Bleed INFINITI QX4 2001 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2191 of 2395

6. If rack sliding force is not within specification, overhaul steer-

ing gear assembly.

7. If rack sliding force is OK, inspect steering column. Refer to

ªInspectionº, ªSTEERING WHEEL AND STEERING

COLUMNº, ST-14.

SST834-F

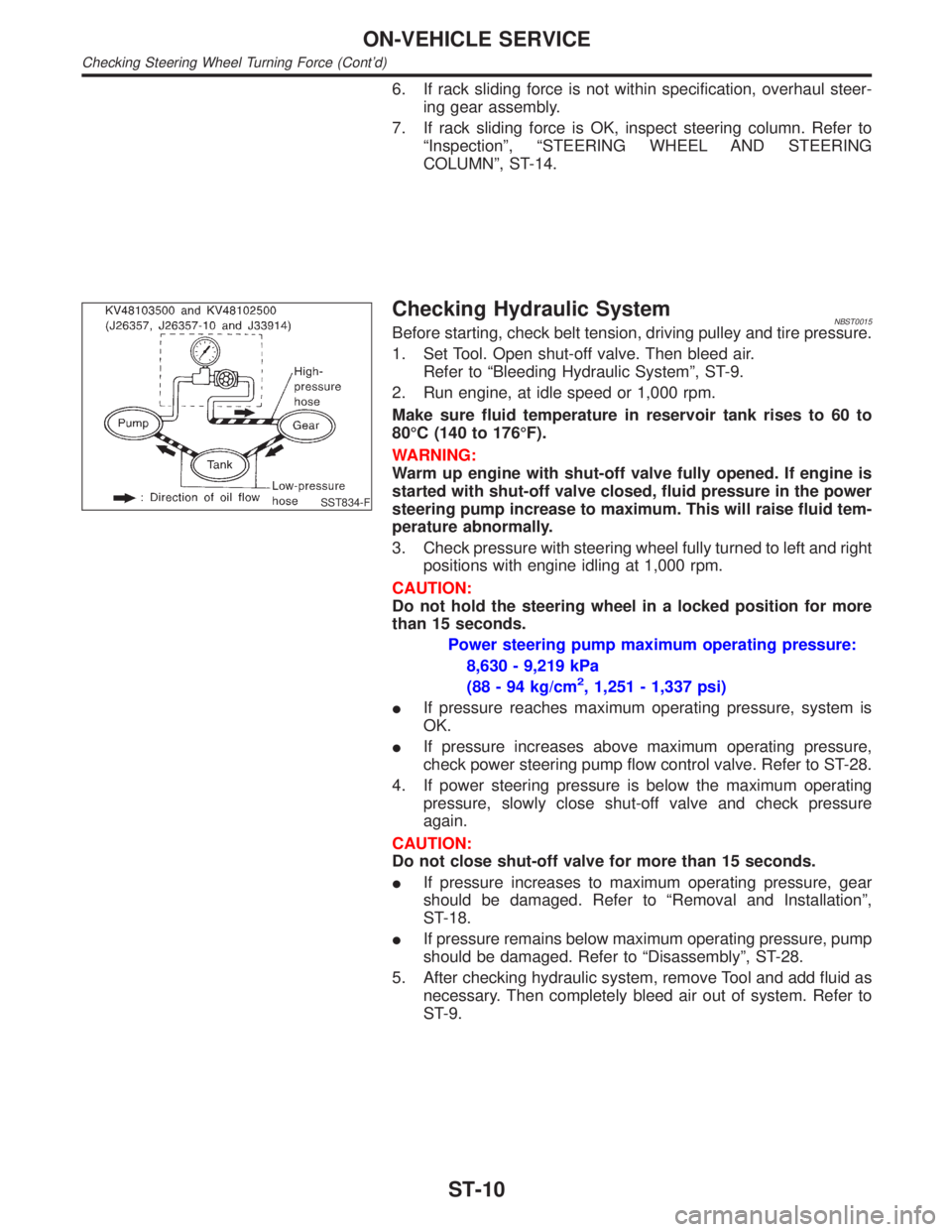

Checking Hydraulic SystemNBST0015Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air.

Refer to ªBleeding Hydraulic Systemº, ST-9.

2. Run engine, at idle speed or 1,000 rpm.

Make sure fluid temperature in reservoir tank rises to 60 to

80ÉC (140 to 176ÉF).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, fluid pressure in the power

steering pump increase to maximum. This will raise fluid tem-

perature abnormally.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Power steering pump maximum operating pressure:

8,630 - 9,219 kPa

(88 - 94 kg/cm

2, 1,251 - 1,337 psi)

IIf pressure reaches maximum operating pressure, system is

OK.

IIf pressure increases above maximum operating pressure,

check power steering pump flow control valve. Refer to ST-28.

4. If power steering pressure is below the maximum operating

pressure, slowly close shut-off valve and check pressure

again.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

IIf pressure increases to maximum operating pressure, gear

should be damaged. Refer to ªRemoval and Installationº,

ST-18.

IIf pressure remains below maximum operating pressure, pump

should be damaged. Refer to ªDisassemblyº, ST-28.

5. After checking hydraulic system, remove Tool and add fluid as

necessary. Then completely bleed air out of system. Refer to

ST-9.

ON-VEHICLE SERVICE

Checking Steering Wheel Turning Force (Cont'd)

ST-10

Page 2206 of 2395

SST718CA

6. Move rack over its entire stroke several times.

7. Measure pinion rotating torque within the range of 180É from

neutral position.

Stop the gear at the point of maximum torque.

8. Loosen adjusting screw, then retighten it to 4.9 to 5.9 N´m (50

to 60 kg-cm, 43 to 52 in-lb).

9. Loosen adjusting screw by 10É to 20É.

SST940C

10. Prevent adjusting screw from turning, and tighten lock nut to

specified torque.

SST718CA

11. Measure pinion rotating torque.

Lock to lock:

Average rotating torque

0.78 - 1.47 N´m (8.0 - 15.0 kg-cm, 6.9 - 13.0 in-lb)

Within±100É from the neutral position:

Maximum torque variation

0.4 N´m (4 kg-cm, 3.5 in-lb)

Outside the above range:

Maximum force variation

0.6 N´m (6 kg-cm, 5.2 in-lb)

IIf pinion rotating torque is not within specifications, readjust it

starting from step 4. If pinion rotating torque is still out of

specifications after readjustment, replace steering gear

assembly.

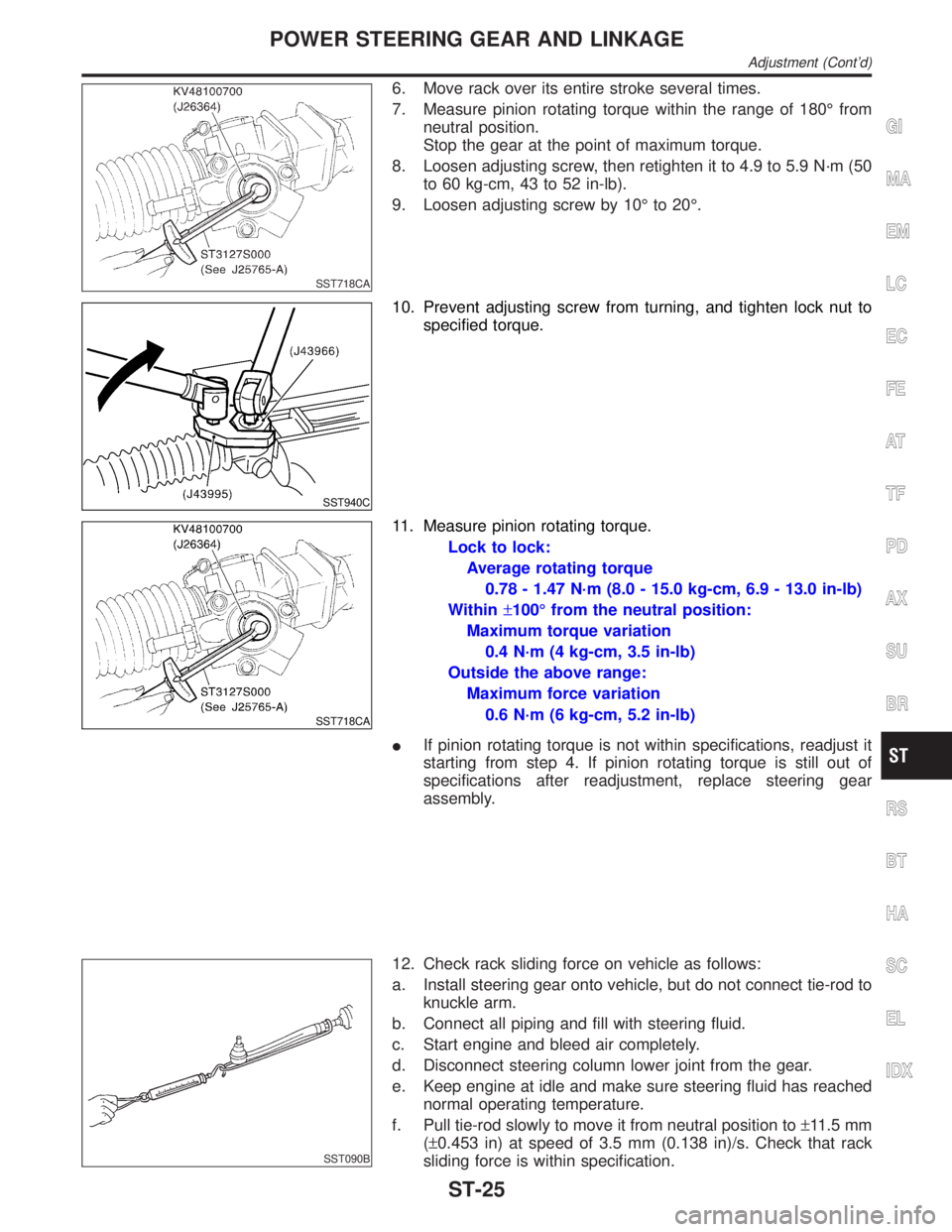

SST090B

12. Check rack sliding force on vehicle as follows:

a. Install steering gear onto vehicle, but do not connect tie-rod to

knuckle arm.

b. Connect all piping and fill with steering fluid.

c. Start engine and bleed air completely.

d. Disconnect steering column lower joint from the gear.

e. Keep engine at idle and make sure steering fluid has reached

normal operating temperature.

f. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

POWER STEERING GEAR AND LINKAGE

Adjustment (Cont'd)

ST-25

Page 2357 of 2395

SMT811D

55. Thrust needle bearing race

56. Clutch piston

57. D-ring

58. Lip seal

59. Oil gutter

60. Center case

61. Stem bleeder

62. Mainshaft rear bearing

63. Thrust washer

64. Speedometer drive gear

65. Snap ring

66. Rear case

67. ATP switch

68. Neutral-4LO switch69. Oil seal

70. Magnet

71. Baffle plate

72. Oil strainer

73. O-ring

74. Control valve assembly

75. Lip seal (7 pieces)

76. Filler plug

77. Inner gear

78. Outer gear

79. Oil pump housing

80. Bushing

81. Oil pump shaft

82. Oil pressure check plug83. Oil pump gasket

84. Sub-oil pump housing

85. Outer gear

86. Inner gear

87. O-ring

88. Sub-oil pump cover

89. O-ring

90. Transfer motor

91. O-ring

92. Oil filter stud

93. O-ring

94. O-ring

95. Oil filter

OVERHAUL

Transfer Components (Cont'd)

TF-122

Page 2358 of 2395

SMT877C

Rear Case

DISASSEMBLYNBTF00771. Remove neutral-4LO switch and ATP switch.

2. Remove bolts.

SMT878C

3. Remove rear case from center case by tapping it lightly with a

plastic hammer.

SMT883C

Center Case

DISASSEMBLYNBTF00781. Remove oil pump shaft from main oil pump.

SMT884C

2. Remove stem bleeder from bleeder hole.

SMT844DB

3. Remove lock nut from companion flange.

IDo not reuse lock nut.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DISASSEMBLY

Rear Case

TF-123

Page 2389 of 2395

SMT894C

4. Make sure the two claws of oil gutter are securely attached to

slots in center case.

SMT895C

5. With the claws of oil gutter held by a finger, install center case

assembly to front case assembly.

CAUTION:

Pay careful attention so that mainshaft end does not damage

radial needle bearing in sun gear assembly.

6. Tap center case lightly with a rubber hammer or the like and

press-fit front drive shaft bearing into front case.

SMT896C

7. Make sure oil gutter rear end protrudes from point ªAº in the

figure.

8. Tighten bolts to specified torque.

: 41 - 48 N´m (4.2 - 4.9 kg-m, 30 - 35 ft-lb)

IBe sure to install air breather hose clamp, connector

bracket and harness clip.

SMT883C

9. Fit double-flat end of oil pump shaft into slot of main oil pump

and install it.

NOTE:

When oil pump shaft is rotated slightly, it drops into position where

both parts fit.

SMT884C

10. Install stem bleeder to center case.

ASSEMBLY

Final Assembly (Cont'd)

TF-154

Page 2390 of 2395

SMT881C

11. Remove rear oil seal.

IDo not reuse oil seal.

SMT882C

12. Apply ATF to the circumference of new rear oil seal, and tap it

using a drift as shown in the figure so that it is aligned with

case tip face.

IApply multi-purpose grease to oil seal lip.

SMT879C

13. Apply sealing fluid 518 (Locktite) to entire rear case mounting

surface of center case as shown in the figure.

CAUTION:

IRemove all foreign materials such as water, oil, and

grease from center case and rear case mating surfaces.

IBe careful not to allow sealing fluid to clog bleeder hole.

14. Install rear case to center case, and tighten bolts to specified

torque.

: 41 - 48 N´m (4.2 - 4.9 kg-m, 30 - 35 ft-lb)

IBe sure to attach harness clips.

SMT880C

15. Remove all the gasket fluid 1215 (Three Bond) from switch

mounting area and inside rear case, with ATP switch and neu-

tral-4LO switch threaded in 1 to 2 pitches, apply gasket fluid

1215 (Three Bond) to the thread of the switches and tighten it

to specified torque.

: 15 - 20 N´m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

16. Install rear case assembly to center case assembly.

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLY

Final Assembly (Cont'd)

TF-155