charging INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1943 of 2395

HFC-134a (R-134a) Service ProcedureNBHA0070SETTING OF SERVICE TOOLS AND EQUIPMENTNBHA0070S01DISCHARGING REFRIGERANTNBHA0070S0101WARNING:

Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Remove HFC-134a (R-134a) from A/C system using certified service equipment meeting require-

ments of SAE J2210 (R-134a recycling equipment) or J2209 (R-134a recovery equipment). If acciden-

tal system discharge occurs, ventilate work area before resuming service. Additional health and safety

information may be obtained from refrigerant and lubricant manufacturers.

SHA179FA

Evacuating System and Charging RefrigerantNBHA0070S0102

SHA180FA

SERVICE PROCEDURE

HFC-134a (R-134a) Service Procedure

HA-144

Page 1947 of 2395

Lubricant Adjusting Procedure for Components

Replacement Except Compressor

=NBHA0071S0201After replacing any of the following major components, add the

correct amount of lubricant to the system.

Amount of lubricant to be added

Part replacedLubricant to be added to

system

Remarks

Amount of lubricant

m(US fl oz, Imp fl oz)

Evaporator 75 (2.5, 2.6) Ð

Condenser 75 (2.5, 2.6) Ð

Liquid tank 5 (0.2, 0.2)Add if compressor is not

replaced. *1

In case of refrigerant

leak30 (1.0, 1.1) Large leak

Ð Small leak *2

*1: If compressor is replaced, addition of lubricant is included in the table.

*2: If refrigerant leak is small, no addition of lubricant is needed.

Lubricant Adjusting Procedure for Compressor

Replacement

NBHA0071S02021. Before connecting ACR4 to vehicle, check ACR4 gauges. No

refrigerant pressure should be displayed. If NG, recover refrig-

erant from equipment lines.

2. Connect ACR4 to vehicle. Confirm refrigerant purity in supply

tank using ACR4 and refrigerant identifier. If NG, refer to

ªCONTAMINATED REFRIGERANTº, HA-2.

3. Confirm refrigerant purity in vehicle A/C system using ACR4

and refrigerant identifier. If NG, refer to ªCONTAMINATED

REFRIGERANTº, HA-2.

4. Discharge refrigerant into the refrigerant recovery/recycling

equipment. Measure lubricant discharged into the recovery/

recycling equipment.

5. Remove the drain plug of the ªoldº (removed) compressor.

Drain the lubricant into a graduated container and record the

amount of drained lubricant.

6. Remove the drain plug and drain the lubricant from the ªnewº

compressor into a separate, clean container.

7. Measure an amount of new lubricant installed equal to amount

drained from ªoldº compressor. Add this lubricant to ªnewº com-

pressor through the suction port opening.

8. Measure an amount of new lubricant equal to the amount

recovered during discharging. Add this lubricant to ªnewº com-

pressor through the suction port opening.

9. Torque the drain plug.

18 - 19 N´m (1.8 - 1.9 kg-m, 13 - 14 ft-lb)

10. If the liquid tank also needs to be replaced, add an additional

5m(0.2 US fl oz, 0.2 Imp fl oz) of lubricant at this time.

Do not add this 5 m(0.2 US fl oz, 0.2 Imp fl oz) of lubri-

cant if only replacing the compressor.

SERVICE PROCEDURE

Maintenance of Lubricant Quantity in Compressor (Cont'd)

HA-148

Page 1954 of 2395

CHECKING FOR REFRIGERANT LEAKS=NBHA0078IPerform a visual inspection of all refrigeration parts, fittings,

hoses and components for signs of A/C lubricant leakage,

damage and corrosion. A/C lubricant leakage may indicate an

area of refrigerant leakage. Allow extra inspection time in these

areas when using either an electronic refrigerant leak detector

or fluorescent dye leak detector.

IIf dye is observed, confirm the leak with an electronic refriger-

ant leak detector. It is possible a prior leak was repaired and

not properly cleaned.

IWhen searching for leaks, do not stop when one leak is found

but continue to check for additional leaks at all system compo-

nents and connections.

IWhen searching for refrigerant leaks using an electronic leak

detector, move the probe along the suspected leak area at 1

to 2 inches per second and no further than 1/4 inch from the

component.

NOTE:

Moving the electronic leak detector probe slower and closer to

the suspected leak area will improve the chances of finding a

leak.

CHECKING SYSTEM FOR LEAKS USING THE

FLUORESCENT LEAK DETECTOR

NBHA01161. Check A/C system for leaks using the UV lamp and safety

glasses (J-42220) in a low sunlight area (area without windows

preferable). Illuminate all components, fittings and lines. The

dye will appear as a bright green/yellow area at the point of

leakage. Fluorescent dye observed at the evaporator drain

opening indicates an evaporator core assembly (tubes, core or

TXV) leak.

2. If the suspected area is difficult to see, use an adjustable mir-

ror or wipe the area with a clean shop rag or cloth, then check

the cloth with the UV lamp for dye residue.

3. After the leak is repaired, remove any residual dye using dye

cleaner (J-43872) to prevent future misdiagnosis.

4. Perform a system performance check and verify the leak repair

with an approved electronic refrigerant leak detector.

NOTE:

IOther gases in the work area or substances on the A/C

components, for example, anti-freeze, windshield washer

fluid, solvents and lubricants, may falsely trigger the leak

detector. Make sure the surfaces to be checked are clean.

Clean with a dry cloth or blow off with shop air.

IDo not allow the sensor tip of the detector to contact with

any substance. This can also cause false readings and

may damage the detector.

DYE INJECTIONNBHA0117(This procedure is only necessary when re-charging the system or

when the compressor has seized and was replaced.)

1. Check A/C system static (at rest) Pressure. Pressure must be

at least 345 kPa (50 psi).

2. Pour one bottle (1/4 ounce /7.4 cc) of the A/C refrigerant dye

into the injector tool (J-41459).

3. Connect the injector tool to the A/C LOW PRESSURE side

service fitting.

4. Start engine and switch A/C ON.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

SERVICE PROCEDURE

Refrigerant Lines (Cont'd)

HA-155

Page 1959 of 2395

CompressorNBHA0081

ModelCALSONIC make V-6

TypeV-6 variable displacement

Displacement

cm

3(cu in)/rev.Max. 184 (11.228)

Min. 14.5 (0.885)

Cylinder bore x stroke

mm (in)37 (1.46) x [2.3 - 28.6 (0.091 - 1.126)]

Direction of rotationClockwise (viewed from drive end)

Drive beltPoly V

LubricantNBHA0082

ModelCALSONIC make V-6

NameNissan A/C System Oil Type S

Part number*KLH00-PAGS0

Capacity

m(US fl oz, Imp fl oz)Total in system 200 (6.8, 7.0)

Compressor (Service part) charging amount 200 (6.8, 7.0)

*: Always check with the Parts Department for the latest parts information.

RefrigerantNBHA0083

TypeHFC-134a (R-134a)

Capacity

kg (lb)0.60 - 0.70 (1.32 - 1.54)

Engine Idling Speed (When A/C is ON)NBHA0084IRefer to EC-649, ªIdle Speed and Ignition Timingº.

Belt TensionNBHA0085IRefer to MA-29, ªEngine Maintenanceº.

SERVICE DATA AND SPECIFICATIONS (SDS)

Compressor

HA-160

Page 1961 of 2395

A

AAC/V - Wiring diagram ...............................EC-425

ABS - Wiring diagram ....................................BR-37

ABS sensor rotor ........................................AX-6, 19

Absolute pressure sensor ............................EC-158

A/C air flow .....................................................HA-25

A/C component layout ....................................HA-19

A/C compressor clutch removal and

installation .................................................HA-150

A/C compressor precaution..............................HA-6

A/C compressor special service tool..............HA-10

A/C control operation (auto A/C) ....................HA-23

A/C diagnostic work flow (auto A/C) ..............HA-65

A/C HFC134a (R134a) system

precaution .....................................................HA-2

A/C HFC134a (R134a) system service

procedure ..................................................HA-144

A/C HFC134a (R134a) system service

tools.............................................................HA-11

A/C HFC134a system service equip-

ment precaution ............................................HA-7

A/C lubricant (R134a)...................................HA-146

A/C operational check ....................................HA-66

A/C performance chart .................................HA-116

A/C performance test diagnoses ..................HA-114

A/C relay .......................................................HA-110

A/C self-diagnoses (auto A/C)........................HA-44

A/C service data specification ......................HA-160

A/C system description (auto A/C) .................HA-23

A/C trouble diagnoses (auto A/C) ..................HA-27

A/C, A - Wiring diagram ...........................HA-31, 36

Accelerator control system ...............................FE-3

Accelerator wire adjustment .............................FE-3

Actuator lever (Transfer) ...............................TF-120

Air bag ............................................................RS-10

Air bag disposal..............................................RS-22

Air bag precautions ...........................................GI-3

Air bleeding for brake system ..........................BR-8

Air cleaner filter replacement .........................MA-17

Air conditioner cut control ..............................EC-31

Air flow meter - See Mass air flow

sensor .......................................................EC-150

Air mix door control linkage adjustment.........HA-85

Air mix. door motor ................................HA-82, 141

Air spoiler, rear................................................BT-35

All - mode 4WD system ..................................TF-10

Alternator ........................................................SC-28

Ambient sensor ............................................HA-129

Angular tightening application..........................EM-3

Antenna - See Power antenna .....................EL-169

Anti-lock brake system - Wiring

diagram .......................................................BR-37

AP/SEN - Wiring diagram ............................EC-160

ASCD (automatic speed control device) ......EL-221

ASCD - Wiring diagram ................................EL-225

A/T - Wiring diagram - AT - FTS ...................AT-107

A/T - Wiring diagram - AT - MAIN ...................AT-96

A/T - Wiring diagram - AT - PNP/SW............AT-101A/T - Wiring diagram - AT - VSS A/T ............AT-113

A/T control ....................................................EC-440

A/T diagnosis communication line................EC-603

A/T fluid temperature sensor .........................AT-110

A/T self-diagnoses...........................................AT-46

A/T shift lock system .....................................AT-265

A/T shift lock system - Wiring diagram .........AT-266

A/T trouble diagnoses .....................................AT-53

A/T Wiring diagram - AT - ENG SS...............AT-117

A/T Wiring diagram AT - 1ST ........................AT-123

A/T Wiring diagram AT - 2ND .......................AT-129

A/T Wiring diagram AT - 3RD .......................AT-135

A/T Wiring diagram AT - 4TH ........................AT-142

A/T Wiring diagram AT - BA/FTS ..................AT-192

A/T Wiring diagram AT - LPSV .....................AT-164

A/T Wiring diagram AT - NONDTC ...............AT-215

A/T Wiring diagram AT - OVRCSV ...............AT-187

A/T Wiring diagram AT - SSV/A ....................AT-169

A/T Wiring diagram AT - SSV/B ....................AT-173

A/T Wiring diagram AT - TCCSIG .................AT-156

A/T Wiring diagram AT - TCV .......................AT-150

A/T Wiring diagram AT - TPS........................AT-179

A/T Wiring diagram AT - VSSMTR................AT-199

AT/C - Wiring diagram ..................................EC-442

ATP switch.....................................................TF-112

ATP warning lamp .........................................TF-102

Audio .............................................................EL-160

AUDIO - Wiring diagram ...............................EL-162

Audio and A/C control removal and

installation - See Instrument panel .............BT-21

AUT/DP - Wiring diagram .............................EL-191

Auto air conditioner - Wiring diagram ......HA-31, 36

Automatic amplifier...................................HA-40, 72

Automatic drive positioner ............................EL-186

Automatic speed control system - See

ASCD ........................................................EL-221

Automatic transmission fluid

replacement ................................................MA-21

Automatic transmission number ......................GI-43

Auxiliary air control (AAC) valve ..................EC-422

Axle housing (rear) .........................................AX-19

B

Back door ........................................................BT-15

Back door opener - See Back door ................BT-15

Back door trim.................................................BT-34

Back-up lamp ..................................................EL-69

BACK/L - Wiring diagram................................EL-69

Ball joint (front) ...............................................SU-12

Base idle air volume initialiging......................EC-57

Basic inspection ...........................................EC-101

Battery ..............................................................SC-4

Battery/Starting/Charging System

Tester ................................................SC-7, 12, 21

Blower motor ..................................................HA-95

Body alignment ...............................................BT-57

Brake booster .................................................BR-19

Brake control valve (Proportioning

valve)...........................................................BR-11

ALPHABETICAL INDEX

IDX-2

Page 1962 of 2395

Brake fluid change ...........................................BR-7

Brake fluid level .............................................MA-25

Brake fluid level and line check .......................BR-7

Brake hydraulic line ..........................................BR-9

Brake inspection ............................................MA-25

Brake lines and cables inspection .................MA-25

Brake lining wear temporary checking ..........MA-26

Brake master cylinder ....................................BR-16

Brake pedal ....................................................BR-14

Bulb specifications ........................................EL-456

Bumper, front ..................................................BT-12

Bumper, rear ...................................................BT-15

BYPS/V - Wiring diagram ....................EC-587, 594

C

Camshaft inspection ......................................EM-42

Camshaft position sensor (PHASE) .............EC-342

Canister-See EVAP canister ..........................EC-32

Center bearing assembly (propeller

shaft) .............................................................PD-9

Center bearing disassembly (propeller

shaft) .............................................................PD-7

Center case (Transfer) ..................................TF-123

CHARGE - Wiring diagram ............................SC-20

Charging system ............................................SC-19

Chassis and body maintenance ....................MA-21

CHIME - Wiring diagram...............................EL-127

CIGAR - Wiring diagram ...............................EL-148

Cigarette lighter.............................................EL-148

Circuit breaker.................................................EL-16

CKPS - Wiring diagram ................................EC-334

Closed loop control (Left bank) ....................EC-491

Closed loop control (Right bank) .................EC-491

Closed throttle position switch .....................EC-431

Clutch drum (Transfer) ..................................TF-125

Clutch force release limit adjustment .............TF-39

Clutch pressure switch (Transfer) .................TF-111

Coil spring (front)..............................................SU-8

Coil spring (rear) ............................................SU-18

Collision diagnosis..........................................RS-59

Combination lamp, front, removal and

installation ...................................................BT-12

Combination lamp, rear, removal and

installation ...................................................BT-35

Combination meter..........................................EL-94

Combination meter removal and instal-

lation - See Instrument panel ......................BT-21

Combination switch .........................................EL-28

COMPAS - Wiring diagram ...........................EL-111

Compass .......................................................EL-110

Component Location (auto A/C).....................HA-27

Compression pressure ...................................EM-14

Compressor clutch removal and

installation .................................................HA-150

Compressor precaution ....................................HA-6

Compressor special service tool ....................HA-10

Connecting rod...............................................EM-65

Connecting rod bearing clearance.................EM-69

Connecting rod bushing clearance ................EM-70Connector inspection .......................................GI-21

Console box - See Instrument panel ..............BT-21

CONSULT for ABS .........................................BR-43

CONSULT for all-mode 4WD ..........................TF-30

CONSULT for engine .....................................EC-81

CONSULT-II general information .....................GI-38

Control valve (A/T) ........................................AT-301

Control valve (Transfer) ................................TF-128

Converter housing installation .......................AT-278

Coolant mixture ratio......................................MA-12

Coolant replacement ......................................MA-14

Cooling circuit (engine) ...................................LC-10

``Crankcase emission control system -

See positive crankcase ventilation''............EC-38

Crankshaft ......................................................EM-67

Crankshaft position sensor (POS) ...............EC-334

Crankshaft position sensor (POS)

chipping ....................................................EC-517

Crankshaft position sensor (REF) ................EC-510

Cruise control - See ASCD ...........................EL-221

Cylinder block ................................................EM-61

Cylinder head .................................................EM-38

Cylinder head bolt tightening .........................EM-49

D

Data link connector for Consult......................EC-81

Daytime light system.......................................EL-46

Daytime running light - See Daytime

light system .................................................EL-46

DEF - Wiring diagram ...................................EL-153

Detonation sensor - See Knock sensor .......EC-328

Diagnostic trouble code (DTC) for OBD

system ....................................................EC-8, 60

Diagnostic trouble code (DTC) inspec-

tion priority chart .......................................EC-116

Differential carrier assembly.....................PD-30, 57

Differential carrier disassembly ......................PD-44

Differential gear oil replacement ....................MA-24

Dimensions ......................................................GI-43

D/LOCK - Wiring diagram .............................EL-256

Dome light - See Interior lamp .......................EL-88

Door glass .......................................................BT-18

Door lock .........................................................BT-18

Door mirror ......................................................BT-56

Door trim .........................................................BT-30

Door, front .......................................................BT-18

Door, rear ........................................................BT-20

Drive belt inspection ......................................MA-13

Drive chain (Transfer) ...................................TF-125

Drive pinion diff. inspection ......................PD-23, 47

Drive pinion height ...................................PD-25, 53

Drive plate runout ..........................................EM-70

Drive shaft (front)............................................AX-10

Dropping resistor (A/T) ..................................AT-167

DTC work support ..........................................EC-93

DTRL - Wiring diagram ...................................EL-51

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

ALPHABETICAL INDEX

IDX-3

Page 1966 of 2395

Propeller shaft greasing .................................MA-23

Propeller shaft inspection ..............................MA-23

Propeller shaft on vehicle service ....................PD-6

Propeller shaft vibration ...................................PD-6

PST/SW - Wiring diagram ............................EC-635

R

Rack retainer adjustment ..................................ST-8

Radiator ....................................................LC-19, 21

Radio - See Audio.........................................EL-160

Rear air spoiler ...............................................BT-35

Rear axle ........................................................AX-17

Rear bumper ...................................................BT-15

Rear case (Transfer) .....................................TF-123

Rear combination lamp removal and

installation ...................................................BT-35

Rear cover packing replacement diff. ............PD-16

Rear door ........................................................BT-20

Rear drum brake ............................................BR-26

Rear heated oxygen sensor

(HO2S) .............................EC-247, 257, 267, 277

Rear heated oxygen sensor (HO2S)

heater ........................................................EC-286

Rear seat ........................................................BT-44

Rear seat belt ...................................................RS-5

Rear side window ...........................................BT-55

Rear suspension ............................................SU-15

Rear washer..................................................EL-141

Rear window defogger ..................................EL-151

Rear wiper.....................................................EL-141

REF - Wiring diagram ..................................EC-510

Refregerant pressure sensor ........................HA-111

Refrigerant connection precaution ...................HA-4

Refrigerant discharging evacuating

charging ....................................................HA-144

Refrigerant general precaution.........................HA-3

Refrigerant lines ...........................................HA-154

Refrigerant pressure sensor.........................EC-639

Refrigeration cycle..........................................HA-14

REMOTE - Wiring diagram ...........................EL-168

Removal and installation (A/T) ......................AT-277

Removal and installation (Transfer) ..............TF-119

Reverse clutch...............................................AT-314

Revolution sensor (A/T).................................AT-115

Ring gear diff. inspection .........................PD-23, 47

RO2H-L - Wiring diagram.............................EC-290

RO2H-R - Wiring diagram ............................EC-289

Road wheel size ..............................................GI-44

Roof trim .........................................................BT-32

Room lamp - See Interior lamp ......................EL-88

RRO2LH - Wiring diagram...EC-251, 261, 271, 281

RRO2RH - Wiring diagram ..EC-250, 260, 270, 280

S

SAE J1930 terminology list .............................GI-51

Screw jack .......................................................GI-45Seal - See Exterior .........................................BT-35

SEAT - Wiring diagram .................................EL-181

Seat belt inspection .............................MA-28, RS-7

Seat belt pre-tensioner .....................................RS-3

Seat belt pre-tensioner disposal ....................RS-22

Seat belt, front ..................................................RS-4

Seat belt, rear...................................................RS-5

Seat, front .......................................................BT-41

Seat, rear ........................................................BT-44

Self-diagnosis (Transfer) .................................TF-27

SHIFT - Wiring diagram ................................AT-266

Shift lock system ...........................................AT-265

Shift schedule ................................................AT-356

Shift solenoid valve A (A/T) ..AT-125, 137, 147, 171

Shift solenoid valve B (A/T) ..AT-125, 131, 147, 175

Shock absorber (rear) ....................................SU-18

Side air bag ....................................................RS-21

Side bearing preload (front final drive

4WD) ...........................................................PD-24

Side trim ..........................................................BT-28

Side window - See Rear side window ............BT-55

Smart entrance control unit ..........................EL-319

SMJ (super multiple junction) .......................Foldout

Spare tire size .................................................GI-44

Spark plug replacement .................................MA-19

Speedometer...................................................EL-94

Spiral cable.....................................................RS-17

Spot lamp ........................................................EL-88

Spring (Wheelarch) height ...............................SU-5

SROOF - Wiring diagram .............................EL-174

SRS - See Supplemental Restraint

System ........................................................RS-10

SRS - Wiring diagram ....................................RS-35

S/SIG - Wiring diagram ................................EC-622

Stabilizer bar (front)........................................SU-10

Stabilizer bar (rear) ........................................SU-20

Stall test (A/T) .................................................AT-59

Standardized relay ............................................EL-7

START - Wiring diagram.................................SC-11

Start signal ...................................................EC-621

Starter .............................................................SC-18

Starting system...............................................SC-10

Steering gear, linkage and transfer

gear inspection ...........................................MA-26

Steering linkage ..............................................ST-17

Steering switch................................................EL-30

Steering transfer gear .....................................ST-15

Steering wheel and column.............................ST-11

Steering wheel play ..........................................ST-7

Steering wheel turning force .............................ST-9

Stop lamp ........................................................EL-67

STOP/L - Wiring diagram................................EL-67

Strut (front) .......................................................SU-8

Sub-oil pump (Transfer) ................................TF-131

Sun gear (Transfer).......................................TF-134

Sun roof, electric ...........................................EL-173

Sunload sensor ............................................HA-135

Sunroof............................................................BT-45

Supplemental Restraint System .....................RS-10

Supplemental restraint system - Wiring

diagram .......................................................RS-35

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

ALPHABETICAL INDEX

IDX-7

Page 2016 of 2395

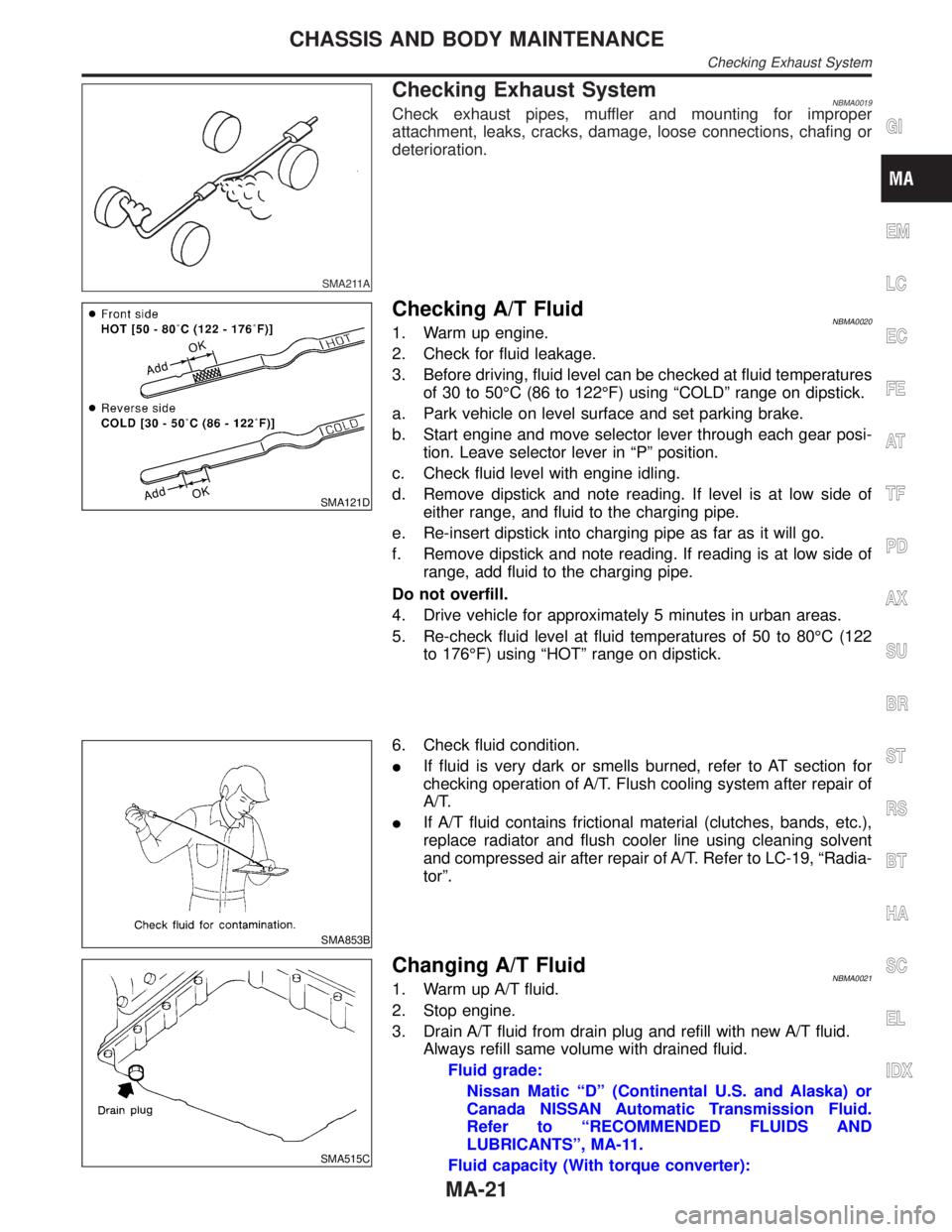

SMA211A

Checking Exhaust SystemNBMA0019Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, loose connections, chafing or

deterioration.

SMA121D

Checking A/T FluidNBMA00201. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50ÉC (86 to 122ÉF) using ªCOLDº range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in ªPº position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of

either range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of

range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80ÉC (122

to 176ÉF) using ªHOTº range on dipstick.

SMA853B

6. Check fluid condition.

IIf fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

IIf A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to LC-19, ªRadia-

torº.

SMA515C

Changing A/T FluidNBMA00211. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

Fluid grade:

Nissan Matic ªDº (Continental U.S. and Alaska) or

Canada NISSAN Automatic Transmission Fluid.

Refer to ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-11.

Fluid capacity (With torque converter):

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CHASSIS AND BODY MAINTENANCE

Checking Exhaust System

MA-21

Page 2129 of 2395

![INFINITI QX4 2001 Factory User Guide SRS701

If no malfunction is detected on ªSELF-DIAG [CURRENT]º even

though malfunction is detected in ªSRS Operation Checkº, check

the battery voltage.

If the battery voltage is less than 9V, charg INFINITI QX4 2001 Factory User Guide SRS701

If no malfunction is detected on ªSELF-DIAG [CURRENT]º even

though malfunction is detected in ªSRS Operation Checkº, check

the battery voltage.

If the battery voltage is less than 9V, charg](/img/42/57027/w960_57027-2128.png)

SRS701

If no malfunction is detected on ªSELF-DIAG [CURRENT]º even

though malfunction is detected in ªSRS Operation Checkº, check

the battery voltage.

If the battery voltage is less than 9V, charge the battery. Then go

to DIAGNOSTIC PROCEDURE 3, page RS-42.

If the battery voltage is OK, go to DIAGNOSTIC PROCEDURE 4,

page RS-44, to diagnose the following cases:

ISelf-diagnostic result ªSELF-DIAG [PAST]º (previously stored

in the memory) might not be erased after repair.

IThe SRS system malfunctions intermittently.

8. Touch ªPRINTº.

9. Compare diagnostic codes to ªCONSULT-II Diagnostic Code

Chartº, page RS-40.

10. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears in order to return to User mode from Diagnosis mode.

11. Turn ignition switch ªOFFº, then turn off and disconnect

CONSULT-II, and disconnect both battery cables.

12. Repair the system as outlined by the ªRepair orderº in ªCON-

SULT-II Diagnostic Code Chartº, that corresponds to the self-

diagnostic result. For replacement procedure of component

parts, refer to RS-15.

13. After repairing the system, go to DIAGNOSTIC PROCEDURE

3, page RS-42 for final checking.

CONSULT-II Diagnostic Code Chart (ªSELF-DIAG

[CURRENT]º)

NBRS0045S0101

Diagnostic item ExplanationRepair order

ªRecheck SRS at each replace-

ment.º

NO DTC IS

DETECTED.When malfunction is

indicated by the ªAIR

BAGº warning lamp in

User modeILow battery voltage (Less than 9V)IGo to DIAGNOSTIC PROCEDURE 3

(RS-42) after charging battery.

ISelf-diagnostic result ªSELF-DIAG

[PAST]º (previously stored in the

memory) might not be erased after

repair.

IIntermittent malfunction has been

detected in the past.IGo to DIAGNOSTIC PROCEDURE 4

(RS-44).

INo malfunction is detected.IGo to DIAGNOSTIC PROCEDURE 3

(RS-42).

AIRBAG MODULE

[OPEN]IDriver's air bag module circuit is open. (including the spiral

cable)1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. Replace driver's air bag module.

(Before disposal of it, it must be

deployed.)

4. Replace the spiral cable.

5. Replace the diagnosis sensor unit.

6. Replace the related harness.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-40

Page 2135 of 2395

SRS704

9. Diagnostic code is displayed on ªTROUBLE DIAG RECORDº.

10. Touch ªPRINTº.

11. Compare diagnostic codes to ªIntermittent Malfunction Diag-

nostic Code Chartº, page RS-46.

12. Touch ªBACKº key of CONSULT-II until ªSELECT SYSTEMº

appears.

13. Turn ignition switch ªOFFº, then turn off and disconnect

CONSULT-II, and disconnect both battery cables.

14. Repair the system as outlined by the ªRepair orderº in ªInter-

mittent Malfunction Diagnostic Code Chartº, that corresponds

to the self-diagnostic result. For replacement procedure of

component parts, refer to RS-15.

15. Go to DIAGNOSTIC PROCEDURE 3, page RS-42, for final

checking.

Intermittent Malfunction Diagnostic Code Chart (ªSELF-

DIAG [PAST]º or ªTROUBLE DIAG RECORDº)

NBRS0045S0401

Diagnostic item Explanation Repair order

NO DTC IS

DETECTED.When malfunction is

indicated by the ªAIR

BAGº warning lamp in

User modeILow battery voltage (Less than 9V)IGo to DIAGNOSTIC PROCEDURE

3 (RS-42) after charging battery.

INo malfunction is detected.IGo to DIAGNOSTIC PROCEDURE

3 (RS-42).

AIRBAG MODULE

[OPEN]IDriver's air bag module circuit is open. (including the spiral

cable)1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. If the harness check result is OK,

replace driver's air bag module

(Before disposal of it, it must be

deployed.), diagnosis sensor unit

and spiral cable. AIRBAG MODULE

[VB-SHORT]IDriver's air bag module circuit is shorted to some power sup-

ply circuit. (including the spiral cable)

AIRBAG MODULE

[GND-SHORT]IDriver's air bag module circuit is shorted to ground. (including

the spiral cable)

AIRBAG MODULE

[SHORT]IDriver's air bag module circuits are shorted to each other.

ASSIST A/B MODULE

[VB-SHORT]IFront passenger air bag module circuit is shorted to some

power supply circuit.1. Visually check the wiring harness

connection.

2. Replace the harness if it has visible

damage.

3. If the harness check result is OK,

replace front air bag module

(Before disposal of it, it must be

deployed.), and diagnosis sensor

unit. ASSIST A/B MODULE

[OPEN]IFront passenger air bag module circuit is open.

ASSIST A/B MODULE

[GND-SHORT]IFront passenger air bag module circuit is shorted to ground.

ASSIST A/B MODULE

[SHORT]IFront passenger air bag module circuits are shorted to each

other.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses with CONSULT-II (Cont'd)

RS-46