turn signal INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 5548 of 5621

TROUBLE DIAGNOSES

WT-23

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

NOTICE:

186 kPa (1.86 kg/cm2 , 27 psi): Standard air pressure is for 230 kpa (2.3 kg/cm2 , 33 psi) vehicles.

How to Erase Self-Diagnostic Results

1. Perform applicable inspection of malfunctioning item and then repair or replace.

2. Start engine, and touch “START (NISSAN BASED VHCL)” “ AIR PRESSURE MONITOR” “SELF-DIAG

RESULTS” “ERASE” in this order to erase the diagnostic memory.

CAUTION:

If memory cannot be erased, repeat step 1, 2.

3. Perform self-diagnosis again, and make sure that DTC memory is erased.

DATA MONITOR MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. Touch “DATA MONITOR”.

3. Select from “SELECT MONITOR ITEM”, screen of data monitor is displayed.

NOTE:

When malfunction is detected, CONSULT-II performs REAL-TIME DIAGNOSIS. Also, any malfunction

detected while in this mode will be displayed in real time.

Display Item List

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or else the actual malfunction location may be different from that dis-

played on CONSULT-II.

ACTIVE TEST MODE

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. “ACTIVE TEST” is displayed.

Display Item List

NOTE:

Before performing the self-diagnosis, be sure to register the ID, or else the actual malfunction location may be different from that dis-

played on CONSULT-II.MONITOR CONDITION SPECIFICATION

VEHICLE SPEED SE Drive vehicle. Vehicle speed (km/h or MPH)

AIR PRESS FL

AIR PRESS FR

AIR PRESS RR

AIR PRESS RL

Drive vehicle for a few minutes.

Tire pressure (kPa or Psi) or

Ignition switch ON and activation tool

is transmitting activation signals.

ID REGST FL 1

ID REGST FR 1

ID REGST RR 1

ID REGST RL 1

Ignition switch ONRegistration ID: DONE

No registration ID: YET

WARNING LAMPLow tire pressure warning lamp on: ON

Low tire pressure warning lamp off: OFF

BUZZERBuzzer in combination meter on: ON

Buzzer in combination meter off: OFF

Test item Content

BUZZER This test is able to check to make sure that the buzzer sounds.

WARNING LAMP This test is able to check to make sure that the warning lamp turns on.

HAZARD LAMP This test is able to check to make sure that hazard lamp turns on.

Page 5549 of 5621

WT-24

TROUBLE DIAGNOSES

Revision: 2006 January2006 M35/M45

LOW TIRE PRESSURE WARNING CONTROL UNIT PART NUMBER

Operation Procedure

1. Perform “CONSULT-II Start Procedure”. Refer to GI-39, "CONSULT-II Start Procedure" .

2. The part number described on low tire pressure warning control unit sticker is displayed.

Diagnosis Procedure with Warning Lamp Function (Without CONSULT-II)NES000K6

DESCRIPTION

During driving, the low tire pressure warning system receives the signal transmitted from the transmitter

installed in each wheel, and gives alarms when the tire pressure becomes low. The control unit (low tire pres-

sure warning control unit) of this system has pressure judgement and trouble diagnosis functions.

FUNCTION

When the low tire pressure warning system detects low inflation pressure or another unusual symptom, the

warning lamps in the combination meter comes on. To start the self-diagnostic results mode, ground terminal

of the tire pressure warning check connector. The malfunction location is indicated by the warning lamp flash-

ing and the buzzer sounds. Regarding location of tire pressure warning check connector, refer to PG-63,

"HARNESS" .

LOW TIRE PRESSURE WARNING LAMP DIAGNOSTIC CHART

Diagnosis

ItemSymptom

(Ignition switch ON)Low tire pressure warning lamp Cause Action

Low tire pres-

sure warning

lampWarning light comes

on immediately and

turns off after 1 sec-

ond.All wheel transmit-

ters are “activated”

(working).None (system OK)

Warning light blinks

on for 2 seconds,

then turns off for 0.2

seconds-repeats.All wheel transmit-

ters are not acti-

vated.Activate all wheel tire pres-

sure transmitters. Refer to

WT-21, "

Transmitter Wake Up

Operation" .

Warning light blinks

1 time.Tire pressure trans-

mitter front LH is not

activated.Activate tire pressure trans-

mitter front LH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

Warning light blinks

2 times.Tire pressure trans-

mitter front RH is not

activated.Activate tire pressure trans-

mitter front RH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

Warning light blinks

3 times.Tire pressure trans-

mitter rear RH is not

activated.Activate tire pressure trans-

mitter rear RH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

SEIA0592E

SEIA0593E

SEIA0594E

SEIA0595E

SEIA0596E

Page 5550 of 5621

TROUBLE DIAGNOSES

WT-25

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

NOTE:

If more than one wheel transmitter is NOT activated, the warning lamp blinking patterns for those wheels will combine. (Example: one

blink/OFF/three blinks = Tire pressure transmitter rear LH and rear RH are not activated.) Low tire pres-

sure warning

lampWarning light blinks

4 times.Tire pressure trans-

mitter rear LH is not

activated.Activate tire pressure trans-

mitter rear LH. Refer to WT-

21, "Transmitter Wake Up

Operation" .

Warning light comes

on and does not turn

off.Tire pressure is low.Check tire pressure with

CONSULT-II. Refer to WT-23,

"DATA MONITOR MODE" .

The fuse for combi-

nation meter from

battery is pulled out.Check the fuse for combina-

tion meter from battery. Install

or replace (if needed).

Low tire pressure

warning control unit

connector pulled outCheck low tire pressure warn-

ing control unit connector. Re-

connect if needed.

Low tire pressure or

low tire pressure

warning system mal-

function.

Perform CONSULT-II Self-

Diagnosis. Refer to WT-22,

"SELF-DIAG RESULT

MODE" .

–Perform ID Registration if

needed. Refer to WT-19,

"ID Registration Procedure"

.

Turn signal

lampTurn signal lamp

does not flash 2

times or buzzer does

not sound after

transmitter activa-

tion.—1. Tool J-45295

[SST]

2. Ignition OFF dur-

ing activation.

3. Tool J-45295

[SST] not posi-

tioned correctly.

4. Transmitters

already activated.1. Install new battery.

2. Make sure ignition is ON

during activation.

3. Position tool correctly dur-

ing activation.

4. None Diagnosis

ItemSymptom

(Ignition switch ON)Low tire pressure warning lamp Cause Action

SEIA0597E

SEIA0598E

Page 5554 of 5621

TROUBLE DIAGNOSES

WT-29

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

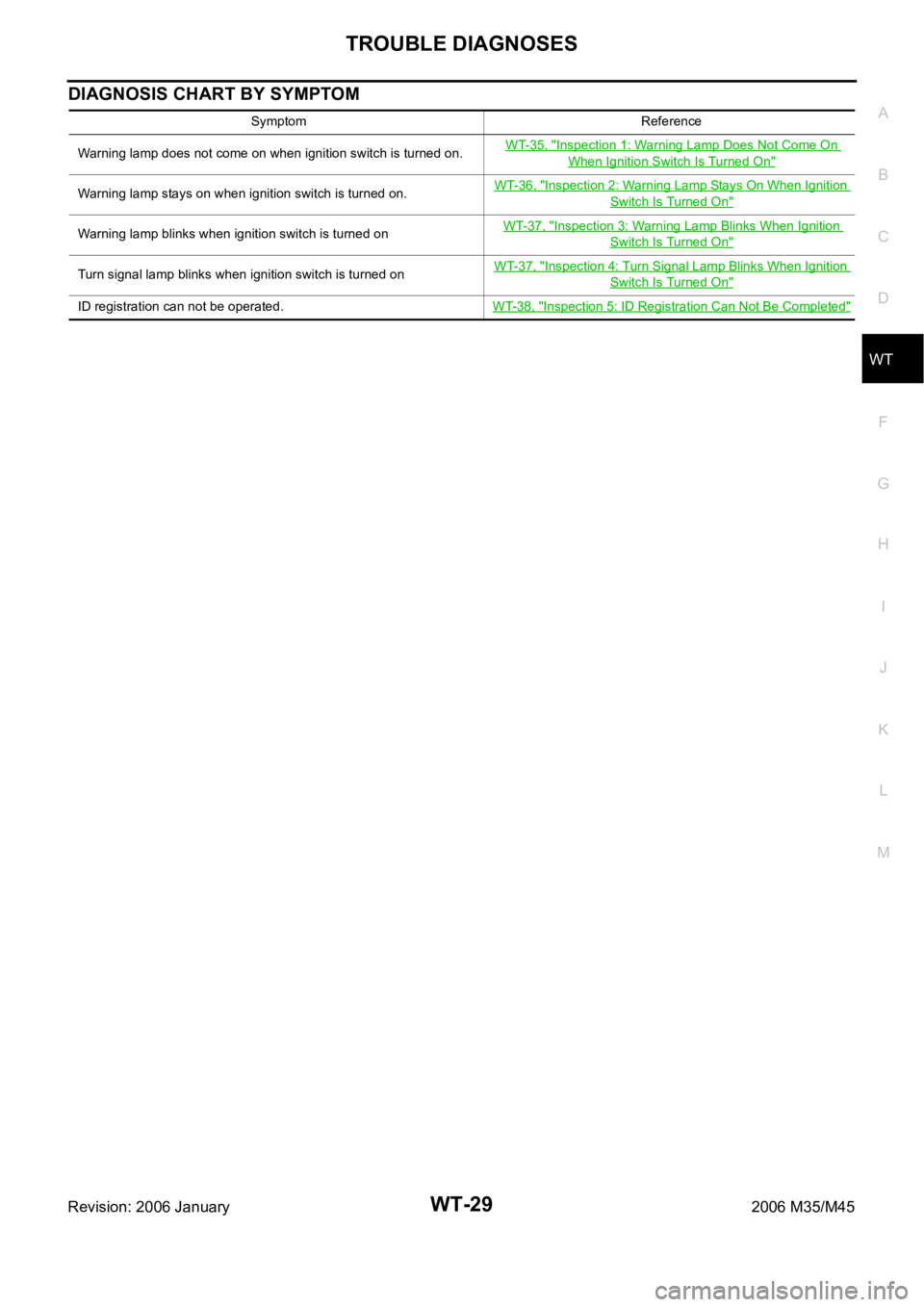

DIAGNOSIS CHART BY SYMPTOM

Symptom Reference

Warning lamp does not come on when ignition switch is turned on.WT-35, "

Inspection 1: Warning Lamp Does Not Come On

When Ignition Switch Is Turned On"

Warning lamp stays on when ignition switch is turned on.WT-36, "Inspection 2: Warning Lamp Stays On When Ignition

Switch Is Turned On"

Warning lamp blinks when ignition switch is turned onWT-37, "Inspection 3: Warning Lamp Blinks When Ignition

Switch Is Turned On"

Turn signal lamp blinks when ignition switch is turned onWT-37, "Inspection 4: Turn Signal Lamp Blinks When Ignition

Switch Is Turned On"

ID registration can not be operated.WT-38, "Inspection 5: ID Registration Can Not Be Completed"

Page 5559 of 5621

WT-34

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Revision: 2006 January2006 M35/M45

2. REPLACE TIRE PRESSURE TRANSMITTER

1. Check low tire pressure warning condition again, and replace malfunctioning tire pressure transmitter.

2. Perform ID registration of all transmitter.

Can ID registration of all tire pressure transmitters be completed?

YES >> GO TO 3.

NO >> GO TO the inspection 1. Refer to WT-30, "

Inspection 1: Transmitter no Data" .

3. VEHICLE DRIVING

Drive at a speed of 40 km/h (25 MPH) or more for 3 minutes, and then drive the vehicle at any speed for 10

minutes. Then check all tire pressures with CONSULT-II “DATA MONITOR” within 5 minutes.

Does

“DATA MONITOR” display tire pressure as normal without any warning lamp?

YES >> INSPECTION END

NO >> Replace malfunctioning transmitter, and perform “Step 3” again.

Inspection 7: Vehicle Speed SignalNES000KG

MALFUNCTION CODE NO. 52

1. CHECK SELF-DIAGNOSIS RESULTS

1. Turn ignition switch OFF.

2. Connect CONSULT-II and CONSULT-II CONVERTER to data link connector.

3. Turn ignition switch ON.

4. Touch “START (NISSAN BASED VHCL)” “AIR PRESSURE MONITOR”.

–If “AIR PRESSURE MONITOR” is not displayed, print the “SELECT SYSTEM” screen. Then refer to LAN-

7, "Precautions When Using CONSULT-II" .

NOTE:

Just after starting engine, or turning ignition switch ON, it may not be displayed even if “START (NISSAN

BASED VHCL)” is touched. In this case, reconnect CONSULT-II and CONSULT-II CONVERTER.

5. Touch “SELF-DIAG RESULTS” on “SELECT DIAG MODE” screen.

6. Check display contents in self-diagnostic results.

Is

“CAN COMM CIRCUIT” displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. GO TO LAN-7, "Precautions When Using CONSULT-

II" .

NO >> No malfunction. Check combination meter refer to DI-18, "

Trouble Diagnosis" .

Inspection 8: CAN Communication System MalfunctionNES000KS

1. CHECK LOW TIRE PRESSURE WARNING CONTROL UNIT CONNECTOR

1. Turn ignition switch OFF, disconnect low tire pressure warning control unit harness connector, and check

terminal for deformation, disconnection, looseness, etc.

2. Reconnect harness connector securely, and perform CONSULT-II self-diagnosis.

Is above displayed on self-diagnosis display?

YES >> If “CAN COMM CIRCUIT [U1000]” is displayed, print out self-diagnosis. And then, go to LAN-7,

"Precautions When Using CONSULT-II" .

NO >> Connector terminal connection is loose, damaged, open, or shorted. Repair or replace the termi-

nal.

Self-diagnostic results

CAN COMM CIRCUIT [U1000]

Page 5562 of 5621

TROUBLE DIAGNOSIS FOR SYMPTOMS

WT-37

C

D

F

G

H

I

J

K

L

MA

B

WT

Revision: 2006 January2006 M35/M45

Inspection 3: Warning Lamp Blinks When Ignition Switch Is Turned OnNES000KJ

NOTE:

If warning lamp blinks below, the system is normal.

Blink Mode A

This mode shows transmitter status is in OFF-mode.

Perform transmitter wake up operation. Refer to WT-21, "

Trans-

mitter Wake Up Operation" .

1. CHECK CONNECTOR

1. Disconnect low tire pressure warning control unit harness connector M19.

2. Check terminals for damage or loose connections.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2. CHECK TIRE PRESSURE WARNING CHECK SWITCH CIRCUIT

Check continuity between low tire pressure warning control unit har-

ness connector M19 and ground.

OK or NG

OK >> Replace low tire pressure warning control unit. Refer to

WT-40, "

Low Tire Pressure Warning Control Unit" .

NG >> Repair or replace harness connector.

Inspection 4: Turn Signal Lamp Blinks When Ignition Switch Is Turned OnNES000KK

1. CHECK TIRE PRESSURE WARNING CHECK SWITCH CIRCUIT

Check continuity between low tire pressure warning control unit har-

ness connector M19 and ground.

OK or NG

OK >> Check turn signal lamp operation. Refer to LT- 2 11 , "Sys-

tem Description" .

NG >> Repair or replace harness connector.

SEIA0347E

Terminal

Continuity

(+) (–)

5 Ground No

SEIA0658E

Terminal

Continuity

(+) (–)

5Ground No

SEIA0658E

Page 5571 of 5621

WW-4

FRONT WIPER AND WASHER SYSTEM

Revision: 2006 January2006 M35/M45

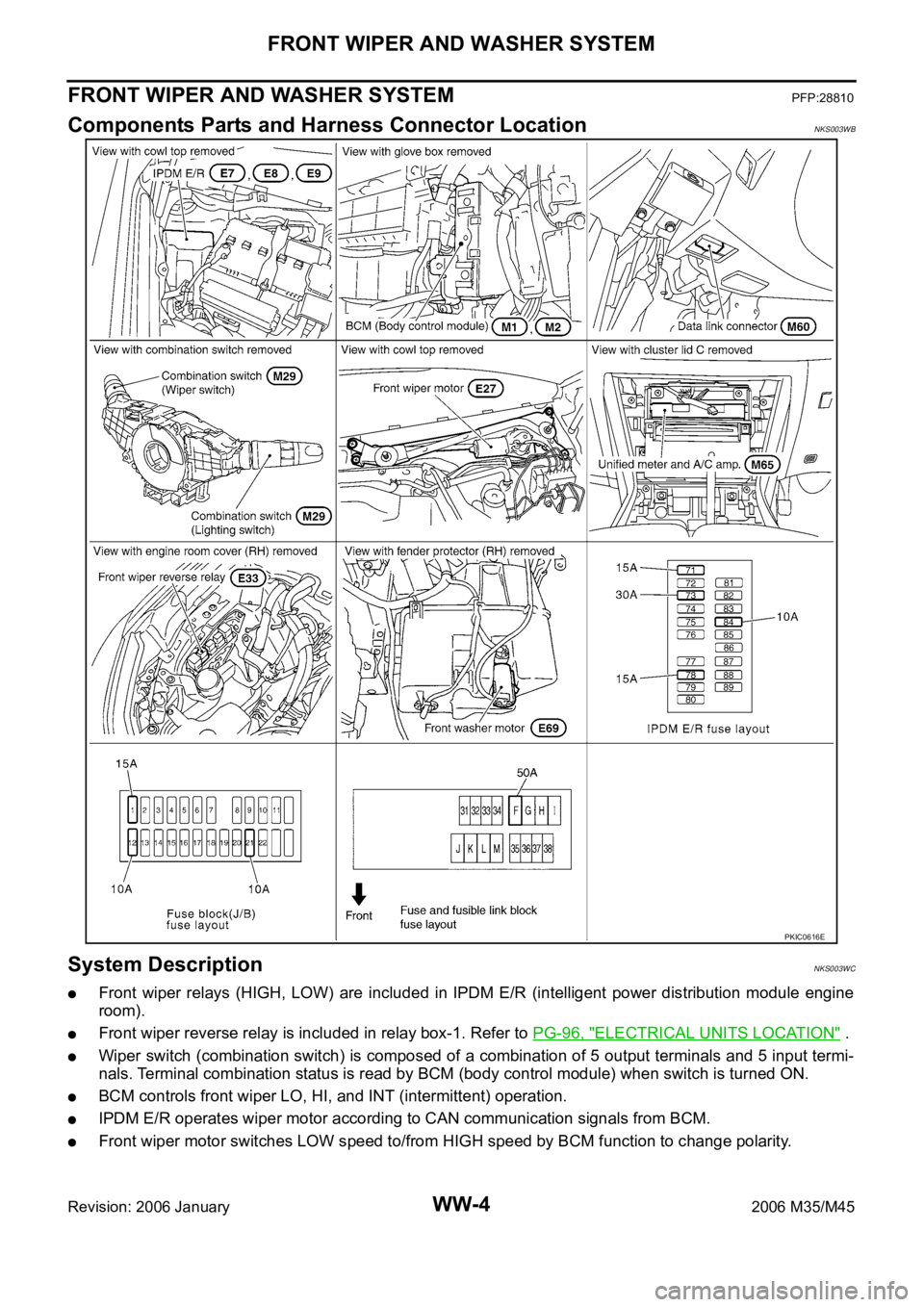

FRONT WIPER AND WASHER SYSTEMPFP:28810

Components Parts and Harness Connector LocationNKS003WB

System DescriptionNKS003WC

Front wiper relays (HIGH, LOW) are included in IPDM E/R (intelligent power distribution module engine

room).

Front wiper reverse relay is included in relay box-1. Refer to PG-96, "ELECTRICAL UNITS LOCATION" .

Wiper switch (combination switch) is composed of a combination of 5 output terminals and 5 input termi-

nals. Terminal combination status is read by BCM (body control module) when switch is turned ON.

BCM controls front wiper LO, HI, and INT (intermittent) operation.

IPDM E/R operates wiper motor according to CAN communication signals from BCM.

Front wiper motor switches LOW speed to/from HIGH speed by BCM function to change polarity.

PKIC0616E

Page 5572 of 5621

FRONT WIPER AND WASHER SYSTEM

WW-5

C

D

E

F

G

H

I

J

L

MA

B

WW

Revision: 2006 January2006 M35/M45

OUTLINE

Power is supplied at all times

to ignition relay, located in IPDM E/R, from battery directly,

through 50 A fusible link (letter F, located in fuse and fusible link block)

to BCM terminal 55,

through 10 A fuse [No. 21, located in fuse block (J/B)]

to BCM terminal 42,

through 30 A fuse (No. 73, located in IPDM E/R)

to front wiper low relay, located in IPDM E/R

to front wiper reverse relay terminal 5,

through 15 A fuse (No. 78, located in IPDM E/R)

to CPU (central processing unit) located in IPDM E/R,

through 15 A fuse (No. 71, located in IPDM E/R)

to CPU located in IPDM E/R.

With the ignition switch in the ON or START position, power is supplied

to ignition relay, located in IPDM E/R,

through 15 A fuse [No. 1, located in fuse block (J/B)]

to BCM terminal 38,

through 10 A fuse [No. 12, located in fuse block (J/B)]

to front wiper reverse relay terminal 1,

through 10 A fuse (No. 84, located in IPDM E/R)

to combination switch terminal 11

to front wiper motor terminal 4.

Ground is supplied

to BCM terminal 52

through grounds M16 and M70,

to IPDM E/R terminals 38 and 51

through grounds E22 and E43,

to combination switch terminal 12

through grounds M16 and M70.

LOW SPEED WIPER OPERATION

When wiper switch is in the LO position, BCM detects low speed wiper ON signal by BCM wiper switch read-

ing function.

BCM sends front wiper request signal (LO) with CAN communication line

from BCM terminals 39 and 40

to IPDM E/R terminals 49 and 50.

When IPDM E/R receives front wiper request signal (LO), it turns ON front wiper low relay, located in IPDM

E/R, power is supplied

through IPDM E/R terminal 23 and front wiper high relay and front wiper low relay

to front wiper motor terminal 3.

Ground is supplied

to front wiper motor terminal 1

through front wiper reverse relay terminals 3 and 4

through grounds E22 and E43.

With power and ground supplied, the front wiper motor operates at low speed.

Page 5573 of 5621

WW-6

FRONT WIPER AND WASHER SYSTEM

Revision: 2006 January2006 M35/M45

HIGH SPEED WIPER OPERATION

When wiper switch is in the HI position, BCM detects high speed wiper ON signal by BCM wiper switch read-

ing function.

BCM sends front wiper request signal (HI) with CAN communication line

from BCM terminals 39 and 40

to IPDM E/R terminals 49 and 50.

When IPDM E/R receives front wiper request signal (HI), it turns ON front wiper high relay (located in IPDM

E/R) and front wiper reverse relay (located in relay box-1), power is supplied

through IPDM E/R terminal 19

through front wiper reverse relay terminals 5 and 3

to front wiper motor terminal 1.

Ground is supplied

to front wiper motor terminal 2

to IPDM E/R terminal 31 and front wiper high relay and front wiper low relay

to IPDM E/R terminal 38

through grounds E22 and E43.

With power and ground supplied, the front wiper motor operates at high speed.

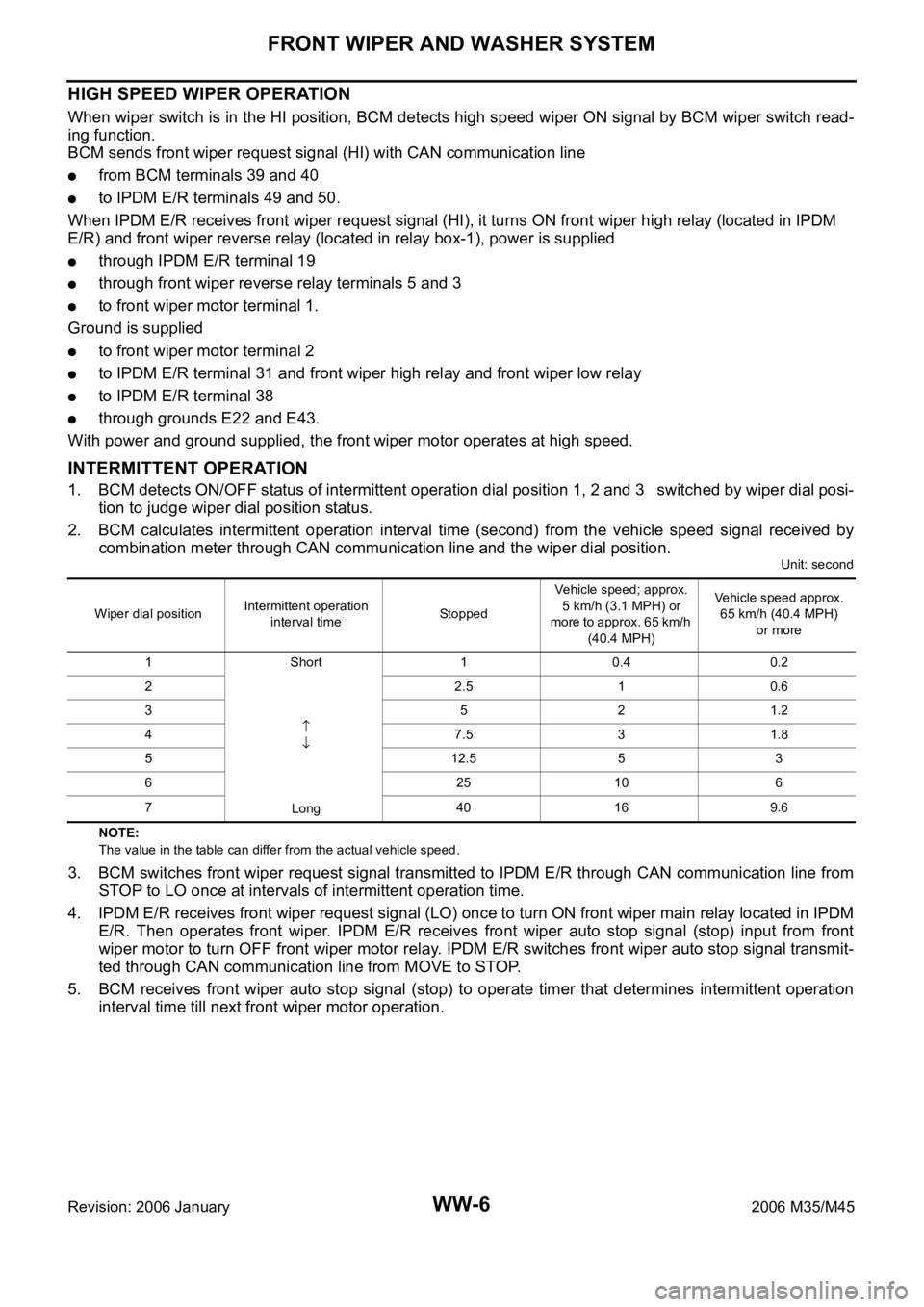

INTERMITTENT OPERATION

1. BCM detects ON/OFF status of intermittent operation dial position 1, 2 and 3 switched by wiper dial posi-

tion to judge wiper dial position status.

2. BCM calculates intermittent operation interval time (second) from the vehicle speed signal received by

combination meter through CAN communication line and the wiper dial position.

Unit: second

NOTE:

The value in the table can differ from the actual vehicle speed.

3. BCM switches front wiper request signal transmitted to IPDM E/R through CAN communication line from

STOP to LO once at intervals of intermittent operation time.

4. IPDM E/R receives front wiper request signal (LO) once to turn ON front wiper main relay located in IPDM

E/R. Then operates front wiper. IPDM E/R receives front wiper auto stop signal (stop) input from front

wiper motor to turn OFF front wiper motor relay. IPDM E/R switches front wiper auto stop signal transmit-

ted through CAN communication line from MOVE to STOP.

5. BCM receives front wiper auto stop signal (stop) to operate timer that determines intermittent operation

interval time till next front wiper motor operation.

Wiper dial positionIntermittent operation

interval timeStoppedVehicle speed; approx.

5 km/h (3.1 MPH) or

more to approx. 65 km/h

(40.4 MPH)Vehicle speed approx.

65 km/h (40.4 MPH)

or more

1 Short

Long10.40.2

2 2.510.6

3521.2

4 7.531.8

5 12.5 5 3

625106

740169.6

Page 5574 of 5621

FRONT WIPER AND WASHER SYSTEM

WW-7

C

D

E

F

G

H

I

J

L

MA

B

WW

Revision: 2006 January2006 M35/M45

AUTO STOP OPERATION

With wiper switch turned OFF, wiper motor will continue to operate until wiper arms reach windshield base.

When wiper arms are not located at base of windshield with wiper switch OFF, ground is provided

from IPDM E/R terminal 23

to front wiper motor terminal 3, in order to continue wiper motor operation at low speed.

When wiper arms reach base of windshield, front wiper motor terminals 4 and 5 are connected

to IPDM E/R terminal 32

through front wiper motor terminals 4 and 5.

Then the IPDM E/R sends auto stop operation signal to BCM with CAN communication line.

When BCM receives auto stop operation signal, BCM sends wiper stop signal to IPDM E/R with CAN commu-

nication line.

IPDM E/R stops wiper motor. Wiper motor will then stop wiper arms at the STOP position.

WAS H ER O P E R ATI O N

When wiper switch is in front wiper washer position with ignition switch ON, BCM detects front wiper washer

signal by BCM wiper switch reading function (refer to BCS-3, "

COMBINATION SWITCH READING FUNC-

TION" ). Combination switch ground is supplied

to front washer motor terminal 2

through combination switch terminal 14

to combination switch terminal 12

through grounds M16 and M70.

And power is supplied

through combination switch terminal 13

to front washer motor terminal 1.

With power and ground supplied, front washer motor is operated.

When BCM detects that front washer motor has operated for 0.4 seconds or longer, BCM operates front wiper

motor for low speed.

When BCM detects washer switch is OFF, low speed operation cycles approximately 2 times and stops.

MIST OPERATION

When the wiper switch is turned to the MIST position, wiper low speed operation cycles once and then stops.

For additional information about wiper operation under this condition, refer to WW-5, "

LOW SPEED WIPER

OPERATION" .

If the switch is held in the MIST position, low speed operation continues.

FAIL-SAFE FUNCTION

If an abnormality occurs in CAN communications, IPDM E/R holds the condition just before fail-safe status is

initiated until ignition switch is turned OFF. (If wipers were operating in LO just before the initiation of fail-safe

status, they continue to operate in LOW until ignition switch is turned OFF.)