air condition INFINITI QX4 2001 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 851 of 2395

4) Make sure that A/C switch is ªOFFº and air conditioner is not

operating. If NG, check air conditioner circuit. Refer to HA-35

or HA-30, ªTROUBLE DIAGNOSESº. After repair, go to the

next step.

5) Check for blocked coolant passage.

a) Warm up engine to normal operating temperature, then grasp

radiator upper hose and lower hose and make sure that cool-

ant flows.

If NG, go to ªDiagnostic Procedureº, EC-316. After repair, go

to the next step.

Be extremely careful not to touch any moving or adjacent

parts.

6) Check for blocked radiator air passage.

a) When market fog lamps have been installed, check for dam-

aged fans and clogging in the condenser and radiator.

b) Check the front end for clogging caused by insects or debris.

c) Check for improper fitting of front-end cover, damaged radia-

tor grille or bumper, damaged vehicle front.

If NG, take appropriate action and then go to the next step.

7) Check function of ECT sensor.

Refer to step 6 of ªDiagnostic Procedureº, EC-316.

If NG, replace ECT sensor and go to the next step.

8) Check ignition timing. Refer to basic inspection, EC-101.

Make sure that ignition timing is 15ɱ5É at idle.

If NG, adjust ignition timing and then recheck.

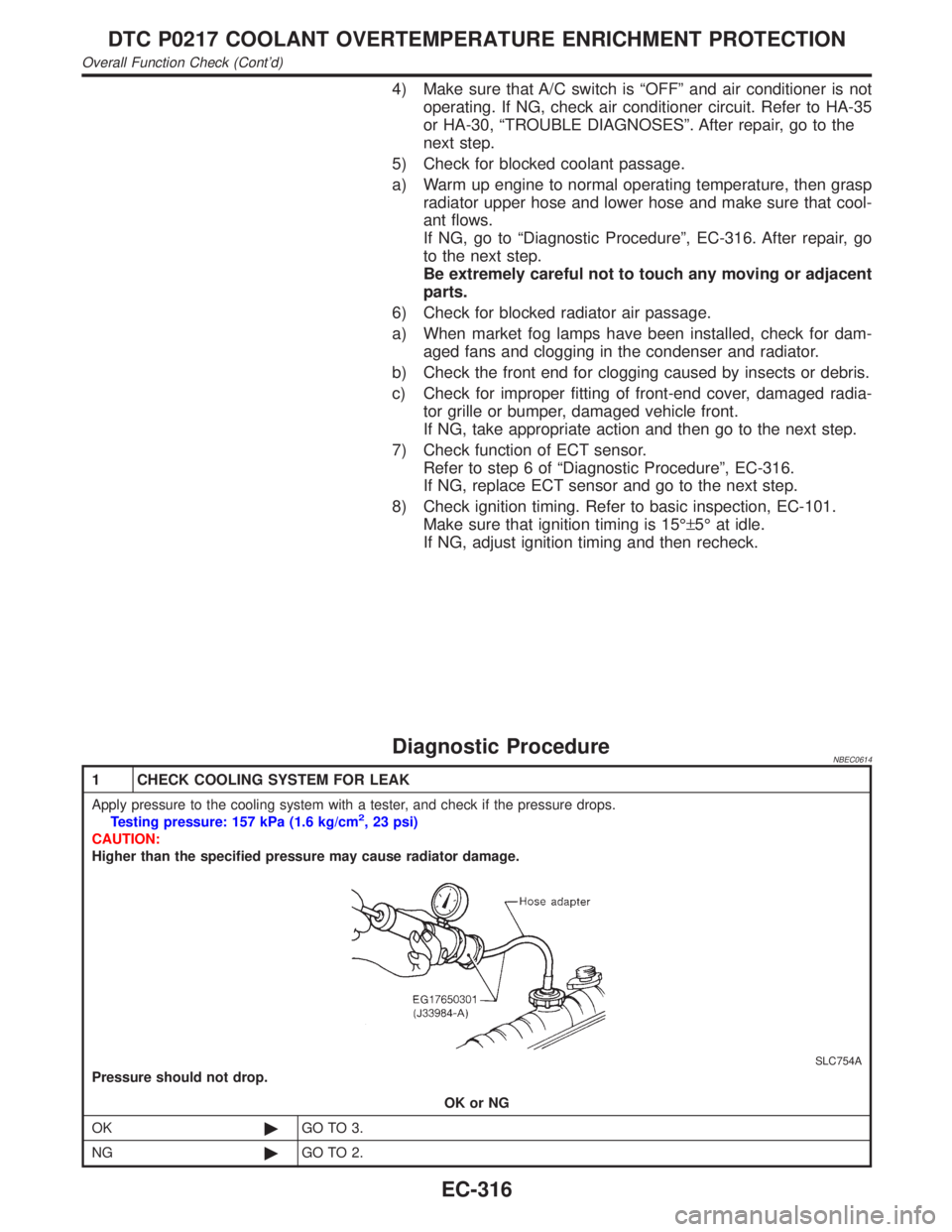

Diagnostic ProcedureNBEC0614

1 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.6 kg/cm2, 23 psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Overall Function Check (Cont'd)

EC-316

Page 852 of 2395

2 DETECT MALFUNCTIONING PART

Check the following for leak.

IHose

IRadiator

IWater pump (Refer to LC-12, ªWater Pumpº.)

©Repair or replace.

3 CHECK RADIATOR CAP

Apply pressure to cap with a tester and check radiator cap relief pressure.

SLC755A

Radiator cap relief pressure:

59 - 98 kPa (0.6 - 1.0 kg/cm2,9-14psi)

OK or NG

OK©GO TO 4.

NG©Replace radiator cap.

4 CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening temperature and valve lift.

SLC343

Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Valve lift:

More than 8.6 mm/90ÉC (0.339 in/194ÉF)

4. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature. For details, refer to LC-16, ªThermostatº.

OK or NG

OK©GO TO 5.

NG©Replace thermostat

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Diagnostic Procedure (Cont'd)

EC-317

Page 855 of 2395

On Board Diagnosis LogicNBEC0182When a misfire occurs, engine speed will fluctuate. If the engine

speed fluctuates enough to cause the CKP sensor signal to vary,

ECM can determine that a misfire is occurring.

Sensor Input Signal to ECM ECM function

Crankshaft position sensor (POS) Engine speed On board diagnosis of misfire

The misfire detection logic consists of the following two conditions.

1. One Trip Detection Logic (Three Way Catalyst Damage)

On the first trip that a misfire condition occurs that can dam-

age the three way catalyst (TWC) due to overheating, the MIL

will blink.

When a misfire condition occurs, the ECM monitors the CKP

sensor signal every 200 engine revolutions for a change.

When the misfire condition decreases to a level that will not

damage the TWC, the MIL will turn off.

If another misfire condition occurs that can damage the TWC

on a second trip, the MIL will blink.

When the misfire condition decreases to a level that will not

damage the TWC, the MIL will remain on.

If another misfire condition occurs that can damage the TWC,

the MIL will begin to blink again.

2. Two Trip Detection Logic (Exhaust quality deterioration)

For misfire conditions that will not damage the TWC (but will

affect vehicle emissions), the MIL will only light when the mis-

fire is detected on a second trip. During this condition, the ECM

monitors the CKP sensor signal every 1,000 engine revolu-

tions.

A misfire malfunction can be detected on any one cylinder or

on multiple cylinders.

Malfunction is detected when multiple cylinders misfire, No. 1 cyl-

inder misfires, No. 2 cylinder misfires, No. 3 cylinder misfires, No.

4 cylinder misfires, No. 5 cylinder misfires and No. 6 cylinder

misfires.

Possible CauseNBEC0490IImproper spark plug

IInsufficient compression

IIncorrect fuel pressure

IThe injector circuit is open or shorted

IInjectors

IIntake air leak

IThe ignition secondary circuit is open or shorted

ILack of fuel

IDrive plate or flywheel

IHeated oxygen sensor 1 (front)

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

On Board Diagnosis Logic

EC-320

Page 856 of 2395

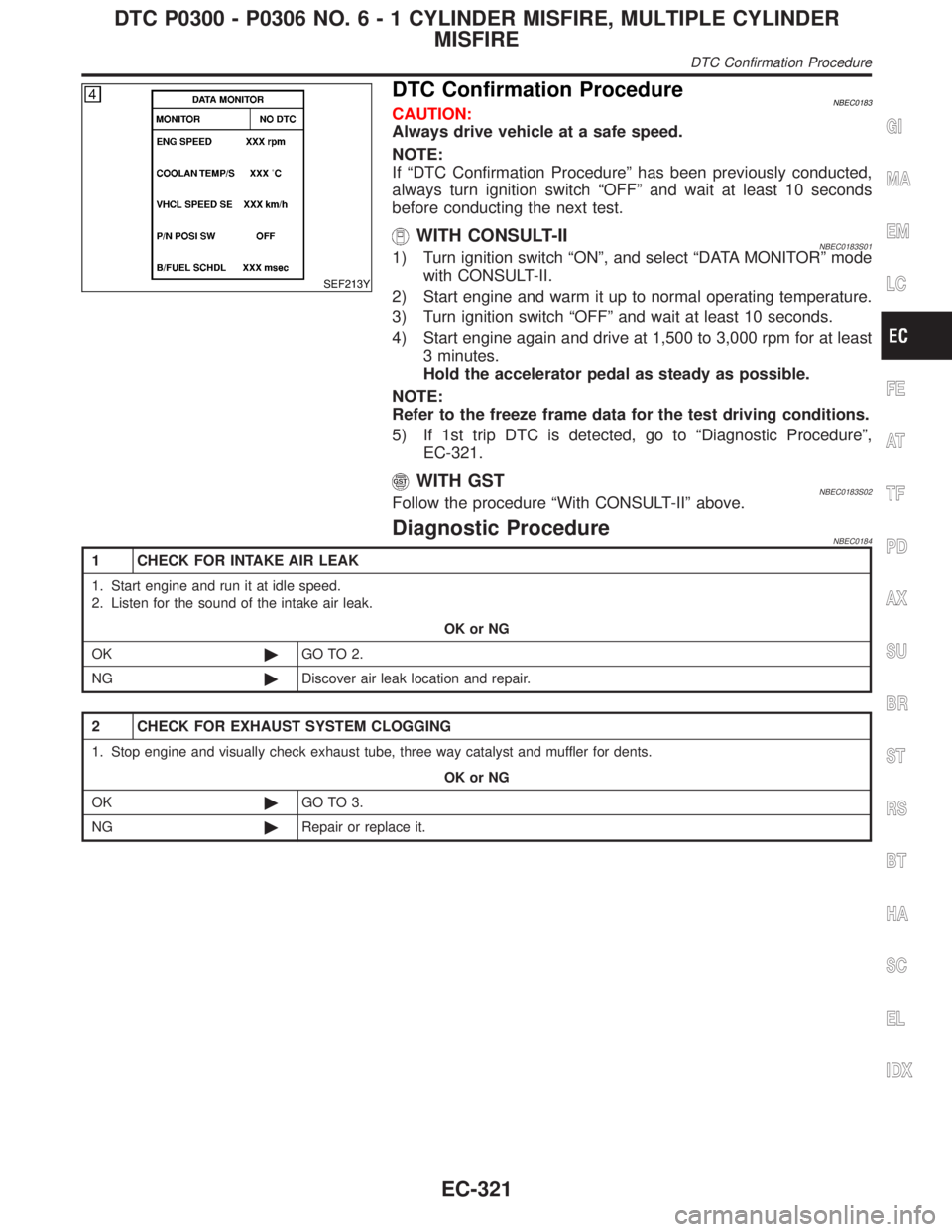

SEF213Y

DTC Confirmation ProcedureNBEC0183CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0183S011) Turn ignition switch ªONº, and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and warm it up to normal operating temperature.

3) Turn ignition switch ªOFFº and wait at least 10 seconds.

4) Start engine again and drive at 1,500 to 3,000 rpm for at least

3 minutes.

Hold the accelerator pedal as steady as possible.

NOTE:

Refer to the freeze frame data for the test driving conditions.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-321.

WITH GSTNBEC0183S02Follow the procedure ªWith CONSULT-IIº above.

Diagnostic ProcedureNBEC0184

1 CHECK FOR INTAKE AIR LEAK

1. Start engine and run it at idle speed.

2. Listen for the sound of the intake air leak.

OK or NG

OK©GO TO 2.

NG©Discover air leak location and repair.

2 CHECK FOR EXHAUST SYSTEM CLOGGING

1. Stop engine and visually check exhaust tube, three way catalyst and muffler for dents.

OK or NG

OK©GO TO 3.

NG©Repair or replace it.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

DTC Confirmation Procedure

EC-321

Page 898 of 2395

17 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-II

Check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

SEF986Y

SEF334X

Without CONSULT-II

Check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

SEF986Y

SEF335X

OK or NG

OK©GO TO 18.

NG©Replace EVAP canister purge volume control solenoid valve.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0440 EVAP CONTROL SYSTEM (SMALL LEAK) (NEGATIVE PRESSURE)

Diagnostic Procedure (Cont'd)

EC-363

Page 902 of 2395

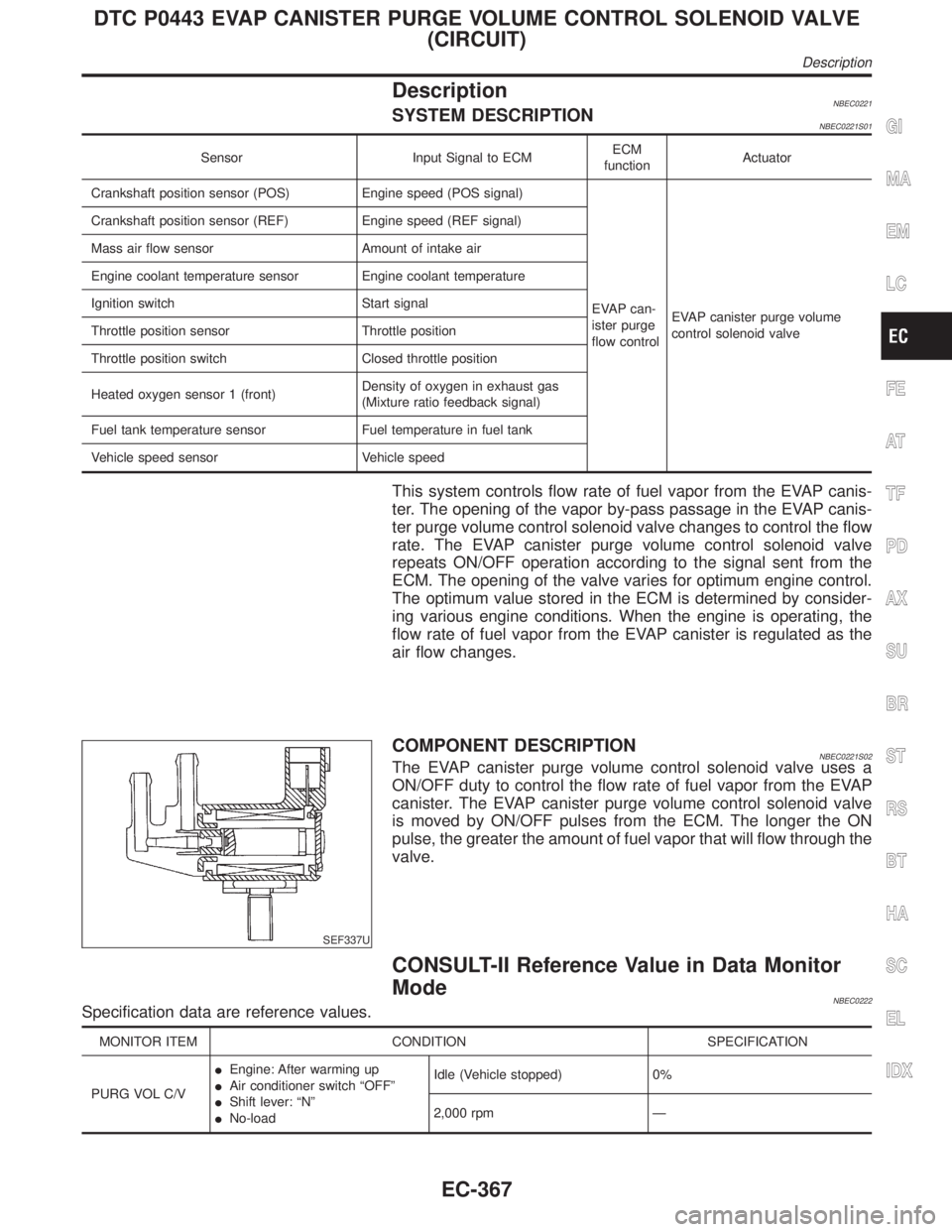

DescriptionNBEC0221SYSTEM DESCRIPTIONNBEC0221S01

Sensor Input Signal to ECMECM

functionActuator

Crankshaft position sensor (POS) Engine speed (POS signal)

EVAP can-

ister purge

flow controlEVAP canister purge volume

control solenoid valve Crankshaft position sensor (REF) Engine speed (REF signal)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Throttle position switch Closed throttle position

Heated oxygen sensor 1 (front)Density of oxygen in exhaust gas

(Mixture ratio feedback signal)

Fuel tank temperature sensor Fuel temperature in fuel tank

Vehicle speed sensor Vehicle speed

This system controls flow rate of fuel vapor from the EVAP canis-

ter. The opening of the vapor by-pass passage in the EVAP canis-

ter purge volume control solenoid valve changes to control the flow

rate. The EVAP canister purge volume control solenoid valve

repeats ON/OFF operation according to the signal sent from the

ECM. The opening of the valve varies for optimum engine control.

The optimum value stored in the ECM is determined by consider-

ing various engine conditions. When the engine is operating, the

flow rate of fuel vapor from the EVAP canister is regulated as the

air flow changes.

SEF337U

COMPONENT DESCRIPTIONNBEC0221S02The EVAP canister purge volume control solenoid valve uses a

ON/OFF duty to control the flow rate of fuel vapor from the EVAP

canister. The EVAP canister purge volume control solenoid valve

is moved by ON/OFF pulses from the ECM. The longer the ON

pulse, the greater the amount of fuel vapor that will flow through the

valve.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0222Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

PURG VOL C/VIEngine: After warming up

IAir conditioner switch ªOFFº

IShift lever: ªNº

INo-loadIdle (Vehicle stopped) 0%

2,000 rpm Ð

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

(CIRCUIT)

Description

EC-367

Page 908 of 2395

5 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-II

Check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

SEF334X

Without CONSULT-II

Check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

SEF335X

OK or NG

OK©GO TO 6.

NG©Replace EVAP canister purge volume control solenoid valve.

6 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0443 EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

(CIRCUIT)

Diagnostic Procedure (Cont'd)

EC-373

Page 915 of 2395

9 CHECK EVAP CANISTER VENT CONTROL VALVE-II

With CONSULT-II

1. Reconnect harness connectors disconnected.

2. Turn ignition switch ªONº.

3. Perform ªVENT CONTROL/Vº in ªACTIVE TESTº mode.

4. Check air passage continuity and operation delay time.

SEF991Y

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF339X

Make sure new O-ring is installed properly.

OK or NG

OK©GO TO 11.

NG©GO TO 10.

10 CHECK EVAP CANISTER VENT CONTROL VALVE-III

1. Clean the air passage (PortionAtoB) of EVAP canister vent control valve using an air blower.

2. Perform Test No. 9 again.

OK or NG

OK©GO TO 11.

NG©Replace EVAP canister vent control valve.

11 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

DTC P0446 EVAPORATIVE EMISSION (EVAP) CANISTER VENT CONTROL

VALVE (CIRCUIT)

Diagnostic Procedure (Cont'd)

EC-380

Page 923 of 2395

11 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

With CONSULT-II

Check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

SEF986Y

SEF334X

Without CONSULT-II

Check air passage continuity of EVAP canister purge volume control solenoid valve under the following conditions.

SEF986Y

SEF335X

OK or NG

OK©GO TO 12.

NG©Replace EVAP canister purge volume control solenoid valve.

DTC P0450 EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM PRESSURE

SENSOR

Diagnostic Procedure (Cont'd)

EC-388

Page 925 of 2395

14 CHECK EVAP CANISTER VENT CONTROL VALVE

With CONSULT-II

1. Perform ªVENT CONTROL/Vº in ªACTIVE TESTº mode.

2. Check air passage continuity and operation delay time under the following conditions.

SEF991Y

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF339X

Make sure new O-ring is installed properly.

OK or NG

OK©GO TO 16.

NG©GO TO 15.

15 CHECK EVAP CANISTER VENT CONTROL VALVE-III

1. Clean the air passage (portionAtoB) of EVAP canister vent control valve using an air blower.

2. Perform Test No. 14 again.

OK or NG

OK©GO TO 16.

NG©Replace EVAP canister vent control valve.

DTC P0450 EVAPORATIVE EMISSION (EVAP) CONTROL SYSTEM PRESSURE

SENSOR

Diagnostic Procedure (Cont'd)

EC-390