Battery INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2180 of 2395

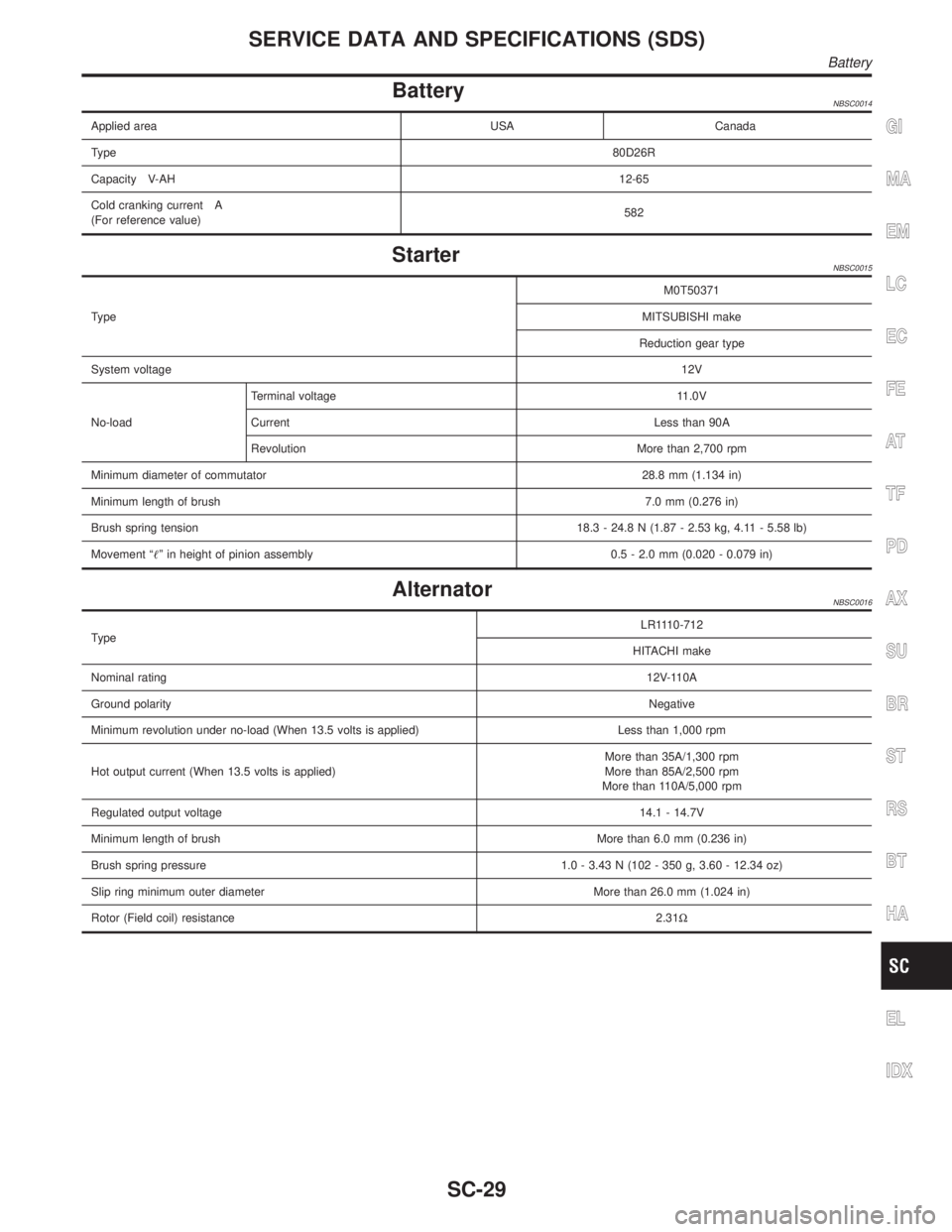

BatteryNBSC0014

Applied area USA Canada

Type80D26R

Capacity V-AH12-65

Cold cranking current A

(For reference value)582

StarterNBSC0015

TypeM0T50371

MITSUBISHI make

Reduction gear type

System voltage12V

No-loadTerminal voltage 11.0V

Current Less than 90A

Revolution More than 2,700 rpm

Minimum diameter of commutator28.8 mm (1.134 in)

Minimum length of brush7.0 mm (0.276 in)

Brush spring tension18.3 - 24.8 N (1.87 - 2.53 kg, 4.11 - 5.58 lb)

Movement ªº in height of pinion assembly 0.5 - 2.0 mm (0.020 - 0.079 in)

AlternatorNBSC0016

TypeLR1110-712

HITACHI make

Nominal rating12V-110A

Ground polarityNegative

Minimum revolution under no-load (When 13.5 volts is applied) Less than 1,000 rpm

Hot output current (When 13.5 volts is applied)More than 35A/1,300 rpm

More than 85A/2,500 rpm

More than 110A/5,000 rpm

Regulated output voltage14.1 - 14.7V

Minimum length of brushMore than 6.0 mm (0.236 in)

Brush spring pressure 1.0 - 3.43 N (102 - 350 g, 3.60 - 12.34 oz)

Slip ring minimum outer diameter More than 26.0 mm (1.024 in)

Rotor (Field coil) resistance2.31W

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Battery

SC-29

Page 2238 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBTF0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRSsection of this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

SEF289H

PrecautionsNBTF0092IBefore connecting or disconnecting the Transfer control

unit harness connector, turn ignition switch OFF and dis-

connect negative battery terminal. Failure to do so may

damage the Transfer control unit. Because battery voltage

is applied to Transfer control unit even if ignition switch

is turned off.

SEF291H

IWhen connecting or disconnecting pin connectors into or

from Transfer control unit, take care not to damage pin

terminals (bend or break).

Make sure that there are not any bends or breaks on

Transfer control unit pin terminal, when connecting pin

connectors.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

TF-3

Page 2264 of 2395

INDICATIONS OF 4WD WARNING LAMPNBTF0011S03

Flickering pattern or flick-

ering conditionMalfunction Check items

1 Front revolution sensor circuit is shorted or open.Revolution sensor (front) circuit,

TF-61.

2 Rear revolution sensor circuit is shorted or open.Revolution sensor (rear) [Refer to

AT-111, ªDTC P0720 Vehicle Speed

Sensor´A/T (Revolution sensor)º.]

3 4WD solenoid valve circuit is shorted or open. 4WD solenoid valve circuit, TF-64.

42-4WD shift solenoid valve circuit is shorted or 2WD switch of

4WD shift switch is shorted.2-4WD shift solenoid valve circuit or

4WD shift switch circuit, TF-66.

5 Transfer motor relay circuit is shorted or open. Transfer motor relay circuit, TF-70.

8Power supply voltage of throttle position sensor is improper. Or

A/D converter of transfer control unit functions improperly.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle Posi-

tion Sensorº.)

9 Transfer fluid temperature sensor circuit is open.Transfer fluid temperature sensor

circuit, TF-73.

10 Neutral-4LO switch circuit is shorted or open. Neutral-4LO switch circuit, TF-76.

112-4WD shift solenoid valve circuit, 2WD switch of 4WD shift

switch circuit or clutch pressure switch circuit is shorted or open.2-4WD shift solenoid valve circuit,

4WD shift switch circuit or clutch

pressure switch circuit, TF-66, 80.

12 Line pressure switch circuit is shorted or open. Line pressure switch circuit, TF-83.

13 Engine speed signal circuit is shorted or open.Engine speed signal (Refer to

AT-116, ªDTC P0725 Engine Speed

Signalº.)

14 Throttle position sensor circuit is shorted or open.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle Posi-

tion Sensorº.)

15 Failure in power supply circuit of transfer control unit. Power supply of transfer control unit

16 4WD shift switch circuit is shorted. 4WD shift switch circuit, TF-66.

17 ABS operation signal circuit is shorted. ABS operation signal circuit, TF-86.

18ATP switch, wait detection switch or neutral-4LO switch circuit is

shorted or open.ATP switch, wait detection switch or

neutral-4LO switch circuit*, TF-76.

19Transfer control device actuator motor is faulty. (Abnormalities

are detected when actuator motor fails to operate while shifting

from ª4Hº to ª4LOº or vice versa.)Actuator motor and motor circuit,

TF-115, 89.

20Transfer control device actuator motor arm position sensing

switch is faulty.Actuator motor arm position sensing

switch and sensing switch circuit,

TF-115, 92.

21Transfer control device actuator circuit is faulty (Abnormalities

are detected when motor relay circuit is open/shorted or relay

monitor circuit is open/shorted.)Actuator motor, actuator motor arm

position sensing switch and their

associated circuits, TF-114, 115 and

94.

Repeats flickering every

2 to 5 sec.Circuits that the self-diagnosis covers have no malfunction. Ð

Repeats flickering every

0.25 sec.IPower supply failure of memory back-up.

IBattery is disconnected for a long time.

IBattery performance is poor.Data erase/display circuit, TF-88.GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis without CONSULT-II (Cont'd)

TF-29

Page 2267 of 2395

Detected items

(Screen terms for CONSULT-II,

ªSELF-DIAG RESULTº mode)Malfunction is detected when... Check items

Throttle position sensor

(THRTL POSI SEN)ISignal voltage from throttle position sensor is abnor-

mally high.

ISignal voltage from throttle position sensor is abnor-

mally low when closed throttle position switch is OFF.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle

Position Sensorº.)

Transfer control unit (ADC)

C/U (ADC)/THRTL SENIPower supply voltage for throttle position sensor is

improper or A/D converter system of transfer control

unit is faulty.Throttle position sensor (Refer to

AT-176, ªDTC P1705 Throttle

Position Sensorº.)

Battery voltage (Note 1)

(BATTERY VOLTAGE)IPower supply voltage for transfer control unit is abnor-

mally low while driving.Power supply circuit (Refer to

AT-96, ªWiring Diagram Ð AT Ð

MAINº.)

4WD shift switch

(4WD MODE SW)IMore than two switch inputs are simultaneously

detected due to short circuit of 4WD shift switch.4WD shift switch circuit, TF-66.

ABS operation signal (Note 4)

(ABS OPER SIGNAL)IWhen a malfunction signal due to disconnection or

shorting is detected.

IWhen a defect signal is entered from the ABS control

unit.ABS operation signal circuit,

TF-86.

Wait detection switch (Note 2)

(WAIT DETECT SWITCH)IImproper signal is input due to open or short circuit.ATP switch, wait detection switch

and neutral-4LO switch circuits

(*2), TF-76.

Shift actuator abnormal

(SHIFT ACT)Transfer control device actuator motor is faulty. (Abnor-

malities are detected when actuator motor fails to oper-

ate while shifting from ª4Hº to ª4LOº or vice versa.)Actuator motor and motor circuit,

TF-115, 89.

Shift actuator position switch

abnormal

(SHIFT ACT P/S)Transfer control device actuator motor arm position sens-

ing switch is faulty.Actuator motor arm position

sensing switch and sensing

switch circuit, TF-115, 92.

Shift actuator circuit abnormal

(SHIFT ACT CIR)Transfer control device actuator circuit is faulty (Abnor-

malities are detected when motor relay circuit is open/

shorted or relay monitor circuit is open/shorted.)Actuator motor, actuator motor

arm position sensing switch and

their associated circuits, TF-114,

115 and 94.

Memory power supply stopIDue to removal of battery which cuts off power supply

to transfer control unit, self-diagnosis memory function

is suspended.Data erase/display circuit, TF-88.

Transfer control unit (RAM)

[CONTROL UNIT (RAM)]IFailure is detected in the memory (RAM) system of

transfer control unit.

Transfer control unit (ROM)

[CONTROL UNIT (ROM)]IFailure is detected in the memory (ROM) system of

transfer control unit.

Transfer control unit (EEPROM)

[CONTROL UNIT (EEPROM)]IFailure is detected in the memory (EEPROM) system

of transfer control unit.

Note 1: When a malfunction occurs, it is only displayed and not stored in the memory.

Note 2: When the wait detection switch has been properly fixed, malfunction information is erased from the memory.

Note 3: If 4WD shift switch is left between 4H and 4LO for a while, this indication may be displayed.

(*1): If the malfunction is detected only while driving in reverse, check the continuity of ªRº position on A/T PNP switch. When there is

nothing wrong with the electrical system, check the hydraulic system.

(*2): If a revolution sensor malfunction is detected at the same time, check the revolution sensor circuit first.

Note 4: When this malfunction is detected with the ABS warning lamp off, first check for disconnection or shorting in the harness between

the transfer control unit and the ABS control unit.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-32

Page 2269 of 2395

![INFINITI QX4 2001 Factory Service Manual SMT963D

12. Monitored data are displayed.

DATA MONITOR ITEMSNBTF0012S04q: StandardH: Option

Item [Unit]Monitor item

Remarks

ECU input

signalsMain sig-

nalsItem menu

selection

Revolution sensor-front [ INFINITI QX4 2001 Factory Service Manual SMT963D

12. Monitored data are displayed.

DATA MONITOR ITEMSNBTF0012S04q: StandardH: Option

Item [Unit]Monitor item

Remarks

ECU input

signalsMain sig-

nalsItem menu

selection

Revolution sensor-front [](/img/42/57027/w960_57027-2268.png)

SMT963D

12. Monitored data are displayed.

DATA MONITOR ITEMSNBTF0012S04q: StandardH: Option

Item [Unit]Monitor item

Remarks

ECU input

signalsMain sig-

nalsItem menu

selection

Revolution sensor-front [km/h (MPH)]qHRevolution sensor installed on T/F

Revolution sensor-rear [km/h (MPH)]qHVehicle speed sensor´A/T

Engine speed [rpm]qH

Throttle position sensor [V]qH

Transfer fluid temperature sensor [V]qH

Battery voltage [V]qH

2WD switch [ON-OFF]qH2WD switch of 4WD shift switch

AUTO switch [ON-OFF]qHAUTO switch of 4WD shift switch

Lock switch [ON-OFF]qH4H switch of 4WD shift switch

4L switch [ON-OFF]qH4LO switch of 4WD shift switch

N position switch TF [ON-OFF]qHN position switch of transfer

Line pressure switch [ON-OFF]qHLine pressure switch

Clutch pressure switch [ON-OFF]qHClutch pressure switch

ATP switch [ON-OFF]qH

N position switch [ON-OFF]qHªNº position on A/T PNP switch

R position switch [ON-OFF]qHªRº position on A/T PNP switch

P position switch [ON-OFF]qHªPº position on A/T PNP switch

Closed throttle position switch

[ON/OFF]qHIdle contact of throttle position switch

ABS operation switch [ON-OFF]qHABS operation switch

Wait detection switch [ON-OFF]qH

Throttle openingqHThrottle opening recognized by transfer control

unit

4WD-modeqH4WD-mode recognized by transfer control unit

(2W, AUTO, 4H & 4LO)

Vehicle speed comp [km/h (MPH)]qHVehicle speed recognized by transfer control

unit

*Control torque [N´m (kg-m, ft-lb)]qHCalculated torque recognized by transfer control

unit

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-34

Page 2272 of 2395

Indicated items

(Screen terms for CONSULT, ªDATA

MONITORº mode)Display Conditions

Clutch pressure switch

(CL PRES SW)OFFIgnition switch in ªONº, and 4WD shift switch in ª2WDº.

(ªWaitº function is not operating.)

ONIgnition switch in ªONº, and 4WD shift switch in ªAUTOº

or ª4Hº and A/T selector lever in ªDº. (ªWaitº function is

not operating.)

Control torque

(COMP CL TORQ)0 kg-m

4WD shift switch

(ªWaitº function is not oper-

ating.)In ª2WDº position

39 - 1,079 N´m

(4 - 110 kg-m, 29 - 796 ft-lb)In ªAUTOº position

1,079 N´m

(110 kg-m, 796 ft-lb)In ª4Hº or ª4LOº position

4WD solenoid

(DUTY SOLENOID)4% In ª2WDº position

94 - 4% In ªAUTOº position

4% In ª4Hº or ª4LOº position

2-4WD shift solenoid valve

(2-4WD SOL)OFF

4WD shift switchIn ª2WDº position

ON (ªWaitº function is not oper-

ating.)

In ªAUTOº position

OFF (ªWaitº function is operat-

ing.)

ON (ªWaitº function is not oper-

ating.)

In ª4Hº position

OFF (ªWaitº function is operat-

ing.)

ON In ª4LOº position

Indicated items Display Conditions

Battery voltage Approx. 12V Key switch ªONº and engine at rest

Approx. 13 - 14V During idling

AUTO switch OFF 4WD shift switch in other than ªAUTOº position

ON 4WD shift switch in ªAUTOº position

4L switch OFF 4WD shift switch in other than ª4LOº position

ON 4WD shift switch in ª4LOº position

N position switch OFF A/T selector lever in other than ªNº position

ON A/T selector lever in ªNº position

R position swtich OFF A/T selector lever in other than ªRº position

ON A/T selector lever in ªRº position

P position switch OFF A/T selector lever in other than ªPº position

ON A/T selector lever in ªPº position

Throttle opening 0.0/8 - 8.0/8 Throttle fully closed (0.0/8) or throttle fully open (8.0/8)

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Trouble Diagnosis with CONSULT-II (Cont'd)

TF-37

Page 2289 of 2395

SMT862D

Transfer Control Unit Terminals and Reference

Value

NBTF0018REMOVAL AND INSTALLATION OF TRANSFER

CONTROL UNIT

NBTF0018S03RemovalNBTF0018S03011. Turn ignition switch OFF and disconnect negative battery ter-

minal.

2. Remove console box.

3. Remove cluster lid C.

4. Remove audio assembly and A/C control unit.

5. Remove instrument lower panel on driver side.

6. Remove glove box.

7. Remove instrument lower panel on passenger side.

8. Remove instrument lower center panel.

9. Remove transfer control unit.

IFor steps 2 through 8 above, refer to BT-21, ªInstrument Panel

Assemblyº.

InstallationNBTF0018S0302IInstallation is in the reverse order of removal.

When installing transfer control unit, tighten transfer control unit

lock nut.

Tightening torque:

: 4.3 - 5.8 N´m (0.44 - 0.59 kg-m, 38 - 51 in-lb)

SMT771D

INSPECTION OF TRANSFER CONTROL UNITNBTF0018S01IMeasure voltage between each terminal and terminal 6 or 45

by following ªTRANSFER CONTROL UNIT INSPECTION

TABLEº, TF-55.

IPin connector terminal layout

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Transfer Control Unit Terminals and Reference Value

TF-54

Page 2290 of 2395

SMT772D

TRANSFER CONTROL UNIT INSPECTION TABLENBTF0018S02(Data are reference values.)

Terminal

No.Item Condition Judgement standard

12-4WD shift solenoid

valve

&

4WD shift switch is set to ª2WDº

position.Less than 1V

4WD shift switch is set to any posi-

tion other than ª2WDº.Battery voltage

24WD shift indicator lamp

(2WD)

Lamp lights while system is operating

properly.Less than 1V

&

2WD indicator lamp does not come

on.Battery voltage

3 Ground Ð Ð

4Transfer shift relay

(High)While actuator is operating

(4H,4LO)Battery voltage

Actuator does not operate. Less than 1V

5 4WD warning lampLamp comes ON. (when engine is

stopped.)

(Fail-safe condition appears on

display, engine is stopped, actuator

position detection switch is

inoperative, oil temperature is too

high and/or tires of different size are

installed.)Less than 1V

Except above Battery voltage

6 Ground Ð Ð Ð

7 PNP switch (R position)

&

A/T selector lever is set to ªreverseº

position.Battery voltage

A/T selector lever is set to any posi-

tion other than ªreverseº.Less than 1V

8ÐÐÐÐ

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Transfer Control Unit Terminals and Reference Value (Cont'd)

TF-55

Page 2291 of 2395

Terminal

No.Item Condition Judgement standard

9 4WD shift switch (2WD)

&

4WD shift switch is set to ª2WDº

position.Battery voltage

4WD shift switch is set to any posi-

tion other than ª2WDº.Less than 1V

10Transfer dropping resis-

tor4WD shift switch is set to ªAUTOº

position.Approx.4-14V

4WD shift switch is set to any posi-

tion other than ª2WDº.Less than 1V

114WD shift indicator lamp

(4H)

ª4Hº indicator lamp comes ON. Less than 1V

4WD shift switch is set to any posi-

tion other than ª4Hº.Battery voltage

124WD shift indicator lamp

(4LO)ª4LOº indicator lamp comes ON. Approx. 0V

4WD shift switch is set to any posi-

tion other than ª4LOº.Battery voltage

13 Transfer shift relay (Low)

&

While actuator is operating

(4LO,4H)Battery voltage

Actuator does not operate. Approx. 0V

14 Transfer motor relayTransfer motor relay is ON. Battery voltage

Transfer motor relay is OFF. Less than 1V

15 PNP switch (N position)A/T selector lever is set to ªNº posi-

tion.Battery voltage

A/T selector lever is set to any posi-

tion other than ªNº position.Less than 1V

16 Power supply ÐIgnition key is set to ªONº position. Battery voltage

Ignition key is set to ªOFFº position. Approx. 0V

17 PNP switch (P position)

&

A/T selector lever is set to ªPº posi-

tion.Battery voltage

A/T selector lever is set to any posi-

tion other than ªPº.Less than 1V

18 4WD shift switch (4H)4WD shift switch is set to ª4Hº posi-

tion.Battery voltage

4WD shift switch is set to any posi-

tion other than ª4Hº.Less than 1V

19 4WD solenoid valve4WD shift switch is set to ªAUTOº

position.Approx. 1.5 - 3V

4WD shift switch is set to any posi-

tion other than ª2WDº.Less than 1V

20ÐÐÐÐ

214WD shift indicator lamp

(AUTO)

ªAUTOº indicator lamp comes ON. Approx. 0V

4WD shift switch is set to any posi-

tion other than ªAUTOº.Battery voltage

22 Power supply ÐIgnition key is set to ªONº position. Battery voltage

Ignition key is set to ªOFFº position. Approx. 0V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Transfer Control Unit Terminals and Reference Value (Cont'd)

TF-56

Page 2292 of 2395

Terminal

No.Item Condition Judgement standard

23 4WD shift switch (4LO)

&

4WD shift switch is set to ª4LOº posi-

tion.Battery voltage

4WD shift switch is set to any posi-

tion other than ª4LOº.Less than 1V

24 4WD shift switch (AUTO)4WD shift switch is set to ªAUTOº

position.Battery voltage

4WD shift switch is set to any posi-

tion other than ªAUTOº.Less than 1V

25 Neutral-4LO switchTransfer is set to ª4LOº position. Approx. 0V

Transfer is set to any position other

than ª4LOº.Power supply

26Throttle position switch

(closed)Throttle valve is closed. Power supply

Throttle valve is in any position other

than ªclosedº.Approx. 0V

27Transfer 4H actuator

switch4WD shift switch is set to ª4Hº posi-

tion.Less than 1V

4WD shift switch is set to any posi-

tion other than ª4Hº.Battery voltage

28Throttle position sensor

(Ground)Throttle valve is closed.

Less than 1V

Throttle valve is fully open.

29TCM signal (Vehicle

speed signal)When moving at 20 km/h (12 MPH),

use the CONSULT-II pulse frequency

measuring function.*1

CAUTION:

Connect the diagnosis data link

cable to the vehicle diagnosis con-

nector.

*1: A circuit tester cannot be used to

test this item.Approximately 225 Hz

30Throttle position sensor

(Power supply for throttle

position sensor)Ignition key is set to ªONº position. Approx. 4.5 - 5.5V

Ignition key is set to ªOFFº position. Approx. 0VGI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Transfer Control Unit Terminals and Reference Value (Cont'd)

TF-57