air condition INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2121 of 2395

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

=NBRS0041A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a malfunction. It is important to fully understand the symp-

toms or conditions for a customer complaint.

INFORMATION FROM CUSTOMERNBRS0041S01WHAT ..... Vehicle model

WHEN ..... Date, Frequencies

WHERE ..... Road conditions

HOW ..... Operating conditions, Symptoms

PRELIMINARY CHECKNBRS0041S02Check that the following parts are in good order.

IBattery [Refer to SC-4, ªBATTERYº.]

IFuse [Refer to EL-16, ªFuseº, ªPOWER SUPPLY ROUTINGº.]

ISystem component-to-harness connections

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

How to Perform Trouble Diagnoses for Quick and Accurate Repair

RS-32

Page 2127 of 2395

SRS800

SRS Operation CheckNBRS0044DIAGNOSTIC PROCEDURE 1NBRS0044S01Checking Air Bag Operation by Using ªAIR BAGº

Warning Lamp Ð User Mode

NBRS0044S01011. After turning ignition switch from ªOFFº to ªONº, ªAIR BAGº

warning lamp operates.

2. Compare ªAIR BAGº warning lamp operation to the chart

below.

ªAIR BAGº warning lamp operation Ð User mode Ð SRS condition Reference item

MRS095A

No malfunction is

detected. No further action

is necessary.

Ð

MRS096A

The system is malfunction-

ing and needs to be

repaired as indicated.Go to DIAGNOSTIC PRO-

CEDURE 2 or 6 (RS-39 or

RS-48).

MRS097A

Air bag is deployed.

Seat belt pre-tensioner is

deployed.Go to COLLISION DIAG-

NOSIS (RS-56).

Air bag fuse, diagnosis

sensor unit or harness is

malfunctioning and needs

to be repaired.Go to DIAGNOSTIC PRO-

CEDURE 9 (RS-59).

MRS098A

One of the following has

occurred and needs to be

repaired.

IMeter fuse is blown.

IªAIR BAGº warning

lamp circuit has open or

short.

IDiagnosis sensor unit is

malfunctioning.Go to DIAGNOSTIC PRO-

CEDURE 10 (RS-58).

NOTE:

If ªAIR BAGº warning lamp operates differently from the

operations shown above, refer to ªAIR BAGº warning lamp

operation Ð Diagnosis mode Ð, DIAGNOSTIC PROCEDURE 6

(step 4), RS-48.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS Operation Check

RS-38

Page 2138 of 2395

No. ªAIR BAGº warning lamp flash pattern Ð Diagnosis mode Ð SRS condition

1

SRS333

athroughbare repeated.IDiagnosis

results (pre-

viously

stored in the

memory)

might not be

erased after

repair.

IIntermittent

malfunction

has been

detected in

the past.

Go to DIAG-

NOSTIC PRO-

CEDURE 8

(RS-55).

2

SRS341

athroughdare repeated.

bÐ Driver and passenger

air bag and seat belt pre-ten-

sioner marker (For identifying

driver air bag, passenger air

bag and/or seat belt pre-ten-

sioners malfunctioning)

dÐ Indicates malfunctioning

part. The number of flash var-

ies with malfunctioning part

(0.5 sec. ON and 0.5 sec.

OFF is counted as one flash.)The system is

malfunctioning

and needs to

be repaired.

3

SRS342-A

athroughfare repeated.

b,c,dÐ Side air bag

marker (For identifying side

air bag malfunctioning)

fÐ Indicates malfunctioning

part. The number of flash var-

ies with malfunctioning part

(0.5 sec. ON and 0.5 sec.

OFF is counted as one flash.)

7. Malfunctioning part is indicated by the number of flashes (part

dorf). Compare the number of flashes to ªAir Bag Warning

Lamp Flash Code Chartº, page RS-50, and locate malfunction-

ing part.

8. Turn ignition switch ªOFFº, and disconnect both battery cables.

9. Repair the system as outlined by the ªRepair orderº in ªWarn-

ing Lamp Flash Code Chartº that corresponds to the flash

code. For replacement procedure of component parts, refer to

RS-15.

10. After repairing the system, go to DIAGNOSTIC PROCEDURE

7, page RS-53.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II (Cont'd)

RS-49

Page 2143 of 2395

No. ªAIR BAGº warning lamp flash pattern Ð Diagnosis mode Ð SRS condition

1

SRS333

athroughbare repeated. No malfunction

is detected or

repair is com-

pleted.

No further

action is nec-

essary.

2

SRS341

athroughdare repeated.

bÐ Driver and passenger air

bag and seat belt pre-tensioner

marker (For identifying driver

air bag, passenger air bag

and/or seat belt pre-tensioners

malfunctioning)

dÐ Indicates malfunctioning

part. The number of flashes

varies with malfunctioning part

(0.5 sec. ON and 0.5 sec. OFF

is counted as one flash.)The system is

malfunctioning

and needs to

be repaired.

3

SRS342-A

athroughfare repeated.

b,c,dÐ Side air bag marker

(For identifying side air bag

malfunctioning)

fÐ Indicates malfunctioning

part. The number of flashes

varies with malfunctioning part

(0.5 sec. ON and 0.5 sec. OFF

is counted as one flash.)

NOTE:

When diagnosis sensor unit is replaced with new one, ªAIR BAGº

warning lamp will operate in User mode. Checking ªAIR BAGº

warning lamp operation in Diagnosis mode is not required. Go to

step 6.

5. If ªAIR BAGº warning lamp operates as shown in No. 1 in chart

above, turn ignition switch ªOFFº to reset from Diagnosis mode

to User mode and to erase the memory of the malfunction.

Then go to step 6.

If ªAIR BAGº warning lamp operates as shown in No. 2 or No.

3 in chart above, the malfunctioning part is not repaired

completely, or another malfunctioning part is detected. Go to

DIAGNOSTIC PROCEDURE 6, page RS-48, and repair mal-

functioning part completely.

6. Turn ignition switch ªONº. ªAIR BAGº warning lamp operates in

User mode. Compare ªAIR BAGº warning lamp operation to

the chart below.

NOTE:

If switching Diagnosis mode to User mode is required while mal-

function is being detected, by turning ignition switch as follows:

1) Turn ignition switch ªONº.

2) After ªAIR BAGº warning lamp lights for 7 seconds, turn igni-

tion switch ªOFFº within 1 second.

3) Wait more than 3 seconds.

4) Repeat steps 1 to 3 three times.

5) Turn ignition switch ªONº.

SRS is now in User mode.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II (Cont'd)

RS-54

Page 2144 of 2395

ªAIR BAGº warning lamp operation Ð User mode Ð SRS condition Reference item

MRS095A

No malfunction is

detected.

No further action is neces-

sary.Ð

MRS096A

The system is malfunction-

ing and needs to be

repaired as indicated.Go to DIAGNOSTIC PRO-

CEDURE 6 (RS-48).

MRS097A

Air bag is deployed.

Seat belt pre-tensioner is

deployed.Go to COLLISION DIAG-

NOSIS (RS-59).

Air bag fuse, diagnosis

sensor unit or harness is

malfunctioning and needs

to be repaired.Go to DIAGNOSTIC PRO-

CEDURE 9 RS-56).

MRS098A

One of the following has

occurred and needs to be

repaired.

IMeter fuse is blown.

IªAIR BAGº warning

lamp circuit has open or

short.

IDiagnosis sensor unit is

malfunctioning.Go to DIAGNOSTIC PRO-

CEDURE 10 (RS-58).

DIAGNOSTIC PROCEDURE 8 (CONTINUED FROM

DIAGNOSTIC PROCEDURE 6)

NBRS0046S03Inspecting SRS malfunctioning record

1 CONSIDER POSSIBILITY OF NOT ERASING SELF-DIAGNOSTIC RESULT AFTER REPAIRING

Is it the first time for maintenance of SRS?

YesorNo

Ye s©Go to DIAGNOSTIC PROCEDURE 5 (RS-44). (Further inspection cannot be performed

without CONSULT-II.)

No©Diagnosis results (previously stored in the memory) might not be erased after repair. Go

to DIAGNOSTIC PROCEDURE 7, step 5 (RS-53).

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses without CONSULT-II (Cont'd)

RS-55

Page 2201 of 2395

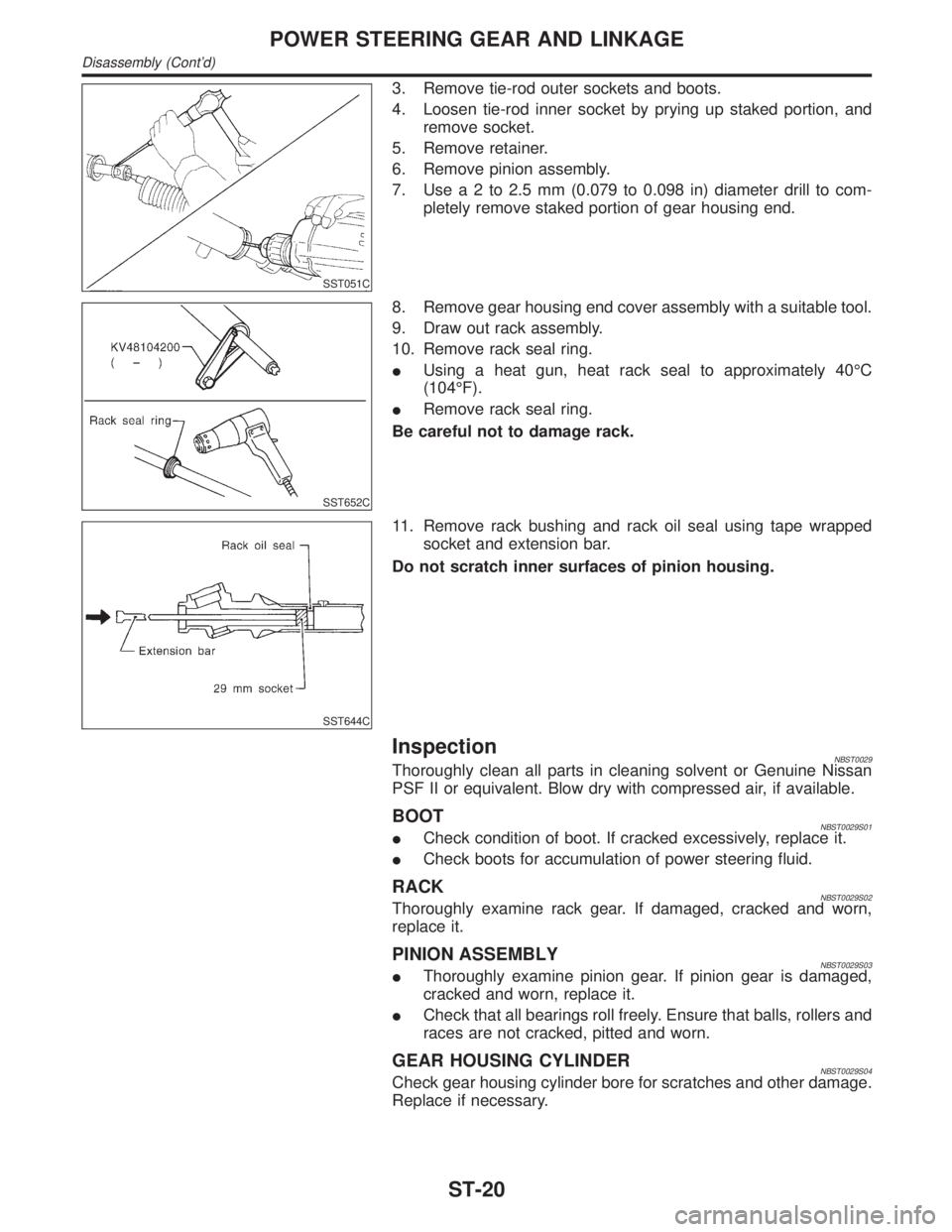

SST051C

3. Remove tie-rod outer sockets and boots.

4. Loosen tie-rod inner socket by prying up staked portion, and

remove socket.

5. Remove retainer.

6. Remove pinion assembly.

7. Usea2to2.5mm(0.079 to 0.098 in) diameter drill to com-

pletely remove staked portion of gear housing end.

SST652C

8. Remove gear housing end cover assembly with a suitable tool.

9. Draw out rack assembly.

10. Remove rack seal ring.

IUsing a heat gun, heat rack seal to approximately 40ÉC

(104ÉF).

IRemove rack seal ring.

Be careful not to damage rack.

SST644C

11. Remove rack bushing and rack oil seal using tape wrapped

socket and extension bar.

Do not scratch inner surfaces of pinion housing.

InspectionNBST0029Thoroughly clean all parts in cleaning solvent or Genuine Nissan

PSF II or equivalent. Blow dry with compressed air, if available.

BOOTNBST0029S01ICheck condition of boot. If cracked excessively, replace it.

ICheck boots for accumulation of power steering fluid.

RACKNBST0029S02Thoroughly examine rack gear. If damaged, cracked and worn,

replace it.

PINION ASSEMBLYNBST0029S03IThoroughly examine pinion gear. If pinion gear is damaged,

cracked and worn, replace it.

ICheck that all bearings roll freely. Ensure that balls, rollers and

races are not cracked, pitted and worn.

GEAR HOUSING CYLINDERNBST0029S04Check gear housing cylinder bore for scratches and other damage.

Replace if necessary.

POWER STEERING GEAR AND LINKAGE

Disassembly (Cont'd)

ST-20

Page 2277 of 2395

Diagnostic WorksheetNBTF0013S0202

1.lListen to customer complaints.TF-44

2.lCheck transfer fluid.TF-44

lLeakage

lFluid condition

lFluid level

3.lRoad testingTF-44

l1. Check before engine is started.

l2. Check at idle.

l3. Cruise test

4.lPerform self-diagnosis NG items (with CONSULT-II and without CONSULT-II). TF-30, TF-27

5.lCheck component. Repair or replace the damaged parts. TF-111

6.lPerform final check. Perform road test (1 through 3). TF-44

TROUBLE DIAGNOSIS Ð INTRODUCTION

Introduction (Cont'd)

TF-42

Page 2278 of 2395

Work Flow=NBTF0014HOW TO PERFORM TROUBLE DIAGNOSES FOR QUICK AND ACCURATE REPAIRNBTF0014S01A good understanding of the malfunction conditions can make troubleshooting faster and more accurate.

In general, each customer feels differently about a problem. It is important to fully understand the symptoms

or conditions for a customer complaint.

Make good use of the two sheets provided, ªInformation from Customerº (Refer to TF-41.) and ªDiagnostic

Worksheetº (Refer to TF-42.), to perform the best troubleshooting possible.

MTF013A

*1: TF-44

*2: TF-44*3: TF-44

*4: TF-98 - TF-109*5: TF-61 - TF-94

*6: TF-44

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð INTRODUCTION

Work Flow

TF-43

Page 2279 of 2395

Listen to Customer ComplaintsNBTF0015IEach customer feels differently about a problem. It is important

to fully understand the symptoms or conditions for a customer

complaint.

IListen to the customer about how and when the malfunction

occurs, and make good use of it when performing the road test.

Transfer Fluid CheckNBTF0016ICheck fluid for leaks and fluid level. Refer to MA-22, ªCheck-

ing All-mode 4WD Transfer Fluidº.

SMT089D

Road TestNBTF0017PREPARATION FOR ROAD TESTNBTF0017S01IThe purpose of the test is to determine overall performance of

transfer and analyze causes of problems.

IThe road test consists of the following three parts:

IWhen a malfunction is found in any part of transfer, perform the

road test to locate the malfunction area and repair the malfunc-

tion parts.

1. Check before engine is started

2. Check at idle

3. Cruise test

IPerform road test and place checks for NG items on the diag-

nostic worksheet. Refer to TF-42.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Listen to Customer Complaints

TF-44