diagram INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1122 of 2395

Wiring DiagramNBEC0351

MEC972C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1490 VACUUM CUT VALVE BYPASS VALVE (CIRCUIT)

Wiring Diagram

EC-587

Page 1124 of 2395

3 CHECK VACUUM CUT VALVE BYPASS VALUE POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect vacuum cut valve bypass valve harness connector.

SEF485T

3. Turn ignition switch ªONº.

4. Check voltage between vacuum cut valve bypass valve terminal 2 and ground with CONSULT-II or tester.

SEF015Z

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M2, B1

IFuse block (J/B) connector M10

IHarness connectors B43, B101 and B151, B152

I10A fuse

IHarness for open or short between vacuum cut valve bypass valve and fuse

©Repair harness or connectors.

5 CHECK VACUUM CUT VALVE BYPASS VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 39 and vacuum cut valve bypass valve terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1490 VACUUM CUT VALVE BYPASS VALVE (CIRCUIT)

Diagnostic Procedure (Cont'd)

EC-589

Page 1126 of 2395

SEF485T

DescriptionNBEC0353COMPONENT DESCRIPTIONNBEC0353S01The vacuum cut valve and vacuum cut valve bypass valve are

installed in parallel on the EVAP purge line between the fuel tank

and the EVAP canister.

The vacuum cut valve prevents the intake manifold vacuum from

being applied to the fuel tank.

The vacuum cut valve bypass valve is a solenoid type valve and

generally remains closed. It opens only for on board diagnosis.

The vacuum cut valve bypass valve responds to signals from the

ECM. When the ECM sends an ON (ground) signal, the valve is

opened. The vacuum cut valve is then bypassed to apply intake

manifold vacuum to the fuel tank.

EVAPORATIVE EMISSION SYSTEM DIAGRAMNBEC0353S02

SEF373Z

CONSULT-II Reference Value in Data Monitor

Mode

NBEC0354Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

VC/V BYPASS/VIIgnition switch: ON OFF

ECM Terminals and Reference ValueNBEC0682Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

39 G/WVacuum cut valve

bypass valve[Ignition switch ªONº]BATTERY VOLTAGE

(11 - 14V)

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Description

EC-591

Page 1129 of 2395

Wiring DiagramNBEC0359

MEC972C

DTC P1491 VACUUM CUT VALVE BYPASS VALVE

Wiring Diagram

EC-594

Page 1142 of 2395

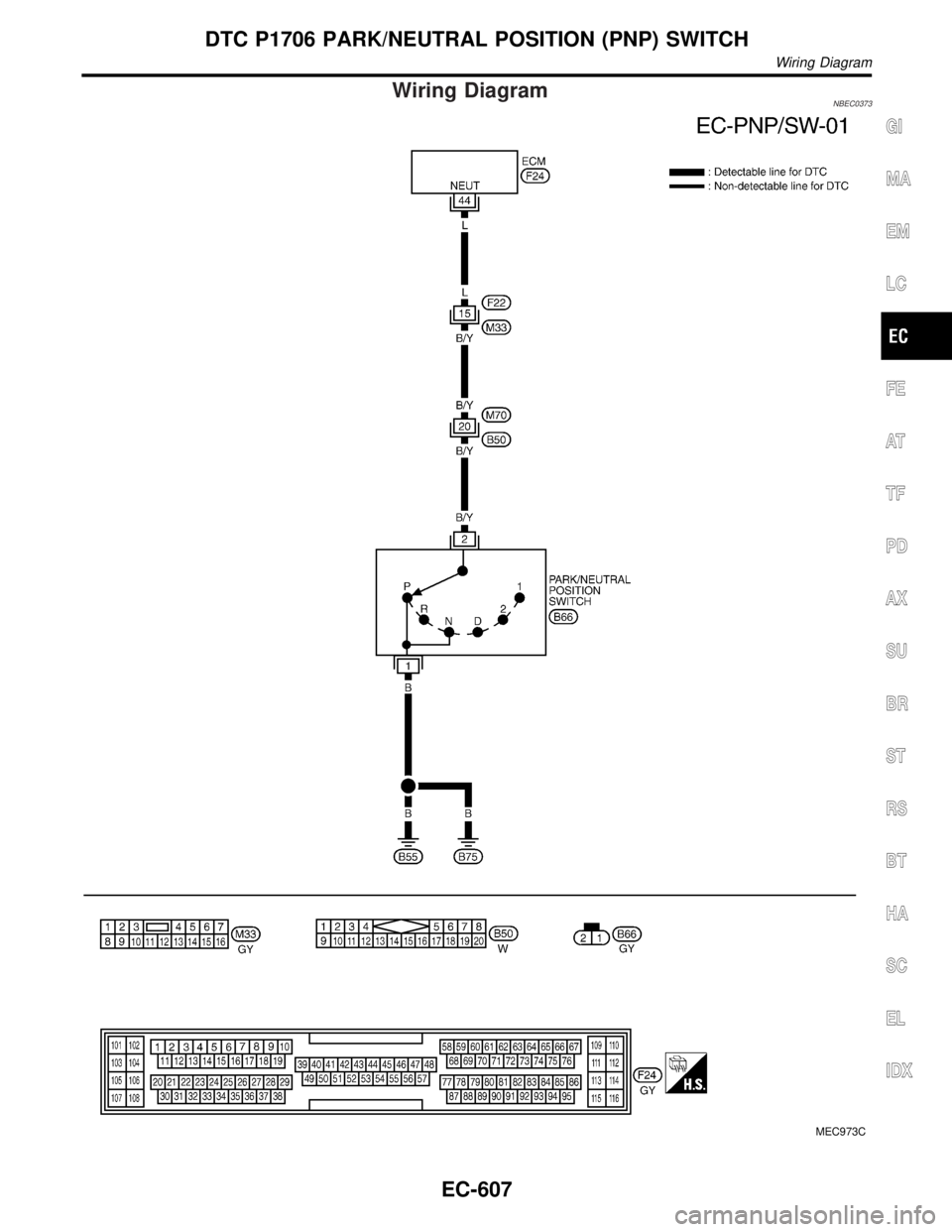

Wiring DiagramNBEC0373

MEC973C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCH

Wiring Diagram

EC-607

Page 1143 of 2395

Diagnostic ProcedureNBEC0374

1 CHECK PNP SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect park/neutral position (PNP) switch harness connector.

SEF011SA

3. Check harness continuity between PNP switch terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check harness for open or short between park/neutral position (PNP) switch and engine ground.

©Repair open circuit or short to power in harness or connectors.

3 CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 44 and PNP switch terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors F22, M33 and M70, B50

IHarness for open or short between ECM and park/neutral position (PNP) switch

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK PARK/NEUTRAL POSITION (PNP) SWITCH

Refer to AT-115, ªDiagnostic Procedureº.

OK or NG

OK©GO TO 6.

NG©Replace park/neutral position (PNP) switch.

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCH

Diagnostic Procedure

EC-608

Page 1147 of 2395

Wiring DiagramNBEC0597

MEC990C

VARIABLE INDUCTION AIR CONTROL SYSTEM (VIAS)

Wiring Diagram

EC-612

Page 1149 of 2395

2 CHECK VIAS CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Stop engine.

2. Disconnect VIAS control solenoid valve harness connector.

SEF019Z

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEF603X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M32, F23

I10A fuse

IHarness continuity between fuse and VIAS control solenoid valve

©Repair harness or connectors.

4 CHECK VIAS CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 16 and terminal 2. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

VARIABLE INDUCTION AIR CONTROL SYSTEM (VIAS)

Diagnostic Procedure (Cont'd)

EC-614

Page 1152 of 2395

Wiring DiagramNBEC0386

MEC974C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

INJECTOR

Wiring Diagram

EC-617

Page 1154 of 2395

3 CHECK INJECTOR POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

SEF023Z

2. Turn ignition switch ªONº.

3. Check voltage between injector terminal 1 and ground with CONSULT-II or tester.

SEF364Z

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors M33, F22

IHarness connectors F5, F100

IFuse block (J/B) connector M10

I10A fuse

IHarness for open or short between injector and fuse

©Repair harness or connectors.

5 CHECK INJECTOR OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between injector terminal 2 and ECM terminals 103, 104, 107, 101, 105, 102. Refer to Wiring

Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©GO TO 6.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

INJECTOR

Diagnostic Procedure (Cont'd)

EC-619