air condition INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1113 of 2395

3 CHECK EVAP CANISTER VENT CONTROL VALVE-II

With CONSULT-II

1. Turn ignition switch ON.

2. Perform ªVENT CONTROL/Vº in ªACTIVE TESTº mode.

3. Check air passage continuity and operation delay time.

SEF991Y

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF339X

Make sure new O-ring is installed properly.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 CHECK EVAP CANISTER VENT CONTROL VALVE-III

1. Clean the air passage (PortionAtoB) of EVAP canister vent control valve using an air blower.

2. Perform Test No. 3 again.

OK or NG

OK©GO TO 5.

NG©Replace EVAP canister vent control valve.

DTC P1448 EVAPORATIVE EMISSION (EVAP) CANISTER VENT CONTROL

VALVE (OPEN)

Diagnostic Procedure (Cont'd)

EC-578

Page 1125 of 2395

6 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors B152, B151 and B101, B43

IHarness connectors B1, M2 and M94, F27

IHarness for open or short between vacuum cut valve bypass valve and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

7 CHECK VACUUM CUT VALVE BYPASS VALVE

With CONSULT-II

1. Reconnect harness disconnected connectors.

2. Turn ignition switch ON.

3. Perform ªVC/V BYPASS/Vº in ªACTIVE TESTº mode.

4. Check air passage continuity and operation delay time under the following conditions.

SEF016Z

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF358X

OK or NG

OK©GO TO 8.

NG©Replace vacuum cut valve bypass valve.

8 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

DTC P1490 VACUUM CUT VALVE BYPASS VALVE (CIRCUIT)

Diagnostic Procedure (Cont'd)

EC-590

Page 1133 of 2395

8 CHECK VACUUM CUT VALVE BYPASS VALVE

With CONSULT-II

1. Perform ªVC/V BYPASS/Vº in ªACTIVE TESTº mode.

2. Check air passage continuity and operation delay time under the following conditions.

SEF016Z

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF358X

OK or NG

OK©GO TO 9.

NG©Replace vacuum cut valve bypass valve.

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-598

Page 1136 of 2395

14 CHECK EVAP CANISTER VENT CONTROL VALVE-I

1. Remove EVAP canister vent control valve from EVAP canister.

2. Check portionBof EVAP canister vent control valve for being rusted.

SEF337X

OK or NG

OK©GO TO 15.

NG©Replace EVAP canister vent control valve.

15 CHECK EVAP CANISTER VENT CONTROL VALVE-II

With CONSULT-II

1. Reconnect harness disconnected connectors.

2. Turn ignition switch ON.

3. Perform ªVENT CONTROL/Vº in ªACTIVE TESTº mode.

4. Check air passage continuity and operation delay time.

SEF991Y

Without CONSULT-II

Check air passage continuity and operation delay time under the following conditions.

SEF339X

Make sure new O-ring is installed properly.

OK or NG

OK©GO TO 17.

NG©GO TO 16.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Diagnostic Procedure (Cont'd)

EC-601

Page 1138 of 2395

Component DescriptionNBEC0361The malfunction information related to A/T (Automatic Transmission) is transferred through the line (circuit)

from TCM (Transmission control module) to ECM. Therefore, be sure to erase the malfunction information such

as DTC not only in TCM (Transmission control module) but also ECM after the A/T related repair.

On Board Diagnosis LogicNBEC0363Malfunction is detected when an incorrect signal from TCM (Trans-

mission control module) is sent to ECM.

Possible CauseNBEC0594IHarness or connectors

[The communication line circuit between ECM and TCM

(Transmission control module) is open or shorted.]

IDead (Weak) battery

ITCM (Transmission control module)

SEF058Y

DTC Confirmation ProcedureNBEC0364NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that bat-

tery voltage is more than 10.5V at idle.

WITH CONSULT-IINBEC0364S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 40 seconds.

4) If 1st trip DTC is detected, go to ªDTC P0600 A/T COMMUNI-

CATION LINE Diagnostic Procedureº, EC-443.

WITH GSTNBEC0364S02Follow the procedure ªWITH CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1605 A/T DIAGNOSIS COMMUNICATION LINE

Component Description

EC-603

Page 1145 of 2395

DescriptionNBEC0596SYSTEM DESCRIPTIONNBEC0596S01

Sensor Input Signal to ECMECM func-

tionActuator

Mass air flow sensor Amount of intake air

VIAS con-

trolVIAS control solenoid valve Throttle position sensor Throttle position

Closed throttle position Throttle valve idle position

Ignition switch Start signal

Crankshaft position sensor (POS) Engine speed (POS signal)

Crankshaft position sensor (REF) Engine speed (REF signal)

Engine coolant temperature sensor Engine coolant temperature

SEF447Z

When the engine is running at low or medium speed, the power

valve is fully closed. Under this condition, the effective suction port

length is equivalent to the total length of the intake manifold collec-

tor's suction port including the intake valve. This long suction port

provides increased air intake which results in improved suction

efficiency and higher torque generation.

The surge tank and one-way valve are provided. When engine is

running at high speed, the ECM sends the signal to the VIAS con-

trol solenoid valve. This signal introduces the intake manifold

vacuum into the power valve actuator and therefore opens the

power valve to two suction passages together in the collector.

Under this condition, the effective port length is equivalent to the

length of the suction port provided independently for each cylinder.

This shortened port length results in enhanced engine output with

reduced suction resistance under high speeds.

VARIABLE INDUCTION AIR CONTROL SYSTEM (VIAS)

Description

EC-610

Page 1146 of 2395

SEF018Z

COMPONENT DESCRIPTIONNBEC0596S02Power ValveNBEC0596S0201The power valve is installed in intake manifold collector and used

to control the suction passage of the variable induction air control

system. It is set in the fully closed or fully opened position by the

power valve actuator operated by the vacuum stored in the surge

tank. The vacuum in the surge tank is controlled by the VIAS con-

trol solenoid valve.

SEF019Z

VIAS Control Solenoid ValveNBEC0596S0202The VIAS control solenoid valve cuts the intake manifold vacuum

signal for power valve control. It responds to ON/OFF signals from

the ECM. When the solenoid is off, the vacuum signal from the

intake manifold is cut. When the ECM sends an ON signal the coil

pulls the plunger downward and feeds the vacuum signal to the

power valve actuator.

ECM Terminals and Reference ValueNBEC0684Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

16 Y/GVIAS control solenoid

valve[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

IEngine speed is above 5,000 rpm.0 - 1.0V

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

VARIABLE INDUCTION AIR CONTROL SYSTEM (VIAS)

Description (Cont'd)

EC-611

Page 1151 of 2395

SEF375Z

Component DescriptionNBEC0383The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the injector circuit, the coil in the injector is

energized. The energized coil pulls the needle valve back and

allows fuel to flow through the injector into the intake manifold. The

amount of fuel injected depends upon the injection pulse duration.

Pulse duration is the length of time the injector remains open. The

ECM controls the injection pulse duration based on engine fuel

needs.

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0384Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

INJ PULSE-B2

INJ PULSE-B1IEngine: After warming up

IAir conditioner switch: ªOFFº

IShift lever: ªNº

INo-loadIdle 2.4 - 3.2 msec

2,000 rpm 1.9 - 2.8 msec

B/FUEL SCHDL dittoIdle 2.0 - 3.2 msec

2,000 rpm 1.4 - 2.6 msec

ECM Terminals and Reference ValueNBEC0685Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

101

102

103

104

105

107R/B

L/W

R/W

PU/R

R/Y

R/LInjector No. 1

Injector No. 5

Injector No. 2

Injector No. 6

Injector No. 3

Injector No. 4[Engine is running]

IIdle speedBATTERY VOLTAGE

(11 - 14V)

INJECTOR

Component Description

EC-616

Page 1172 of 2395

4 CHECK POWER STEERING OIL PRESSURE SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect power steering oil pressure switch harness connector.

SEF028Z

3. Check harness continuity between power steering oil pressure switch terminal 2 and engine ground. Refer to Wiring

Diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to power in harness or connectors.

5 CHECK POWER STEERING OIL PRESSURE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 47 and power steering oil pressure switch terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK POWER STEERING OIL PRESSURE SWITCH

1. Disconnect power steering oil pressure switch harness connector then start engine.

2. Check continuity between power steering oil pressure switch terminals 1 and 2 under the following conditions.

SEF364X

OK or NG

OK©GO TO 7.

NG©Replace power steering oil pressure switch.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure (Cont'd)

EC-637

Page 1174 of 2395

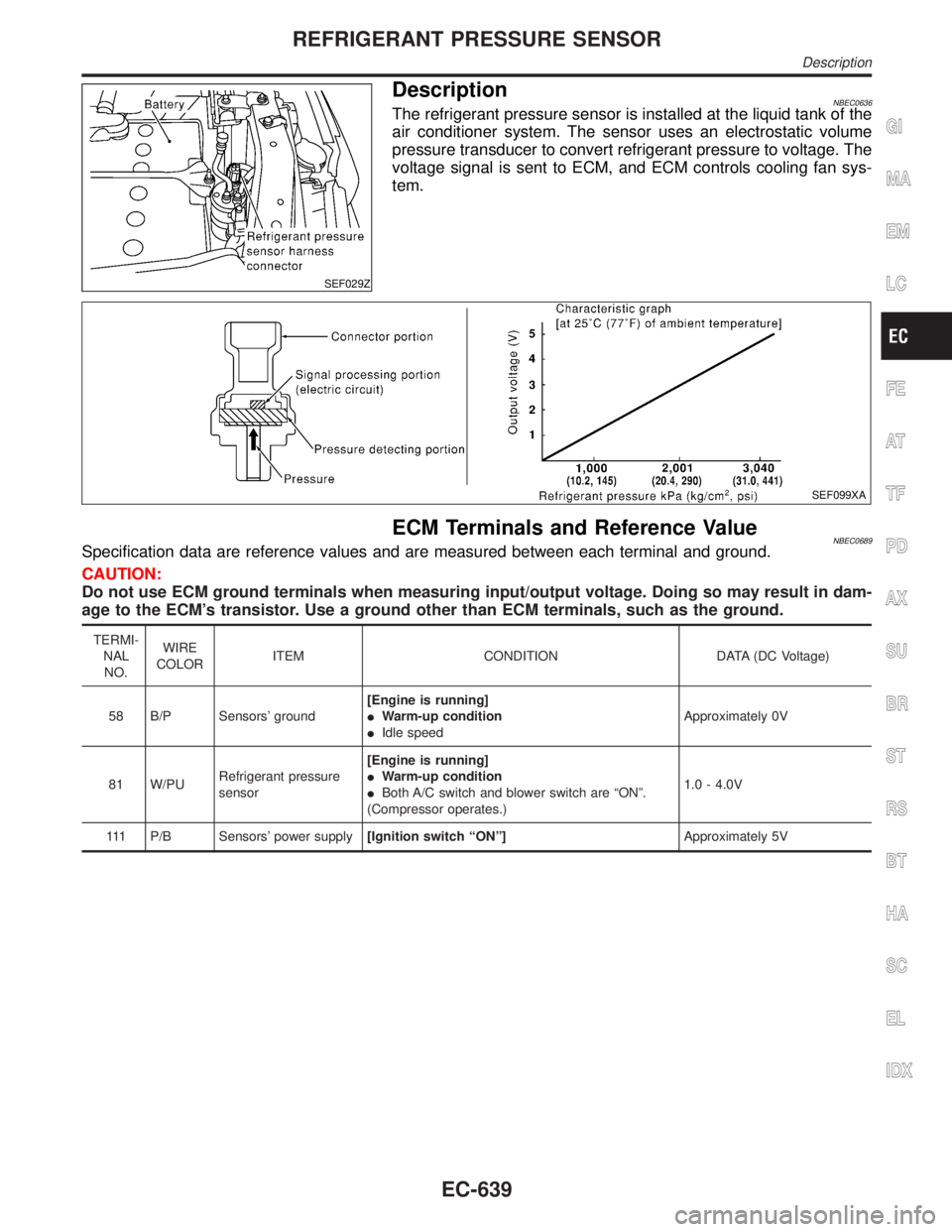

SEF029Z

DescriptionNBEC0636The refrigerant pressure sensor is installed at the liquid tank of the

air conditioner system. The sensor uses an electrostatic volume

pressure transducer to convert refrigerant pressure to voltage. The

voltage signal is sent to ECM, and ECM controls cooling fan sys-

tem.

SEF099XA

ECM Terminals and Reference ValueNBEC0689Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

58 B/P Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

81 W/PURefrigerant pressure

sensor[Engine is running]

IWarm-up condition

IBoth A/C switch and blower switch are ªONº.

(Compressor operates.)1.0 - 4.0V

111 P/B Sensors' power supply[Ignition switch ªONº]Approximately 5V

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REFRIGERANT PRESSURE SENSOR

Description

EC-639