turn signal INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5034 of 5621

SUNROOF

RF-21

C

D

E

F

G

H

J

K

L

MA

B

RF

Revision: 2006 January2006 M35/M45

Sunroof Switch CheckNIS00240

1. SUNROOF SWITCH INPUT SIGNAL CHECK

1. Turn ignition switch ON.

2. Check voltage between sunroof motor assembly connector and ground.

OK or NG

OK >> Sunroof switch system is OK.

NG >> GO TO 2.

2. SUNROOF SWITCH CIRCUIT CHECK

1. Turn ignition switch OFF.

2. Disconnect sunroof motor assembly and sunroof switch connector.

3. Check continuity between sunroof motor assembly connector and sunroof switch connector.

4. Check continuity between sunroof motor assembly connector

and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

Sunroof

motor

assembly

connectorTerminals

ConditionVoltage (V)

(Approx.)

(+) (–)

M1864

GroundSunroof switch is operated

TILT DOWN or SLIDE OPEN0

Other than above Battery voltage

11Sunroof switch is operated

TILT UP or SLIDE CLOSE0

Other than above Battery voltage

PIIB5908E

AB

Continuity

Sunroof motor

assembly connectorTerminalSunroof switch

connectorTerminal

M1864

R531

Ye s

11 3

A

GroundContinuity

Sunroof motor

assembly connectorTerminal

M1864

No

11

PIIB5909E

Page 5036 of 5621

SUNROOF

RF-23

C

D

E

F

G

H

J

K

L

MA

B

RF

Revision: 2006 January2006 M35/M45

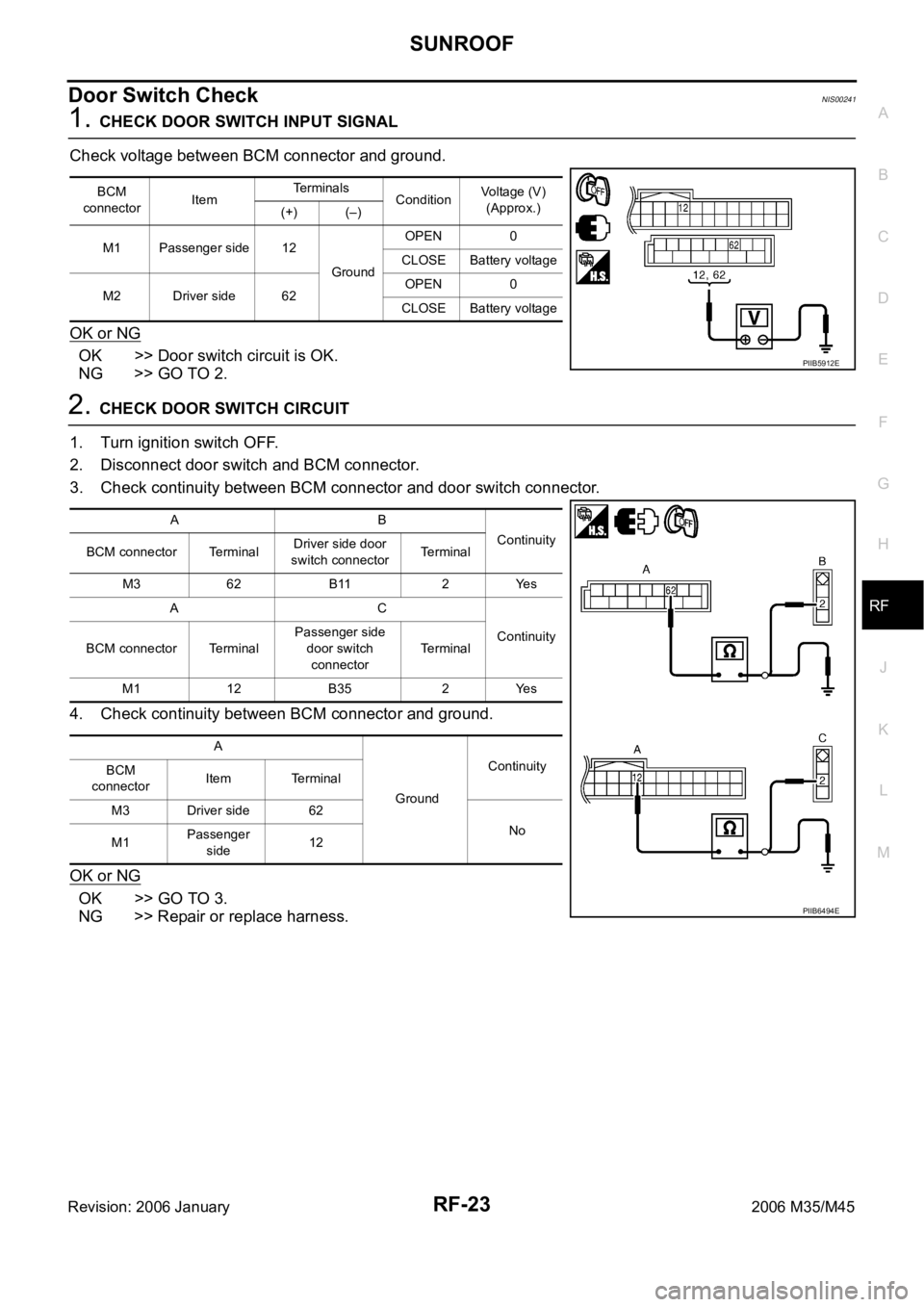

Door Switch Check NIS00241

1. CHECK DOOR SWITCH INPUT SIGNAL

Check voltage between BCM connector and ground.

OK or NG

OK >> Door switch circuit is OK.

NG >> GO TO 2.

2. CHECK DOOR SWITCH CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect door switch and BCM connector.

3. Check continuity between BCM connector and door switch connector.

4. Check continuity between BCM connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

BCM

connectorItemTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (–)

M1 Passenger side 12

GroundOPEN 0

CLOSE Battery voltage

M2 Driver side 62OPEN 0

CLOSE Battery voltage

PIIB5912E

AB

Continuity

BCM connector TerminalDriver side door

switch connectorTerminal

M3 62 B11 2 Yes

AC

Continuity

BCM connector TerminalPassenger side

door switch

connectorTerminal

M1 12 B35 2 Yes

A

GroundContinuity

BCM

connectorItem Terminal

M3 Driver side 62

No

M1Passenger

side12

PIIB6494E

Page 5118 of 5621

PRE-CRASH SEAT BELT

SB-19

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Seat Belt Buckle Switch (Driver Side) Circuit CheckNHS0008B

1. CHECK PRE-CRASH SEAT BELT CONTROL UNIT INPUT SIGNAL

With CONSULT-II

Select “SB SW LH SIG” on DATA MONITOR screen, and then make sure that ON/OFF display changes syn-

chronized with the insertion operation to the seat belt buckle.

Without CONSULT-II

1. Turn the ignition switch ON.

2. Check voltage between seat belt buckle switch (driver side) har-

ness connector and ground.

OK or NG

OK >> Seat belt buckle switch (driver side) circuit is OK.

NG >> GO TO 2.SB SW LH SIG

When driver seat belt is not fastened : OFF

When driver seat belt is fastened : ON

PHIA0765E

Terminal

ConditionVoltage (V)

(Approx.) (+)

(–) Seat belt buckle

switch connector

(driver side)Te r m i n a l

B203 1 GroundWhen seat belt is

unfastened0

When seat belt is

fastenedBattery

voltage

PHIA1129E

Page 5120 of 5621

PRE-CRASH SEAT BELT

SB-21

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

Seat Belt Buckle Switch (Passenger Side) Circuit CheckNHS0008C

1. CHECK PRE-CRASH SEAT BELT CONTROL UNIT INPUT SIGNAL

With CONSULT-II

Select “SB SW RH SIG” on DATA MONITOR screen, and then make

sure that ON/OFF display changes synchronized with the insertion

operation to the seat belt buckle.

Without CONSULT-II

1. Turn the ignition switch ON.

2. Check voltage between seat belt buckle switch (passenger side)

harness connector and ground.

OK or NG

OK >> Seat belt buckle switch (passenger side) circuit is OK.

NG >> GO TO 2.

2. CHECK SEAT BELT BUCKLE SWITCH (PASSENGER SIDE) HARNESS

1. Turn ignition switch OFF.

2. Disconnect pre-crash seat belt control unit and seat belt buckle switch (passenger side) connector.

3. Check continuity between pre-crash seat belt control unit har-

ness connector and seat belt buckle switch (passenger side)

harness connector.

4. Check continuity between pre-crash seat belt control unit har-

ness connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.SB SW RH SIG

When passenger seat belt is not fastened :OFF

When passenger seat belt is fastened :ON

PHIA0764E

Terminal

ConditionVoltage (V)

(Approx.) (+)

(–) Seat belt buckle

switch connector

(passenger side) Te r m i n a l

B253 1 GroundWhen seat belt is

unfastened0

When seat belt is

fastened5

PHIA1129E

AB

Continuity Pre-crash seat

belt control unit

connectorTerminalSeat belt buckle

switch (passenger

side) connectorTerminal

B142 8 B253 1 Yes

A

GroundContinuity

Pre-crash seat belt

control unit connectorTerminal

B142 8 No

PHIA1133E

Page 5122 of 5621

PRE-CRASH SEAT BELT

SB-23

C

D

E

F

G

I

J

K

L

MA

B

SB

Revision: 2006 January2006 M35/M45

2. CHECK PRE-CRASH SEAT BELT CONTOROL UNIT INPUT SIGNAL

With CONSULT-II

Select “B PEDAL SIG1” and “B PEDAL SIG2”, and then make sure that the voltage changes synchronized

with brake pedal operation.

Without CONSULT-II

1. Turn the ignition switch ON.

2. Check voltage between pre-crash seat belt control unit harness

connector and ground.

OK or NG

OK >> Brake pedal stroke sensor system is normal.

NG >> GO TO 3.B PEDAL SIG1

Brake released

depressed : Approx. 1 4V

B PEDAL SIG 2

Brake released

depressed : Approx. 4 1V

PHIA0766E

Terminal

ConditionVoltage (V)

(Approx.) (+)

(–) Pre-crash seat

belt control unit

connectorTe r m i n a l

B14216

GroundBrake released

depressed1 4

20 4

1PHIA1134E

Page 5129 of 5621

SB-30

SEAT BELTS

Revision: 2006 January2006 M35/M45

SEAT BELTSPFP:86884

System DescriptionNHS0008I

SEAT BELT WARNING CHIME

With ignition switch turned ON and seat belt unfastened (seat belt switch ON), warning chime will sound

for approximately 6 seconds.

If warning chime does not sound, refer to DI-74, "Seat Belt Buckle Switch Signal Inspection" .

SEAT BELT WARNING LAMP

Fasten driver's seat belt.

The seat belt warning lamp should go out.

If the seat belt warning lamp does not go out, refer to DI-43, "Wiring Diagram — WARN —" .

Removal and Installation of Front Seat Belt NHS0008J

CAUTION:

Before servicing SRS, turn the ignition switch off, disconnect both battery cables and wait at least 3

minutes.

REMOVAL OF SEAT BELT RETRACTOR

1. Remove the outer anchor.

Remove the belt tension sensor cover and cover protector (passenger side only).

Disconnect the belt tension sensor connector (passenger side only).

Remove the fixing bolt of the outer anchor.

1. Outer anchor 2. Shoulder anchor 3. Pre-tensioner seat belt retractor

4. Belt tension sensor cover (passen-

ger side only)5. Cover protector (passenger side

only)6. Belt tension sensor connector (pas-

senger side only)

7. Anchor bolt 8. Anchor nut 9. Seat belt pre-tensioner connector

10. Pre-crash seat belt connector 11. Bolt 12. Seat belt adjuster

PHIA1106E

Page 5215 of 5621

SE-34

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

21 SBMirror sensor (RH horizon-

tal) signalWhen mirror motor RH is LEFT or

RIGHT operationChanges between 3.5 (close to left

edge) 0.5 (close to right edge)

22 O/LMirror sensor (LH horizontal)

signalWhen mirror motor LH is LEFT or

RIGHT operationChanges between 0.5 (close to left

edge) 3.5 (close to right edge)

23 GR Telescopic sensor inputTelescopic position : Top 4.6

Telescopic position : Bottom 0.4

24 BR/W Set switch signalSet switch ON 0

Other than above 5

25 LG/B Memory switch 2 signalMemory switch 2 ON 0

Other than above 5

26 P UART LINE (RX) Tilt switch is operated

27 WTelescopic switch backward

signalTelescopic switch turned to backward 0

Other than above 5

30 GRMirror motor RH DOWN sig-

nalWhen mirror motor RH DOWN opera-

tionBattery voltage

Other than above 0

Mirror motor RH RIGTH sig-

nalWhen mirror motor RH RIGHT opera-

tionBattery voltage

Other than above 0

31 BR Mirror motor LH UP signalWhen mirror motor LH UP operation Battery voltage

Other than above 0

32 V Mirror motor LH LEFT signalWhen mirror motor LH LEFT operation Battery voltage

Other than above 0

33 W Sensor power supply — 5

34 R Power source (Fuse) — Battery voltage

35 LG Tilt motor UP signalTilt switch is UP operation Battery voltage

Other than above 0

36 PTelescopic motor forward sig-

nalTelescopic switch is forward operation Battery voltage

Other than above 0

39 L Power source (C/B) — Battery voltage

40 B Ground — 0

41 Y Sensor ground — 0

42 G Tilt motor DOWN signalTilt switch is DOWN operation Battery voltage

Other than above 0

44 GTelescopic motor backward

signalTelescopic switch is backward opera-

tionBattery voltage

Other than above 0

48 B Ground — 0 Termi-

nal Wire

colorItem ConditionVoltage (V)

(Approx)

SKIA0175E

Page 5216 of 5621

AUTOMATIC DRIVE POSITIONER

SE-35

C

D

E

F

G

H

J

K

L

MA

B

SE

Revision: 2006 January2006 M35/M45

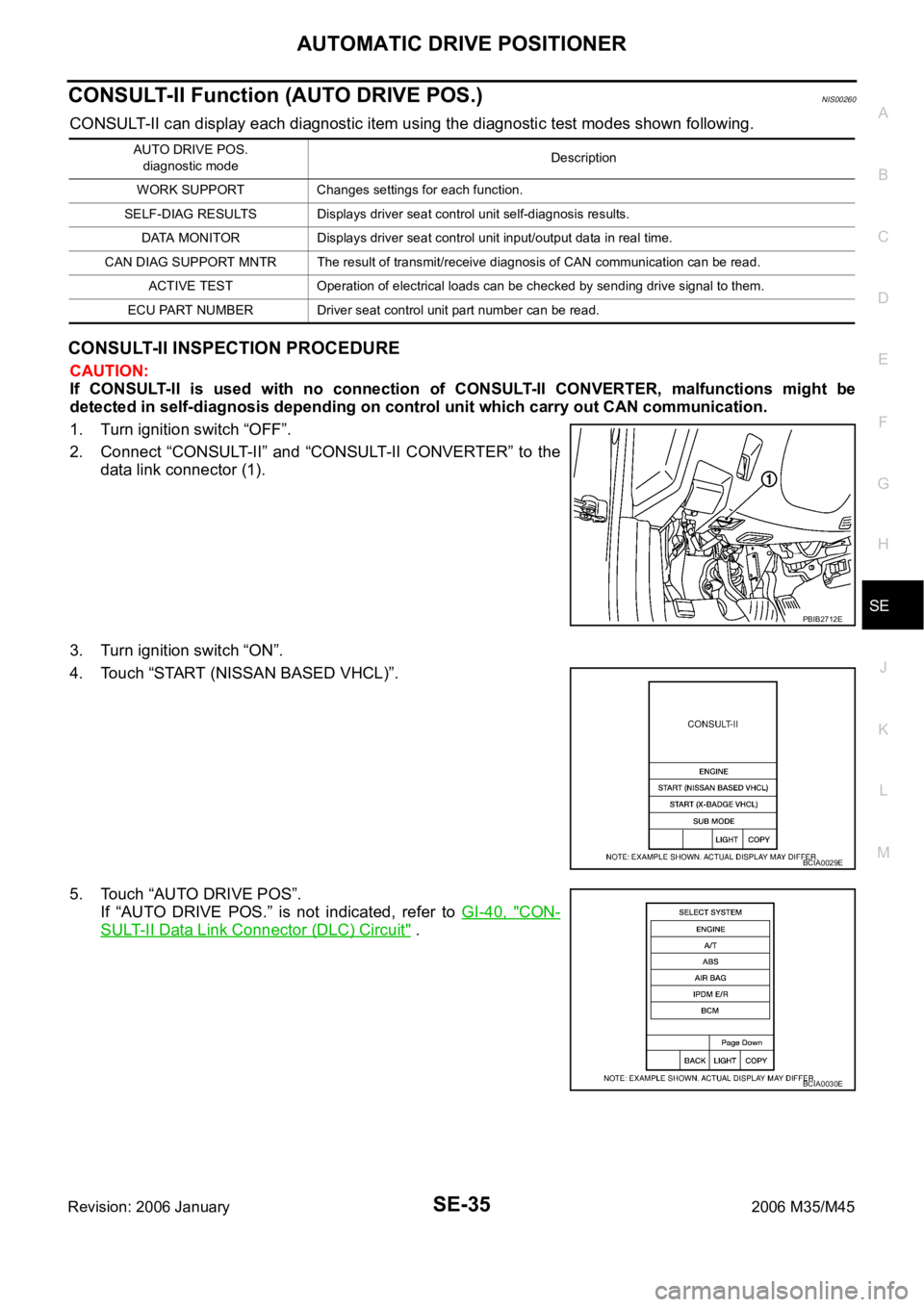

CONSULT-II Function (AUTO DRIVE POS.)NIS00260

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II INSPECTION PROCEDURE

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carry out CAN communication.

1. Turn ignition switch “OFF”.

2. Connect “CONSULT-II” and “CONSULT-II CONVERTER” to the

data link connector (1).

3. Turn ignition switch “ON”.

4. Touch “START (NISSAN BASED VHCL)”.

5. Touch “AUTO DRIVE POS”.

If “AUTO DRIVE POS.” is not indicated, refer to GI-40, "

CON-

SULT-II Data Link Connector (DLC) Circuit" .

AUTO DRIVE POS.

diagnostic modeDescription

WORK SUPPORT Changes settings for each function.

SELF-DIAG RESULTS Displays driver seat control unit self-diagnosis results.

DATA MONITOR Displays driver seat control unit input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

ECU PART NUMBER Driver seat control unit part number can be read.

PBIB2712E

BCIA0029E

BCIA0030E

Page 5225 of 5621

SE-44

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

Sliding Motor Circuit CheckNIS00267

1. CHECK SEAT SLIDING MECHANISM

Check the following.

Operation malfunction caused by sliding rail deformation, pinched harness or other foreign materials

Operation malfunction caused by foreign materials adhered to the sliding motor or sliding rail connector

rod

Operation malfunction and interference with other parts by poor installation

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning part and check again.

2. CHECK FUNCTION

With CONSULT-II

Check operation with “SEAT SLIDE” in ACTIVE TEST.

OK or NG

OK >> Sliding motor circuit is OK.

NG >> GO TO 3.

3. CHECK SLIDING MOTOR CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit and sliding motor connector.

3. Check continuity between driver seat control unit connector and sliding motor connector.

4. Check continuity between driver seat control unit connector and

ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

Test item Description

SEAT SLIDE The sliding motor is activated by receiving the drive signal.

PIIA0265E

AB

Continuity

Driver seat control

unit connectorTe r m i n a lSliding motor

connectorTerminal

B20535

B20735

Ye s

42 42

A

GroundContinuity

Driver seat control unit

connectorTerminal

B20535

No

42

PIIB6132E

Page 5227 of 5621

SE-46

AUTOMATIC DRIVE POSITIONER

Revision: 2006 January2006 M35/M45

3. CHECK RECLINING MOTOR CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit and reclining motor connector.

3. Check continuity between driver seat control unit connector and reclining motor connector.

4. Check continuity between driver seat control unit connector and

ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4. CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1. Connect the driver seat control unit connector.

2. Check voltage between driver seat control unit connector and

ground.

OK or NG

OK >> Replace reclining motor.

NG >> Replace driver seat control unit.

Front Lifting Motor Circuit CheckNIS00269

1. CHECK FRONT END SEAT LIFTING MECHANISM

Check the following.

Operation malfunction caused by lifter mechanism deformation, pinched harness or other foreign materi-

als

Operation malfunction caused by foreign materials adhered to the front lifting motor or lead screws

Operation malfunction and interference with other parts by installation

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning part and check again.

AB

Continuity

Driver seat control

unit connectorTe r m i n a lReclining motor

connectorTerminal

B20536

B20836

Ye s

44 44

A

GroundContinuity

Driver seat control unit

connectorTerminal

B20536

No

44

PIIB6134E

Driver seat

control unit

connectorTerminals

ConditionVoltage (V)

(Approx.)

(+) (–)

B20536

GroundReclining switch ON

(FORWARD operation)Battery voltage

Other than above 0

44Reclining switch ON

(BACKWARD operation)Battery voltage

Other than above 0

PIIB6135E