display INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2146 of 2395

4 CHECK DIAGNOSIS SENSOR UNIT

Connect CONSULT-II and touch ªSTARTº.

IIs ªAIR BAGº displayed on CONSULT-II?

SRS771

YesorNo

Ye s©GO TO 5.

No©Visually check the wiring harness connection of diagnosis sensor unit. If the harness

connection check result is OK, replace diagnosis sensor unit.

5 CHECK HARNESS CONNECTION

Is harness connection between warning lamp and diagnosis sensor unit OK?

OK or NG

OK©Replace diagnosis sensor unit.

NG©Connect ªAIR BAGº warning lamp and diagnosis sensor unit connector properly. If ªAIR

BAGº warning lamp still does not go off, replace harness.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Trouble Diagnoses: ªAIR BAGº Warning Lamp Does Not Turn Off (Cont'd)

RS-57

Page 2159 of 2395

SEL406X

5. Locate the battery type and rating stamped or written on the

top case of the battery to be tested.

NOTE:

The battery type and rating will have either of the following.

CCA: Cold Cranking Amps (490 CCA, 550 CCA, etc.)

JIS: Japanese Industrial Standard.

Battery is stamped with a number such as:

80D26L: 80 (rank of output), D (physical size-depth), 26 (width

in cm). The last character L (post configuration) is not input into

the tester.

The tester requires the rating for the battery be entered exactly

as it is written or stamped on the battery. Do not attempt a CCA

conversion for JIS stamped batteries. JIS must be input

directly.

6. Using the arrow and ªENTERº keys alternately, select the bat-

tery type and rating.

NOTE:

The tester lists five choices; CCA, JIS, IEC, DIN, and EN. Only use

CCA or JIS.

SEL407X

7. Press ªENTERº to begin the test. Diagnosis results are dis-

played on the tester. Refer to ªDIAGNOSTIC RESULT ITEM

CHARTº SC-9.

SEL576X

8. Press ªENTERº, then test output code is displayed. Record the

test output code on the repair order.

9. Toggle back to the ªDIAGNOSTIC SCREENº for test results.

NOTE:

IIf necessary, the tester will ask the user to determine if the

battery has just been charged. Choose the appropriate selec-

tion by pressing the up or down arrow button and then press

the ªENTERº button to make the selection.

IWhen testing a battery installed in a vehicle that has recently

been driven, select ªBEFORE CHANGEº.

IIf the battery has just been slow charged due to a ªCHARGE

& RETESTº decision by the tester, and the tester asks the user

ªBEFORE CHARGE/AFTER CHARGEº, select ªAFTER

CHARGEº.

BATTERY

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-8

Page 2163 of 2395

Trouble Diagnoses with

Battery/Starting/Charging System Tester

NBSC0019NOTE:

To ensure a complete and thorough diagnosis, the battery, starter

and alternator test segments must be done as a set from start to

finish.

SEL408X

1. Turn off all loads on the vehicle electrical system.

2. Perform battery test with Battery/Starting/Charging system

tester. Refer to SC-7.

3. Press ªENTERº to begin the starting system test.

SEL409X

4. Start the engine.

SEL410X

5. Diagnosis result is displayed on the tester. Refer to ªDIAG-

NOSTIC RESULT ITEM CHARTº, SC-13.

NOTE:

IIf the starter performs normally but the engine does not start,

perform engine diagnosis.

IFor intermittent ªNO CRANKº or ªNO STARTER OPERATIONº

incidents, go to DIAGNOSTIC PROCEDURE 2.

STARTING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester

SC-12

Page 2172 of 2395

Trouble Diagnoses with

Battery/Starting/Charging System Tester

NBSC0020NOTE:

To ensure a complete and thorough diagnosis, the battery, starter

and alternator test segments must be done as a set from start to

finish.

SEL417X

1. Turn off all loads on the vehicle electrical system.

2. Perform battery and starting system test with Battery/Starting/

Charging system tester.

3. Press ªENTERº to begin the charging system test.

4. Start engine.

SEL418X

5. Press ªENTERº until ªLOADS OFF REV ENGINE 5 SECº is

displayed.

6. Raise and hold the engine speed at 1,500 to 2,000 rpm for

about 5 seconds, then return to the engine to idle.

Once the increase in engine rpm is detected, press ªENTERº

to continue.

NOTE:

IIf after 30 seconds an increase in engine idle speed is not

detected, ªRPM NOT DETECTEDº will display.

ISome engines may have a higher idle initially after starting,

particularly when the engine is cold. The tester may detect this

without any other action being taken. If this occurs, continue on

with the testing process. The final results will not be affected.

SEL419X

7. The tester now checks the engine at idle and performs the

DIODE/RIPPLE check.

8. When complete, the tester will prompt you to turn on the fol-

lowing electrical loads.

IHeater fun set to highest. Do not run the A/C or windshield

defroster.

IHeadlamp high beam

IRear window defogger

NOTE:

Do not run the windshield wipers or any other cyclical loads.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester

SC-21

Page 2173 of 2395

SEL420X

9. Press ªENTERº to continue.

SEL421X

10. Raise and hold the engine speed at 1,500 to 2,000 rpm for

about 5 seconds, then return the engine to idle. Once the

increase in engine rpm is detected, press ªENTERº to con-

tinue.

NOTE:

If after 30 seconds an increase in engine idle speed is not detected,

ªRPM NOT DETECTEDº will be displayed. Press ªENTERº to

restart the test.

SEL422X

11. Diagnostic result is displayed on the tester. Refer to ªDIAG-

NOSTIC RESULT ITEM CHARTº, SC-23.

SEL577X

12. Press ªENTERº then test output code is displayed. Record the

test output code on the repair order.

13. Toggle back to the ªDIAGNOSTIC SCREENº for test results.

CHARGING SYSTEM

Trouble Diagnoses with Battery/Starting/Charging System Tester (Cont'd)

SC-22

Page 2237 of 2395

LINE PRESSURE SWITCH...........................................83

Diagnostic Procedure ................................................83

ABS OPERATION SIGNAL...........................................86

Diagnostic Procedure ................................................86

DATA ERASE/DISPLAY...............................................88

Diagnostic Procedure ................................................88

SHIFT ACTUATOR........................................................89

Diagnostic Procedure ................................................89

SHIFT ACTUATOR POSITION SWITCH......................92

Diagnostic Procedure ................................................92

SHIFT ACTUATOR CIRCUIT........................................94

Diagnostic Procedure ................................................94

TROUBLE DIAGNOSES FOR SYMPTOMS.................98

Symptom 1. 4WD Shift Indicator Lamp Does Not

Turn ON .....................................................................98

Symptom 2. 4WD Warning Lamp Does Not Turn

ON............................................................................100

Symptom 3. 4WD Shift Indicator Lamp Does Not

Turn OFF .................................................................102

Symptom 4. ATP Warning Lamp Does Not Turn

ON............................................................................102

Symptom 5. 4LO Indicator Lamp Does Not Turn

ON............................................................................104

Symptom 6. 4WD Shift Indicator Lamp Does Not

Indicate²4H²............................................................106

Symptom 7. 4WD Shift Indicator Lamp Repeats

Flickering..................................................................107

Symptom 8. Tight Corner Braking Symptom...........108

Symptom 9. 4WD System Does Not Operate.........109

COMPONENT INSPECTION....................................... 111

4WD Shift Switch ..................................................... 111

2-4WD Shift Solenoid Valve and Transfer Fluid

Temperature Sensor ................................................ 111

4WD Solenoid Valve, Clutch Pressure Switch

and Line Pressure Switch........................................ 111

Front Revolution Sensor .......................................... 112

Transfer Dropping Resistor...................................... 112

ATP Switch, Neutral-4LO Switch and Wait

Detection Switch ...................................................... 112

Transfer Motor ......................................................... 113

Transfer Motor Relay ............................................... 113

Transfer Sub-harness .............................................. 113

FRONT REVOLUTION SENSOR SUB-HARNESS

CONNECTOR

........................................................ 113

TRANSFER SWITCH ASSEMBLY SUB-HARNESS

CONNECTOR

........................................................ 114

TRANSFER TERMINAL CORD ASSEMBLY SUB-

HARNESS CONNECTOR

....................................... 114

Transfer Shift Relay (High & low) ............................ 114

Actuator & Actuator Position Switch ........................ 115

ACTUATOR........................................................... 115

ACTUATOR POSITION SWITCH............................ 115

ON-VEHICLE SERVICE.............................................. 116

Replacing Oil Seal ................................................... 116

FRONT CASE OIL SEAL........................................ 116

SHIFT SHAFT OIL SEAL........................................ 117

REAR OIL SEAL.................................................... 117

Transfer Motor ......................................................... 117

REMOVAL............................................................. 117

INSTALLATION...................................................... 117

Transfer Oil Filter ..................................................... 118

REMOVAL............................................................. 118

INSTALLATION...................................................... 118

REMOVAL AND INSTALLATION............................... 119

Removal ................................................................... 119

Installation ................................................................ 119

OVERHAUL.................................................................120

Transfer Gear Control ..............................................120

Transfer Components ..............................................121

DISASSEMBLY............................................................123

Rear Case................................................................123

DISASSEMBLY......................................................123

Center Case.............................................................123

DISASSEMBLY......................................................123

Front Case ...............................................................133

DISASSEMBLY......................................................133

REPAIR FOR COMPONENT PARTS.........................137

Front Case ...............................................................137

INSPECTION.........................................................137

Center Case.............................................................138

INSPECTION.........................................................138

ASSEMBLY..................................................................141

Front Case ...............................................................141

ASSEMBLY...........................................................141

Center Case.............................................................145

ASSEMBLY...........................................................145

Final Assembly.........................................................153

SERVICE DATA AND SPECIFICATIONS (SDS).......157

General Specifications .............................................157

Inner Gear and Outer Gear .....................................157

SUB-OIL PUMP.....................................................157

MAIN OIL PUMP....................................................157

Control Valve ...........................................................157

VALVE..................................................................157

SPRING................................................................157

Clutch .......................................................................158

DRIVE PLATE.......................................................158

DRIVEN PLATE.....................................................158

RETURN SPRING..................................................158

RETAINING PLATE................................................158

Seal Ring (Mainshaft side) ......................................159

Bearing Race (Thrust needle bearing side) ............159

Snap Ring (Sun gear side) ......................................159

CONTENTS(Cont'd)

TF-2

Page 2264 of 2395

INDICATIONS OF 4WD WARNING LAMPNBTF0011S03

Flickering pattern or flick-

ering conditionMalfunction Check items

1 Front revolution sensor circuit is shorted or open.Revolution sensor (front) circuit,

TF-61.

2 Rear revolution sensor circuit is shorted or open.Revolution sensor (rear) [Refer to

AT-111, ªDTC P0720 Vehicle Speed

Sensor´A/T (Revolution sensor)º.]

3 4WD solenoid valve circuit is shorted or open. 4WD solenoid valve circuit, TF-64.

42-4WD shift solenoid valve circuit is shorted or 2WD switch of

4WD shift switch is shorted.2-4WD shift solenoid valve circuit or

4WD shift switch circuit, TF-66.

5 Transfer motor relay circuit is shorted or open. Transfer motor relay circuit, TF-70.

8Power supply voltage of throttle position sensor is improper. Or

A/D converter of transfer control unit functions improperly.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle Posi-

tion Sensorº.)

9 Transfer fluid temperature sensor circuit is open.Transfer fluid temperature sensor

circuit, TF-73.

10 Neutral-4LO switch circuit is shorted or open. Neutral-4LO switch circuit, TF-76.

112-4WD shift solenoid valve circuit, 2WD switch of 4WD shift

switch circuit or clutch pressure switch circuit is shorted or open.2-4WD shift solenoid valve circuit,

4WD shift switch circuit or clutch

pressure switch circuit, TF-66, 80.

12 Line pressure switch circuit is shorted or open. Line pressure switch circuit, TF-83.

13 Engine speed signal circuit is shorted or open.Engine speed signal (Refer to

AT-116, ªDTC P0725 Engine Speed

Signalº.)

14 Throttle position sensor circuit is shorted or open.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle Posi-

tion Sensorº.)

15 Failure in power supply circuit of transfer control unit. Power supply of transfer control unit

16 4WD shift switch circuit is shorted. 4WD shift switch circuit, TF-66.

17 ABS operation signal circuit is shorted. ABS operation signal circuit, TF-86.

18ATP switch, wait detection switch or neutral-4LO switch circuit is

shorted or open.ATP switch, wait detection switch or

neutral-4LO switch circuit*, TF-76.

19Transfer control device actuator motor is faulty. (Abnormalities

are detected when actuator motor fails to operate while shifting

from ª4Hº to ª4LOº or vice versa.)Actuator motor and motor circuit,

TF-115, 89.

20Transfer control device actuator motor arm position sensing

switch is faulty.Actuator motor arm position sensing

switch and sensing switch circuit,

TF-115, 92.

21Transfer control device actuator circuit is faulty (Abnormalities

are detected when motor relay circuit is open/shorted or relay

monitor circuit is open/shorted.)Actuator motor, actuator motor arm

position sensing switch and their

associated circuits, TF-114, 115 and

94.

Repeats flickering every

2 to 5 sec.Circuits that the self-diagnosis covers have no malfunction. Ð

Repeats flickering every

0.25 sec.IPower supply failure of memory back-up.

IBattery is disconnected for a long time.

IBattery performance is poor.Data erase/display circuit, TF-88.GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis without CONSULT-II (Cont'd)

TF-29

Page 2266 of 2395

SMT965D

6. Touch ªSELF-DIAG RESULTSº on SELECT DIAG MODE

screen.

SMT966D

7. Self-diagnostic results are displayed.

SELF-DIAGNOSTIC ITEMSNBTF0012S02

Detected items

(Screen terms for CONSULT-II,

ªSELF-DIAG RESULTº mode)Malfunction is detected when... Check items

Revolution sensor (front) (Note 3)

(VHCL SPEED SEN´FR)IFront revolution sensor (installed on T/F) signal is not

input due to open circuit.

IImproper signal is input while driving.Revolution sensor (front) circuit,

TF-61.

Revolution sensor (rear)

(VHCL SPEED SEN´RR)ISignal from vehicle speed sensor 1 (installed on A/T)

is not input due to open circuit.

IImproper signal is input while driving.Revolution sensor (rear) [Refer to

AT-111, ªDTC P0720 Vehicle Speed

Sensor´A/T (Revolution sensor)º.]

4WD solenoid valve

(DUTY SOLENOID)

IProper voltage is not applied to solenoid valve due to

open or short circuit.4WD solenoid valve, TF-64.

2-4WD shift solenoid valve

(2-4WD SOLENOID)2-4WD shift solenoid valve or

4WD shift switch circuit, TF-66.

Transfer motor relay

(MOTOR RELAY)IMotor does not operate properly due to open or short

circuit in transfer motor or motor relay.Transfer motor relay circuit,

TF-70.

Transfer fluid temperature sensor

(FLUID TEMP SENSOR)ISignal voltage from fluid temperature sensor is abnor-

mally high (T/F fluid temperature is abnormally low)

while driving.Transfer fluid temperature sensor

circuit, TF-73.

Neutral-4LO switch

(N POSI SW TF)IImproper signal is input while driving. Neutral-4LO switch, TF-76.

Clutch pressure

(CLUTCH PRESSURE)IImproper signal is input due to open or short circuit.

IMalfunction occurs in clutch pressure hydraulic circuit.Clutch pressure switch circuit

(*1), TF-80.

Line pressure

(LINE PRESSURE)IImproper signal is input due to open or short circuit.

IMalfunction occurs in line pressure hydraulic circuit.Line pressure switch circuit (*1),

TF-83.

Engine speed signal (Note 1)

(ENGINE SPEED SIG)IEngine speed is abnormally low while driving.Engine speed signal (Refer to

AT-116, ªDTC P0725 Engine Speed

Signalº.)

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-31

Page 2267 of 2395

Detected items

(Screen terms for CONSULT-II,

ªSELF-DIAG RESULTº mode)Malfunction is detected when... Check items

Throttle position sensor

(THRTL POSI SEN)ISignal voltage from throttle position sensor is abnor-

mally high.

ISignal voltage from throttle position sensor is abnor-

mally low when closed throttle position switch is OFF.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle

Position Sensorº.)

Transfer control unit (ADC)

C/U (ADC)/THRTL SENIPower supply voltage for throttle position sensor is

improper or A/D converter system of transfer control

unit is faulty.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle

Position Sensorº.)

Battery voltage (Note 1)

(BATTERY VOLTAGE)IPower supply voltage for transfer control unit is abnor-

mally low while driving.Power supply circuit (Refer to

AT-96, ªWiring Diagram Ð AT Ð

MAINº.)

4WD shift switch

(4WD MODE SW)IMore than two switch inputs are simultaneously

detected due to short circuit of 4WD shift switch.4WD shift switch circuit, TF-66.

ABS operation signal (Note 4)

(ABS OPER SIGNAL)IWhen a malfunction signal due to disconnection or

shorting is detected.

IWhen a defect signal is entered from the ABS control

unit.ABS operation signal circuit,

TF-86.

Wait detection switch (Note 2)

(WAIT DETECT SWITCH)IImproper signal is input due to open or short circuit.ATP switch, wait detection switch

and neutral-4LO switch circuits

(*2), TF-76.

Shift actuator abnormal

(SHIFT ACT)Transfer control device actuator motor is faulty. (Abnor-

malities are detected when actuator motor fails to oper-

ate while shifting from ª4Hº to ª4LOº or vice versa.)Actuator motor and motor circuit,

TF-115, 89.

Shift actuator position switch

abnormal

(SHIFT ACT P/S)Transfer control device actuator motor arm position sens-

ing switch is faulty.Actuator motor arm position

sensing switch and sensing

switch circuit, TF-115, 92.

Shift actuator circuit abnormal

(SHIFT ACT CIR)Transfer control device actuator circuit is faulty (Abnor-

malities are detected when motor relay circuit is open/

shorted or relay monitor circuit is open/shorted.)Actuator motor, actuator motor

arm position sensing switch and

their associated circuits, TF-114,

115 and 94.

Memory power supply stopIDue to removal of battery which cuts off power supply

to transfer control unit, self-diagnosis memory function

is suspended.Data erase/display circuit, TF-88.

Transfer control unit (RAM)

[CONTROL UNIT (RAM)]IFailure is detected in the memory (RAM) system of

transfer control unit.

Transfer control unit (ROM)

[CONTROL UNIT (ROM)]IFailure is detected in the memory (ROM) system of

transfer control unit.

Transfer control unit (EEPROM)

[CONTROL UNIT (EEPROM)]IFailure is detected in the memory (EEPROM) system

of transfer control unit.

Note 1: When a malfunction occurs, it is only displayed and not stored in the memory.

Note 2: When the wait detection switch has been properly fixed, malfunction information is erased from the memory.

Note 3: If 4WD shift switch is left between 4H and 4LO for a while, this indication may be displayed.

(*1): If the malfunction is detected only while driving in reverse, check the continuity of ªRº position on A/T PNP switch. When there is

nothing wrong with the electrical system, check the hydraulic system.

(*2): If a revolution sensor malfunction is detected at the same time, check the revolution sensor circuit first.

Note 4: When this malfunction is detected with the ABS warning lamp off, first check for disconnection or shorting in the harness between

the transfer control unit and the ABS control unit.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-32

Page 2268 of 2395

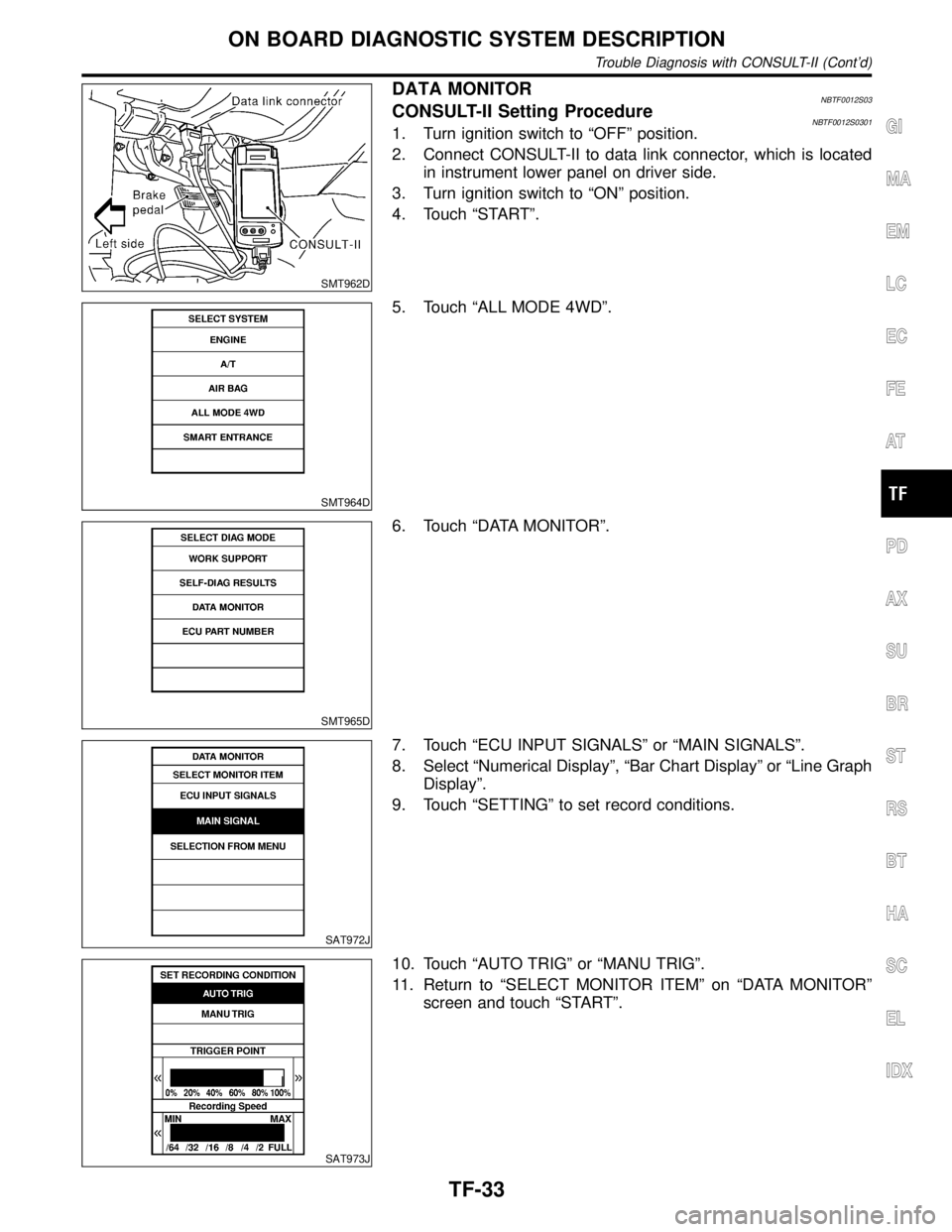

SMT962D

DATA MONITORNBTF0012S03CONSULT-II Setting ProcedureNBTF0012S03011. Turn ignition switch to ªOFFº position.

2. Connect CONSULT-II to data link connector, which is located

in instrument lower panel on driver side.

3. Turn ignition switch to ªONº position.

4. Touch ªSTARTº.

SMT964D

5. Touch ªALL MODE 4WDº.

SMT965D

6. Touch ªDATA MONITORº.

SAT972J

7. Touch ªECU INPUT SIGNALSº or ªMAIN SIGNALSº.

8. Select ªNumerical Displayº, ªBar Chart Displayº or ªLine Graph

Displayº.

9. Touch ªSETTINGº to set record conditions.

SAT973J

10. Touch ªAUTO TRIGº or ªMANU TRIGº.

11. Return to ªSELECT MONITOR ITEMº on ªDATA MONITORº

screen and touch ªSTARTº.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-33