headlamp INFINITI M35 2006 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2006, Model line: M35, Model: INFINITI M35 2006Pages: 5621, PDF Size: 65.56 MB

Page 22 of 5621

![INFINITI M35 2006 Factory Service Manual LASER BEAM AIMING ADJUSTMENT

ACS-13

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

LASER BEAM AIMING ADJUSTMENTPFP:00026

OutlineNKS004CM

Adjust the laser beam aiming every time th INFINITI M35 2006 Factory Service Manual LASER BEAM AIMING ADJUSTMENT

ACS-13

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

LASER BEAM AIMING ADJUSTMENTPFP:00026

OutlineNKS004CM

Adjust the laser beam aiming every time th](/img/42/57023/w960_57023-21.png)

LASER BEAM AIMING ADJUSTMENT

ACS-13

[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

Revision: 2006 January2006 M35/M45

LASER BEAM AIMING ADJUSTMENTPFP:00026

OutlineNKS004CM

Adjust the laser beam aiming every time the ICC sensor integrated unit is removed or installed.

CAUTION:

Adjust laser beam aiming at a horizontal place as far as 12 m (39 ft) forward the vehicle can be

seen.

Adjust laser beam aiming 5 seconds after starting engine.

Never view ICC sensor integrated unit body window directly during laser beam aiming adjustment.

Follow the CONSULT-II when adjusting the laser beam aiming (laser beam aiming adjustment can-

not be operated without CONSULT-II).

Never ride on vehicle during laser beam aiming adjustment.

Idle and turn headlamps OFF during laser beam aiming adjustment.

PreparationNKS004CN

Adjust the tire pressure to the specified value.

See that there is no load in the vehicle.

Coolant, engine oil filled up to correct level and full fuel tank.

Shift the gear into “P” position and release the parking brake.

Clean the ICC sensor integrated unit with a soft cloth.

Remove the front bumper grille. Refer to EI-13, "Removal and

Installation of Front Bumper Grille" .

Outline of Adjustment ProcedureNKS004CO

1. Set up the ICC target board [KV99110100 (J-45718)].

2. Adjust the sensor following the procedure on CONSULT-II. (Turn manually the screw for up-down position

adjustment. ICC sensor integrated unit automatically adjust the right-left position.)

Setting the ICC Target BoardNKS004CP

Accurate ICC target board setting is required for the laser beam aiming adjustment.

CAUTION:

ICC system does not function normally if laser beam aiming is not accurate.

ADJUSTING HEIGHT OF THE TARGET

1. Attach a triangle scale at 28 mm (1.10 in) below the center.

PKIB8350E

PKIB8351E

Page 925 of 5621

BCS-4

BCM (BODY CONTROL MODULE)

Revision: 2006 January2006 M35/M45

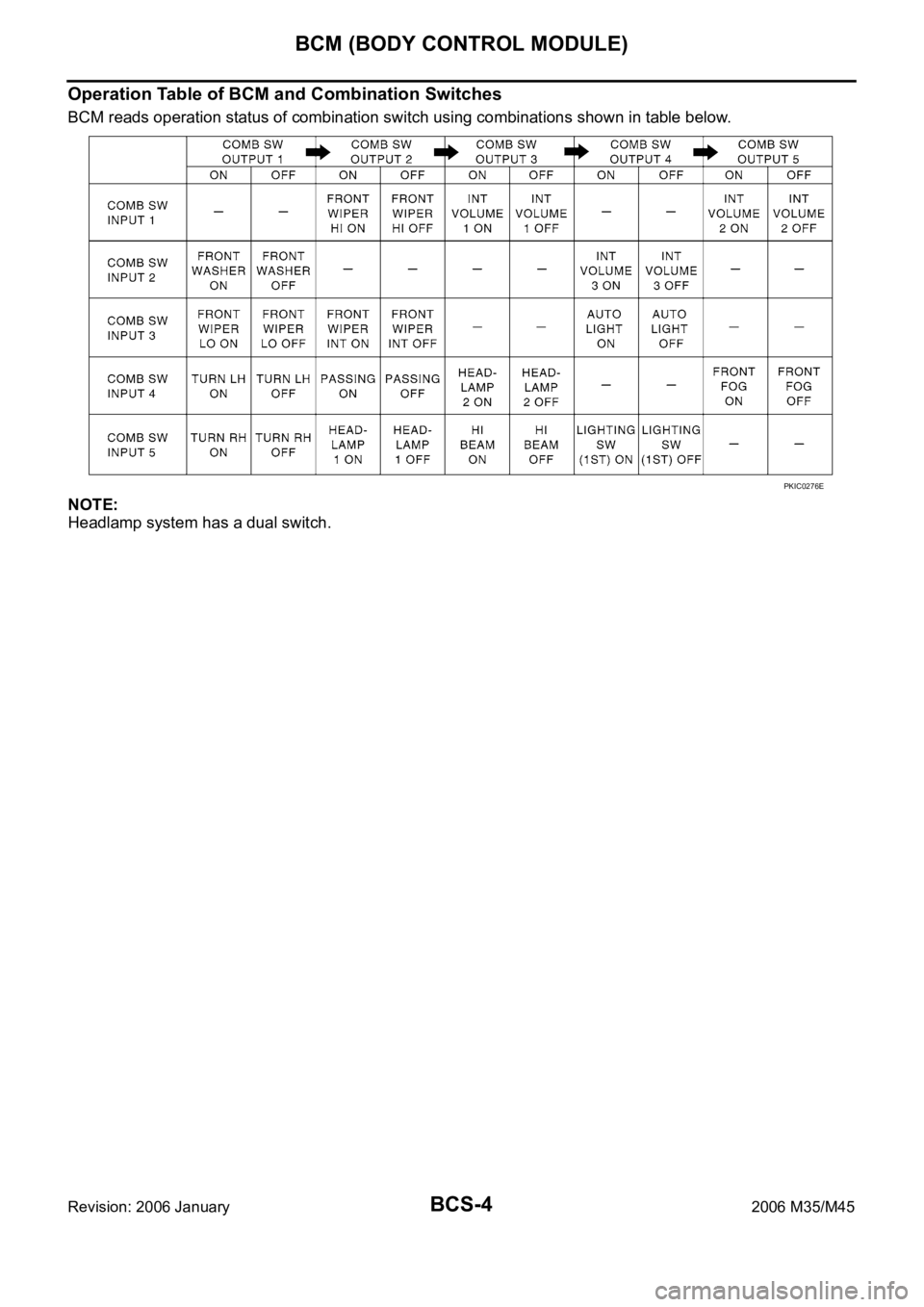

Operation Table of BCM and Combination Switches

BCM reads operation status of combination switch using combinations shown in table below.

NOTE:

Headlamp system has a dual switch.

PKIC0276E

Page 929 of 5621

BCS-8

BCM (BODY CONTROL MODULE)

Revision: 2006 January2006 M35/M45

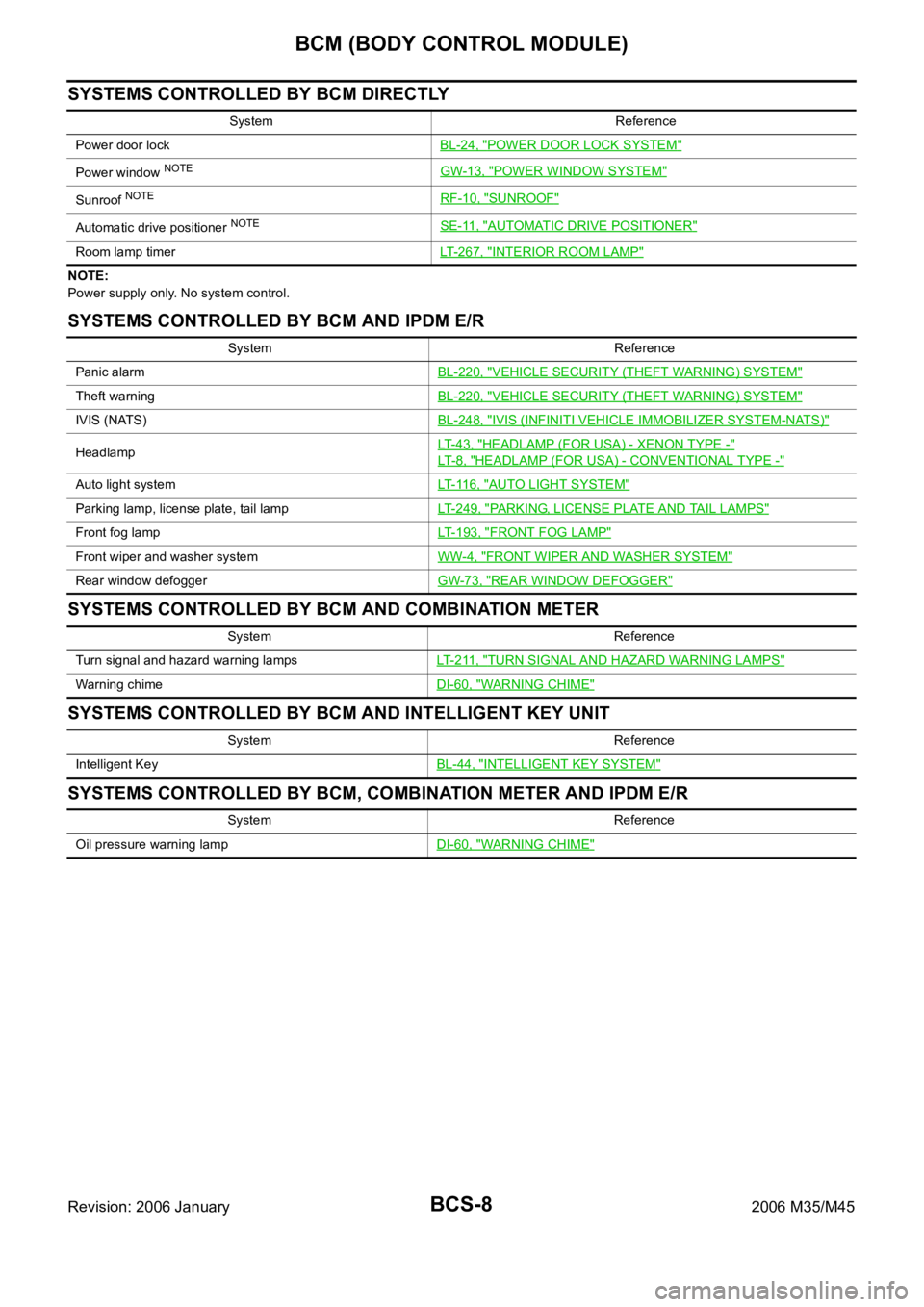

SYSTEMS CONTROLLED BY BCM DIRECTLY

NOTE:

Power supply only. No system control.

SYSTEMS CONTROLLED BY BCM AND IPDM E/R

SYSTEMS CONTROLLED BY BCM AND COMBINATION METER

SYSTEMS CONTROLLED BY BCM AND INTELLIGENT KEY UNIT

SYSTEMS CONTROLLED BY BCM, COMBINATION METER AND IPDM E/R

System Reference

Power door lockBL-24, "

POWER DOOR LOCK SYSTEM"

Power window NOTEGW-13, "POWER WINDOW SYSTEM"

Sunroof NOTERF-10, "SUNROOF"

Automatic drive positioner NOTESE-11, "AUTOMATIC DRIVE POSITIONER"

Room lamp timerLT-267, "INTERIOR ROOM LAMP"

System Reference

Panic alarmBL-220, "

VEHICLE SECURITY (THEFT WARNING) SYSTEM"

Theft warningBL-220, "VEHICLE SECURITY (THEFT WARNING) SYSTEM"

IVIS (NATS)BL-248, "IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-NATS)"

HeadlampLT- 4 3 , "HEADLAMP (FOR USA) - XENON TYPE -"

LT- 8 , "HEADLAMP (FOR USA) - CONVENTIONAL TYPE -"

Auto light systemLT- 11 6 , "AUTO LIGHT SYSTEM"

Parking lamp, license plate, tail lampLT-249, "PARKING, LICENSE PLATE AND TAIL LAMPS"

Front fog lampLT-193, "FRONT FOG LAMP"

Front wiper and washer systemWW-4, "FRONT WIPER AND WASHER SYSTEM"

Rear window defoggerGW-73, "REAR WINDOW DEFOGGER"

System Reference

Turn signal and hazard warning lampsLT- 2 11 , "

TURN SIGNAL AND HAZARD WARNING LAMPS"

Warning chimeDI-60, "WARNING CHIME"

System Reference

Intelligent KeyBL-44, "

INTELLIGENT KEY SYSTEM"

System Reference

Oil pressure warning lampDI-60, "

WARNING CHIME"

Page 930 of 5621

BCM (BODY CONTROL MODULE)

BCS-9

C

D

E

F

G

H

I

J

L

MA

B

BCS

Revision: 2006 January2006 M35/M45

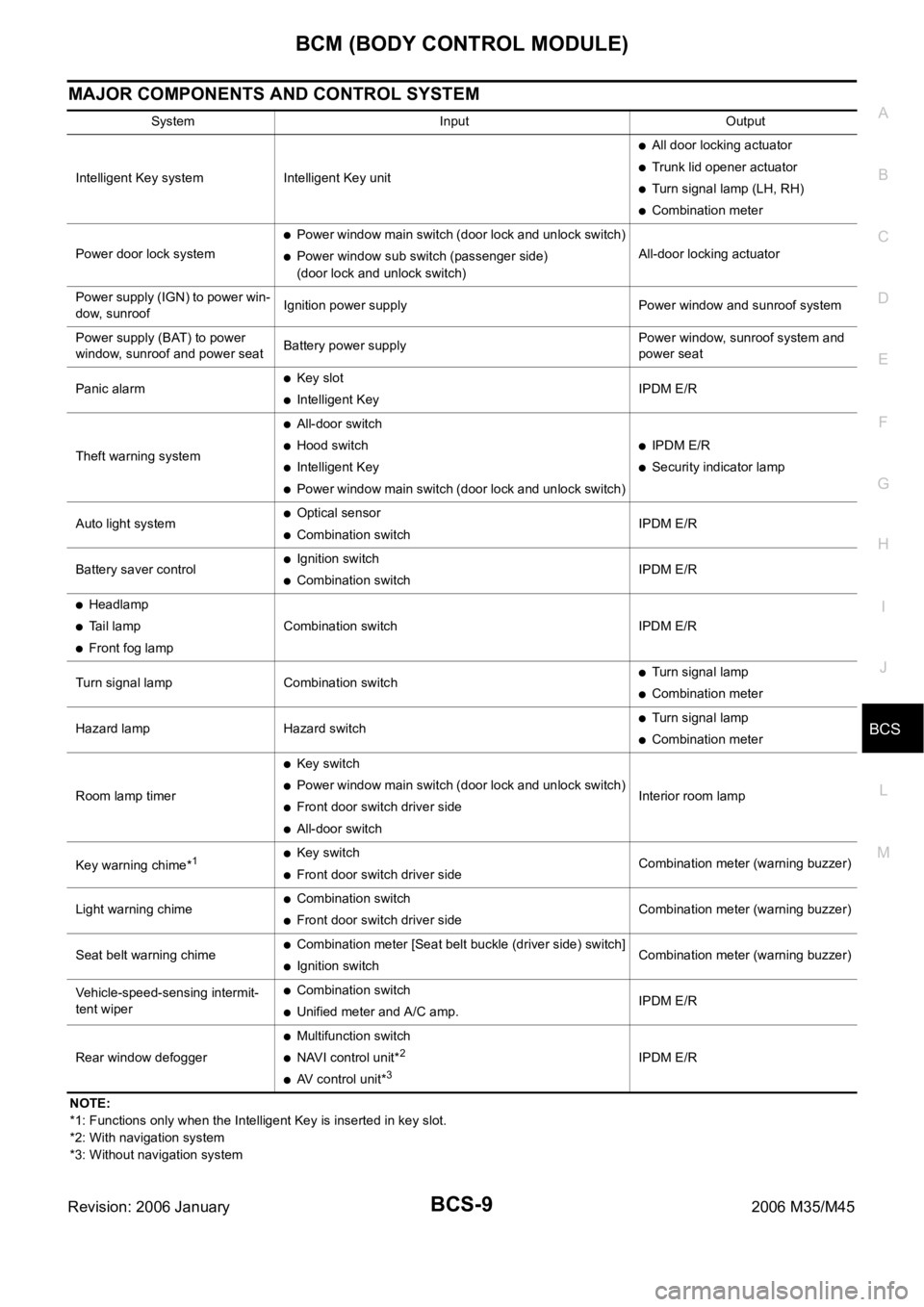

MAJOR COMPONENTS AND CONTROL SYSTEM

NOTE:

*1: Functions only when the Intelligent Key is inserted in key slot.

*2: With navigation system

*3: Without navigation systemSystem Input Output

Intelligent Key system Intelligent Key unit

All door locking actuator

Trunk lid opener actuator

Turn signal lamp (LH, RH)

Combination meter

Power door lock system

Power window main switch (door lock and unlock switch)

Power window sub switch (passenger side)

(door lock and unlock switch)All-door locking actuator

Power supply (IGN) to power win-

dow, sunroofIgnition power supply Power window and sunroof system

Power supply (BAT) to power

window, sunroof and power seatBattery power supplyPower window, sunroof system and

power seat

Panic alarm

Key slot

Intelligent KeyIPDM E/R

Theft warning system

All-door switch

Hood switch

Intelligent Key

Power window main switch (door lock and unlock switch)

IPDM E/R

Security indicator lamp

Auto light system

Optical sensor

Combination switchIPDM E/R

Battery saver control

Ignition switch

Combination switchIPDM E/R

Headlamp

Tail lamp

Front fog lampCombination switch IPDM E/R

Turn signal lamp Combination switch

Turn signal lamp

Combination meter

Hazard lamp Hazard switch

Turn signal lamp

Combination meter

Room lamp timer

Key switch

Power window main switch (door lock and unlock switch)

Front door switch driver side

All-door switchInterior room lamp

Key warning chime*

1Key switch

Front door switch driver sideCombination meter (warning buzzer)

Light warning chime

Combination switch

Front door switch driver sideCombination meter (warning buzzer)

Seat belt warning chime

Combination meter [Seat belt buckle (driver side) switch]

Ignition switchCombination meter (warning buzzer)

Vehicle-speed-sensing intermit-

tent wiper

Combination switch

Unified meter and A/C amp.IPDM E/R

Rear window defogger

Multifunction switch

NAVI control unit*2

AV control unit*3

IPDM E/R

Page 935 of 5621

BCS-14

BCM (BODY CONTROL MODULE)

Revision: 2006 January2006 M35/M45

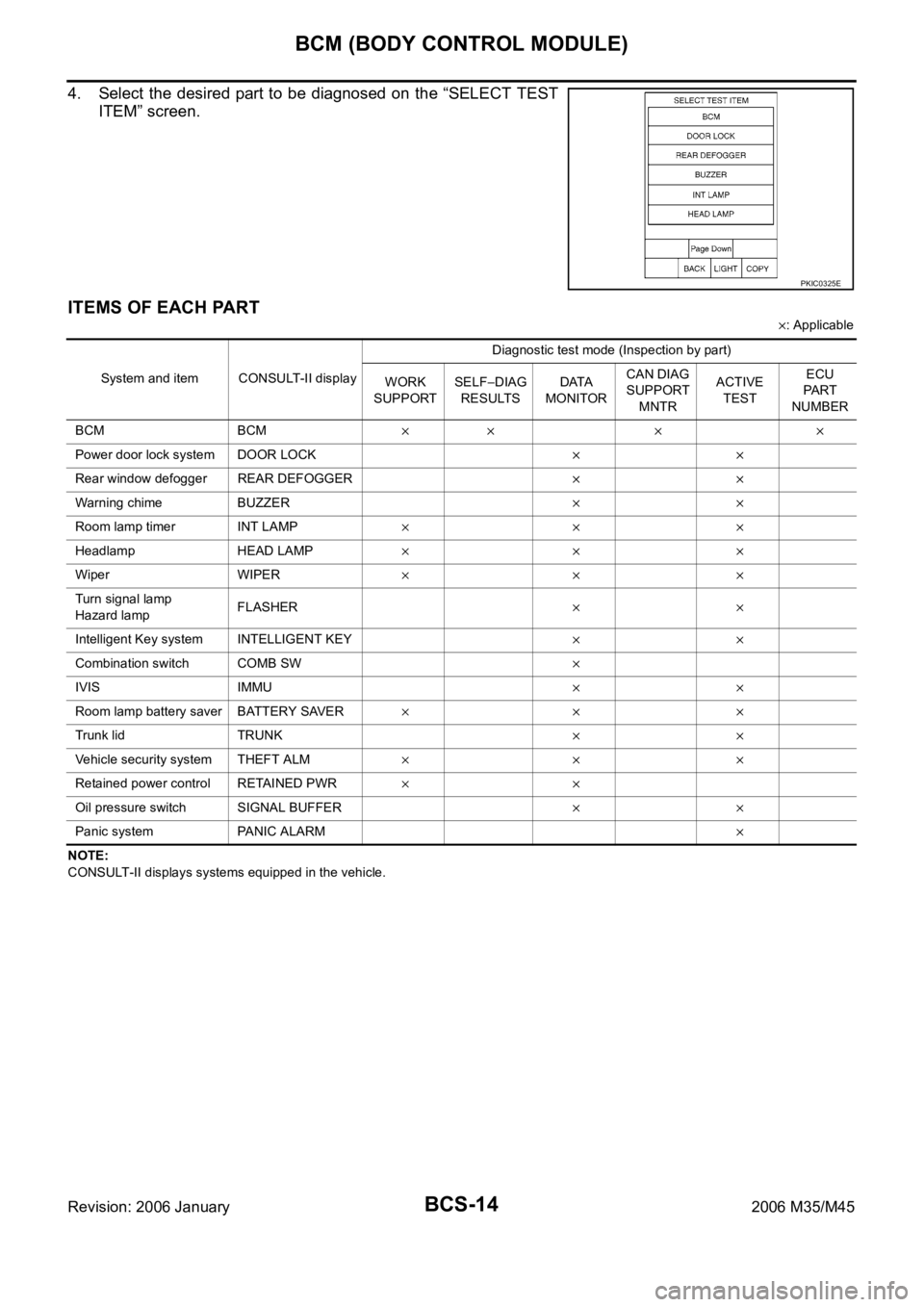

4. Select the desired part to be diagnosed on the “SELECT TEST

ITEM” screen.

ITEMS OF EACH PART

: Applicable

NOTE:

CONSULT-II displays systems equipped in the vehicle.

PKIC0325E

System and item CONSULT-II displayDiagnostic test mode (Inspection by part)

WORK

SUPPORTSELFDIAG

RESULTSDATA

MONITORCAN DIAG

SUPPORT

MNTRACTIVE

TESTECU

PA R T

NUMBER

BCM BCM

Power door lock system DOOR LOCK

Rear window defogger REAR DEFOGGER

Warning chime BUZZER

Room lamp timer INT LAMP

Headlamp HEAD LAMP

Wiper WIPER

Turn signal lamp

Hazard lampFLASHER

Intelligent Key system INTELLIGENT KEY

Combination switch COMB SW

IVIS IMMU

Room lamp battery saver BATTERY SAVER

Trunk lid TRUNK

Vehicle security system THEFT ALM

Retained power control RETAINED PWR

Oil pressure switch SIGNAL BUFFER

Panic system PANIC ALARM

Page 943 of 5621

BL-4Revision: 2006 January2006 M35/M45 Terminals and Reference Value for BCM ..............213

CONSULT-II Function (BCM) ................................214

CONSULT-II INSPECTION PROCEDURE ........214

DATA MONITOR ................................................215

ACTIVE TEST ...................................................215

Trouble Diagnosis .................................................216

TRUNK DOSE NOT OPEN WITH TRUNK LID

OPENER SWITCH / WITH INTELLIGENT KEY .216

VEHICLE SECURITY (THEFT WARNING) SYSTEM .220

Component Parts and Harness Connector Location .220

System Description ...............................................222

DESCRIPTION ..................................................222

POWER SUPPLY AND GROUND CIRCUIT .....223

INITIAL CONDITION TO ACTIVATE THE SYS-

TEM ...................................................................223

VEHICLE SECURITY SYSTEM ALARM OPER-

ATION ................................................................224

VEHICLE SECURITY SYSTEM DEACTIVATION .224

PANIC ALARM OPERATION .............................224

CAN Communication System Description ............224

CAN Communication Unit .....................................224

Schematic .............................................................225

Wiring Diagram —VEHSEC— ..............................226

Terminals and Reference Value of BCM ...............232

Terminals and Reference Value of IPDM E/R .......232

CONSULT-II Function (BCM) ................................233

CONSULT-II APPLICATION ITEM .....................234

Trouble Diagnosis Work Flow ...............................235

Preliminary Check ................................................235

Trouble Diagnosis Symptom Chart .......................237

Diagnostic Procedure 1 ........................................238

DOOR SWITCH CHECK ...................................238

HOOD SWITCH CHECK ...................................241

TRUNK ROOM LAMP SWITCH CHECK ..........243

Diagnostic Procedure 2 ........................................245

SECURITY INDICATOR LAMP CHECK ............245

Diagnostic Procedure 3 ........................................246

FRONT DOOR KEY CYLINDER SWITCH

CHECK ..............................................................246

Diagnostic Procedure 4 ........................................246

VEHICLE SECURITY HORN ALARM CHECK . 246

Diagnostic Procedure 5 ........................................247

VEHICLE SECURITY HEADLAMP ALARM

CHECK ..............................................................247

Diagnostic Procedure 6 ........................................247

DOOR LOCK AND UNLOCK SWITCH CHECK .247

Diagnostic Procedure 7 ........................................247

VEHCLE SECURITY HAZARD LAMP ALARM

CHECK ..............................................................247

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS) ......................................................................248

Component Parts and Harness Connector Location .248

System Description ...............................................250

DESCRIPTION ..................................................250

PRECAUTIONS FOR KEY REGISTRATION ....250

SECURITY INDICATOR ....................................250

Operation Description ...........................................251

SYSTEM DIAGRAM ..........................................251

OPERATION WHEN INSERTING TO KEY SLOT .251OPERATION WHEN INTELLIGENT KEY IS

CARRIED ...........................................................251

PUSH-BUTTON IGNITION SWITCH OPERA-

TION PROCEDURE ..........................................251

ECM Re-Communicating Function .......................252

Schematic .............................................................254

Wiring Diagram — NATS — ..................................256

Terminals and Reference Value for Intelligent Key

Unit ........................................................................264

Terminals and Reference Value for Steering Lock

Unit ........................................................................266

Terminals and Reference Value for BCM ..............266

Terminals and Reference Value for IPDM E/R ......267

Terminals and Reference Value for PDU ..............267

CONSULT-II ..........................................................268

CONSULT-II INSPECTION PROCEDURE ........268

CONSULT-II DIAGNOSTIC TEST MODE FUNC-

TION ..................................................................270

HOW TO READ SELF-DIAGNOSTIC RESULTS .270

“NATS V5.0” SELF-DIAGNOSTIC RESULTS

ITEM CHART .....................................................271

“NATS BCM OR S/ENT” SELF-DIAGNOSTIC

RESULTS ITEM CHART ....................................271

“NATS I-KEY” SELF-DIAGNOSTIC RESULTS

ITEM CHART .....................................................272

Work Flow .............................................................272

Trouble Diagnoses Flow Chart for IVIS (NATS) ....275

Symptom Chart for Security Indicator ...................277

CONDITIONS OF VEHICLE (OPERATING CON-

DITIONS) ...........................................................277

Check Security Indicator Harness .........................277

DTC P1612 CHAIN of ECM-IMMU .......................278

DTC P1611 ID DISCORD, IMM-ECM ...................280

Removal and Installation of Key Slot ....................280

REMOVAL ..........................................................280

INSTALLATION ..................................................280

INTEGRATED HOMELINK TRANSMITTER ...........281

Wiring Diagram —TRNSCV— ..............................281

Trouble Diagnoses ................................................282

DIAGNOSTIC PROCEDURE .............................282

BODY REPAIR ........................................................284

Body Exterior Paint Color ......................................284

Body Component Parts .........................................285

UNDERBODY COMPONENT PARTS ...............285

BODY COMPONENT PARTS ............................287

Corrosion Protection ..........................................

...289

DESCRIPTION ..................................................289

UNDERCOATING ..............................................290

Body Sealing .........................................................291

DESCRIPTION ..................................................291

Body Construction .................................................294

BODY CONSTRUCTION ...................................294

Body Alignment .....................................................295

BODY CENTER MARKS ...................................295

PANEL PARTS MATCHING MARKS .................296

DESCRIPTION ..................................................297

ENGINE COMPARTMENT ................................298

UNDERBODY ....................................................300

PASSENGER COMPARTMENT ........................302

Page 955 of 5621

BL-16

HOOD

Revision: 2006 January2006 M35/M45

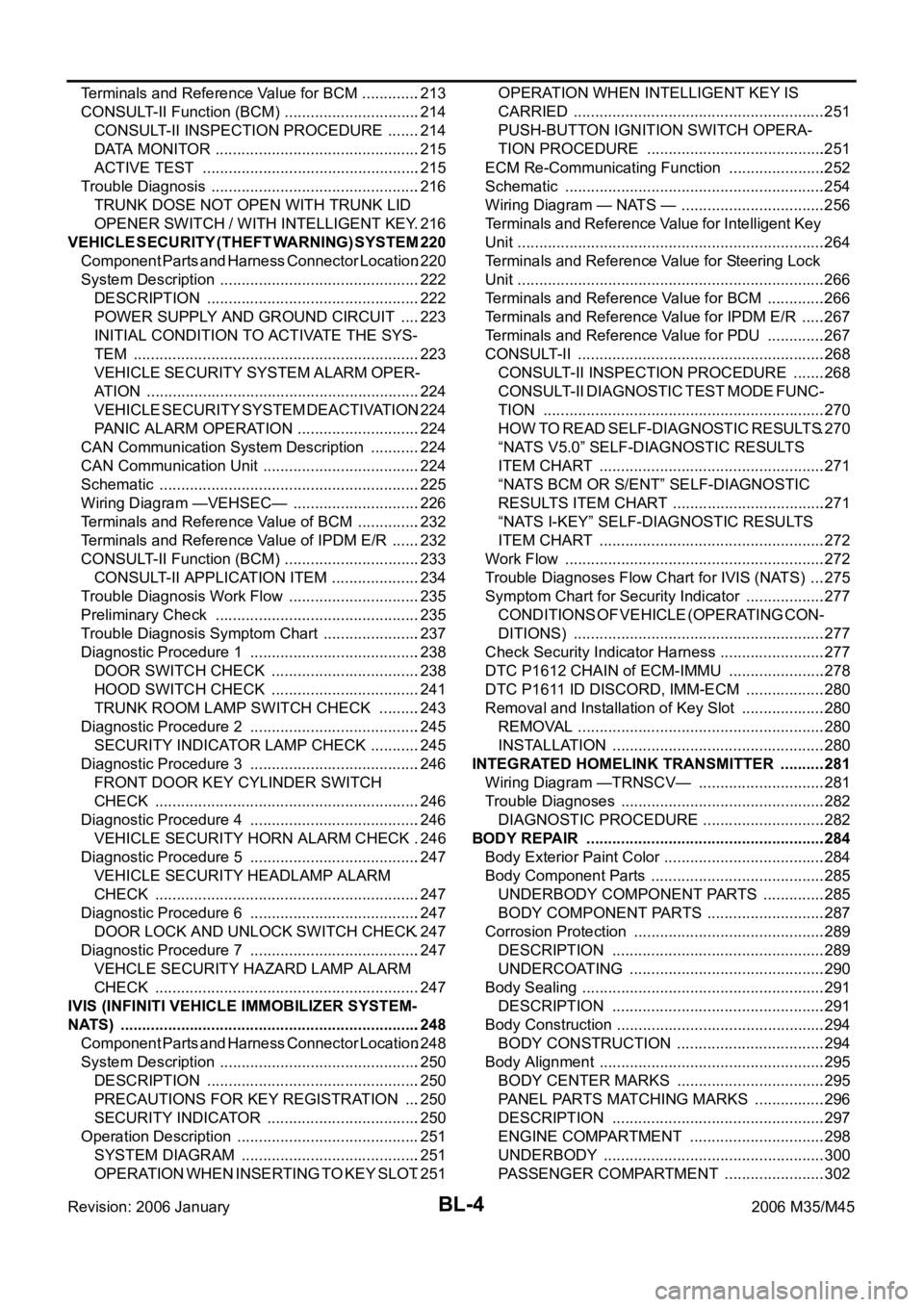

1. Check the clearance and the surface height between the hood and each part by visual and tactile feeling.

(Fitting standard dimension in the table below should be satisfied.)

* Unit: mm (in)

2. In case out of specification, adjust them according to the procedures shown below.

3. Remove the hood lock and adjust the height by rotating the

bumper rubber until the hood becomes 1 to1.5 mm (0.04 to

0.059 in) lower than the fender.

4. Temporarily tighten the hood lock, and position by engaging it with the hood striker. Check the lock and

striker for looseness and adjust the clearance and evenness by the striker to satisfy the specification.

5. Adjust A and B shown in the figure to the following value with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height or the hood pressed lightly (approx. 29 N (3 kg)).

6. After adjustment tighten lock bolts to the specified torque.

1. Hood hinge 2. Hood lock assembly 3. Hood assembly

4. Hood top molding 5. Bumper fascia assembly 6. Headlamp

7. Front fender

Parts Standard Parallelism (MAX)Right/left clearance

(MAX)

A – Aa Clearance 0.5 - 1.2 (0.02 -0.05) 1.0 (0.04) —

e Surface height 0.5 - 2.5 (0.02 - 0.10) 1.5 (0.06) —

B – Bb Clearance 1.5 - 5.5 (0.06 - 0.22) — 2.5 (0.01)

f Surface height -1.0 - 3.0 (-0.04 - 0.12) — 2.0 (0.08)

C – Cc Clearance 1.5 - 5.5 (0.06 - 0.22) — 2.0 (0.08)

g Surface height -1.0 - 3.0 (-0.40 - 0.12) 2.0 (0.08) 2.0 (0.08)

D – Dd Clearance 2.0 - 5.0 (0.08 - 0.20) 1.0 (0.04) 1.5 (0.06)

h Surface height -1.0 - 1.0 (-0.04 - 0.04) 1.0 (0.04) 1.5 (0.06)

PIIB3872J

1. Hood striker 2. Primary latch 3. Secondary striker

4. Secondary latch

A : 20 mm (0.79 in)

B : 6.8 mm (0.27 in)

PIIB5794E

Page 960 of 5621

RADIATOR CORE SUPPORT

BL-21

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

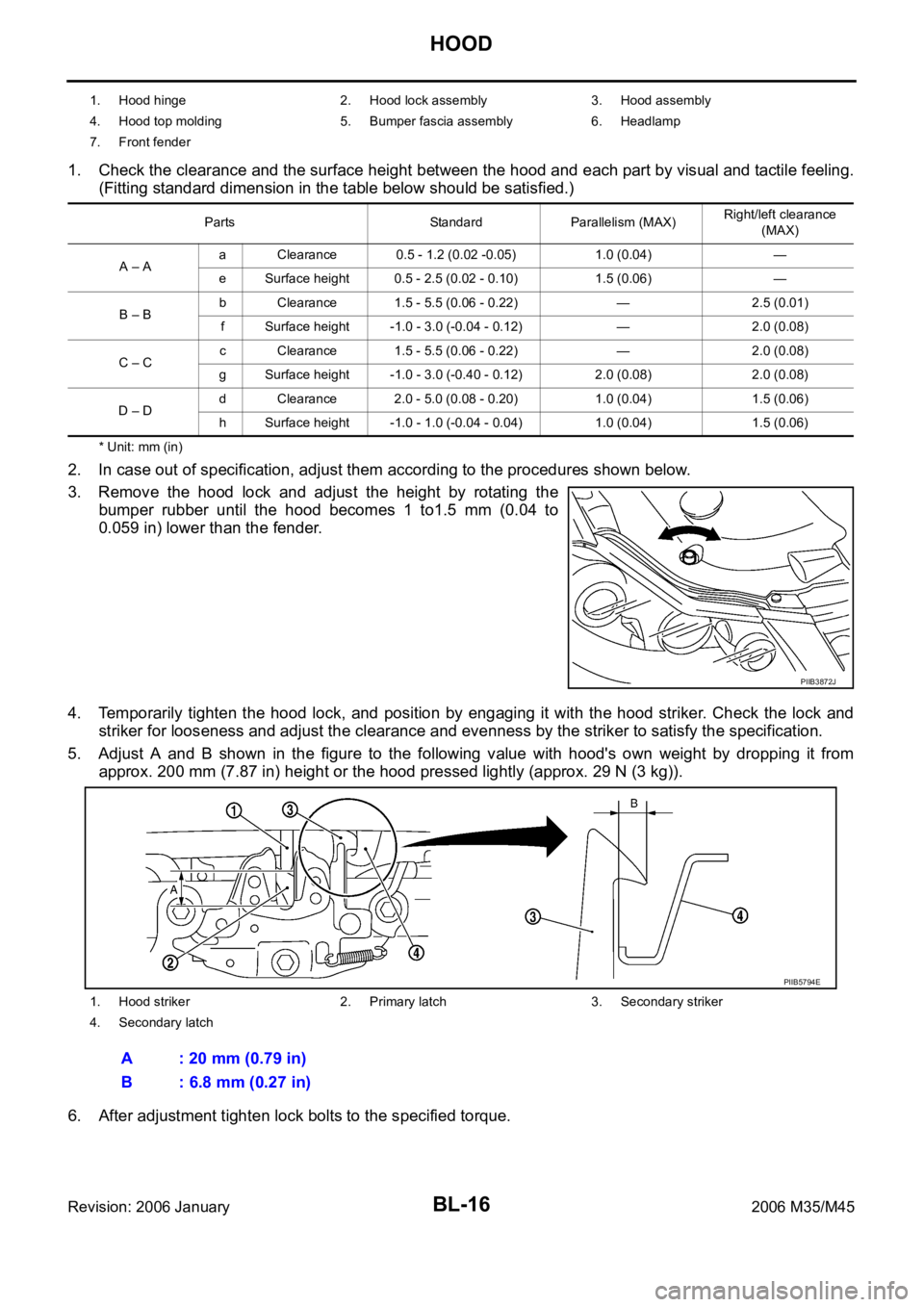

RADIATOR CORE SUPPORTPFP:62500

Removal and InstallationNIS001WN

REMOVAL

1. Remove front bumper, bumper reinforcement. Refer toEI-14, "Removal and Installation" .

2. Remove headlamp (LH/RH). Refer to LT- 4 1 , "

Removal and Installation" .

3. Remove air duct. Refer to EM-17, "

Removal and Installation" (VQ35DE models),EM-177, "Removal and

Installation" (VK45DE models).

4. Remove hood lock assembly, then remove hood lock cable. Refer to BL-18, "

Removal and Installation of

Hood Lock Control" .

5. Remove washer tank. Refer to WW-47, "

Removal and Installation of Washer Tank" .

6. Remove ambient sensor. Refer to ATC-126, "

Removal and Installation" .

7. Remove crash zone sensor. Refer to SRS-45, "

Removal and Installation" .

1. Headlamp (RH) 2. Radiator core support side (RH) 3. Washer tank

4. Air guide (RH) 5. Horn (High) 6. Air guide (LH)

7. Radiator core support side (LH) 8. Horn (Low) 9. Headlamp (LH)

10. Radiator core support center 11. Upper radiator bracket (LH) 12. Upper radiator bracket (RH)

13. Power steering tube assembly

PIIB5804E

Page 962 of 5621

FRONT FENDER

BL-23

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

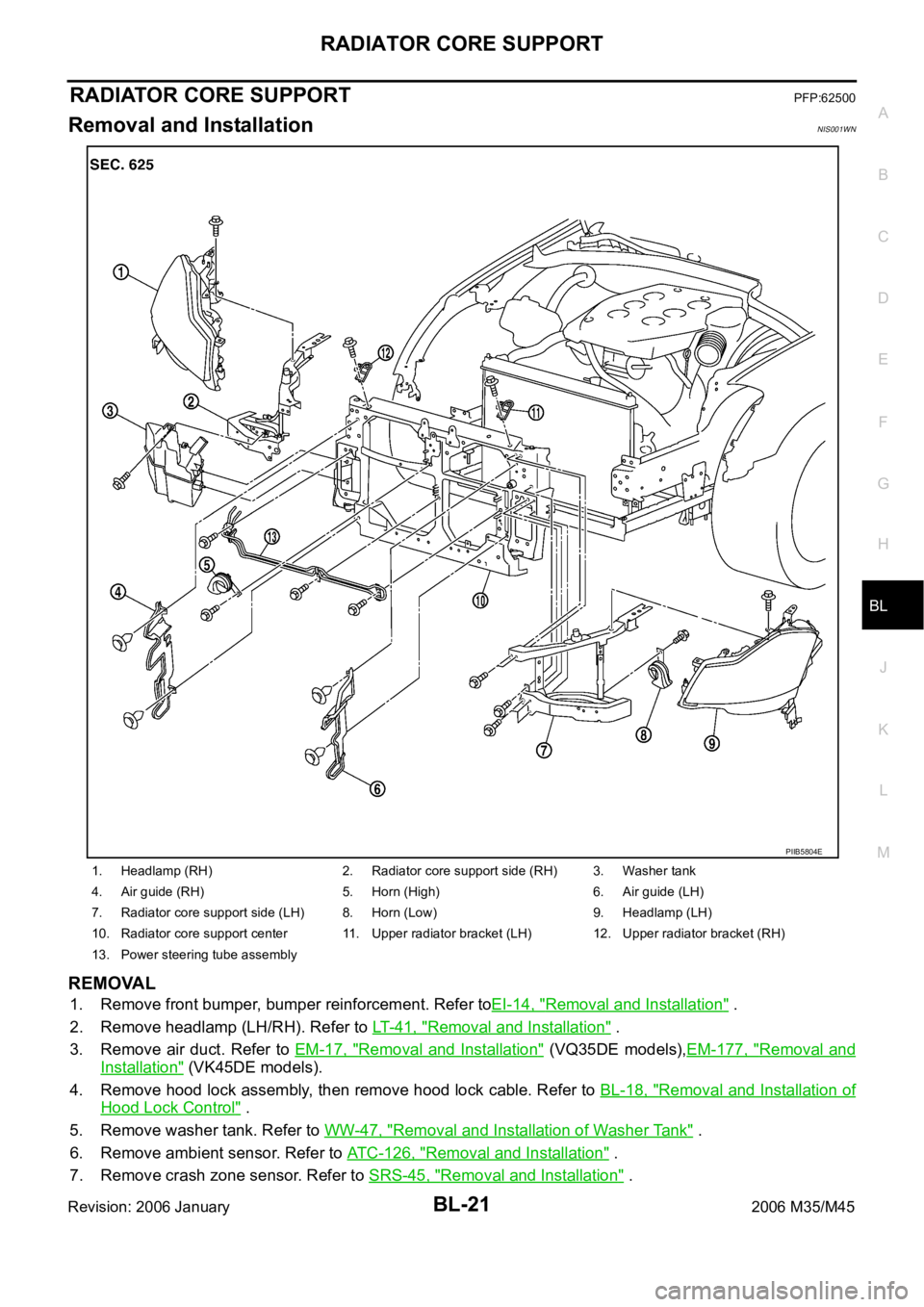

FRONT FENDERPFP:63100

Removal and InstallationNIS001WO

REMOVAL

1. Remove the front bumper. Refer to EI-11, "Removal and Installation" .

2. Remove the headlamp. Refer to LT-41, "

Removal and Installation" .

3. Remove the turn signal lamp. Refer to LT-229, "

Removal and Installation of Front Turn Signal Lamp" .

4. Remove the front fender protector. Refer to EI-20, "

FENDER PROTECTOR" .

5. Remove the center mud guard. Refer toEI-22, "

Removal and Installation" .

6. Remove the mounting bolt and remove the front fender.

CAUTION:

While removing use a shop cloth to protect body from damaging.

INSTALLATION

Install in the reverse order of removal.

CAUTION:

After installing, apply touch-up paint (the body color) onto the head of the front fender mounting

bolts.

After installing, check front fender adjustment. Refer to BL-15, "Fitting Adjustment" and BL-190,

"Fitting Adjustment" .

PIIB3893J

Page 992 of 5621

INTELLIGENT KEY SYSTEM

BL-53

C

D

E

F

G

H

J

K

L

MA

B

BL

Revision: 2006 January2006 M35/M45

Hazard and Horn Reminder Function

When doors are locked or unlocked by Intelligent Key, Intelligent Key unit sends hazard and horn request sig-

nal to BCM via CAN communication line.

BCM flashes hazard warning lamps as a reminder and sends horn chirp signal to IPDM E/R. IPDM E/R

sounds horn as a reminder.

The hazard and horn reminder has a horn chirp mode (C mode) and a non-horn chirp mode (S mode).

Operating function of hazard and horn reminder

Hazard and horn reminder does not operate if any door switch is ON (any door is OPEN).

How to change hazard and horn reminder mode

With CONSULT-II

Hazard and horn reminder can be changed using “HORN WITH KEYLESS LOCK” and “HAZARD ANSWER

BACK” mode in “WORK SUPPORT”.Refer to BL-83, "

WORK SUPPORT" .

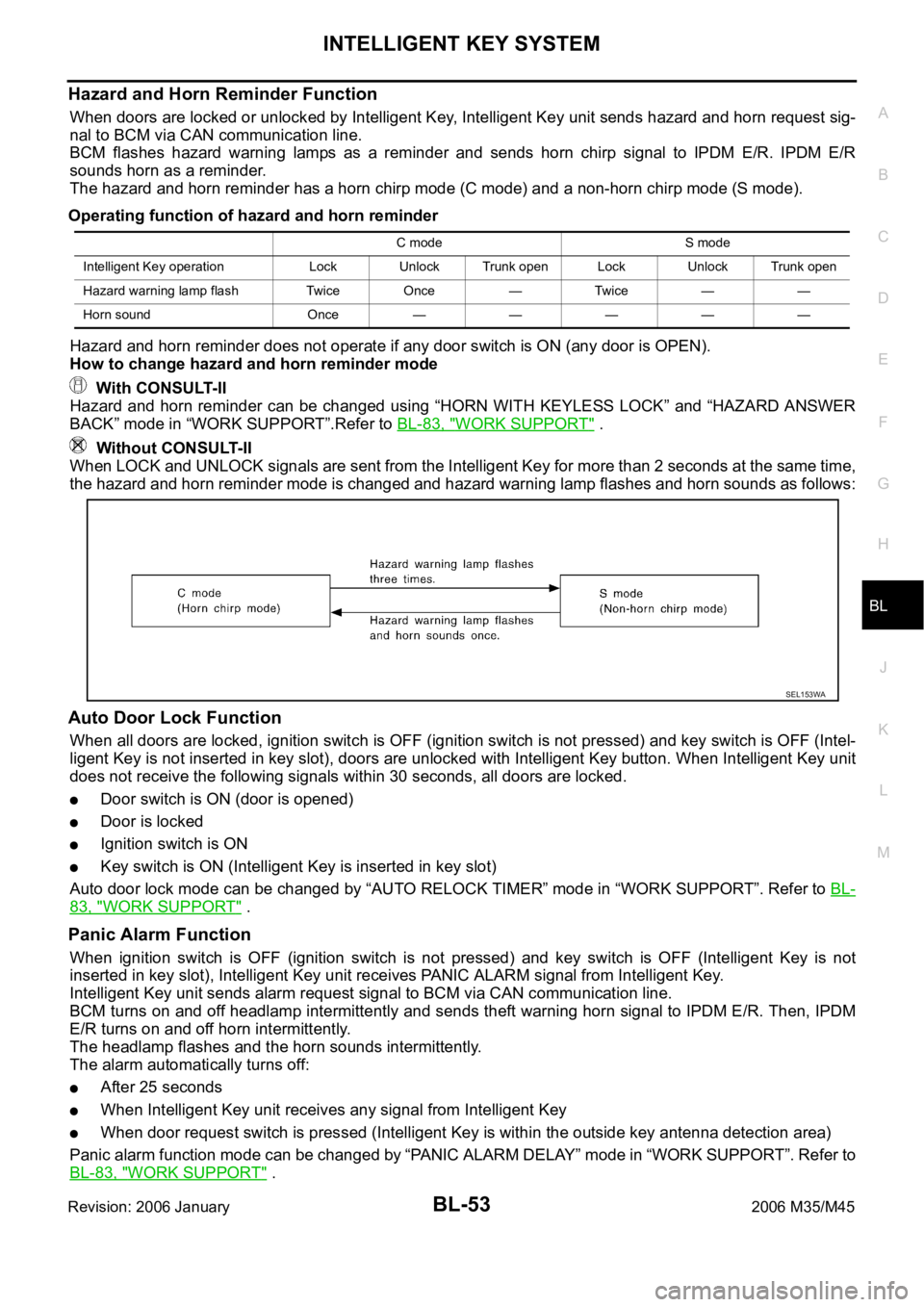

Without CONSULT-II

When LOCK and UNLOCK signals are sent from the Intelligent Key for more than 2 seconds at the same time,

the hazard and horn reminder mode is changed and hazard warning lamp flashes and horn sounds as follows:

Auto Door Lock Function

When all doors are locked, ignition switch is OFF (ignition switch is not pressed) and key switch is OFF (Intel-

ligent Key is not inserted in key slot), doors are unlocked with Intelligent Key button. When Intelligent Key unit

does not receive the following signals within 30 seconds, all doors are locked.

Door switch is ON (door is opened)

Door is locked

Ignition switch is ON

Key switch is ON (Intelligent Key is inserted in key slot)

Auto door lock mode can be changed by “AUTO RELOCK TIMER” mode in “WORK SUPPORT”. Refer to BL-

83, "WORK SUPPORT" .

Panic Alarm Function

When ignition switch is OFF (ignition switch is not pressed) and key switch is OFF (Intelligent Key is not

inserted in key slot), Intelligent Key unit receives PANIC ALARM signal from Intelligent Key.

Intelligent Key unit sends alarm request signal to BCM via CAN communication line.

BCM turns on and off headlamp intermittently and sends theft warning horn signal to IPDM E/R. Then, IPDM

E/R turns on and off horn intermittently.

The headlamp flashes and the horn sounds intermittently.

The alarm automatically turns off:

After 25 seconds

When Intelligent Key unit receives any signal from Intelligent Key

When door request switch is pressed (Intelligent Key is within the outside key antenna detection area)

Panic alarm function mode can be changed by “PANIC ALARM DELAY” mode in “WORK SUPPORT”. Refer to

BL-83, "

WORK SUPPORT" .

C mode S mode

Intelligent Key operation Lock Unlock Trunk open Lock Unlock Trunk open

Hazard warning lamp flash Twice Once — Twice — —

Horn sound Once—————

SEL153WA