power steering INFINITI QX4 2001 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1407 of 2395

System DescriptionNBEL0216Refer to Owner's Manual for ASCD operating instructions.

POWER SUPPLY AND GROUNDNBEL0216S01Power is supplied at all times:

Ithrough 10A fuse [No. 14, located in the fuse block (J/B)]

Ito the stop lamp switch terminal 1, and

Ithrough 7.5A fuse (No. 52, located in fuse and fusible link box)

Ito the horn relay terminals 1 and 3.

When ignition switch is in the ON or START position, power is supplied:

Ithrough 7.5A fuse [No. 11, located in the fuse block (J/B)]

Ito ASCD brake switch terminal 1 and

Ito ASCD control unit terminal 5,

Ithrough 10A fuse [No. 18, located in the fuse block (J/B)]

Ito park/neutral position relay terminal 1,

Ithrough 10A fuse [No. 8, located in the fuse block (J/B)]

Ito combination meter terminal 66, and

When park/neutral position switch is in the P or N position, ground is supplied:

Ito park/neutral position relay terminal 2

Ithrough park/neutral position switch and body grounds B55 and B75.

When ASCD main switch is depressed (ON), ground is supplied:

Ito ASCD control unit terminal 9

Ifrom ASCD steering switch terminal 4

Ito ASCD steering switch terminal 5

Ithrough body grounds M4, M66 and M147

then ASCD control unit holds CRUISE condition and illuminates CRUISE indicator.

Ground is supplied:

Ifrom ASCD control unit terminal 15

Ito combination meter terminal 46.

OPERATIONNBEL0216S02Set OperationNBEL0216S0201To activate the ASCD, all following conditions must exist.

IGround supply to ASCD control unit terminal 9 (Main switch is in ON position.)

IPower supply to ASCD control unit terminal 8 (Brake pedal is released and A/T selector lever is in other

than P and N position.)

IVehicle speed is between 40 km/h (25 MPH) and 144 km/h (89 MPH). (Signal from combination meter)

When the SET/COAST switch is depressed, power is supplied:

Ifrom ASCD steering switch terminal 2

Ito ASCD control unit terminal 11.

And then ASCD pump is activated to control throttle wire and ASCD control unit supply ground

Ito combination meter terminals 51 to illuminate SET indicator.

A/T Overdrive Control during Cruise Control DrivingNBEL0216S0202When the vehicle speed is approximately 3 km/h (2 MPH) below set speed, a signal is sent

Ifrom ASCD control unit terminal 10

Ito TCM (transmission control module) terminal 24.

When this occurs, the TCM (transmission control module) cancels overdrive.

After vehicle speed is approximately 1 km/h (1 MPH) below set speed, overdrive is reactivated.

ASCD Shifting ControlNBEL0216S0203During ASCD cruise, ASCD control unit controls A/T shifting to avoid uncomfortable shifting.

This is used to control the signals below.

IThrottle position sensor from ECM

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System Description

EL-222

Page 1408 of 2395

IA/T shift solenoid valve A

Coast OperationNBEL0216S0204When the SET/COAST switch is depressed during cruise control driving, ASCD actuator returns the throttle

cable to decrease vehicle set speed until the switch is released. And then ASCD will keep the new set speed.

Accel OperationNBEL0216S0205When the RESUME/ACCEL switch is depressed, power is supplied

Ifrom ASCD steering switch terminal 3

Ito ASCD control unit terminal 24.

If the RESUME/ACCEL switch is depressed during cruise control driving, ASCD actuator pulls the throttle cable

to increase the vehicle speed until the switch is released or vehicle speed is reached to maximum controlled

speed by the system. And then ASCD will keep the new set speed.

Cancel OperationNBEL0216S0206When any of following condition exists, cruise operation will be canceled.

ICANCEL switch is depressed. (Power supply to ASCD control unit terminals 11 and 24)

IBrake pedal is depressed. (Power supply to ASCD control unit terminal 23 from stop lamp switch)

IBrake pedal is depressed or A/T selector lever is shifted to P or N position. (Power supply to ASCD con-

trol unit terminal 8 is interrupted.)

If MAIN switch is turned to OFF during ASCD is activated, all of ASCD operation will be canceled and vehicle

speed memory will be erased.

Resume OperationNBEL0216S0207When the RESUME/ACCEL switch is depressed after cancel operation other than depressing MAIN switch is

performed, vehicle speed will return to last set speed. To resume vehicle set speed, vehicle condition must

meet following conditions.

IBrake pedal is released.

IA/T selector lever is in other than P and N position.

IVehicle speed is between 40 km/h (25 MPH) and 144 km/h (89 MPH).

ASCD PUMP OPERATIONNBEL0216S03The ASCD pump consists of a vacuum motor, an air valve and a release valve. When the ASCD activates,

power is supplied

Ifrom terminal 12 of ASCD control unit

Ito ASCD pump terminal 1.

Ground is supplied to vacuum motor, air valve and release valve from ASCD control unit depending on the

operated condition as shown in the below table.

The pump is connected to ASCD actuator by vacuum hose. When the ASCD pump is activated, the ASCD

pump vacuum the diaphragm of ASCD actuator to control throttle cable.

Air valve (*1) Release valve (*1) Vacuum motorActuator inner pres-

sure

ASCD not operating Open Open Stopped Atmosphere

ASCD operatingReleasing throttle

cableOpen Closed Stopped Vacuum

Holding throttle

positionClosed Closed Stopped Vacuum (*2)

Pulling throttle cable Closed Closed Operated Vacuum

*1: When power and ground is supplied, valve is closed.

*2: Set position held.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

System Description (Cont'd)

EL-223

Page 1414 of 2395

SEL255W

Fail-safe SystemNBEL0217DESCRIPTIONNBEL0217S01When the fail-safe system senses a malfunction, it deactivates

ASCD operation. The SET indicator in the combination meter will

then flash.

MALFUNCTION DETECTION CONDITIONSNBEL0217S02

Detection conditionsASCD operation during malfunc-

tion detection

IASCD steering (RESUME/ACCEL, CANCEL, SET/COAST) switch is stuck.

IVacuum motor ground circuit or power circuit is open or shorted.

IAir valve ground circuit or power circuit is open or shorted.

IRelease valve ground circuit or power circuit is open or shorted.

IVehicle speed sensor is faulty.

IASCD control unit internal circuit is malfunctioning.IASCD is deactivated.

IVehicle speed memory is can-

celed.

IASCD brake switch or stop lamp switch is faulty.IASCD is deactivated.

IVehicle speed memory is not

canceled.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Fail-safe System

EL-229

Page 1415 of 2395

Trouble DiagnosesNBEL0218SYMPTOM CHARTNBEL0218S01

PROCEDURE Diagnostic procedure

REFERENCE PAGE (EL- ) 231 232 233 234 235 235 237

SYMPTOM

FAIL-SAFE SYSTEM CHECK

POWER SUPPLY AND GROUND CIRCUIT CHECK

ASCD BRAKE/STOP LAMP SWITCH CHECK

ASCD STEERING SWITCH CHECK

VEHICLE SPEED SENSOR CHECK

ASCD PUMP CIRCUIT CHECK

ASCD ACTUATOR/PUMP CHECK

ASCD cannot be set. (ªCRUISEº indica-

tor lamp does not ON.)XXH3

ASCD cannot be set. (ªSETº indicator

lamp does not blink.)XXX

ASCD cannot be set. (ªSETº indicator

lamp blinks.H1)X XXXX

Vehicle speed does not decrease after

SET/COAST switch has been pressed.XX

Vehicle speed does not return to the set

speed after RESUME/ACCEL switch has

been pressed.H2XX

Vehicle speed does not increase after

RESUME/ACCEL switch has been

pressed.XX

System is not released after CANCEL

switch (steering) has been pressed.XX

Large difference between set speed and

actual vehicle speed.XXX

Deceleration is greatest immediately

after ASCD has been set.XXX

H1: It indicates that system is in fail-safe. After completing diagnostic procedures, perform ªFAIL-SAFE SYSTEM CHECKº (EL-231) to

verify repairs.

H2: If vehicle speed is greater than 40 km/h (25 MPH) after system has been released, pressing RESUME/ACCEL switch returns vehicle

speed to the set speed previously achieved. However, doing so when the ASCD main switch is turned to ªOFFº, vehicle speed will not

return to the set speed since the memory is canceled.

H3: Check only main switch built-in steering switch.

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Trouble Diagnoses

EL-230

Page 1419 of 2395

ASCD STEERING SWITCH CHECK=NBEL0218S05

1 CHECK ASCD STEERING SWITCH CIRCUIT FOR ASCD CONTROL UNIT

Check voltage between ASCD control unit harness connector terminals and ground.

SEL260WC

Refer to wiring diagram in EL-226.

OK or NG

OK©ASCD steering switch is OK.

NG©GO TO 2.

2 CHECK POWER SUPPLY FOR ASCD STEERING SWITCH

Does horn work?

Ye s©GO TO 3.

No©Check the following.

I7.5A fuse (No. 52, located in the relay box)

IHorn relay

IHorn circuit

3 CHECK ASCD STEERING SWITCH

1. Disconnect ASCD steering switch.

2. Check continuity between terminals by pushing each switch.

SEL764WA

OK or NG

OK©Check harness for open or short between ASCD steering switch and ASCD control unit.

NG©Replace ASCD steering switch.

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Trouble Diagnoses (Cont'd)

EL-234

Page 1555 of 2395

NOTE:

After replacing IVCS unit, set up the replaced IVCS unit. Refer

to ªSystem Setting (When IVCS Unit is Replaced.)º in EL-381.

SYMPTOM CHART 2 (BASED ON SYMPTOM)NBEL0184S04Before referencing this chart, confirm the operation of the indicator

lamps. Refer to ªPRELIMINARY CHECKº in EL-369. If the indica-

tors show the system is malfunctioning, perform the self-diagnosis

using CONSULT-II.

Symptom Diagnoses/service procedure Reference page

ªMAYDAYº, ªINFORMATIONº, ªRE-DIALº,

ªNO SERVICEº indicator lamps do not illu-

minate when ignition switch is turned to ON

position. (Bulb check is NG.)1. Power supply and ground circuit for IVCS unit check EL-371

2. Indicator lamps check EL-372

Mayday/Information call does not operate.1. IVCS switch check EL-373

2. INFINITI Communicator operation check in demonstration

modeEL-379

Remote door unlocking function does not

operate.1. Back door handle switch check EL-374

2. Remote door unlock function check EL-374

3. INFINITI Communicator operation check in demonstration

modeEL-379

Stolen vehicle tracking function does not

operate.1. Stolen vehicle tracking setting check

(Check whether the function is disabled or not.)EL-375

2. INFINITI Communicator operation check in demonstration

modeEL-379

Alarm notification function does not oper-

ate.1. Alarm notification setting check

(Check whether the function is disabled or not.)EL-375

2. INFINITI Communicator operation check in demonstration

modeEL-379

Hands free telephone cannot be operated

by using steering switch.

(Cellular phone operates properly by using

handset.)1. Telephone steering switch check EL-377

No sounds related to the telephone are

heard from Front RH speaker. (If the audio

does not operate properly, check the audio

system.)1. Check harness for open or short between IVCS unit and

audio unit.Ð

The ªNO SERVICEº indicator lamp is not

turned off. (Even if a contract with tele-

phone carrier has not been made, the indi-

cator lamp remains illuminated.)1. Make sure the vehicle is in an area with cellular service. Ð

2. Check cellular phone antenna feeder cable connection. Ð

Cellular phone does not operate properly.1. Check hand set connector connection. Ð

2. Check hand set. Ð

No sound is transmitted to the other party

by hands free telephone.1. Check harness for open or short between IVCS unit and

microphone.Ð

2. Replace microphone. (IVCS switch assembly) Ð

INFINITI COMMUNICATOR (IVCS)

Trouble Diagnoses (Cont'd)

EL-370

Page 1562 of 2395

TELEPHONE STEERING SWITCH CHECK=NBEL0184S14

1 CHECK POWER SUPPLY FOR STEERING SWITCH

Check power supply for steering switch.

Does horn work?

Ye s©Check the following.

I10A fuse (No. 54, located in fuse and fusible link box)

IHorn relay

IHarness for open or short

No©GO TO 2.

2 CHECK STEERING SWITCH SUB-HARNESS

1. Remove driver's air bag module. For removal procedure, refer to RS section.

2. Check steering switch sub-harness for open or short and ground screw.

For details of the harness circuit, refer to ªSTEERING SWITCHº, EL-30.

OK or NG

OK©Check harness for open or short between telephone steering switch and IVCS unit. If the

circuit is OK, replace telephone steering switch.

NG©Replace or repair the harness.

Trouble Diagnoses for Intermittent IncidentNBEL0185DESCRIPTIONNBEL0185S01An intermittent incident may be occurring if all of the following conditions exist.

IBoth ªMAYDAYº emergency and ªINFORMATIONº indicators have shown that the system is malfunction-

ing.

ICONSULT-II self-diagnosis result screen indicates a trouble code with ªTIME=1orgreaterº.

IThe INFINITI Communicator system has not been previously serviced.

To find out the cause of a malfunction, follow the procedures shown below.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

INFINITI COMMUNICATOR (IVCS)

Trouble Diagnoses (Cont'd)

EL-377

Page 1643 of 2395

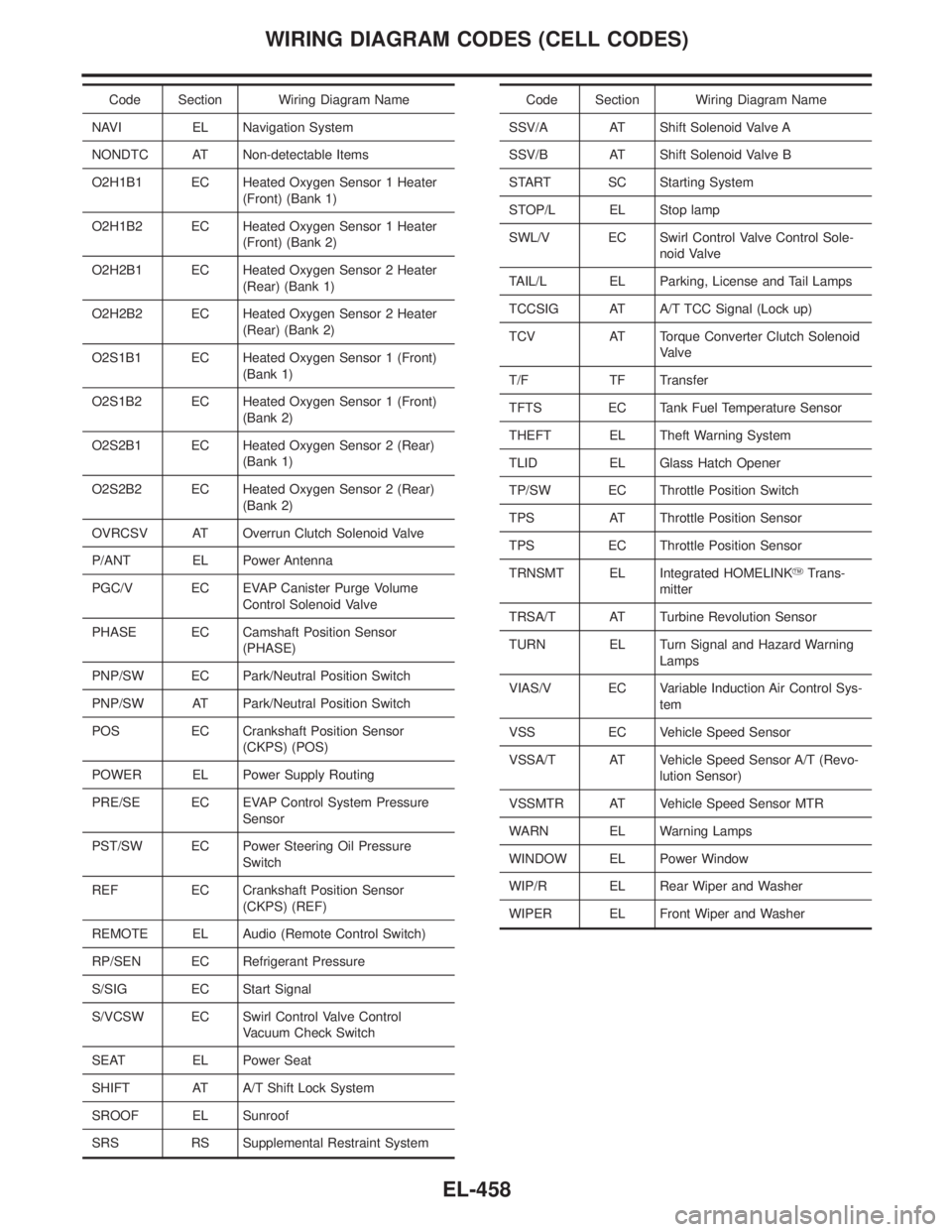

Code Section Wiring Diagram Name

NAVI EL Navigation System

NONDTC AT Non-detectable Items

O2H1B1 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 1)

O2H1B2 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 2)

O2H2B1 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 1)

O2H2B2 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 2)

O2S1B1 EC Heated Oxygen Sensor 1 (Front)

(Bank 1)

O2S1B2 EC Heated Oxygen Sensor 1 (Front)

(Bank 2)

O2S2B1 EC Heated Oxygen Sensor 2 (Rear)

(Bank 1)

O2S2B2 EC Heated Oxygen Sensor 2 (Rear)

(Bank 2)

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V EC EVAP Canister Purge Volume

Control Solenoid Valve

PHASE EC Camshaft Position Sensor

(PHASE)

PNP/SW EC Park/Neutral Position Switch

PNP/SW AT Park/Neutral Position Switch

POS EC Crankshaft Position Sensor

(CKPS) (POS)

POWER EL Power Supply Routing

PRE/SE EC EVAP Control System Pressure

Sensor

PST/SW EC Power Steering Oil Pressure

Switch

REF EC Crankshaft Position Sensor

(CKPS) (REF)

REMOTE EL Audio (Remote Control Switch)

RP/SEN EC Refrigerant Pressure

S/SIG EC Start Signal

S/VCSW EC Swirl Control Valve Control

Vacuum Check Switch

SEAT EL Power Seat

SHIFT AT A/T Shift Lock System

SROOF EL Sunroof

SRS RS Supplemental Restraint SystemCode Section Wiring Diagram Name

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L EL Stop lamp

SWL/V EC Swirl Control Valve Control Sole-

noid Valve

TAIL/L EL Parking, License and Tail Lamps

TCCSIG AT A/T TCC Signal (Lock up)

TCV AT Torque Converter Clutch Solenoid

Valve

T/F TF Transfer

TFTS EC Tank Fuel Temperature Sensor

THEFT EL Theft Warning System

TLID EL Glass Hatch Opener

TP/SW EC Throttle Position Switch

TPS AT Throttle Position Sensor

TPS EC Throttle Position Sensor

TRNSMT EL Integrated HOMELINKYTrans-

mitter

TRSA/T AT Turbine Revolution Sensor

TURN EL Turn Signal and Hazard Warning

Lamps

VIAS/V EC Variable Induction Air Control Sys-

tem

VSS EC Vehicle Speed Sensor

VSSA/T AT Vehicle Speed Sensor A/T (Revo-

lution Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-458

Page 1659 of 2395

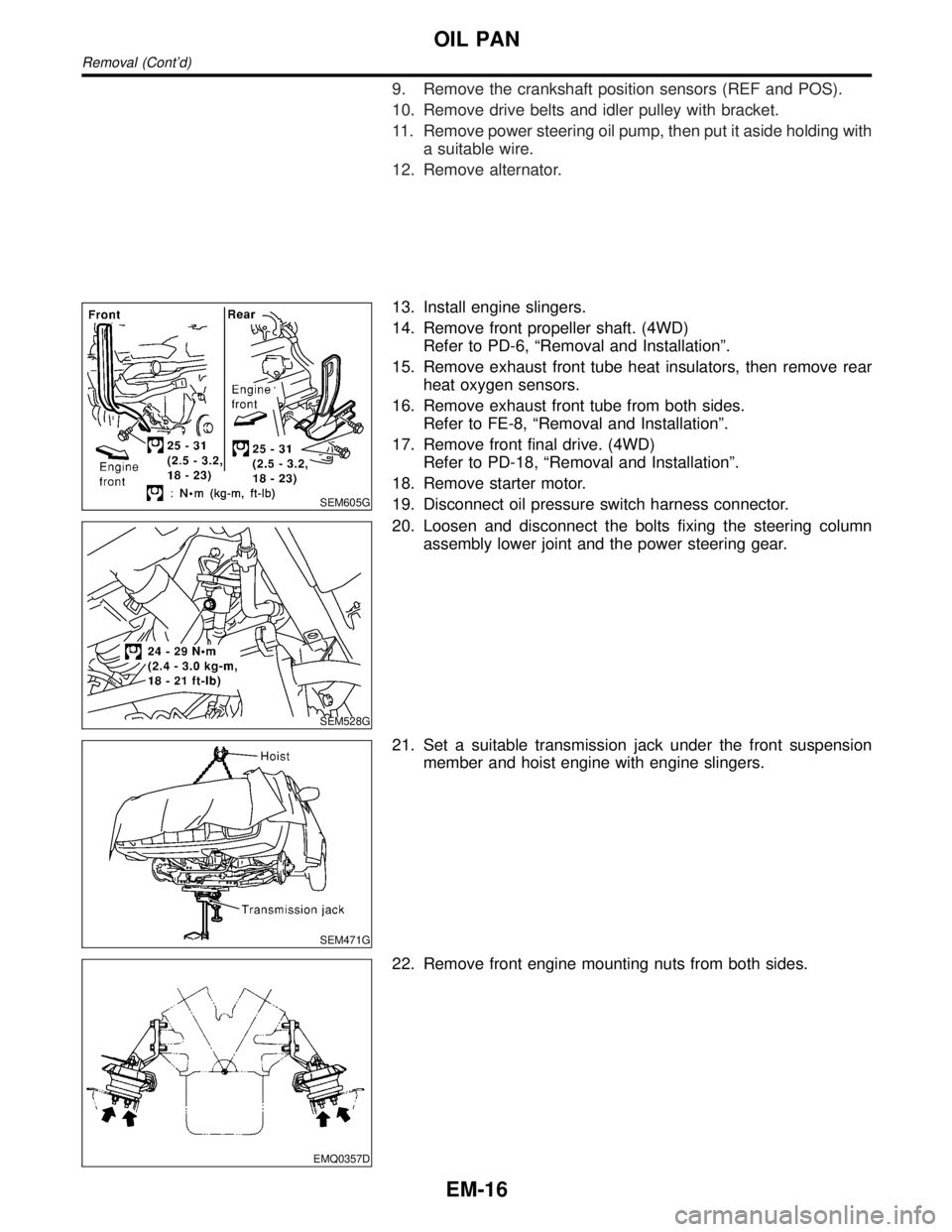

9. Remove the crankshaft position sensors (REF and POS).

10. Remove drive belts and idler pulley with bracket.

11. Remove power steering oil pump, then put it aside holding with

a suitable wire.

12. Remove alternator.

SEM605G

13. Install engine slingers.

14. Remove front propeller shaft. (4WD)

Refer to PD-6, ªRemoval and Installationº.

15. Remove exhaust front tube heat insulators, then remove rear

heat oxygen sensors.

16. Remove exhaust front tube from both sides.

Refer to FE-8, ªRemoval and Installationº.

17. Remove front final drive. (4WD)

Refer to PD-18, ªRemoval and Installationº.

18. Remove starter motor.

19. Disconnect oil pressure switch harness connector.

SEM528G

20. Loosen and disconnect the bolts fixing the steering column

assembly lower joint and the power steering gear.

SEM471G

21. Set a suitable transmission jack under the front suspension

member and hoist engine with engine slingers.

EMQ0357D

22. Remove front engine mounting nuts from both sides.

OIL PAN

Removal (Cont'd)

EM-16

Page 1666 of 2395

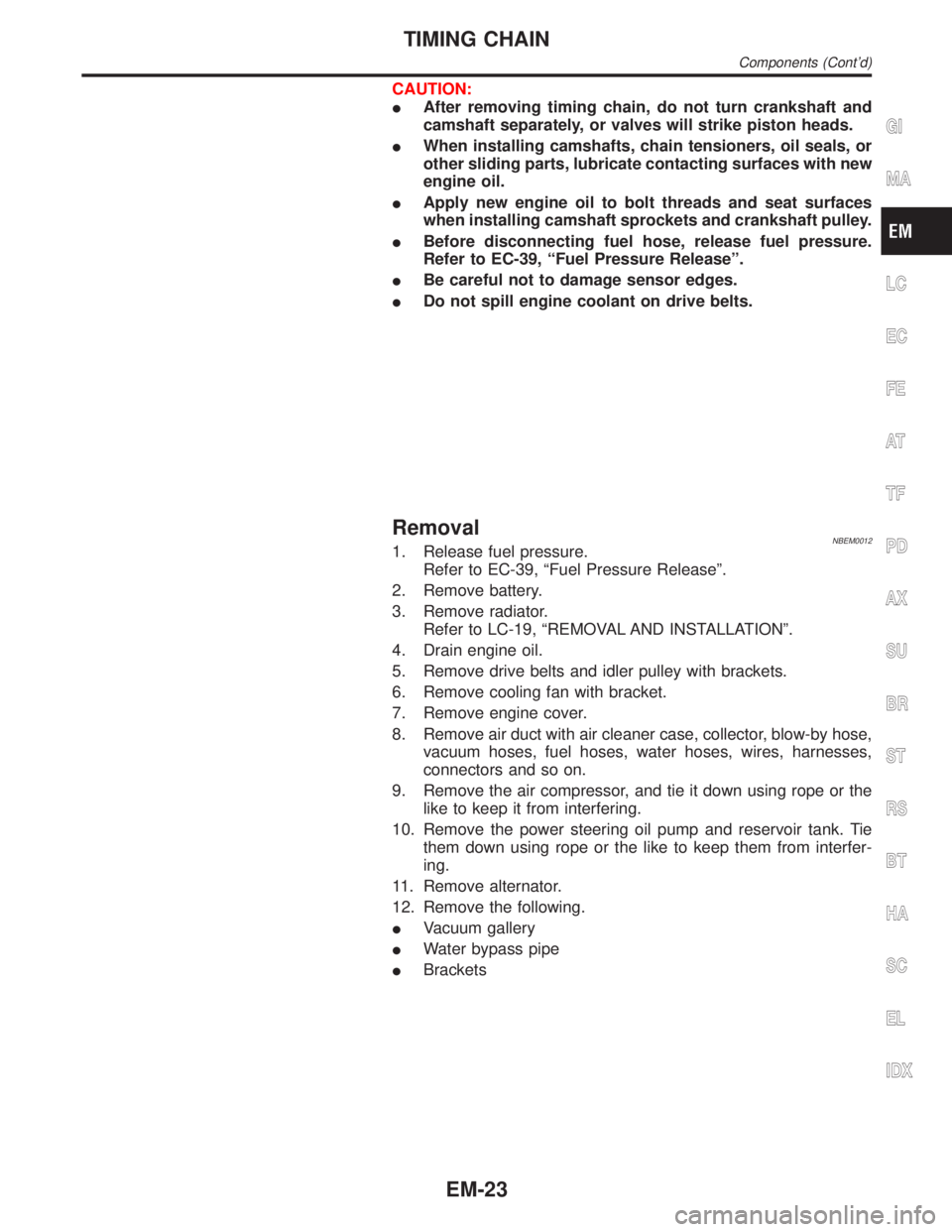

CAUTION:

IAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

IWhen installing camshafts, chain tensioners, oil seals, or

other sliding parts, lubricate contacting surfaces with new

engine oil.

IApply new engine oil to bolt threads and seat surfaces

when installing camshaft sprockets and crankshaft pulley.

IBefore disconnecting fuel hose, release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

IBe careful not to damage sensor edges.

IDo not spill engine coolant on drive belts.

RemovalNBEM00121. Release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

2. Remove battery.

3. Remove radiator.

Refer to LC-19, ªREMOVAL AND INSTALLATIONº.

4. Drain engine oil.

5. Remove drive belts and idler pulley with brackets.

6. Remove cooling fan with bracket.

7. Remove engine cover.

8. Remove air duct with air cleaner case, collector, blow-by hose,

vacuum hoses, fuel hoses, water hoses, wires, harnesses,

connectors and so on.

9. Remove the air compressor, and tie it down using rope or the

like to keep it from interfering.

10. Remove the power steering oil pump and reservoir tank. Tie

them down using rope or the like to keep them from interfer-

ing.

11. Remove alternator.

12. Remove the following.

IVacuum gallery

IWater bypass pipe

IBrackets

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Components (Cont'd)

EM-23