display INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5501 of 5621

TF-36

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

3. CHECK SYSTEM FOR AWD SOLENOID

Perform trouble diagnosis for AWD solenoid system. Refer to TF-28, "

AWD Solenoid" .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4. CHECK ELECTRIC CONTROLLED COUPLING

1. Turn ignition switch “OFF”.

2. Set the selector lever to “N” (neutral) position and disengage the parking brake.

3. Lift up the vehicle.

4. Rotate the rear propeller shaft by hand.

5. Hold front propeller shaft lightly.

Does front propeller shaft rotate?

YES >> Replace electric controlled coupling for mechanical malfunction (clutch sticking etc.). Refer to TF-

45, "Disassembly and Assembly" .

NO >> GO TO 5.

5. SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> GO TO 6.

6. CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e s" .

OK or NG

OK >>INSPECTION END

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

Vehicle Does Not Enter AWD Mode Even Though AWD Warning Lamp Turned to

OFF

NDS000DX

DIAGNOSTIC PROCEDURE

1. CHECK AWD WARNING LANP

Turn ignition switch “ON”. (Do not start engine.)

Does AWD warning lamp turn on?

YES >> GO TO 2.

NO >> Go to TF-33, "

AWD Warning Lamp Does Not Turn ON When The Ignition Switch Is Turned to ON"

.

2. CHECK SYSTEM FOR CAN COMMUNICATION LINE

Perform self-diagnosis. Refer to TF-22, "

SELF-DIAG RESULT MODE" .

Is the

“CAN COMM CIRCUIT [U1000]” displayed?

YES >> Perform trouble diagnosis for CAN communication line. Refer to TF-32, "CAN Communication

Line" .

NO >> GO TO 3.

Page 5503 of 5621

TF-38

TROUBLE DIAGNOSIS FOR SYMPTOMS

Revision: 2006 January2006 M35/M45

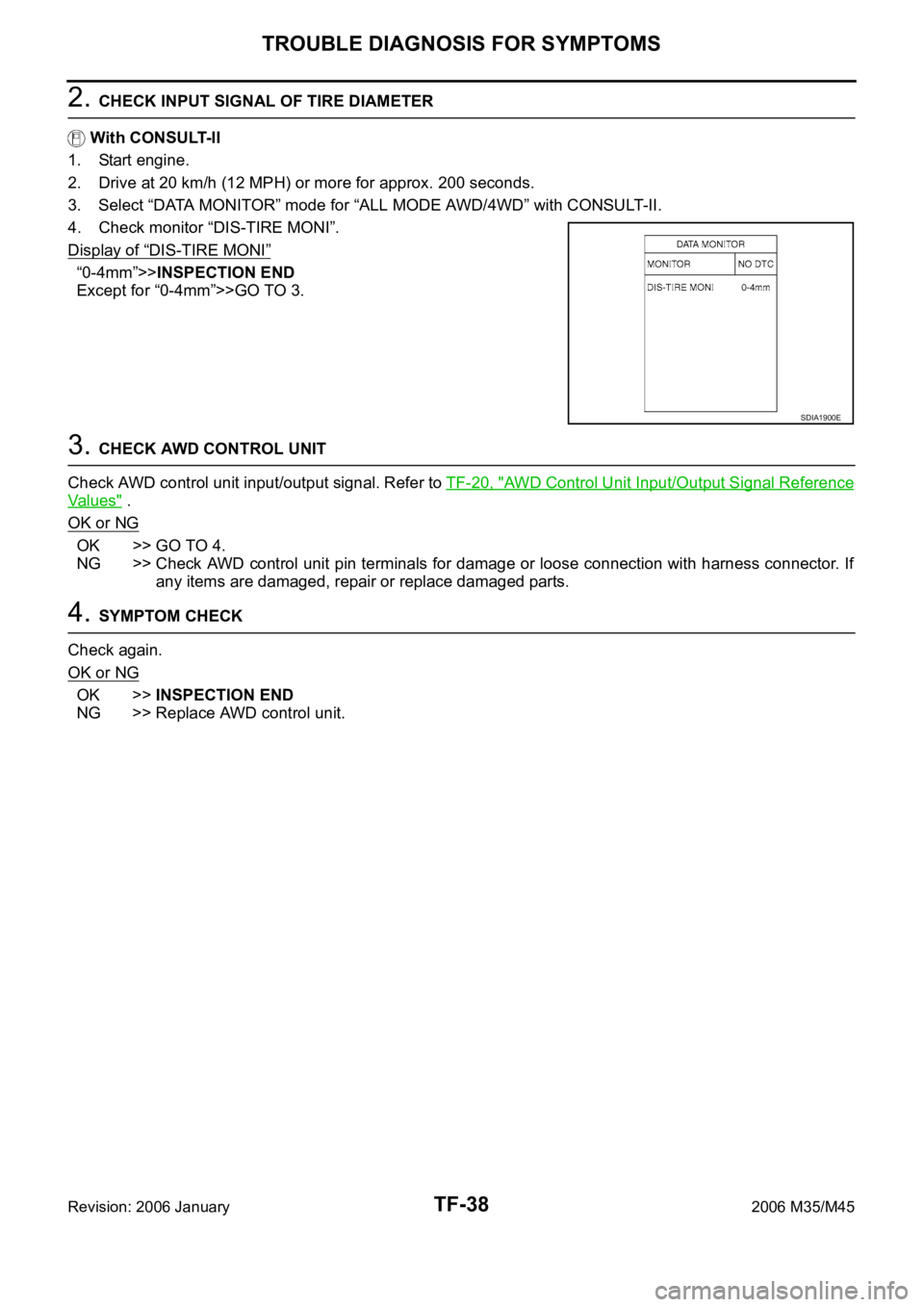

2. CHECK INPUT SIGNAL OF TIRE DIAMETER

With CONSULT-II

1. Start engine.

2. Drive at 20 km/h (12 MPH) or more for approx. 200 seconds.

3. Select “DATA MONITOR” mode for “ALL MODE AWD/4WD” with CONSULT-II.

4. Check monitor “DIS-TIRE MONI”.

Display of

“DIS-TIRE MONI”

“0-4mm”>>INSPECTION END

Except for “0-4mm”>>GO TO 3.

3. CHECK AWD CONTROL UNIT

Check AWD control unit input/output signal. Refer to TF-20, "

AWD Control Unit Input/Output Signal Reference

Va l u e s" .

OK or NG

OK >> GO TO 4.

NG >> Check AWD control unit pin terminals for damage or loose connection with harness connector. If

any items are damaged, repair or replace damaged parts.

4. SYMPTOM CHECK

Check again.

OK or NG

OK >>INSPECTION END

NG >> Replace AWD control unit.

SDIA1900E

Page 5526 of 5621

WT-1

ROAD WHEELS & TIRES

E SUSPENSION

CONTENTS

C

D

F

G

H

I

J

K

L

M

SECTION WT

A

B

WT

Revision: 2006 January2006 M35/M45

ROAD WHEELS & TIRES

PRECAUTIONS .......................................................... 3

Precautions .............................................................. 3

PREPARATION ........................................................... 4

Special Service Tools [SST] ..................................... 4

Commercial Service Tools ........................................ 4

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

ROAD WHEEL ............................................................ 6

Inspection ................................................................. 6

ALUMINUM WHEEL ............................................. 6

STEEL WHEEL ..................................................... 6

ROAD WHEEL TIRE ASSEMBLY .............................. 7

Balancing Wheels (Bonding Weight Type) ............... 7

REMOVAL ........................................................

..... 7

WHEEL BALANCE ADJUSTMENT ...................... 7

Rotation .................................................................... 8

LOW TIRE PRESSURE WARNING SYSTEM ............ 9

System Components ................................................ 9

System Description .................................................. 9

TRANSMITTER ..................................................... 9

RECEIVER .......................................................

... 10

LOW TIRE PRESSURE WARNING CONTROL

UNIT .................................................................... 10

LOW TIRE PRESSURE WARNING LAMP ......... 10

DISPLAY UNIT ..................................................... 11

CAN COMMUNICATION .......................................... 12

System Description ................................................ 12

TROUBLE DIAGNOSES .......................................... 13

How to Perform Trouble Diagnoses ....................... 13

BASIC CONCEPT ............................................... 13

Schematic .............................................................. 14

Wiring Diagram — T/WARN — .............................. 15

Control Unit Input/Output Signal Standard ............. 18

ID Registration Procedure ...................................... 19

ID REGISTRATION WITH ACTIVATION TOOL ... 19

ID REGISTRATION WITHOUT ACTIVATION

TOOL .................................................................. 20

Transmitter Wake Up Operation ............................. 21

WITH TRANSMITTER ACTIVATION TOOL ........ 21CONSULT-II Function (AIR PRESSURE MONI-

TOR) ....................................................................... 21

FUNCTION .......................................................

... 21

CONSULT-II SETTING PROCEDURE ................ 21

WORK SUPPORT MODE ................................... 22

SELF-DIAG RESULT MODE ............................... 22

DATA MONITOR MODE ...................................... 23

ACTIVE TEST MODE ......................................... 23

LOW TIRE PRESSURE WARNING CONTROL

UNIT PART NUMBER ......................................... 24

Diagnosis Procedure with Warning Lamp Function

(Without CONSULT-II) ............................................ 24

DESCRIPTION .................................................... 24

FUNCTION .......................................................

... 24

LOW TIRE PRESSURE WARNING LAMP DIAG-

NOSTIC CHART .................................................. 24

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ...................................................... 26

INTRODUCTION ................................................. 26

WORK FLOW ...................................................... 26

Preliminary Check .................................................. 27

Trouble Diagnosis Chart ......................................... 28

SELF-DIAGNOSIS .............................................. 28

DIAGNOSIS CHART BY SYMPTOM .................. 29

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC

ITEMS ........................................................................ 30

Inspection 1: Transmitter no Data ........................... 30

MALFUNCTION CODE NO. 21, 22, 23, 24 ......... 30

Inspection 2: Receiver Data Error .......................... 31

MALFUNCTION CODE NO. 25, 26, 27, 28 ......... 31

Inspection 3: Transmitter Pressure Data Error ....... 32

MALFUNCTION CODE NO. 35, 36, 37, 38 ......... 32

Inspection 4: Transmitter Function Code Error ....... 32

MALFUNCTION CODE NO. 41, 42, 43, 44 ......... 32

Inspection 5: Transmitter Battery Voltage Low ....... 33

MALFUNCTION CODE NO. 45, 46, 47, 48 ......... 33

Inspection 6: Receiver ID No Registration .............. 33

MALFUNCTION CODE NO. 51 ........................... 33

Inspection 7: Vehicle Speed Signal ........................ 34

Page 5534 of 5621

LOW TIRE PRESSURE WARNING SYSTEM

WT-9

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

LOW TIRE PRESSURE WARNING SYSTEMPFP:40300

System ComponentsNES000JR

System DescriptionNES000JS

TRANSMITTER

A sensor-transmitter integrated with a valve is installed on a wheel,

and transmits a detected air pressure signal in the form of a radio

wave.

1. Tire pressure transmitter front LH 2. Tire pressure transmitter front RH 3. Tire pressure receiver front LH

4. Tire pressure receiver front RH 5. Low tire pressure warning control

unit6. Low tire pressure warning lamp

7. Display unit 8. Tire pressure transmitter rear LH 9. Tire pressure transmitter rear RH

10. Tire pressure receiver rear LH 11. Tire pressure receiver rear RH

SEIA0648E

SEIA0521E

Page 5536 of 5621

LOW TIRE PRESSURE WARNING SYSTEM

WT-11

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

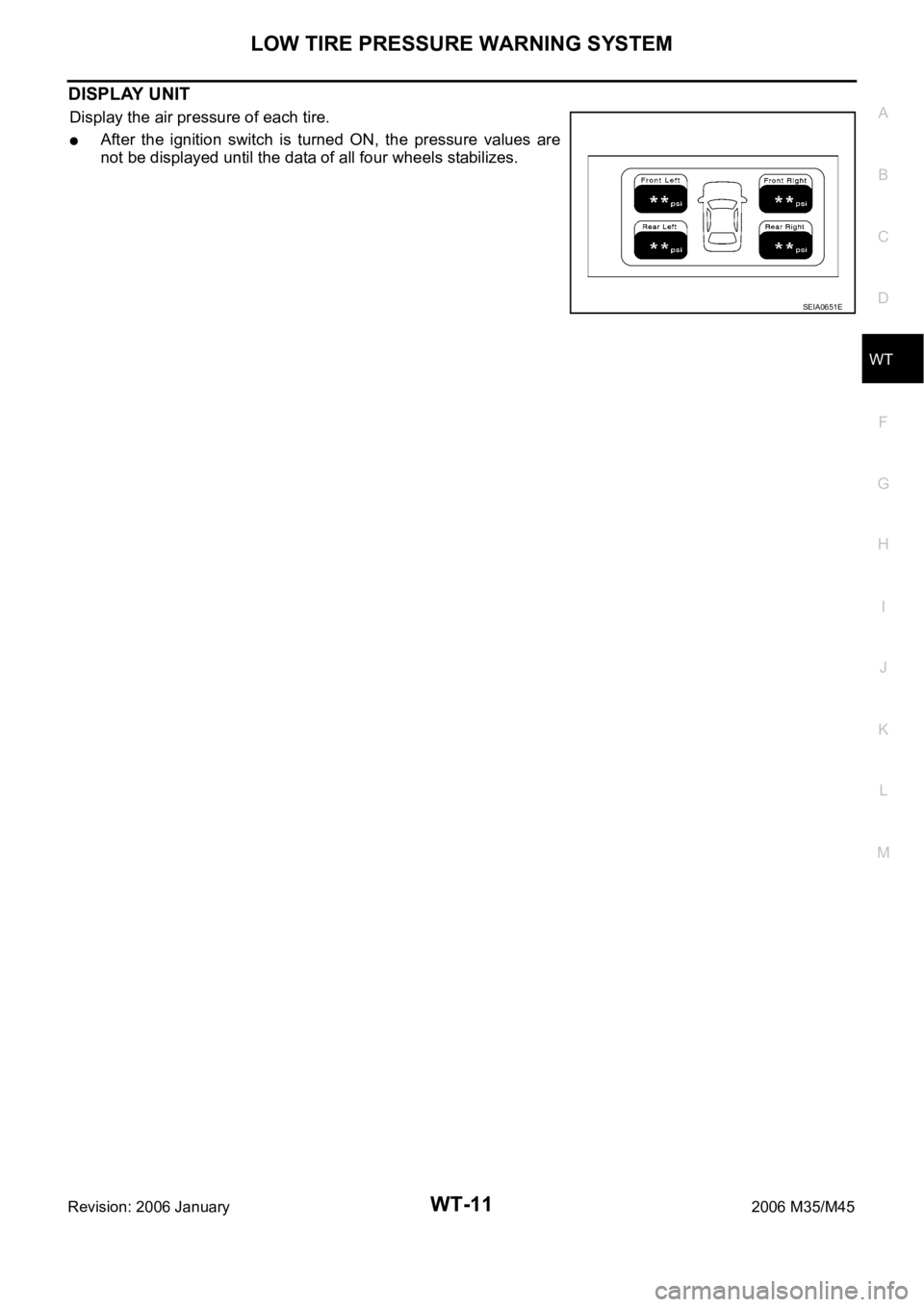

DISPLAY UNIT

Display the air pressure of each tire.

After the ignition switch is turned ON, the pressure values are

not be displayed until the data of all four wheels stabilizes.

SEIA0651E

Page 5544 of 5621

TROUBLE DIAGNOSES

WT-19

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

ID Registration ProcedureNES000JY

ID REGISTRATION WITH ACTIVATION TOOL

This procedure must be done after replacement of a tire pressure transmitter, low tire pressure warn-

ing control unit, or tire rotation.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunction might be detected

during self-diagnosis depending on control unit which performs CAN communication.

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)” “AIR PRESSURE MONITOR”.

If “AIR PRESSURE MONITOR” is not displayed, print the “SELECT SYSTEM” screen. Then refer to

LAN-7, "

Precautions When Using CONSULT-II"

NOTE:

Just after starting engine, or turning ignition switch ON, it may not be displayed even if “START (NIS-

SAN BASED VHCL)” is touched. In this case, reconnect CONSULT-II and CONSULT-II CONVERTER.

5. Touch “WORK SUPPORT” on “SELECT DIAG MODE” screen.

6. Touch “ID REGIST” on “SELECT WORK ITEM”.

7. With the activation tool [SST: J-45295] pushed against the front-

left tire pressure transmitter position of the tire air valve, press

and hold the button for 5 seconds.

8. Register the IDs in order from FR LH, FR RH, RR RH, RR LH.

When ID registration of each wheel has been completed, a

buzzer sounds and turn signal lamp blinks.

9. After completing all ID registrations, press “END” to complete the procedure.

NOTE:

Be sure to register the IDs in order from FR LH, FR RH, RR RH, to RR LH, or the self-diagnosis results

display will not function properly.

SEIA0460E

Activation tire position Buzzer Turn signal lamp CONSULT-II

1 Front LH Once

2 times flashing“YET”

“DONE” 2 Front RH 2 times

3 Rear RH 3 times

4 Rear LH 4 times

Page 5545 of 5621

WT-20

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

ID REGISTRATION WITHOUT ACTIVATION TOOL

This procedure must be done after replacement of a tire pressure transmitter, low tire pressure warn-

ing control unit, or tire rotation.

CAUTION:

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunction might be detected

during self-diagnosis depending on control unit which performs CAN communication.

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)” “AIR PRESSURE MONITOR”.

If “AIR PRESSURE MONITOR” is not displayed, print the “SELECT SYSTEM” screen. Then refer to

LAN-7, "

Precautions When Using CONSULT-II" .

NOTE:

Just after starting engine, or turning ignition switch ON, it may not be displayed even if “START (NIS-

SAN BASED VHCL)” is touched. In this case, reconnect CONSULT-II and CONSULT-II CONVERTER.

5. Touch “WORK SUPPORT” on “SELECT DIAG MODE” screen.

6. Touch “ID REGIST” on “SELECT WORK ITEM”.

7. Adjust the tire pressure to the values shown in the table below for ID registration, and drive the vehicle at

40 km/h (25 MPH) or more for a few minutes.

8. After completing all ID registrations, press “END” to complete the procedure.

9. Inflate all tires to proper pressure. Refer to WT-41, "

SERVICE DATA AND SPECIFICATIONS (SDS)" .

Tire position

Tire pressure kPa (kg/cm2 , psi)

Front

Left 240 (2.4, 34)

Front

Right 220 (2.2, 31)

Rear

Right 200 (2.0, 29)

Rear

Left 180 (1.8, 26)

Activation tire position CONSULT-II

Front LH

“YET”

“DONE” Front RH

Rear RH

Rear LH

Page 5546 of 5621

![INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES

WT-21

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

Transmitter Wake Up OperationNES000JZ

WITH TRANSMITTER ACTIVATION TOOL

1. With the activation tool [SST: J-45295] p INFINITI M35 2006 Factory Service Manual TROUBLE DIAGNOSES

WT-21

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

Transmitter Wake Up OperationNES000JZ

WITH TRANSMITTER ACTIVATION TOOL

1. With the activation tool [SST: J-45295] p](/img/42/57023/w960_57023-5545.png)

TROUBLE DIAGNOSES

WT-21

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

Transmitter Wake Up OperationNES000JZ

WITH TRANSMITTER ACTIVATION TOOL

1. With the activation tool [SST: J-45295] pushed against the front-

left transmitter, press and hold the button for 5 seconds.

When ignition switch ON, as the low tire pressure warning

lamp blinks per the follow diagram, the respective transmitter

then must be woken up.

2. Register the ID of wheel that warning lamp flashes. When wake up of registered wheel has been com-

pleted, turn signal lamp flashes two times.

3. After completing wake up all transmitters, make sure low tire pressure warning lamp goes out.

CONSULT-II Function (AIR PRESSURE MONITOR)NES000K0

FUNCTION

CONSULT-II can display each diagnosis item using the diagnosis test modes shown following.

CONSULT-II SETTING PROCEDURE

Refer to GI-39, "CONSULT-II Start Procedure" .

SEIA0460E

SEIA0378E

Mode Function Reference

WORK SUPPORTThis mode enables a technician to adjust some devices faster and

more accurately by following the indications on CONSULT-II.WT-22, "

WORK SUP-

PORT MODE"

SELF-DIAG RESULTSReceives self-diagnosis results from low tire pressure warning con-

trol unit and indicates DTCs. WT-22, "SELF-DIAG

RESULT MODE"

DATA MONITORReceives input/output signals from low tire pressure warning control

unit and indicates and stores them to facilitate locating cause of mal-

functions.WT-23, "DATA MONITOR

MODE"

CAN DIAG SUPPORT MNTR Monitors transmitting/receiving status of CAN communication.WT-12, "CAN COMMUNI-

CATION"

ACTIVE TESTDiagnostic Test Mode in with CONSULT-II drives some actuators

apart from the low tire pressure warning control unit and also shifts

some parameters in a specified range.WT-23, "ACTIVE TEST

MODE"

ECU PART NUMBER Displays low tire pressure warning control unit part number. WT-24, "

LOW TIRE PRES-

SURE WARNING CON-

TROL UNIT PART

NUMBER"

Page 5547 of 5621

WT-22

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

WORK SUPPORT MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. Perform the “ID Regist”. Refer to WT-19, "

ID Registration Procedure" .

SELF-DIAG RESULT MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. The self-diagnostic results are displayed. (Touch “PRINT” to print out the self-diagnostic results if neces-

sary.) Check low tire pressure warning lamp if “NO FAILURE” is displayed.

3. Perform the appropriate inspection from the display item list, and repair or replace the malfunctioning

component. Refer to WT-22, "

Display Item List" .

Display Item List

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or else the actual malfunction location may be different from that dis-

played on CONSULT-II.DTC Diagnostic item Diagnostic item is detected when ꞏꞏꞏ Check items

C1700 FLAT_TIRE_FLFront-left tire pressure drops to * kPa (* kg/cm

2 , * psi) or less.

(Notice)

— C1701 FLAT_TIRE_FRFront-right tire pressure drops to * kPa (* kg/cm

2 , * psi) or less.

(Notice)

C1702 FLAT_TIRE_RRRear-right tire pressure drops to * kPa (* kg/cm

2 , * psi) or less.

(Notice)

C1703 FLAT_TIRE_RLRear-left tire pressure drops to * kPa (* kg/cm

2 , * psi) or less.

(Notice)

C1708 [NO_DATA]_FL Data from front-left transmitter cannot be received.

WT-30

C1709 [NO_DATA]_FR Data from front-right transmitter cannot be received.

C1710 [NO_DATA]_RR Data from rear-right transmitter cannot be received.

C1711 [NO_DATA]_RL Data from rear-left transmitter cannot be received.

C1716 [PRESSDATA_ERR]_FL Air pressure data from front-left transmitter is malfunctioning.

WT-32

C1717 [PRESSDATA_ERR]_FR Air pressure data from front-right transmitter is malfunctioning.

C1718 [PRESSDATA_ERR]_RR Air pressure data from rear-right transmitter is malfunctioning.

C1719 [PRESSDATA_ERR]_RL Air pressure data from rear-left transmitter is malfunctioning.

C1720 [CODE_ERROR]_FL Function code data from front-left transmitter is malfunctioning.

WT-32

C1721 [CODE_ERROR]_FR Function code data from front-right transmitter is malfunctioning.

C1722 [CODE_ERROR]_RR Function code data from rear-right transmitter is malfunctioning.

C1723 [CODE_ERROR]_RL Function code data from rear-left transmitter is malfunctioning.

C1724 [BATT_VOLT_LOW]_FL Battery voltage of front-left transmitter drops.

WT-33

C1725 [BATT_VOLT_LOW]_FR Battery voltage of front-right transmitter drops.

C1726 [BATT_VOLT_LOW]_RR Battery voltage of rear-right transmitter drops.

C1727 [BATT_VOLT_LOW]_RL Battery voltage of rear-left transmitter drops.

C1728 RECEIVER_ID_NO_REG ID registration of receiver is not completed.WT-33

C1729 VHCL_SPEED_SIG_ERR Vehicle speed signal is error.WT-34

C1750 [RECEIVER_ERR]_FL Data from front-left receiver cannot be received.

WT-31

C1751 [RECEIVER_ERR]_FR Data from front-right receiver cannot be received.

C1752 [RECEIVER_ERR]_RR Data from rear-right receiver cannot be received.

C1753 [RECEIVER_ERR]_RL Data from rear-left receiver cannot be received.

U1000 CAN COMM CIRCUITWhen a control unit (except for low tire pressure) is not transmit-

ting or receiving CAN communication signal 2 seconds or less. WT-34

Page 5548 of 5621

TROUBLE DIAGNOSES

WT-23

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

NOTICE:

186 kPa (1.86 kg/cm2 , 27 psi): Standard air pressure is for 230 kpa (2.3 kg/cm2 , 33 psi) vehicles.

How to Erase Self-Diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repair or replace.

2. Start engine, and touch “START (NISSAN BASED VHCL)” “ AIR PRESSURE MONITOR” “SELF-DIAG

RESULTS” “ERASE” in this order to erase the diagnostic memory.

CAUTION:

If memory cannot be erased, repeat step 1, 2.

3. Perform self-diagnosis again, and make sure that DTC memory is erased.

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS. Also, any malfunction

detected while in this mode will be displayed in real time.

Display Item List

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or else the actual malfunction location may be different from that dis-

played on CONSULT-II.

ACTIVE TEST MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. “ACTIVE TEST” is displayed.

Display Item List

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or else the actual malfunction location may be different from that dis-

played on CONSULT-II.MONITOR CONDITION SPECIFICATION

VEHICLE SPEED SE Drive vehicle. Vehicle speed (km/h or MPH)

AIR PRESS FL

AIR PRESS FR

AIR PRESS RR

AIR PRESS RL

Drive vehicle for a few minutes.

Tire pressure (kPa or Psi) or

Ignition switch ON and activation tool

is transmitting activation signals.

ID REGST FL 1

ID REGST FR 1

ID REGST RR 1

ID REGST RL 1

Ignition switch ONRegistration ID: DONE

No registration ID: YET

WARNING LAMPLow tire pressure warning lamp on: ON

Low tire pressure warning lamp off: OFF

BUZZERBuzzer in combination meter on: ON

Buzzer in combination meter off: OFF

Test item Content

BUZZER This test is able to check to make sure that the buzzer sounds.

WARNING LAMP This test is able to check to make sure that the warning lamp turns on.

HAZARD LAMP This test is able to check to make sure that hazard lamp turns on.