service INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1999 of 2395

NBMA0003

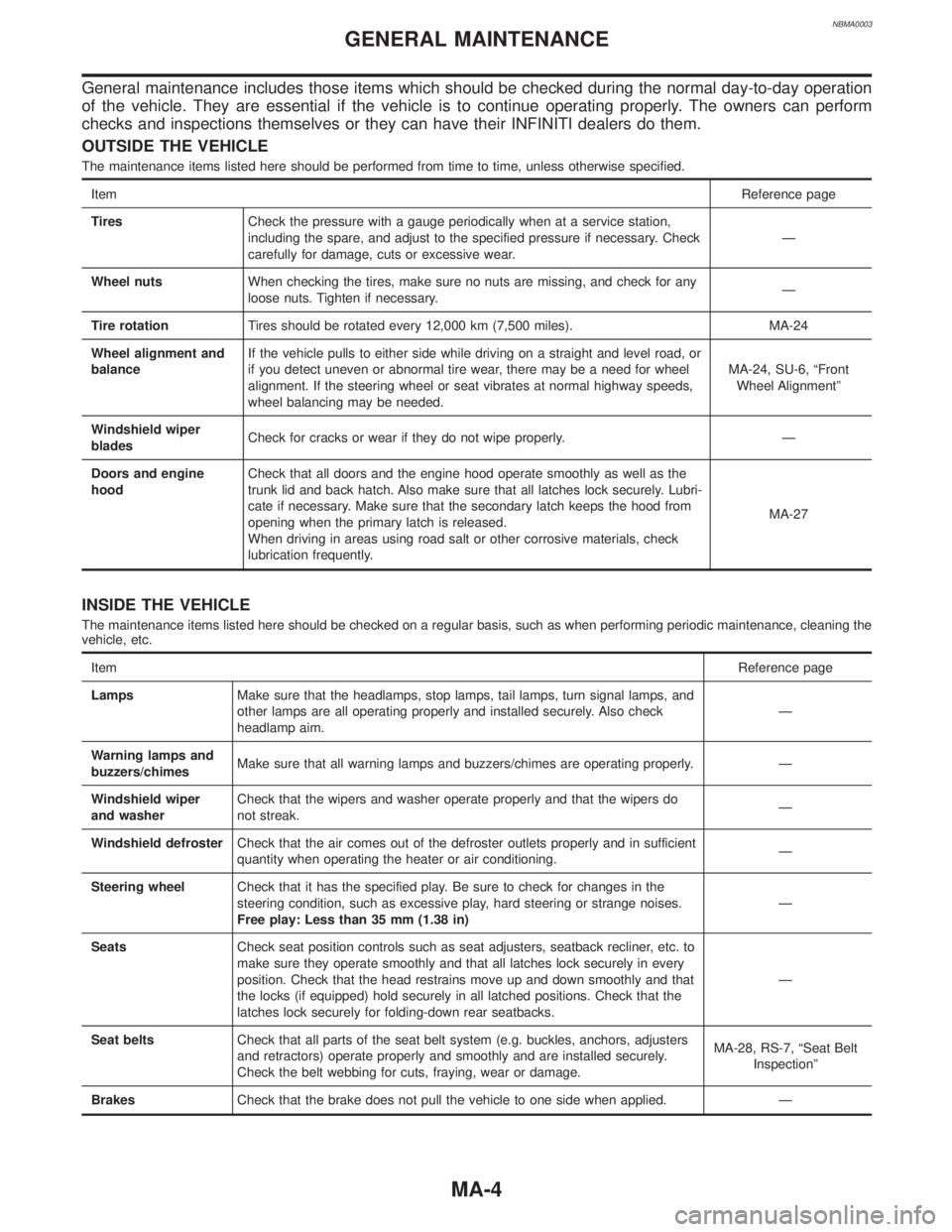

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or they can have their INFINITI dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

ItemReference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.Ð

Wheel nutsWhen checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.Ð

Tire rotationTires should be rotated every 12,000 km (7,500 miles). MA-24

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or

if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed.MA-24, SU-6, ªFront

Wheel Alignmentº

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the

trunk lid and back hatch. Also make sure that all latches lock securely. Lubri-

cate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check

lubrication frequently.MA-27

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

ItemReference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.Ð

Warning lamps and

buzzers/chimesMake sure that all warning lamps and buzzers/chimes are operating properly. Ð

Windshield wiper

and washerCheck that the wipers and washer operate properly and that the wipers do

not streak.Ð

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning.Ð

Steering wheelCheck that it has the specified play. Be sure to check for changes in the

steering condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

SeatsCheck seat position controls such as seat adjusters, seatback recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every

position. Check that the head restrains move up and down smoothly and that

the locks (if equipped) hold securely in all latched positions. Check that the

latches lock securely for folding-down rear seatbacks.Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.MA-28, RS-7, ªSeat Belt

Inspectionº

BrakesCheck that the brake does not pull the vehicle to one side when applied. Ð

GENERAL MAINTENANCE

MA-4

Page 2024 of 2395

Engine Maintenance

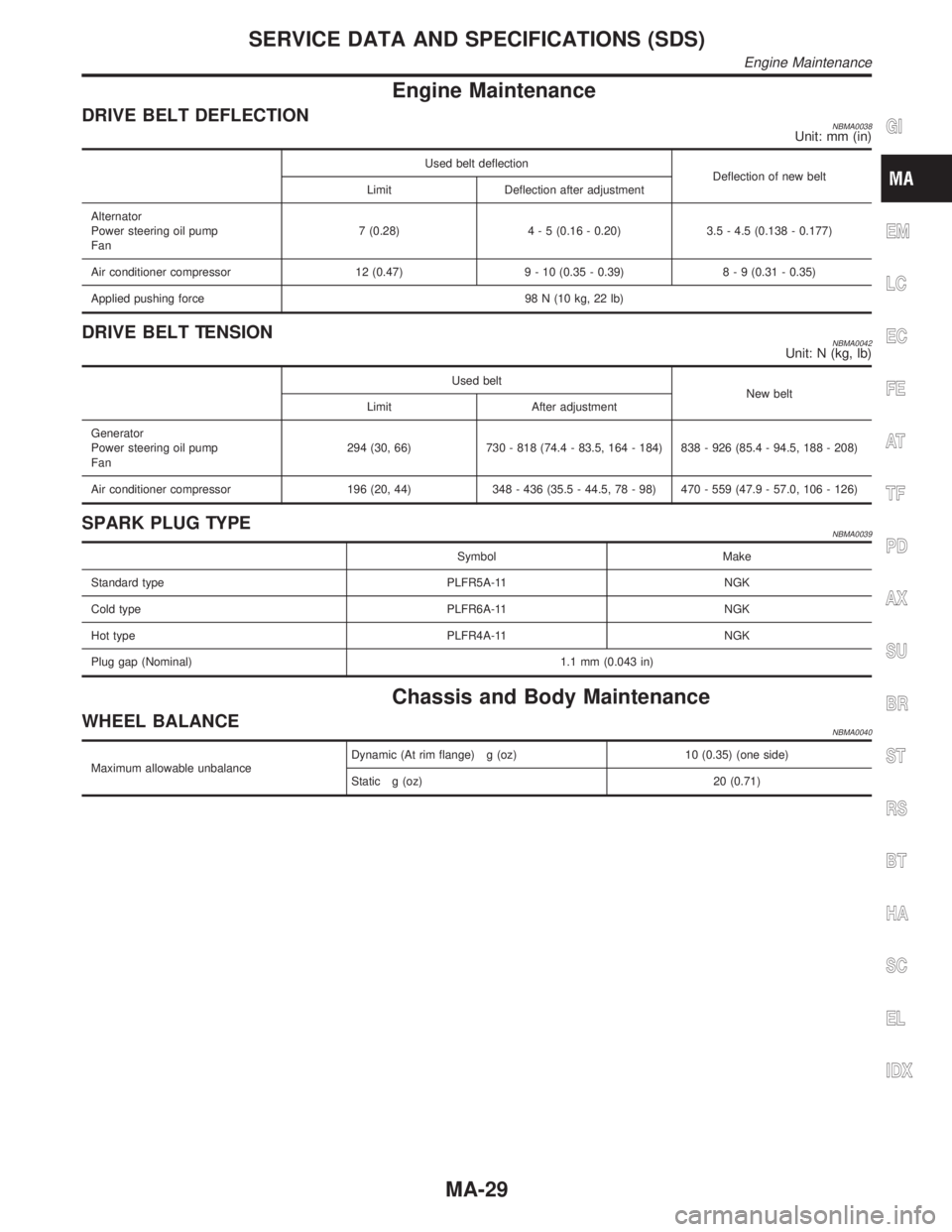

DRIVE BELT DEFLECTIONNBMA0038Unit: mm (in)

Used belt deflection

Deflection of new belt

Limit Deflection after adjustment

Alternator

Power steering oil pump

Fan7 (0.28)4 - 5 (0.16 - 0.20) 3.5 - 4.5 (0.138 - 0.177)

Air conditioner compressor 12 (0.47) 9 - 10 (0.35 - 0.39)8 - 9 (0.31 - 0.35)

Applied pushing force 98 N (10 kg, 22 lb)

DRIVE BELT TENSIONNBMA0042Unit: N (kg, lb)

Used belt

New belt

Limit After adjustment

Generator

Power steering oil pump

Fan294 (30, 66) 730 - 818 (74.4 - 83.5, 164 - 184) 838 - 926 (85.4 - 94.5, 188 - 208)

Air conditioner compressor 196 (20, 44) 348 - 436 (35.5 - 44.5, 78 - 98) 470 - 559 (47.9 - 57.0, 106 - 126)

SPARK PLUG TYPENBMA0039

Symbol Make

Standard type PLFR5A-11 NGK

Cold type PLFR6A-11 NGK

Hot type PLFR4A-11 NGK

Plug gap (Nominal) 1.1 mm (0.043 in)

Chassis and Body Maintenance

WHEEL BALANCENBMA0040

Maximum allowable unbalanceDynamic (At rim flange) g (oz) 10 (0.35) (one side)

Static g (oz) 20 (0.71)

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Engine Maintenance

MA-29

Page 2026 of 2395

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PROPELLER SHAFT......................................................3

Noise, Vibration and Harshness (NVH)

Troubleshooting ...........................................................3

NVH TROUBLESHOOTING CHART............................3

Components.................................................................4

FRONT PROPELLER SHAFT.....................................4

REAR PROPELLER SHAFT.......................................5

On-vehicle Service.......................................................6

PROPELLER SHAFT VIBRATION...............................6

APPEARANCE CHECKING........................................6

Removal and Installation .............................................6

Inspection.....................................................................7

Disassembly.................................................................7

CENTER BEARING - 2WD -.......................................7

JOURNAL (71H AND 80B)..........................................8

Assembly .....................................................................9

CENTER BEARING - 2WD -.......................................9

JOURNAL (71H AND 80B)..........................................9

Service Data and Specifications (SDS)..................... 11

GENERAL SPECIFICATIONS................................... 11

SERVICE DATA....................................................... 11

SNAP RING (80B).................................................... 11

SNAP RING (71H)...................................................12

R200A

FRONT FINAL DRIVE...................................................13

Preparation ................................................................13

SPECIAL SERVICE TOOLS......................................13

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................15

On-vehicle Service.....................................................15

FRONT OIL SEAL REPLACEMENT...........................15

REAR COVER GASKET REPLACEMENT..................16

Components...............................................................17

Removal and Installation ...........................................18

REMOVAL...............................................................18

INSTALLATION........................................................18

Disassembly...............................................................18

PRE-INSPECTION...................................................18

FINAL DRIVE HOUSING..........................................19

DIFFERENTIAL CASE..............................................21

DIFFERENTIAL SIDE SHAFT...................................22

Inspection...................................................................23

RING GEAR AND DRIVE PINION.............................23

DIFFERENTIAL CASE ASSEMBLY...........................23

BEARING................................................................23

Adjustment .................................................................24

SIDE BEARING PRELOAD.......................................24

PINION GEAR HEIGHT AND PINION BEARING

PRELOAD

...............................................................25

TOOTH CONTACT...................................................29

Assembly ...................................................................30

DIFFERENTIAL SIDE SHAFT...................................30

DIFFERENTIAL CASE..............................................31

FINAL DRIVE HOUSING..........................................32

Service Data and Specifications (SDS).....................36

R200A.....................................................................36

H233B

REAR FINAL DRIVE.....................................................38

Preparation ................................................................38

SPECIAL SERVICE TOOLS......................................38

Noise, Vibration and Harshness (NVH)

Troubleshooting .........................................................40

On-vehicle Service.....................................................40

FRONT OIL SEAL REPLACEMENT...........................40

Components...............................................................42

Removal and Installation ...........................................43

REMOVAL...............................................................43

INSTALLATION........................................................43

Disassembly...............................................................43

PRE-INSPECTION...................................................43

DIFFERENTIAL CARRIER........................................44

DIFFERENTIAL CASE..............................................46

Inspection...................................................................47

RING GEAR AND DRIVE PINION.............................47

DIFFERENTIAL CASE ASSEMBLY...........................47

BEARING................................................................47

Limited Slip Differential ..............................................47

PREPARATION FOR DISASSEMBLY........................47

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 2027 of 2395

DISASSEMBLY........................................................48

INSPECTION...........................................................49

ADJUSTMENT.........................................................50

ASSEMBLY.............................................................51

Adjustment .................................................................53

PINION GEAR HEIGHT............................................53

TOOTH CONTACT...................................................56Assembly ...................................................................57

DIFFERENTIAL CASE..............................................57

DIFFERENTIAL CARRIER........................................58

Service Data and Specifications (SDS).....................62

H233B.....................................................................62

CONTENTS(Cont'd)

PD-2

Page 2031 of 2395

SPD356A

On-vehicle Service

PROPELLER SHAFT VIBRATIONNBPD0003If vibration is present at high speed, inspect propeller shaft runout

first.

1. Raise rear wheels.

2. Measure propeller shaft runout at several points by rotating

final drive companion flange with hands.

Runout limit: 0.6 mm (0.024 in)

SPD523A

Propeller shaft runout measuring points:

Unit: mm (in)

Distance A B C

3F80B-2BJ 372.5 (14.67) 240 (9.45) 240 (9.45)

2S80B-T 280 (11.02) 463.5 (18.25) 266.5 (10.49)

2F71H 173.5 (6.83) Ð Ð

SPD102

3. If runout exceeds specifications, disconnect propeller shaft at

final drive companion flange; then rotate companion flange

180 degrees and reconnect propeller shaft.

4. Check runout again. If runout still exceeds specifications,

replace propeller shaft assembly.

5. Perform road test.

APPEARANCE CHECKINGNBPD0004IInspect propeller shaft tube surface for dents or cracks.

If damaged, replace propeller shaft assembly.

IIf center bearing is noisy or damaged, replace center bearing.

SPD103

Removal and InstallationNBPD0005IPut matchmarks on flanges and separate propeller shaft from

final drive.

PROPELLER SHAFT

On-vehicle Service

PD-6

Page 2036 of 2395

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS=NBPD00092WD ModelNBPD0009S01

TransmissionA/T

Propeller shaft model3F80B-2BJ

Number of joints3

Coupling method with transmissionFlange type

Type of journal bearings Solid type (disassembly type Ð without birfield joint Ð)

Distance between yokes mm (in)80 (3.15)

Shaft length (Spider to spider) mm (in)1st 650 (25.59)

2nd 749 (29.49)

Shaft outer diameter mm (in)1st 75 (2.95)

2nd 65 (2.56)

4WD ModelNBPD0009S02

LocationFront Rear

Propeller shaft model 2F71H 2S80B-T

Number of joints2

Coupling method with transmission Flange type Sleeve type

Type of journal bearingsSolid type (disassembly type)

Distance between yokes mm (in) 71 (2.80) 80 (3.15)

Shaft length (Spider to spider) mm (in) 553 (21.77) 927 (36.50)

Shaft outer diameter mm (in) 50.8 (2.000) 75 and 63.5 (2.95 and 2.500)

SERVICE DATANBPD0010Unit: mm (in)

Propeller shaft runout limit0.6 (0.024)

Journal axial play0.02 (0.0008) or less

SNAP RING (80B)NBPD0011Unit: mm (in)

Thickness Color Part number*

1.99 (0.0783) White 37146-C9400

2.02 (0.0795) Yellow 37147-C9400

2.05 (0.0807) Red 37148-C9400

2.08 (0.0819) Green 37149-C9400

2.11 (0.0831) Blue 37150-C9400

2.14 (0.0843) Light brown 37151-C9400

2.17 (0.0854) Black 37152-C9400

2.20 (0.0866) No paint 37153-C9400

*: Always check with the Parts Department for the latest parts information.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PROPELLER SHAFT

Service Data and Specifications (SDS)

PD-11

Page 2037 of 2395

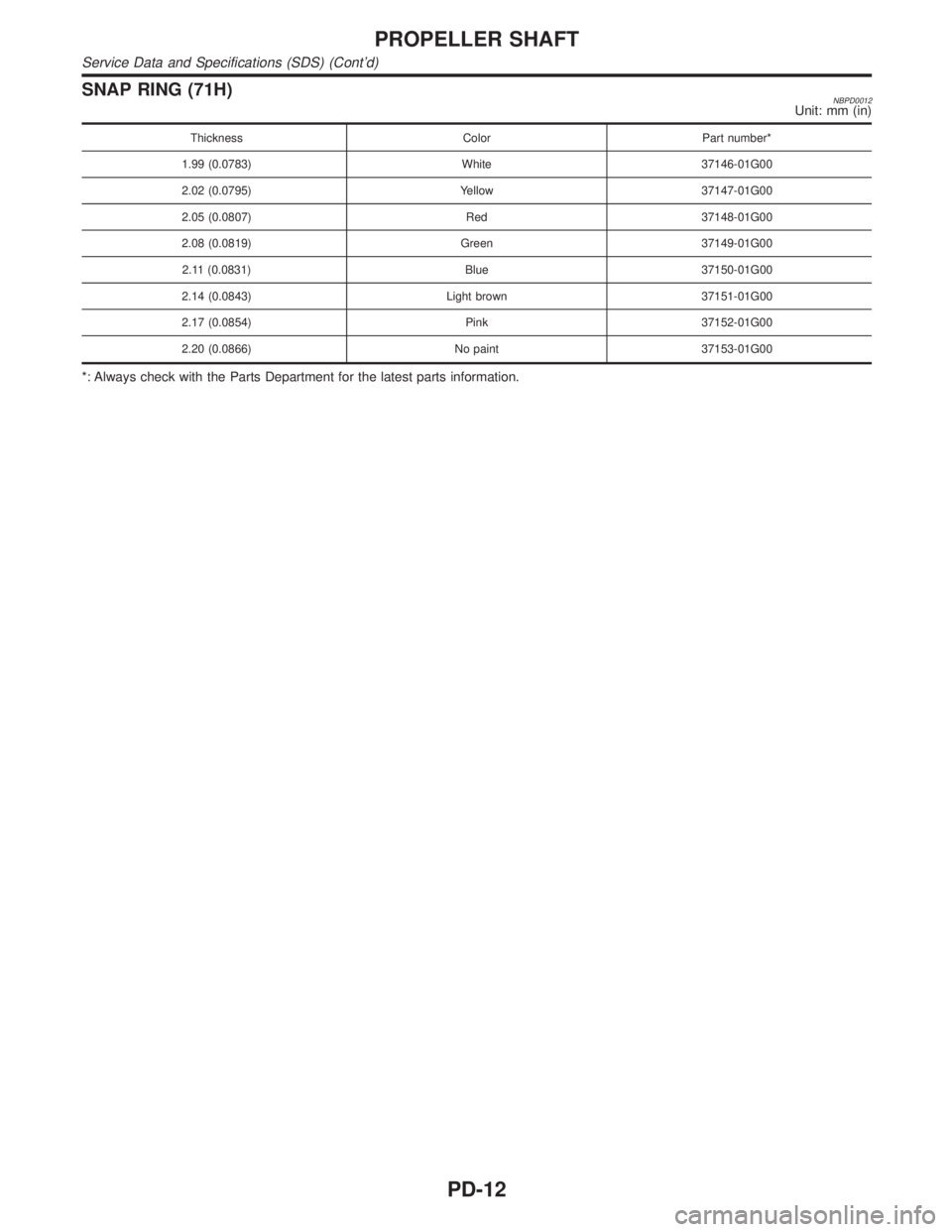

SNAP RING (71H)NBPD0012Unit: mm (in)

Thickness Color Part number*

1.99 (0.0783) White 37146-01G00

2.02 (0.0795) Yellow 37147-01G00

2.05 (0.0807) Red 37148-01G00

2.08 (0.0819) Green 37149-01G00

2.11 (0.0831) Blue 37150-01G00

2.14 (0.0843) Light brown 37151-01G00

2.17 (0.0854) Pink 37152-01G00

2.20 (0.0866) No paint 37153-01G00

*: Always check with the Parts Department for the latest parts information.

PROPELLER SHAFT

Service Data and Specifications (SDS) (Cont'd)

PD-12

Page 2038 of 2395

Preparation

SPECIAL SERVICE TOOLSNBPD0013The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST3127S000

(See J25765-A)

Preload gauge

1 GG91030000

(J25765)

Torque wrench

2 HT62940000

(Ð)

Socket adapter

3 HT62900000

(Ð)

Socket adapter

NT124

Measuring pinion bearing preload and total preload

KV38100800

(J34310, J25604-01)

Differential attachment

NT119

Mounting final drive

(To use, make a new hole.)

a: 152 mm (5.98 in)

KV38108300

(J44195)

Companion flange

wrench

NT771

Removing and installing propeller shaft lock nut,

and drive pinion lock nut

ST3090S000

(Ð)

Drive pinion rear inner

race puller set

1 ST30031000

(J22912-01)

Puller

2 ST30901000

(J26010-01)

Base

NT527

Removing and installing drive pinion rear inner

cone

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35 mm (1.38 in) dia.

ST3306S001

Differential side bearing

puller set

1 ST33051001

(J22888-20)

Body

2 ST33061000

(J8107-2)

Adapter

NT072

Removing and installing differential side bearing

inner cone

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.

KV38100300

(J25523)

Differential side bearing

drift

NT085

Installing side bearing inner cone

a: 54 mm (2.13 in) dia.

b: 46 mm (1.81 in) dia.

c: 32 mm (1.26 in) dia.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Preparation

PD-13

Page 2040 of 2395

Tool number

(Kent-Moore No.)

Tool nameDescription

(J8129)

Spring gauge

NT127

Measuring carrier turning torque

Noise, Vibration and Harshness (NVH)

Troubleshooting

NBPD0050Refer to ªNVH TROUBLESHOOTING CHARTº, PD-3.

SPD476A

On-vehicle Service

FRONT OIL SEAL REPLACEMENTNBPD00141. Remove front propeller shaft.

2. Loosen drive pinion nut.

Tool number: KV38108300 (J44195)

SPD734

3. Remove companion flange.

SPD735

4. Remove front oil seal.

GI

MA

EM

LC

EC

FE

AT

TF

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT FINAL DRIVER200A

Preparation (Cont'd)

PD-15

Page 2041 of 2395

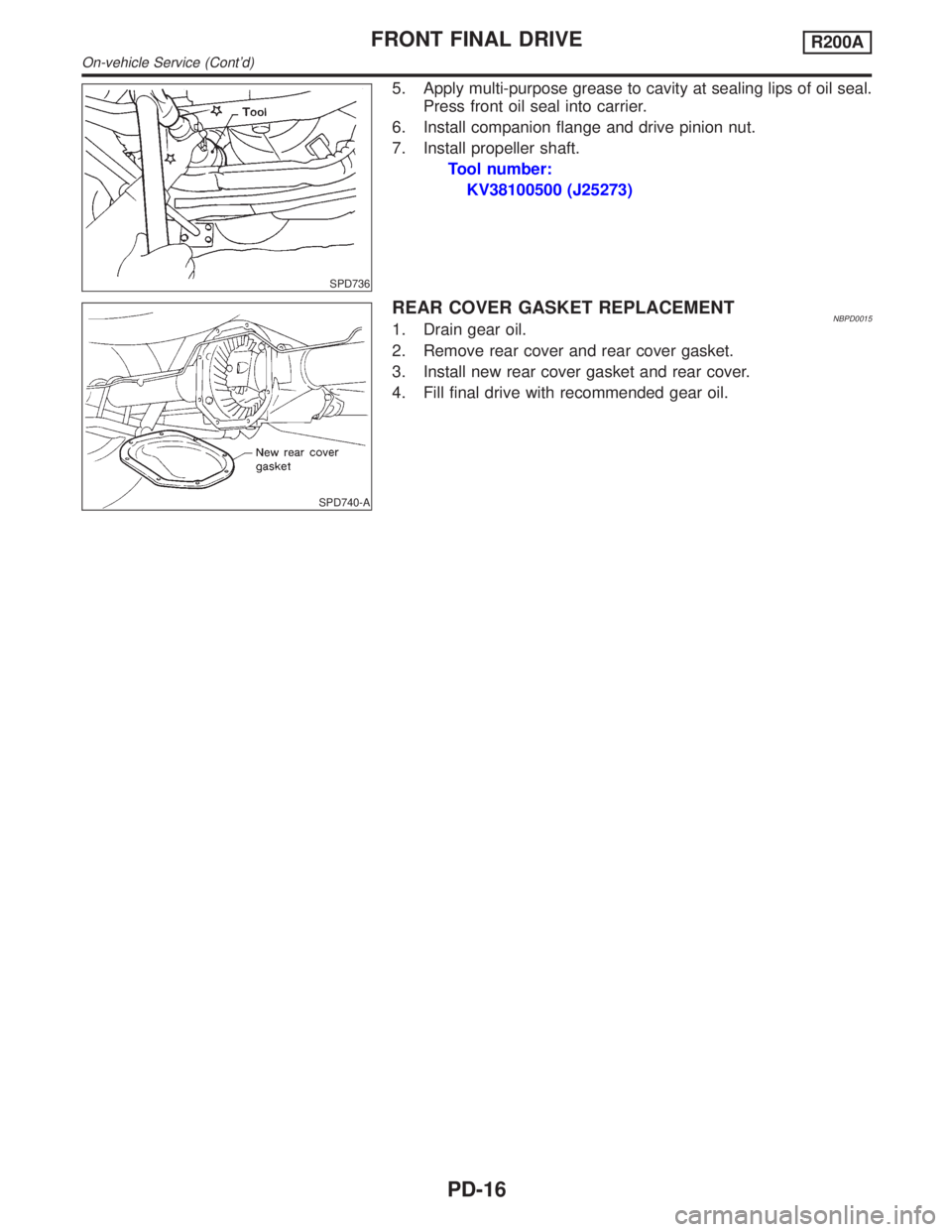

SPD736

5. Apply multi-purpose grease to cavity at sealing lips of oil seal.

Press front oil seal into carrier.

6. Install companion flange and drive pinion nut.

7. Install propeller shaft.

Tool number:

KV38100500 (J25273)

SPD740-A

REAR COVER GASKET REPLACEMENTNBPD00151. Drain gear oil.

2. Remove rear cover and rear cover gasket.

3. Install new rear cover gasket and rear cover.

4. Fill final drive with recommended gear oil.

FRONT FINAL DRIVER200A

On-vehicle Service (Cont'd)

PD-16