wheel alignment INFINITI QX4 2001 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2226 of 2395

SFA449BA

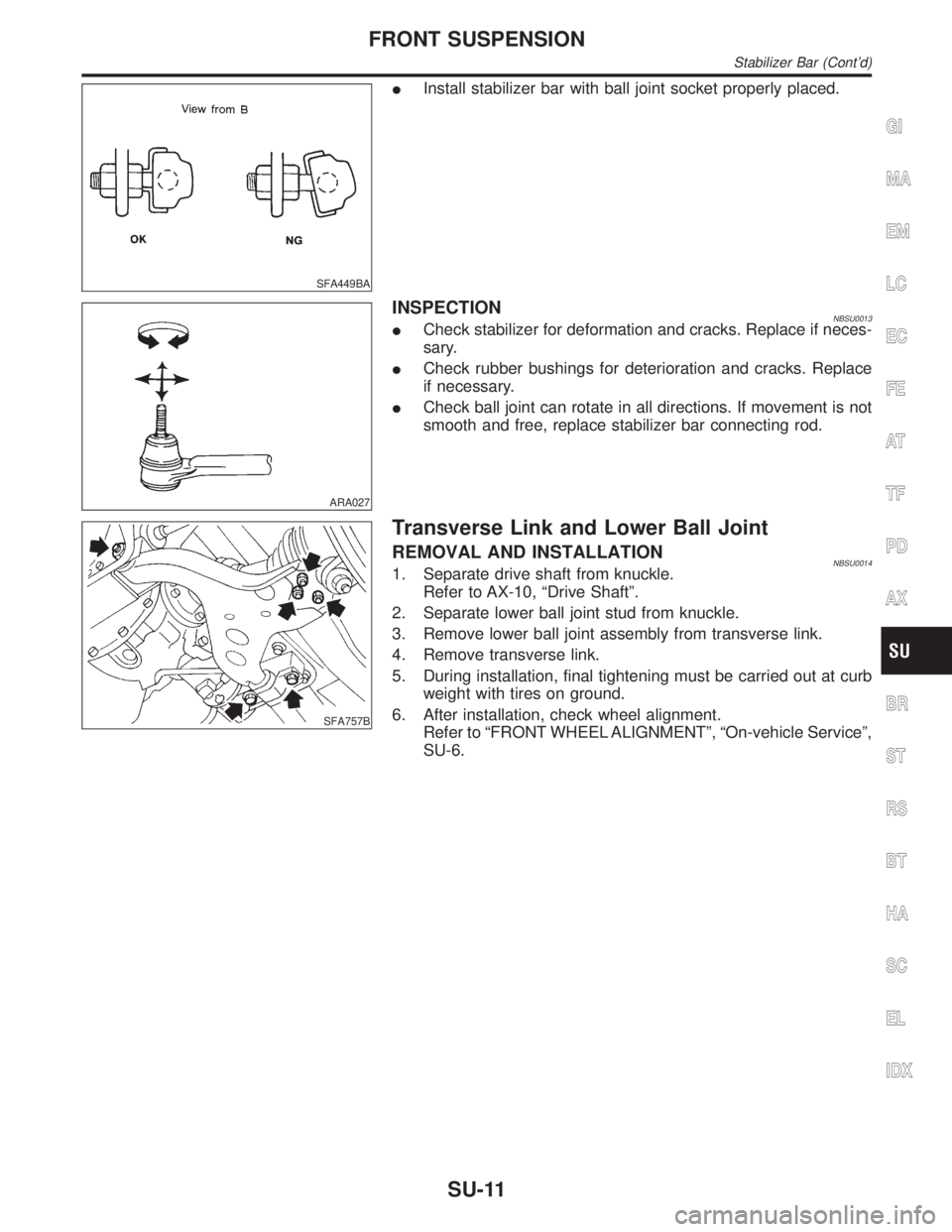

IInstall stabilizer bar with ball joint socket properly placed.

ARA027

INSPECTIONNBSU0013ICheck stabilizer for deformation and cracks. Replace if neces-

sary.

ICheck rubber bushings for deterioration and cracks. Replace

if necessary.

ICheck ball joint can rotate in all directions. If movement is not

smooth and free, replace stabilizer bar connecting rod.

SFA757B

Transverse Link and Lower Ball Joint

REMOVAL AND INSTALLATIONNBSU00141. Separate drive shaft from knuckle.

Refer to AX-10, ªDrive Shaftº.

2. Separate lower ball joint stud from knuckle.

3. Remove lower ball joint assembly from transverse link.

4. Remove transverse link.

5. During installation, final tightening must be carried out at curb

weight with tires on ground.

6. After installation, check wheel alignment.

Refer to ªFRONT WHEEL ALIGNMENTº, ªOn-vehicle Serviceº,

SU-6.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT SUSPENSION

Stabilizer Bar (Cont'd)

SU-11

Page 2228 of 2395

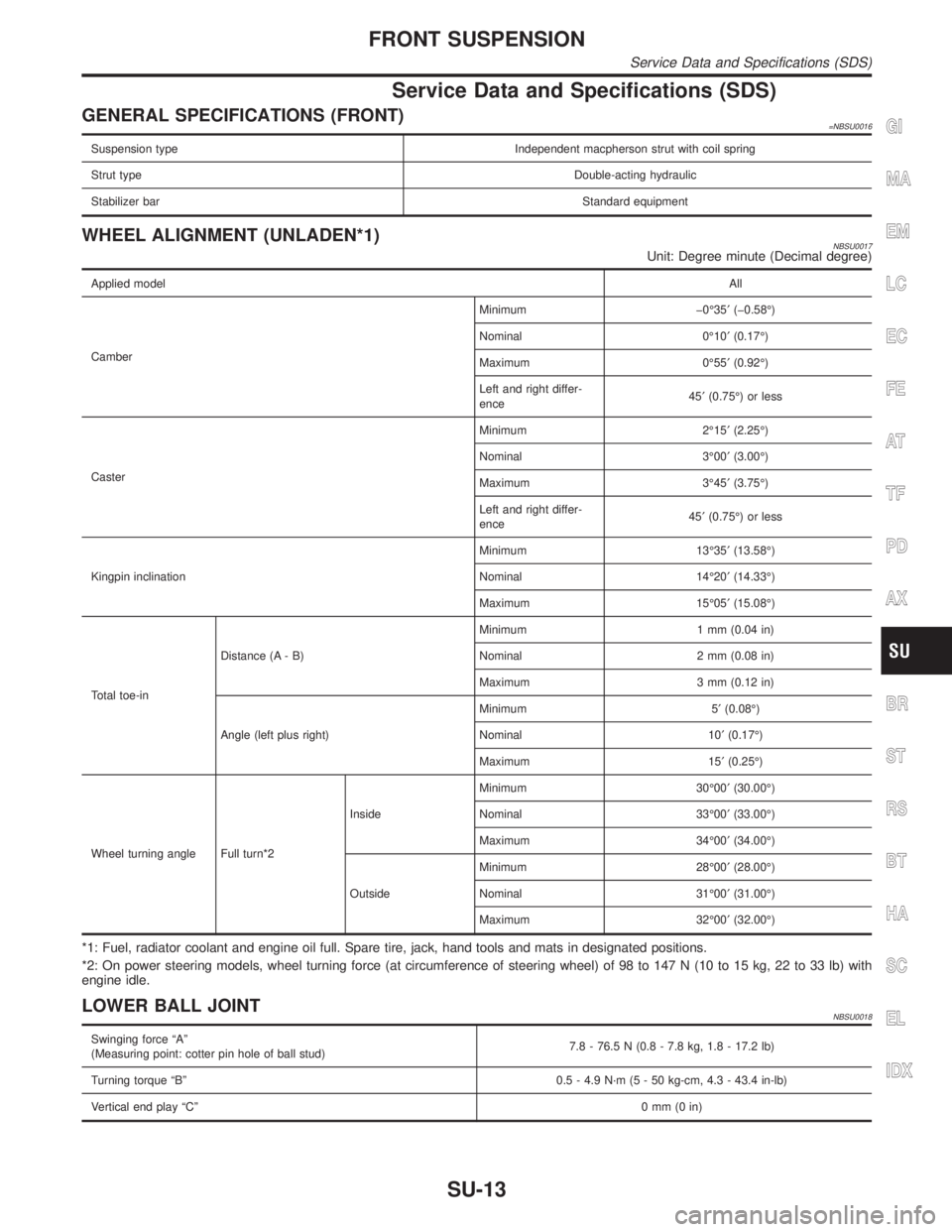

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS (FRONT)=NBSU0016

Suspension type Independent macpherson strut with coil spring

Strut typeDouble-acting hydraulic

Stabilizer barStandard equipment

WHEEL ALIGNMENT (UNLADEN*1)NBSU0017Unit: Degree minute (Decimal degree)

Applied modelAll

CamberMinimum þ0É35¢(þ0.58É)

Nominal 0É10¢(0.17É)

Maximum 0É55¢(0.92É)

Left and right differ-

ence45¢(0.75É) or less

CasterMinimum 2É15¢(2.25É)

Nominal 3É00¢(3.00É)

Maximum 3É45¢(3.75É)

Left and right differ-

ence45¢(0.75É) or less

Kingpin inclinationMinimum 13É35¢(13.58É)

Nominal 14É20¢(14.33É)

Maximum 15É05¢(15.08É)

Total toe-inDistance (A - B)Minimum 1 mm (0.04 in)

Nominal 2 mm (0.08 in)

Maximum 3 mm (0.12 in)

Angle (left plus right)Minimum 5¢(0.08É)

Nominal 10¢(0.17É)

Maximum 15¢(0.25É)

Wheel turning angle Full turn*2InsideMinimum 30É00¢(30.00É)

Nominal 33É00¢(33.00É)

Maximum 34É00¢(34.00É)

OutsideMinimum 28É00¢(28.00É)

Nominal 31É00¢(31.00É)

Maximum 32É00¢(32.00É)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: On power steering models, wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with

engine idle.

LOWER BALL JOINTNBSU0018

Swinging force ªAº

(Measuring point: cotter pin hole of ball stud)7.8 - 76.5 N (0.8 - 7.8 kg, 1.8 - 17.2 lb)

Turning torque ªBº 0.5 - 4.9 N´m (5 - 50 kg-cm, 4.3 - 43.4 in-lb)

Vertical end play ªCº0mm(0in)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT SUSPENSION

Service Data and Specifications (SDS)

SU-13

Page 2230 of 2395

SBR686C

Precautions

PRECAUTIONSNBSU0021IWhen installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

IUse flare nut wrench when removing and installing brake

tubes.

IAfter installing removed suspension parts, check wheel

alignment and adjust if necessary.

IAlways torque brake lines when installing.

Preparation

COMMERCIAL SERVICE TOOLSNBSU0023

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBSU0036Refer to ªNoise, Vibration and Harshness (NVH) Troubleshootingº,

ªFRONT SUSPENSIONº, SU-3.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

REAR SUSPENSION

Precautions

SU-15