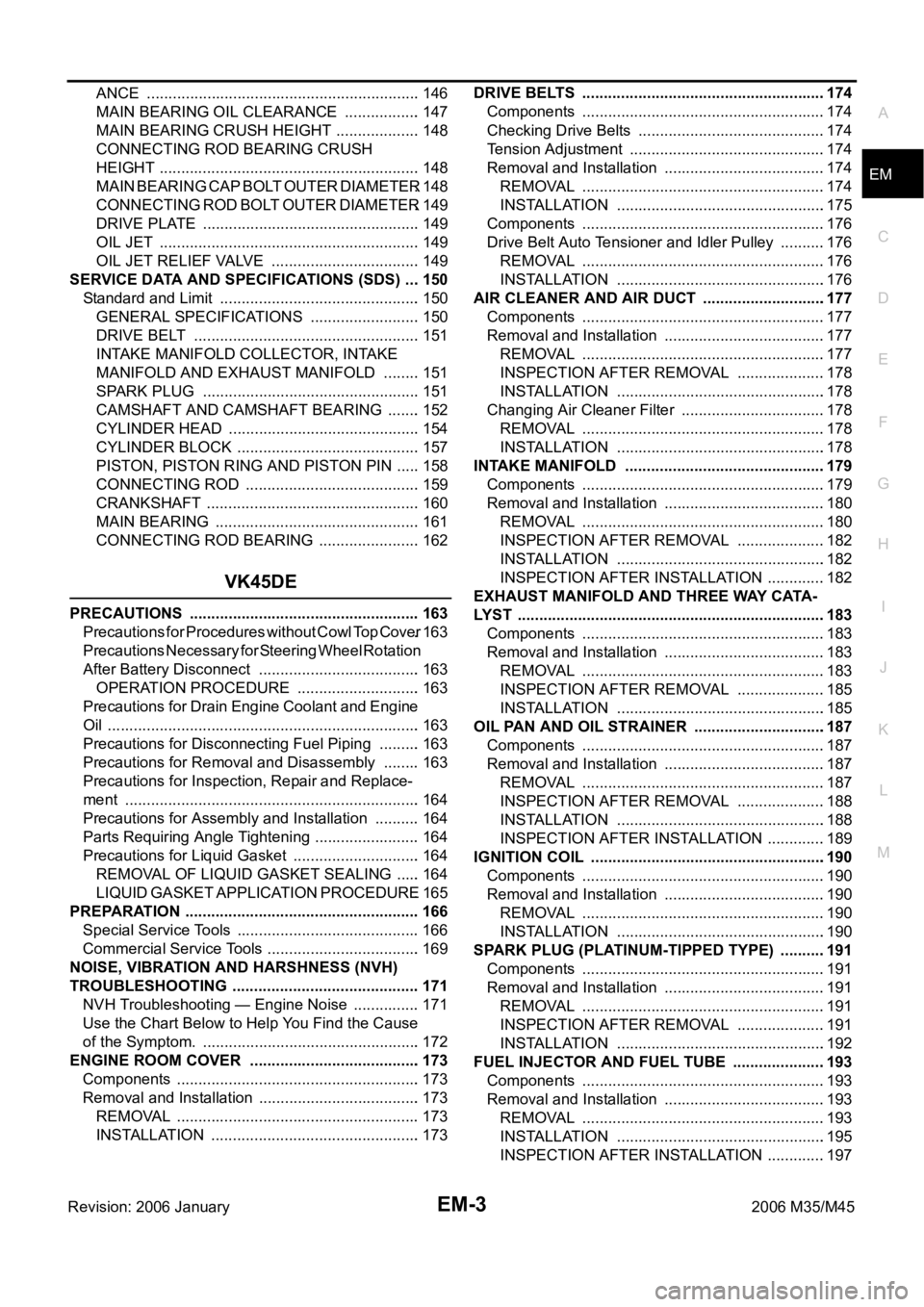

EM-3

C

D

E

F

G

H

I

J

K

L

M

EMA

Revision: 2006 January2006 M35/M45 ANCE ................................................................146

MAIN BEARING OIL CLEARANCE ..................147

MAIN BEARING CRUSH HEIGHT ....................148

CONNECTING ROD BEARING CRUSH

HEIGHT .............................................................148

MAIN BEARING CAP BOLT OUTER DIAMETER .148

CONNECTING ROD BOLT OUTER DIAMETER .149

DRIVE PLATE ...................................................149

OIL JET .............................................................149

OIL JET RELIEF VALVE ...................................149

SERVICE DATA AND SPECIFICATIONS (SDS) ....150

Standard and Limit ...............................................150

GENERAL SPECIFICATIONS ..........................150

DRIVE BELT .....................................................151

INTAKE MANIFOLD COLLECTOR, INTAKE

MANIFOLD AND EXHAUST MANIFOLD .........151

SPARK PLUG ...................................................151

CAMSHAFT AND CAMSHAFT BEARING ........152

CYLINDER HEAD .............................................154

CYLINDER BLOCK ...........................................157

PISTON, PISTON RING AND PISTON PIN ......158

CONNECTING ROD .........................................159

CRANKSHAFT ..................................................160

MAIN BEARING ................................................161

CONNECTING ROD BEARING ........................162

VK45DE

PRECAUTIONS ......................................................163

Precautions for Procedures without Cowl Top Cover .163

Precautions Necessary for Steering Wheel Rotation

After Battery Disconnect ......................................163

OPERATION PROCEDURE .............................163

Precautions for Drain Engine Coolant and Engine

Oil .........................................................................163

Precautions for Disconnecting Fuel Piping ..........163

Precautions for Removal and Disassembly .........163

Precautions for Inspection, Repair and Replace-

ment .....................................................................164

Precautions for Assembly and Installation ...........164

Parts Requiring Angle Tightening .........................164

Precautions for Liquid Gasket ..............................164

REMOVAL OF LIQUID GASKET SEALING ......164

LIQUID GASKET APPLICATION PROCEDURE .165

PREPARATION .......................................................166

Special Service Tools ...........................................166

Commercial Service Tools ....................................169

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ............................................171

NVH Troubleshooting — Engine Noise ................171

Use the Chart Below to Help You Find the Cause

of the Symptom. ...................................................172

ENGINE ROOM COVER ........................................173

Components .........................................................173

Removal and Installation ......................................173

REMOVAL ........................................................

.173

INSTALLATION .................................................173DRIVE BELTS .........................................................174

Components .........................................................174

Checking Drive Belts ............................................174

Tension Adjustment .............................................

.174

Removal and Installation ......................................174

REMOVAL ........................................................

.174

INSTALLATION .................................................175

Components .........................................................176

Drive Belt Auto Tensioner and Idler Pulley ...........176

REMOVAL ........................................................

.176

INSTALLATION .................................................176

AIR CLEANER AND AIR DUCT .............................177

Components .........................................................177

Removal and Installation ......................................177

REMOVAL ........................................................

.177

INSPECTION AFTER REMOVAL .....................178

INSTALLATION .................................................178

Changing Air Cleaner Filter ..................................178

REMOVAL ........................................................

.178

INSTALLATION .................................................178

INTAKE MANIFOLD ..............................................

.179

Components .........................................................179

Removal and Installation ......................................180

REMOVAL ........................................................

.180

INSPECTION AFTER REMOVAL .....................182

INSTALLATION .................................................182

INSPECTION AFTER INSTALLATION ..............182

EXHAUST MANIFOLD AND THREE WAY CATA-

LYST ........................................................................183

Components .........................................................183

Removal and Installation ......................................183

REMOVAL ........................................................

.183

INSPECTION AFTER REMOVAL .....................185

INSTALLATION .................................................185

OIL PAN AND OIL STRAINER ...............................187

Components .........................................................187

Removal and Installation ......................................187

REMOVAL ........................................................

.187

INSPECTION AFTER REMOVAL .....................188

INSTALLATION .................................................188

INSPECTION AFTER INSTALLATION ..............189

IGNITION COIL .......................................................190

Components .........................................................190

Removal and Installation ......................................190

REMOVAL ........................................................

.190

INSTALLATION .................................................190

SPARK PLUG (PLATINUM-TIPPED TYPE) ...........191

Components .........................................................191

Removal and Installation ......................................191

REMOVAL ........................................................

.191

INSPECTION AFTER REMOVAL .....................191

INSTALLATION .................................................192

FUEL INJECTOR AND FUEL TUBE ......................193

Components .........................................................193

Removal and Installation ......................................193

REMOVAL ........................................................

.193

INSTALLATION .................................................195

INSPECTION AFTER INSTALLATION ..............197

Page 3068 of 5621

![INFINITI M35 2006 Factory Repair Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced INFINITI M35 2006 Factory Repair Manual PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the proced](/img/42/57023/w960_57023-3067.png)

PRECAUTIONS

EM-5

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VQ35DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004MF

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectNBS005RR

NOTE:

This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the

ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the

LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precautions for Drain Engine Coolant and Engine OilNBS004MH

Drain engine coolant and engine oil when the engine is cooled.

Precautions for Disconnecting Fuel PipingNBS004MI

Before starting work, make sure no fire or spark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyNBS004MJ

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

PIIB3706J

Page 3177 of 5621

![INFINITI M35 2006 Factory Repair Manual EM-114

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

REMOVAL

Outline

At first, remove the engine and the transmission assembly with front suspension member from vehicle down-

ward. Then INFINITI M35 2006 Factory Repair Manual EM-114

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

REMOVAL

Outline

At first, remove the engine and the transmission assembly with front suspension member from vehicle down-

ward. Then](/img/42/57023/w960_57023-3176.png)

EM-114

[VQ35DE]

ENGINE ASSEMBLY

Revision: 2006 January2006 M35/M45

REMOVAL

Outline

At first, remove the engine and the transmission assembly with front suspension member from vehicle down-

ward. Then separate the engine from transmission.

Preparation

1. Release fuel pressure. Refer to EC-98, "FUEL PRESSURE RELEASE" .

2. Drain engine coolant from radiator. Refer to CO-11, "

Changing Engine Coolant" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery cables. Refer to SC-4, "

BATTERY" .

4. Remove the following parts:

Engine room cover (RH and LH); Refer toEM-14, "ENGINE ROOM COVER" .

Engine cover; Refer to EM-19, "INTAKE MANIFOLD COLLECTOR" .

Front road wheel and tires (power tool)

Front and rear engine undercover (power tool)

Cowl top cover (RH); Refer to EI-18, "COWL TOP" .

Air duct and air cleaner case assembly; EM-17, "AIR CLEANER AND AIR DUCT" .

5. Discharge refrigerant from A/C circuit. Refer to ATC-151, "

REFRIGERANT LINES" .

6. Remove radiator hoses (upper and lower). Refer to CO-14, "

RADIATOR" .

Engine Room LH

1. Disconnect heater hose from vehicle-side, and fit a plug onto hose end to prevent engine coolant leak.

2. Disconnect wire bonding (between vehicle to left bank cylinder head).

3. Disconnect A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to

AT C - 1 5 1 , "

REFRIGERANT LINES" .

4. Disconnect brake booster vacuum hose.

Engine Room RH

1. Disconnect battery positive cable at vehicle side and temporarily fasten it on engine.

2. Disconnect grounding cable.

3. Disconnect fuel feed hose (with damper) and EVAP hose. Refer to EM-45, "

FUEL INJECTOR AND FUEL

TUBE" .

CAUTION:

Fit plugs onto disconnected hoses to prevent fuel leak.

4. Remove reservoir tank of power steering oil pump and piping from vehicle, and temporarily secure them

on engine. Refer to PS-29, "

POWER STEERING OIL PUMP" .

CAUTION:

When temporarily securing, keep the reservoir tank upright to avoid a fluid leak.

Vehicle inside

Follow procedure below to disconnect engine room harness connectors at passenger room side, and tempo-

rarily secure them on engine.

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "

BODY SIDE

TRIM" and IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect engine room harness connectors at unit sides TCM, ECM and other.

3. Disengage intermediate fixing point. Pull out engine room harnesses to engine room side, and temporarily

secure them on engine.

CAUTION:

When pulling out harnesses, take care not to damage harnesses and connectors.

After temporarily securing, cover connectors with vinyl or similar material to protect against for-

eign material adhesion.

Page 3182 of 5621

![INFINITI M35 2006 Factory Repair Manual ENGINE ASSEMBLY

EM-119

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

If items or work required are not covered by the engine section, refer to the applicable sections.

Always u INFINITI M35 2006 Factory Repair Manual ENGINE ASSEMBLY

EM-119

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

If items or work required are not covered by the engine section, refer to the applicable sections.

Always u](/img/42/57023/w960_57023-3181.png)

ENGINE ASSEMBLY

EM-119

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

If items or work required are not covered by the engine section, refer to the applicable sections.

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for

unavoidable reasons, support at rear axle jacking point with transmission jack or similar tool

before starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-42, "Garage Jack and

Safety Stand and 2-Pole Lift" .

REMOVAL

Outline

At first, remove the engine, the transmission assembly, the transfer assembly and the front final drive assem-

bly with front suspension member from vehicle downward. Then separate the engine, the transmission assem-

bly, the transfer and the front final drive assembly.

Preparation

1. Release fuel pressure. Refer to EC-98, "FUEL PRESSURE RELEASE" .

2. Drain engine coolant from radiator. Refer to CO-11, "

Changing Engine Coolant" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery terminals. Refer to SC-4, "

BATTERY" .

4. Remove the following parts:

Engine room cover (RH and LH); Refer to EM-14, "ENGINE ROOM COVER" .

Engine cover; Refer to EM-19, "INTAKE MANIFOLD COLLECTOR" .

Front road wheel and tires (power tool)

Front and rear engine undercover (power tool)

Front cross bar; Refer to FSU-23, "FRONT SUSPENSION ASSEMBLY" .

Cowl top cover (RH); Refer to EI-18, "COWL TOP" .

Air duct and air cleaner case assembly; EM-17, "AIR CLEANER AND AIR DUCT" .

5. Discharge refrigerant from A/C circuit. Refer to ATC-151, "

REFRIGERANT LINES" .

6. Remove radiator hoses (upper and lower). Refer to CO-14, "

RADIATOR" .

Engine Room LH

1. Disconnect heater hose from vehicle-side, and fit a plug onto hose end to prevent engine coolant leak.

2. Disconnect wire bonding (between vehicle to left bank cylinder head).

3. Disconnect A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to

AT C - 1 5 1 , "

REFRIGERANT LINES" .

4. Disconnect brake booster vacuum hose.

Engine Room RH

1. Disconnect battery positive cable vehicle side and temporarily fasten it on engine.

2. Disconnect grounding cables.

3. Disconnect fuel feed hose (with damper) and EVAP hose. Refer to EM-45, "

FUEL INJECTOR AND FUEL

TUBE" .

CAUTION:

Fit plugs onto disconnected hoses to prevent fuel leak.

4. Remove reservoir tank of power steering oil pump and piping from vehicle, and temporarily secure them

on engine. Refer to PS-29, "

POWER STEERING OIL PUMP" .

CAUTION:

When temporarily securing, keep the reservoir tank upright to avoid a fluid leak.

Vehicle inSide

Follow procedure below to disconnect engine room harness connectors at passenger room side, and tempo-

rarily secure them on engine.

Page 3226 of 5621

![INFINITI M35 2006 Factory Repair Manual PRECAUTIONS

EM-163

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VK45DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004O5

When performing the proc INFINITI M35 2006 Factory Repair Manual PRECAUTIONS

EM-163

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VK45DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004O5

When performing the proc](/img/42/57023/w960_57023-3225.png)

PRECAUTIONS

EM-163

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

[VK45DE]PRECAUTIONSPFP:00001

Precautions for Procedures without Cowl Top CoverNBS004O5

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

Precautions Necessary for Steering Wheel Rotation After Battery DisconnectNBS005RS

NOTE:

This Procedure is applied only to models with Intelligent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

Remove and install all control units after disconnecting both battery cables with the ignition knob in the

LOCK position.

Always use CONSULT-II to perform self-diagnosis as a part of each function inspection after finishing

work. If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the

ACC position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the

LOCK position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT-II.

Precautions for Drain Engine Coolant and Engine OilNBS004O7

Drain engine coolant and engine oil when engine is cooled.

Precautions for Disconnecting Fuel PipingNBS004O8

Before starting work, make sure no fire or spark producing items are in the work area.

Release fuel pressure before disconnecting and disassembly.

After disconnecting pipes, plug openings to stop fuel leakage.

Precautions for Removal and DisassemblyNBS004O9

When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

Exercise maximum care to avoid damage to mating or sliding surfaces.

Cover openings of engine system with tape or the equivalent, if necessary, to seal out foreign materials.

PIIB3706J

Page 3308 of 5621

![INFINITI M35 2006 Factory Repair Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li INFINITI M35 2006 Factory Repair Manual ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type li](/img/42/57023/w960_57023-3307.png)

ENGINE ASSEMBLY

EM-245

[VK45DE]

C

D

E

F

G

H

I

J

K

L

MA

EM

Revision: 2006 January2006 M35/M45

Always use the support point specified for lifting.

Use either 2-pole lift type or separate type lift as best you can. If board-on type is used for

unavoidable reasons, support at the rear axle jacking point with transmission jack or similar tool

before starting work, in preparation for the backward shift of center of gravity.

For supporting points for lifting and jacking point at rear axle, refer to GI-42, "Garage Jack and

Safety Stand and 2-Pole Lift" .

REMOVAL

Outline

At first, remove engine, transmission assembly with front suspension member from vehicle downward. Then

separate engine from transmission.

Preparation

1. Release fuel pressure. Refer to EC-809, "FUEL PRESSURE RELEASE" .

2. Drain engine coolant from radiator. Refer to CO-40, "

Changing Engine Coolant" .

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belts.

3. Disconnect both battery cables. Refer to SC-4, "

BATTERY" .

4. Remove crankshaft position sensor (POS) from transmission.

CAUTION:

Handle carefully to avoid dropping and shocks.

Do not disassemble.

Do not allow metal powder to adhere to magnetic part at sensor tip.

Do not place sensors in a location where they are exposed to magnetism.

5. Remove the following parts:

Front and rear engine undercover (power tool)

Air duct (inlet), air duct and air cleaner case assembly; Refer to EM-177, "AIR CLEANER AND AIR

DUCT" .

Front road wheels and tires (power tool)

Engine Room LH

1. Disconnect heater hoses, and install plugs to avoid leakage of engine coolant.

2. Disconnect wire bonding from exhaust manifold cover to vehicle.

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Discharge refrigerant from A/C circuit. Refer to ATC-151, "

REFRIGERANT LINES" .

5. Remove A/C piping from A/C compressor, and temporarily fasten it on vehicle with a rope. Refer to AT C -

151, "REFRIGERANT LINES" .

Engine Room RH

1. Disconnect fuel feed hose and EVAP hose. Refer to EM-193, "FUEL INJECTOR AND FUEL TUBE" .

CAUTION:

Fit plugs onto disconnected hose to prevent fuel leak.

2. Disconnect ground cable (between vehicle and right bank cylinder head).

3. Disconnect vacuum hose between vehicle and engine and set it aside.

4. Disconnect reservoir tank of power steering oil pump from engine, and move it aside for easier work.

CAUTION:

When temporarily securing, keep reservoir tank upright to avoid a fluid leak.

Ve h i c le i n s i d e

Follow procedure below to disconnect engine room harness connectors at passenger room side, and tempo-

rarily secure them on engine.

1. Remove passenger-side kicking plate, dash side finisher, and glove box. Refer to EI-37, "

BODY SIDE

TRIM" and IP-10, "INSTRUMENT PANEL ASSEMBLY" .

2. Disconnect engine room harness connectors at unit sides TCM, ECM and other.