INFINITI QX4 2001 Factory Service Manual

QX4 2001

INFINITI

INFINITI

https://www.carmanualsonline.info/img/42/57027/w960_57027-0.png

INFINITI QX4 2001 Factory Service Manual

Page 1032 of 2395

4 CHECK SWIRL CONTROL VALVE CONTROL VACUUM CHECK SWITCH INPUT SIGNAL CIRCUIT FOR

OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 55 and swirl control valve control vacuum check switch terminal 1.

Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit, short to ground or short to power in harness connectors.

5 CHECK SWIRL CONTROL VALVE CONTROL VACUUM CHECK SWITCH

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum hose connected to swirl control valve control vacuum check switch.

3. Attach vacuum pump to swirl control valve control vacuum check switch.

4. Turn ignition switch ªONº.

5. Check voltage between ECM terminal 55 and ground under the following conditions.

SEF709X

OK or NG

OK©GO TO 6.

NG©Replace swirl control valve control vacuum check switch.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1165 SWIRL CONTROL VALVE CONTROL VACUUM CHECK SWITCH

Diagnostic Procedure (Cont'd)

EC-497

Page 1036 of 2395

Wiring DiagramNBEC0290

MEC969C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1320 IGNITION SIGNAL

Wiring Diagram

EC-501

Page 1037 of 2395

MEC970C

DTC P1320 IGNITION SIGNAL

Wiring Diagram (Cont'd)

EC-502

Page 1038 of 2395

MEC971C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1320 IGNITION SIGNAL

Wiring Diagram (Cont'd)

EC-503

Page 1040 of 2395

4 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect condenser harness connector.

SEF008Z

3. Turn ignition switch ON.

4. Check voltage between condenser terminal 1 and ground with CONSULT-II or tester.

SEF367X

OK or NG

OK©GO TO 10.

NG©GO TO 5.

5 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

2. Disconnect ECM relay.

SEF009Z

3. Check harness continuity between ECM relay terminal 3 and condenser terminal 1. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1320 IGNITION SIGNAL

Diagnostic Procedure (Cont'd)

EC-505

Page 1042 of 2395

10 CHECK CONDENSER GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between condenser terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 11.

NG©Repair open circuit or short to power in harness or connectors.

11 CHECK CONDENSER

Check resistance between condenser terminals 1 and 2.

SEF369X

OK or NG

OK©GO TO 12.

NG©Replace condenser.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1320 IGNITION SIGNAL

Diagnostic Procedure (Cont'd)

EC-507

Page 1043 of 2395

12 CHECK IGNITION COIL POWER SUPPLY CIRCUIT-V

1. Turn ignition switch OFF.

2. Reconnect harness connectors disconnected.

3. Disconnect ignition coil harness connector.

SEF975Y

4. Turn ignition switch ON.

5. Check voltage between ignition coil terminal 3 and ground with CONSULT-II or tester.

SEF370X

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 DETECT MALFUNCTIONING PART

Check the harness for open or short between ignition coil and harness connector F22.

©Repair or replace harness or connectors.

14 CHECK IGNITION COIL GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Check harness continuity between ignition coil terminal 2 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 15.

NG©Repair open circuit or short to power in harness or connectors.

DTC P1320 IGNITION SIGNAL

Diagnostic Procedure (Cont'd)

EC-508

Page 1044 of 2395

15 CHECK IGNITION COIL OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminals 21, 22, 23, 30, 31, 32 and ignition coil terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

16 CHECK IGNITION COIL WITH POWER TRANSISTOR

Check resistance between ignition coil terminals 2 and 3.

SEF371X

OK or NG

OK©GO TO 17.

NG©Replace ignition coil with power transistor.

17 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1320 IGNITION SIGNAL

Diagnostic Procedure (Cont'd)

EC-509

Page 1048 of 2395

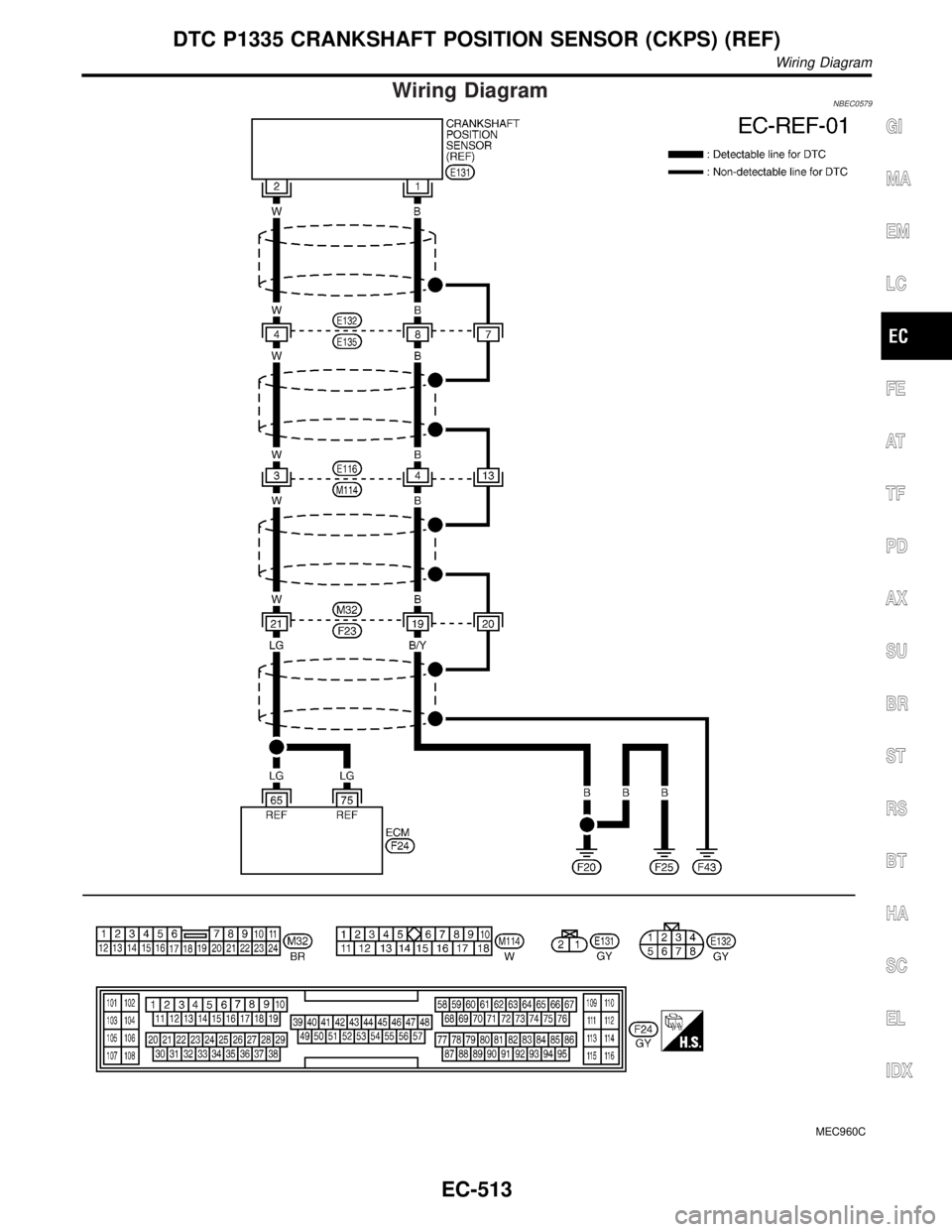

Wiring DiagramNBEC0579

MEC960C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1335 CRANKSHAFT POSITION SENSOR (CKPS) (REF)

Wiring Diagram

EC-513

Page 1049 of 2395

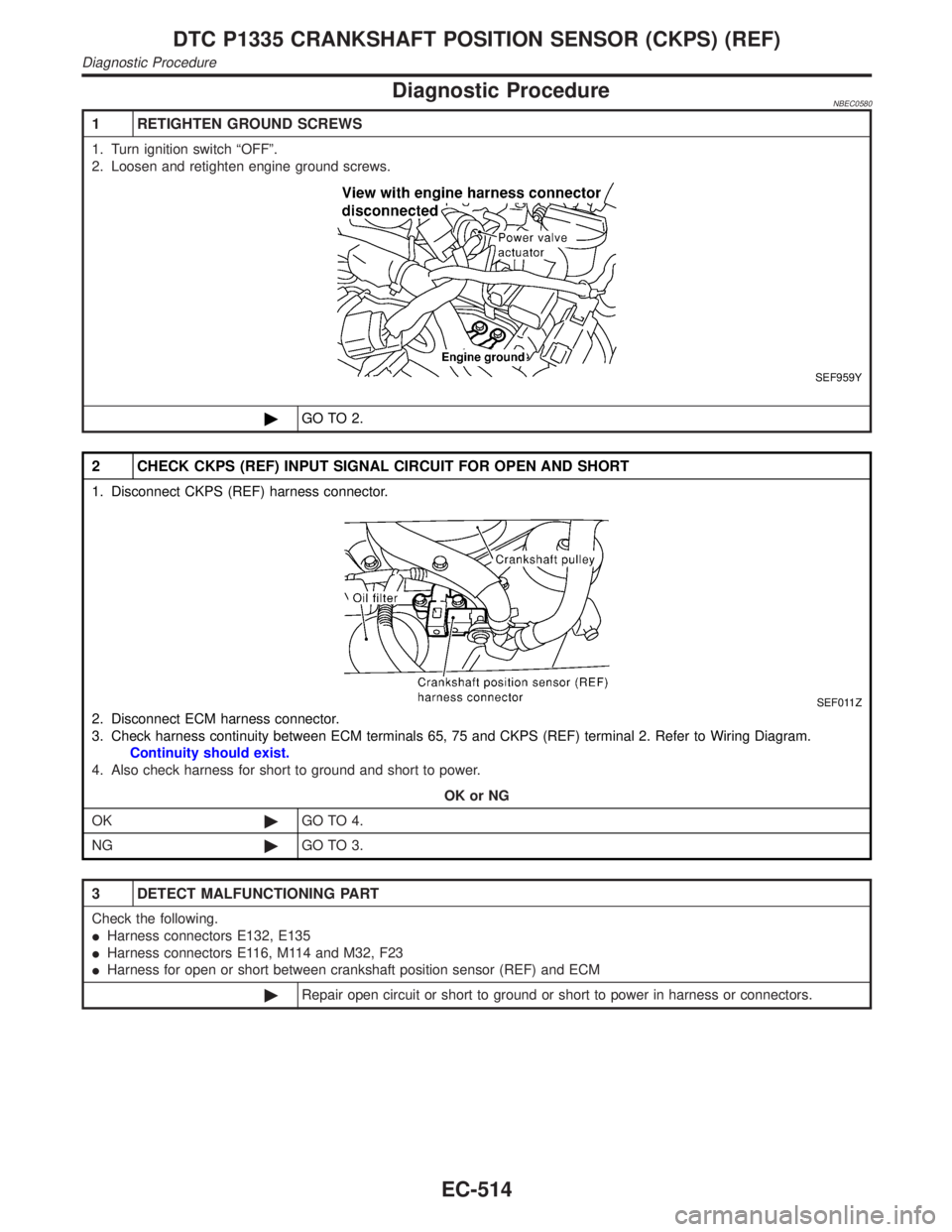

Diagnostic ProcedureNBEC0580

1 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF959Y

©GO TO 2.

2 CHECK CKPS (REF) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect CKPS (REF) harness connector.

SEF011Z

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 65, 75 and CKPS (REF) terminal 2. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E132, E135

IHarness connectors E116, M114 and M32, F23

IHarness for open or short between crankshaft position sensor (REF) and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1335 CRANKSHAFT POSITION SENSOR (CKPS) (REF)

Diagnostic Procedure

EC-514